Payment for goods and downloading of the book in electronic form (PDF format) is made on the website.

To do this, you need to find the book you are interested in and click on the “Buy” button. The price of the book is indicated on the button.

For convenience, the price on the website for residents of Russia, Belarus and Kazakhstan is presented in rubles.

For residents of Ukraine in hryvnias, and for all other countries - dollars.

After clicking on the “BUY” button, a payment window will open where you can select a payment system with which you can pay for the selected book using any bank card (Visa, MasterCard, MIR, etc.)

When you click on the “Pay by bank card” button, the Portmone payment system will open, which is the easiest way to make a payment.

In addition, the website offers four payment systems for payment:

- Yandex (payment from any bank cards, Yandex Money account, QIWI Wallet, terminals, etc.);

- Portmone (payment from any bank cards, Portmone account);

- PayPal (payment from any bank cards, PayPal account);

- WebMoney (payment from any bank cards, payment from WebMoney wallets).

Payment via Yandex Cashier

After selecting payment via Yandex, the Yandex Cashier payment system will launch, where you need to select a convenient payment method (bank card, QIWI, Yandex Money account, etc.)

After specifying payment details and confirming payment, payment for the goods will occur.

If you have a bank card in a currency other than the ruble, then the money will be debited from the card at the rate of the Central Bank of Russia at the time of the purchase.

This payment method is optimal for residents of Russia, Kazakhstan and Belarus.

Official website of the Yandex Kassa payment system https://kassa.yandex.ru

GUR Valdai

Gur Valdai. Power steering Valdai.

Price 35,000 rub.

Valdai power steering is definitely a necessary mechanism for this truck. If the operation of the Gazelle is still allowed with a mechanical steering mechanism without power steering. In Valdai, unfortunately, it is simply impossible to turn the steering wheel without power steering. As a result, Valdai power steering is a very important and vital unit. Which in turn requires careful care and maintenance. Repair of the power steering Valdai power steering is only possible under factory conditions. And only on specialized high-precision tuning equipment. However, the plant’s specialists do not recommend repairing the Valdai hydraulic booster in artisanal conditions. Carefully adjusting the plunger parts to each other is possible only in the factory. High-precision modern imported equipment is required. Attempts to repair the Valdai hydraulic booster lead to a waste of time and disappointment. Leave Valdai power steering repairs to experienced specialists. The weight of the Valdai power steering is 20 kg.

Payment via Portmone

After selecting payment through Portmone, the payment system will launch, where you need to select the payment method: bank card or Portmone account.

The price in the Portmone payment system is converted into dollars at the exchange rate of the Central Bank of the country where you are located.

If you have a bank card in a currency other than the dollar, then the money will be debited from the card at the rate of the Central Bank of your country at the time of the purchase.

After specifying payment details and confirming payment, payment for the goods will occur.

Official website of the Portmone payment system https://www.portmone.com

Steering without power steering

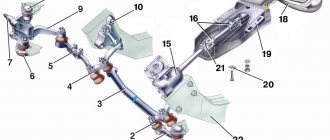

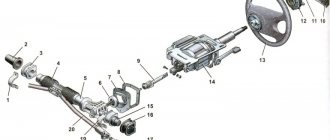

The vehicle is equipped with a steering system consisting of a steering column with a wheel, a steering mechanism and a steering drive.

The steering column allows you to change the position of the steering wheel in height and angle.

The upper end of the steering column shaft is connected to the steering wheel with conical splines, and the lower end is connected to the steering gear screw through universal joints.

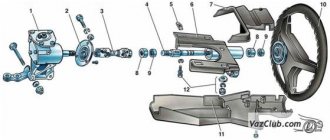

The steering mechanism consists of an aluminum housing, a screw with a ball nut and a sector shaft.

Payment via PayPal

After selecting payment via PayPal, the PayPal payment system will launch, where you need to select the payment method: bank card or PayPal account.

If you already have a PayPal account, then you need to log into it and make a payment.

If you do not have a PayPal account and you want to pay using a bank card via PayPal, you need to click on the “Create an Account” button - shown with an arrow in the picture.

PayPal will then prompt you to select your country and provide your credit card information.

After specifying the information required to make the payment, you must click on the “Pay Now” button.

Official website of the PayPal payment system https://www.paypal.com

Work order

Professional steering adjustment on Gazelle models begins with its careful dismantling. Next, remove the top plastic cover from the mechanism along with the foam rubber seal and the head of the 13 key, and unscrew the four fastening bolts of the metal protection. We remove one of the adjusting shims located inside, assemble the device in the reverse order, check the play and, if there is any play, disassemble the unit back, removing another spacer ring.

When it has been possible to ensure that there is no backlash, it is necessary to adjust the gap when engaging the nut pair - shaft-sector. To perform this operation, you should install the bipod on the shaft and successively rotate the screw to move it to the middle position, and then turn the sector shaft directly behind the bipod. The play of the bipod tip should not be felt or exceed 0.3 mm.

When the mentioned indicator is greater, then using a plastic screwdriver we dismantle the plastic cover of the gearbox, after which we remove the two plugs. Using metal pliers, remove the spring rings on both sides of the body and straighten the holes on the edge of the outer ring. The eccentric outer rings are rotated clockwise until the gaps with the sector shaft are removed. To prevent the rings from turning, we fix them by bending the collars in the grooves of the crankcase. We assemble and install the mechanism in the reverse order.

Thus, adjusting the steering gear on a Gazelle car is an important repair measure that allows you to restore the functionality of vehicle control, significantly increasing the safety of passengers while driving.

Payment via WebMoney

After selecting payment via WebMoney, the payment system will launch, where you need to select the payment method: bank card or WebMoney wallet.

If you already have a WebMoney wallet, then you need to log into it and make a payment.

If you do not have a WebMoney wallet and you want to pay in another way, you need to select any of the methods that WebMoney offers and make the payment

After specifying payment details and confirming payment, payment for the goods will occur.

Official website of the WebMoney payment system https://www.webmoney.ru/

Signs that repairs are needed

Gazelle steering gear repair

In any car, the steering parts are subject to the greatest degree of wear, since they bear heavy loads when driving on uneven roads, cornering, and sudden braking. Therefore, the Gazelle steering gear often fails, as a result of which it is urgently adjusted. The list of signs of malfunction of the unit in question usually includes:

- Vibration or knocking in the device transmitted through the steering wheel;

- Having difficulty turning the steering wheel;

- Presence of play in the gearbox;

- Oil leaks in the mechanism.

If one or several signs appear, immediate adjustment of the steering gear is required, which will allow timely elimination of malfunctions in the operation of the device and reduce the risk of failure of other components of the vehicle.

Gazelle steering gear

Downloading a book

After successfully completing the payment (by any method) and returning to the KrutilVertel store from the payment system website, you will be taken to the successful payment page:

On this page you need to indicate your e-mail, where access to download the book will be sent.

If you are already registered on our website, then simply follow the link to your personal account.

The book you purchased will be in your personal account, from where you can always download it.

Please note that after making the payment, you need to return back from the payment system website to the KrutilVertel website.

If for some reason you did not return back to the site and closed the payment system tab with a message about the successful completion of the payment, please let us know - we will send you a letter indicating access to download the book.

Repair of GAZelle steering gear

Because of a good life, no one wants to remove the steering gear with their own hands, and the reasons for this must be more than compelling. This is mainly necessary if the steering wheel has become noticeably heavier, characteristic knocking noises have appeared in the gearbox housing, or there is a clear lubricant leak. The gearbox always sweats, but if the leak is too active, then the seals need to be replaced. In this case, it is necessary to check the condition of the shaft and, if necessary, remove traces of corrosion by grinding.

You can make adjustments without completely dismantling the gearbox, but it will be safer if you still remove it and inspect it carefully.

For the curious or for those in a hurry, here is the technology for removing the gearbox from under the hood:

- Loosen the front wheels.

- We hang the front axle on a stand and remove the wheels.

- We turn the steering wheel all the way to the right and from under the hood we knock out the steering rod with fittings of suitable length.

- We do the same on the left.

- From under the hood we remove the gearbox along with the bipod, which is more convenient to remove on a workbench.

Once we have the gearbox in our hands, we can repair it. Replacing parts should not present any difficulties, since the design of the gearbox is extremely simple and clear, and the adjustment requires some attention and reference to the factory adjustment data. They are also extremely simple.

For cargo GAZelles, the permissible play is 25˚, for passenger ones - 20˚. According to factory tolerances, there cannot be any play in the gearbox bearings. Adjustment of the clearance in the screw bearings is carried out in a vice on a workbench. It is more comfortable. We remove the plastic protection and the foam seal, then unscrew the four bolts securing the cover, remove one of the adjusting shims, and then reassemble everything in the reverse order. If there is play, repeat the operation to dismantle the gasket. So until you are completely satisfied and the play on the bipod is eliminated.

Problems when paying with bank cards

Sometimes difficulties may arise when paying with Visa/MasterCard bank cards. The most common of them:

- There is a restriction on the card for paying for online purchases

- A plastic card is not intended for making payments online.

- The plastic card is not activated for making payments online.

- There are not enough funds on the plastic card.

In order to solve these problems, you need to call or write to the technical support of the bank where you are served. Bank specialists will help you resolve them and make payments.

That's basically it. The entire process of paying for a book in PDF format on car repair on our website takes 1-2 minutes.

If you still have any questions, you can ask them using the feedback form, or write us an email at [email protected]

Features of the GAZ 3302 steering gear

Like the whole car, the GAZelle’s steering mechanism does not suffer from sophistication in design, but many believe that this is for the better. Regardless of whether the car has power steering or without power steering, repairing and adjusting the steering is extremely simple and does not require deep encyclopedic knowledge or special tools from the driver. The very minimum of both – and you can move on.

Video review of GAZelle 3302

It is still different from the prehistoric GAZ worm-roller gearboxes, and even has its positive aspects. The most pleasant feature from the point of view of car architecture is that the GAZelle gearbox mechanism is quite compact and at the same time has good efficiency. What is especially noticeable on cars without power steering is that driving even a loaded car does not require the use of brute physical force. The designers achieved this by using rolling instead of sliding. It cannot be said that this introduction brought revolutionary changes to the global auto industry at the end of the 20th century, but the steering wheel became noticeably lighter. This made it possible to increase the service life of the entire assembly, since it does not wear out as intensively as a worm pair, and rarely requires adjustment.

There were some shortcomings, although the designers had nothing to do with it. The working pair of screw/ball nut is a non-removable element, and during the first 10-15 years of the car's production it was quite difficult to find a replacement pair. Now this stuff is enough, so replacing a working pair can cost 5-6 thousand rubles. Adjusting the steering gear requires its complete dismantling, which also does not delight users. Moreover, to adjust the gap, in addition to a special profile wrench, you also need level and skillful hands, since the bearings can be skewed in no time if you do not use a torque wrench.

Preventive measures

Prevention and proper operation of the power steering system in this case can often significantly extend the life of the mechanism. The hydraulic booster is a fairly reliable and unpretentious spare part, and with proper operation it can last about 100...200 thousand kilometers. However, in order to extend the life of the hydraulic booster, you must follow simple rules, including:

- Monitor the power steering fluid level . This factor directly affects the normal operation of the pump. If necessary, it must be added to the required level. Moreover, it is advisable to use the same liquid that was poured in before; mixing them is extremely undesirable, and liquids belonging to different classes are completely unacceptable!

- Change power steering fluid according to regulations . You will find exact information for a specific car in the manual. However, for most modern passenger cars equipped with power steering, this gap is about 80...100 thousand kilometers. You can replace the fluid at routine maintenance that is close in mileage.

- Use recommended fluid . As mentioned above, there are currently a wide variety of them, but only the car manufacturer specifies in the service manual exactly what type of lubricant should be used for a particular car.

- Use power steering correctly . In particular, you should not hold the steering wheel in extreme positions for a long time. The maximum allowable time is 5...10 seconds (depending on the specific vehicle). Inverted wheels cause the pump to wear out, which significantly reduces its overall service life.

- Check the condition of the steering rack boots . This is a very important requirement, since the entry of dust and dirt into the system contributes to the wear of elements of both the rack in general and the hydraulic booster in particular. In addition, if the seals wear out, oil leakage may occur.

- When parked, the car must be parked with its wheels aligned . As stated above, this requirement is to avoid placing undue stress on the power steering pump.

- In cold weather, do not immediately turn the steering wheel after starting the engine . Instead, especially after being parked for a long time (for example, in the morning), allow the power steering system to warm up along with the engine before turning the steering wheel.

- Do not drive with inoperative power steering . This can kill all steering in the long run. Of course, you can get to a car service center or garage, but you can’t drive constantly.

- Timely diagnosis . If you detect the slightest suspicion of a malfunction of the hydraulic booster (the appearance of a hum during a turn or simply while driving, “heaviness” of the steering wheel), it is necessary to carry out diagnostics as quickly as possible in order, firstly, to reduce wear on parts, and secondly, to save for possible upcoming renovations.

Following the simple rules listed above will allow the car owner not only to significantly increase the service life of the power steering by avoiding malfunctions, but also to save on possible repairs.

Source

Do-it-yourself repair of power steering tractor T-40

The price for a T-40 power steering ranges from 10-13 thousand rubles; a comprehensive repair will cost about the same amount. Therefore, making repairs yourself and performing maintenance yourself is the best option for the tractor owner. Thanks to the video, you can learn in more detail about the repair of the T-40 steering column.

Disassembly and assembly

Disassembling the T-40 power steering is performed according to the following instructions:

- when disassembling the piston assembly, press the pin located in the rear nut all the way;

- the nut must be unscrewed and removed together with the spring washer;

- The screw is pushed towards the front cover, then the spool with springs and stops is removed.

Assembly is performed in reverse order, but the following tips should be followed:

- make sure that when assembling the pin is on the side of the back cover;

- the spool must move freely, without friction or jamming;

- before assembling the power steering, the component parts are washed with clean diesel fuel;

- The spool also needs to be washed and treated with diesel oil.

Do not allow clogs or foreign debris to get into the piston. This can lead to power steering failure or component wear.

How to properly install the power steering of the T-40 tractor

When installing and assembling the T-40 power steering, special attention should be paid to the position of the screw, since it is equipped with a multi-start thread. You will need to select the correct position for its entry, leaving a gap of 1 mm between the piston and the nut (preferably without deviations).

Replacing power steering hoses

Drain the oil from the power steering system, remove the hoses from the reservoir pipes (see section “7.1.3. Maintenance of the hydraulic steering system”). We remove the engine splash guard (see section “9.1.1. Removing and replacing external body parts”).

Using a 22mm wrench, unscrew the bolt fitting from the power steering and remove the drain hose (see above, “Removing the power steering mechanism”).

Using a 17mm wrench, unscrew the fitting of the injection hose. For clarity, all subsequent operations are shown on the removed power steering pump (see section “7.1.5. Power steering pump”). We install new hoses in the reverse order, then fill in the oil and bleed the hydraulic system (see section “7.1.3. Maintenance of the hydraulic steering system”).

Source

Device

Both the electric power steering on the Gazelle and the power steering are designed for more comfortable steering. First, let's analyze the power steering device on the Gazelle. We are talking about both the Gazelle Business with the 405 engine and other models in this line.

So, what is the system device:

- Power steering pump. This circuit element ensures optimal circulation of consumables in the system, as well as pressure.

- Steering gearbox with distribution element. This device allows you to provide the air flow necessary to direct the oil into the desired cylinder cavity or back into the tank.

- Another component of the system is the cylinder. With its help, the pressure of the consumable material is converted into the movement of the piston, as well as the rod.

- The consumable material itself, that is, oil. The fluid transmits force from the power steering pump to the cylinder. In addition, the oil provides lubrication of all rubbing elements of the device.

Elimination of power steering pump defects

The faults have been found, now we begin to eliminate them.

We will need rags, white alcohol, sandpaper with grit P1000/P1500/P2000, a triangular needle file, a drill bit of Ø12mm (or more) and an electric drill. With the shaft everything is much simpler, you will need P1500 sandpaper and with it we begin to clean all the edges of the grooves on the shaft (we clean the outer and side ones on both sides) in all possible ways. We work without fanaticism, the main task is to remove only sharp burrs.

For one thing, you can immediately polish both sides of the shaft a little on a flat surface, it is advisable to use P2000 sandpaper.

Next, we need to check the result of our work, we check visually and by touch, everything is perfectly smooth and does not cling.

The most difficult thing will be with the surface of the cylinder; personally, I couldn’t figure out anything simpler than how to make a spherical grinder from sandpaper, a drill and a thick drill (F12). To begin with, we take the P1000 sandpaper and a drill bit that can be inserted into the drill.

Next, you need to tightly screw the skin against the rotation of the drill, two or three turns, there should be no gaps.

Holding the tightly twisted structure, it needs to be inserted into the drill (the skin should also be clamped).

Afterwards, using the most convenient methods for you, we carefully begin to grind the cylinder, you need to grind evenly, press the cylinder tightly and move it relative to the axis of rotation (at maximum speed). As we eat the skins, we change them, eventually we reach the smallest skin P2000.

The desired result is obtained,

Now everything needs to be thoroughly wiped with a trail of white alcohol. The shaft itself with the blades can be rinsed in it.

After we begin the assembly, everything is put in the reverse order of removal.

Inspection and identification of defects

Carefully inspect the contents and remember (you can take a photo) what was placed where and how (more attention should be paid to the position of the cylinder). You can twist the power steering pulley and carefully use tweezers to check how the blades move in the grooves of the shaft.

All parts should be pulled out without effort, since they do not have any fixations, but the central axis is firmly fixed and cannot be removed.

We inspect the shaft from the reverse side, parts (power steering housing and cover wall) touching them, for burrs or grooves, everything is perfect for me.

Now we remove the entire internal economy onto “clean” rags and begin to study it.

We carefully examine the shaft; all its grooves have very sharp edges on all sides. One of the end sides of each groove has a pronounced sharpness inward, which, when moving the blade inside the groove with a constant slope towards this side, will greatly complicate its movement (this may be the first component of poor power steering performance). The side parts of the shaft grooves are also “sharpened”; this can be felt if you run your finger in different directions along the end (outer circumference), as well as along the side parts of the shaft in different directions. Otherwise the shaft is perfect, has no flaws or nicks.