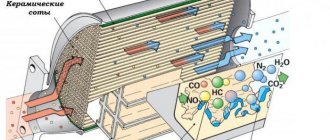

All modern cars are equipped with a honeycomb exhaust gas emission neutralizer - a catalyst. It is named after the principle of chemical reactions occurring there, where the noble elements of the filling accelerate and make possible the processing of harmful substances into neutral ones at high speed. But sometimes this useful device itself becomes a source of big problems.

Do you need an oxygen sensor emulator?

- The ECU puts the engine into emergency mode when the engine operates according to the specified fuel maps without taking into account the readings of the oxygen sensors.

- The “Check Engine” indicator lights up on the dashboard and an enriched fuel mixture enters the cylinders.

- Soot on the spark plugs increases, the power of the internal combustion engine decreases and the oil becomes contaminated.

- Increased fuel consumption entails extra financial costs.

Almost all automakers recommend replacing a faulty converter. But not every car owner will do this, because the price of some copies, for example, for VAZ, reaches 60,000 rubles. It is also worth adding the cost of installing the device. Therefore, many car enthusiasts are interested in what a do-it-yourself catalyst blende is and the scheme for its implementation.

The essence of the emulator's operation is to change the real sensor readings, after which the ECU switches to normal operation. In this case, the neutralizer itself can be cut out or replaced with a flame arrester. The procedure for installing a simulator is no more complicated than increasing the ground clearance of a Renault Duster.

Types of homemade decoys

To understand the principle of operation of the emulator, it is worth considering each type separately, since the lambda probe trick works differently in each case. The key goal of the emulator is to “fuss the brains” of the car’s ECU if the catalytic converter is broken. The decoy gives a signal about the optimal operation of the catalyst and the permissible oxygen content in the exhaust. So, let's look at three ways to deceive the electronics of a modern car.

Reflashing the controller

The only requirement in this case is to use the services of a specialist if you are not strong in electronics. It is advisable to use the method in case of failure of both the sensor and the catalyst. It is necessary to electronically disable the oxygen sensor by entering the appropriate program. Next, the appropriate changes are made and, if everything is done correctly, a message about critical faults will no longer be displayed on the dashboard. The engine will operate as usual without a lambda probe. The main problem with this method is that if done incorrectly, the computer will no longer operate at its optimal level. This can only be corrected by factory firmware, which is expensive and generally not so easy to obtain.

Mechanical emulator

Making a lambda probe with your own hands in the mechanical version is much easier. Essentially, it’s just a spacer called a bushing; it is installed in the area between the probe itself and the place where the sensor is fixed. We are talking about the surface of the collector or exhaust pipe. Bronze or high-quality heat-resistant steel is used to make the bushing. Visually, it is a hollow cylinder containing crushed ceramic chips inside. A thin axial hole and thread are located on the side of the spacer to which the exhaust system element is fixed.

As for the implementation of this method, it is necessary to change the position of the sensor so that it is further from the exhaust pipe or manifold. After passing through a thin hole, the exhaust gases will fall to a small extent on the ceramic chips, where they will enter into an oxidation reaction under the influence of the temperature factor. Of course, the content of harmful substances will be significantly reduced. Considering the fact that this method involves to some extent deceiving the sensor, the advisability of its use is observed only in the event of a catalyst failure. The latter must be replaced with a flame arrester or completely removed from the exhaust system.

You can make a mechanical overlay yourself without any extra effort if you have the skills of a lathe. Prepare a bronze or steel blank, a lathe and a diagram of the part with the necessary parameters. If turning skills are not your thing, just buy a finished part or order it with the specified parameters. The cost of the finished version can range from 200 to 800 rubles - it all depends on the complexity of the product and its variety.

As for the further installation of a part purchased or made by yourself, there will be no problems in this case, even if you do not have special skills. Find where the oxygen sensor is located, unplug it, remove it and install the bushing in its place. Next, simply screw the sensor into the spacer and connect the modified structure to the network.

Electronic snag

A more complex device from a technological point of view is the electronic decoy of the lambda probe. The feasibility of its use is also observed in similar cases of failure of factory parts. The secret of functionality lies in converting the signal from the sensor into a signal with characteristics corresponding to optimal operation of the catalyst.

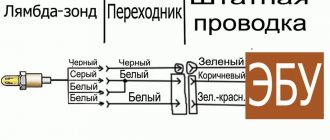

The snag should be connected directly to the wires going from the probe to the controller.

A programmable microprocessor often acts as the basis for this kind of deception, but you can assemble a basic interpretation yourself if you know how to use a soldering iron. The relevance of using the emulator described below is observed when the second sensor, located in the area after the catalyst, fails. This option is extremely primitive at first glance, but in practice its performance has been repeatedly proven. Prepare the following materials:

- soldering kit, including everything you need;

- resistor with a resistance of 1 Mohm;

- a non-polar capacitor with a capacity of 1 µF.

Traditionally, the electronic snag of the second lambda probe has two black, white and blue wires.

The sequence of installing the blende is as follows:

- At the initial stage of work, the ground wire must be completely disconnected from the battery.

- We don't need black ones, just break the blue conductor and install a resistor at the break site.

- The blue and white wires should be connected through the capacitor.

- The area under the connector is the most suitable place to install such a homemade emulator. This could be in the engine compartment, under the dashboard, or between the front seats.

How to make a mechanical corrector for the exhaust system?

To implement a mechanical blende for the catalyst with your own hands, it is recommended to use blanks made of heat-resistant steel or bronze. This way the parts will not be deformed due to high temperature. There are two designs, but both options require a lathe or the help of an experienced turner.

First option

It is a sleeve 40-100 mm long. On one side, a standard sensor is screwed in, and on the other, the circulation of gases is limited by a small diameter hole. The essence of the “device” is that the composition of the exhaust mixture is averaged, because the lambda probe is removed from the gas stream itself and, accordingly, catches fewer toxic substances. Due to this, it is possible to deceive the ECU.

A typical drawing with spacer dimensions can be changed in terms of dimensions, it depends on the model and brand of the car. The optimal inlet diameter remains unchanged - 1.5-2 mm. In some cases, the length of the bushing may not allow it to be installed in its original place. As a result, you have to weld the mount elsewhere in the exhaust pipe.

Second option

- Exhaust gases enter the bushing body through a small diameter hole.

- In the volume of the spacer, excess CH and CO are subject to oxidation by oxygen, as a result of which the concentration of harmful substances decreases.

- The ongoing processes change the shape of the sinusoid, and the electronic system believes that the catalytic converter is operating normally.

A do-it-yourself catalyst blende made according to the above diagram has advantages similar to the previous option. Here the standard probe will be raised by 32 mm, although this is less than 40-100 mm.

Features of spacer installation

The installation procedure is not difficult, and begins with placing the car on an overpass or lift. Further actions occur according to the following scheme:

- Disconnect the negative terminal of the battery.

- Unscrew the controller.

- Screw the bushing onto the probe.

- Screw the upgraded unit into place.

- Connect the battery.

Mechanical method

The method involves using a metal spacer or bushing that is placed between the oxygen sensor and the exhaust pipe. Anyone with some degree of turning skill can do the cool-down on their own. Bronze or heat-resistant steel is used to make the part. In addition, you will need the makeup chart itself, which is easy to find since many people have computers. In his absence, you can use the help of friends or acquaintances.

At the end of the bushing there is a small hole with a diameter of 2 mm for the passage of exhaust gases. It is noteworthy that deciphering the catalyst with your own hands is quite simple. Its design assumes the presence of a ceramic chip with a catalytic coating on the inside.

It's all about the following. Exhaust gases first enter the bushing and pass through the ceramic filler. As a result, a chemical reaction occurs that reduces the concentration of carbon monoxide and hydrocarbons (CO and CH). The gases then reach the oxygen sensor, which transmits normal readings to the ECU.

From a constructive point of view, blende is the same catalyst, only in a much smaller size. To install it, follow the simple instructions:

- Remove the “-” terminal from the battery.

- Get to the position of the second oxygen sensor (after the catalyst), if necessary, perform partial disassembly.

- Disconnect the connector, unscrew the lambda probe with a 22mm wrench and install the bushing.

- Screw the oxygen sensor into the latch and insert the connector.

As you can see, installing the mixture on the catalyst is not as complicated as it might seem at first glance. It is more convenient to carry out all work on a pit or a lift.

Do-it-yourself electronic catalyst blende and emulator circuit

A real electronic emulator is a microprocessor device consisting of a single-chip microcircuit. The principle of its operation is based on the formation of an output signal, which in shape corresponds to the information in the working neutralizer. This option is difficult to do on your own, so you should immediately consider a simpler method. To implement it you need to prepare:

- Electric soldering iron.

- Solder and rosin.

- Knife and side cutters.

- Resistance 200 Kom, power 0.25 W.

- The capacitor is non-polar with a capacity of 4.7 microfarads.

The principle of operation of the system is to average the readings of the oxygen sensor, which is installed after the converter. The method of connecting emulator components is simple and universal. All elements are connected directly to the vehicle’s on-board network conductors. Before connecting the electronic decoy to the catalyst with your own hands, you should disconnect the battery to eliminate the possibility of a short circuit. After the implementation of the project, the car demonstrates good dynamics. However, the effect of over-enrichment of the combustible mixture may occur, which causes the deposition of a layer of soot in the exhaust manifold. In addition, on some models error P0133 appears, indicating a low response rate of the lambda probe.

Select car brand

Our services

Engine chip tuning

Firmware for EURO 2

Installation of flame arresters

Computer diagnostics

Turn off EGR, AGR

Removing the diesel particulate filter

What do spare parts manufacturers offer?

On the shelves of auto stores you can find all kinds of parts for tuning the exhaust system. The production of mechanical simulators of the normal operation of the catalytic converter is made of bronze or chrome-plated steel. The price of such devices ranges from 400 to 800 rubles, and a standard installation at a service station will cost about 500 rubles.

A spacer with a minicatalyst is offered much more expensive than its elementary counterpart, its cost is 1,500-4,000 rubles. Simple electronic emulators of industrial production are sold for 1,500-3,000 rubles. The range of prices for flashing ECU software is quite wide - from 1,000 to 30,000 rubles.

Good day everyone! In previous entries I wrote that I wanted to install a lambda probe (mechanical) but the idea was not successful... - I could not unscrew the sensors...

In the end, I decided to make an electronic deception and install it, read a lot of information on the Internet, consulted with smart people and began to implement the decoy =)

Then, as usual, the photo is of poor quality =)

I don’t have a photo from the installation, I didn’t have time to make it clear from the diagram how to install it

I’ll tell you a few things right away:

1. wires we have black (signal), gray (ground) and 2 white (heating)

2. experimentally and on the advice of “experienced” people, it turned out that all the diagrams on the Internet are nonsense... the installation is correct, but the components are not the same...

Everywhere they write that you need to install a non-polar capacitor - I agree with this, but a 1 MΩ resistor gives a not entirely accurate amplitude on an oscilloscope... yes, if Jackie-Chan appears, this option will work, but the sensor will not work quite accurately... But during installation a 150 kOhm resistor, the amplitude will be almost similar to the amplitude when there is a catalyst...

in general, think for yourself... I decided to try both options... 1 was dropped immediately, because after riding for a couple of days, I didn’t notice any difference at all, but when I installed the second option... then it’s a completely different matter! I’ve been driving with it for about a week now, so far the consumption has dropped, but not by much... earlier, with active driving, the BC showed more than 13 liters... which was not pleasing, now it’s 10.5 with active mode, 9 with “grandfather” mode, in general, consumption has dropped and is not increasing =)

Excerpt from Murzilka:

Excess air in the mixture is measured in a very original way - by determining the residual oxygen content (O2) in the exhaust gases. That's why the lambda probe is located in the exhaust manifold in front of the catalyst. The electrical signal from the sensor is read by the electronic control unit of the fuel injection system (ECU), which in turn optimizes the mixture composition by changing the amount of fuel supplied to the cylinders. Some modern car models have another lambda probe. It is located at the outlet of the catalyst. This achieves greater accuracy in preparing the mixture and controls the efficiency of the catalyst.

Design, principle of operation and installation location

Only cars with injection engines are equipped with the sensor. Location in the exhaust pipe after the catalyst. A dual configuration oxygen sensor can be located before the catalyst, providing enhanced control over the gas composition, thereby ensuring more efficient operation of the device.

Operating principle:

- The car's electronics, which are responsible for fuel dosage, sends a signal requesting supply to the injector.

- Accordingly, the oxygen device determines the required amount of air to form the correct mixture.

- The device settings allow you to comply with the requirements for the environmental and economic components of the issue of car operation - to eliminate excessive fuel consumption and environmental pollution.

Modern cars are equipped with progressive devices - catalysts and paired sensors - that allow them to reduce the negative effects of exhaust emissions and the consumption of expensive fuel and lubricants. However, if an expensive version of the sensor breaks down, the “treatment” will cost a considerable amount.

Lambda probe design

Externally, the device looks like a steel elongated electrode body with output wires and platinum coating. Inside the device is as follows:

- A contact connecting wires to an electrical element.

- Sealing dielectric cuff for safety with an air inlet hole.

- A hidden zirconium electrode enclosed in a ceramic tip, heated by current to 300–1000 degrees.

- Protective temperature screen with exhaust gas outlet.

Sensors are either point-to-point or broadband. The classification of devices does not affect the external and internal structure, however, it makes a significant difference on the principle of operation. The device described above is a two-point device, the second is a modernized version.

More about it:

In addition to the two-point design, the sensor also contains a pumping element. The point of the work is that when the constant voltage between the electrodes fluctuates, a signal is sent to the control unit. The current supply to the injection element is increased or decreased, a portion of air enters the gap for analysis, where the level of concentration of exhaust vapors is determined.

Oxygen sensor

The lambda probe is a residual oxygen sensor. Installed in the exhaust manifold of vehicle engines, as well as in the chimney of modern heating boilers. Indicated by the Greek alphabet symbol λ probe. In simple terms, a lambda probe is a sensor that reads how much unburnt oxygen is left in the exhaust gases. To comply with international environmental standards, car manufacturers are required to install such electronic devices. They reduce the amount of harmful substances.

Catalytic convectors burn carbon and nitrogen oxides in the exhaust system before it all goes outside. The lambda probe is one of the components of this device and is an integral part for the proper operation of the device. Why and how to fake a lambda probe?

Due to the poor quality of the road surface and not always high-quality fuel, it often happens that the lambda probe breaks along with the catalyst.

In this case, it is necessary to replace broken parts or install a fake oxygen sensor.

Diagnostic methods

It is advisable to carry out diagnostics of the sensors every 10,000 km of the vehicle or at the first signs of a probe malfunction, which are described below.

Multimeter

Very often, the reason for the oxygen probe not working is damage to the heater coil or contact with the heater. It is easy to check whether this is true with a multimeter by switching it to the ohmmeter operating mode. Typically, pins 3 and 4 (in a 4-wire sensor) go to the heating element. The resistance value should be within 4.5 - 5.5 Ohms. If the readings exceed this value, the probe requires replacement because the heating element has failed.

To check the signal received by the electronic unit, you need to start the car, press the gas pedal to keep the engine in high-speed mode for some time. We connect the signal wire of the probe (usually black) to the positive probe of the multimeter, and connect the negative probe to ground, switching the device to voltmeter mode (2000 mV). When you hold down the gas pedal and suddenly release it, the readings of the device should be in the range from 1000 mV to 100 mV. If the readings remain unchanged within 400 - 500 mV when manipulating the gas pedal, then the probe is faulty.

Oscilloscope

The quality of testing with an oscilloscope is manifested in the ability to find out the time period of change in the output voltage signal. To check, you need to connect the oscilloscope to the wire that gives a signal to the electronic unit (black). Next, you need to start the engine and wait until it warms up to 70˚C. As the sensor warms up to 400˚C, the device will begin to show a wave-like graph. When the engine is running at about 3000 rpm, the device should show a smooth wave-like graph with a low signal level limit (at least 0.1 V) and a high signal level (no more than 0.8 - 1 V).

If a graph is drawn on the screen at the extreme (upper or lower) points, as well as at a position of about 0.6 V at maximum engine operation, then the λ probe is faulty.

Automotive oxygen sensor

The ECU, after receiving information from the oxygen sensor, determines what concentration of the fuel-air mixture to supply in the following cycles. Thus, the computer regulates the balance in the operation of the internal combustion engine.

Where is the oxygen sensor located? Answer: The lambda probe is located in front of the catalyst on the exhaust pipe or on the manifold outlet pipe.

Principle of operation

The working element of the oxygen sensor is a galvanic cell, which consists of a solid ceramic electrolyte based on zirconium dioxide.

A galvanic cell has electrodes made of a sponge plate. Coated with doped sodium oxide.

One electrode of the device determines how much oxygen (O2) is contained in the exhaust gases, and the second - how much oxygen is in the environment. When the oxygen sensor heats up to +300 degrees and due to the difference in oxygen content, an output voltage appears.

Based on the voltage value, the on-board computer determines which mixture is supplied to the engine.

If the lambda sensor or controller malfunctions or breaks down, the following symptoms will appear:

- A critical error message appears.

- The exhaust gases from the muffler will be expressed in a bright shade, maybe black smoke, maybe white. The normal color of exhaust gases is grey.

- The engine does not pull either uphill or in a straight line.

- Fuel consumption is higher than before.

Second lambda probe

Some makes and models of cars have two oxygen sensors. In this case, one sensor is installed on the manifold or on the intake pipe, and the second is installed in the catalytic converter.

Engine detonation may be caused by a faulty oxygen sensor.

The second lambda sensor measures how much air is contained in the exhaust gases at the outlet of the catalyst.

Some drivers install a deceptive lambda sensor, either store-bought or home-made.

Clean the lambda probe

Often soot accumulates on the oxygen sensor, and combustion products settle inside. This prevents him from working at full capacity. The car loses traction, the maximum speed decreases and fuel consumption increases. One solution to the problem is cleaning the lambda probe.

How to clean the oxygen sensor:

- Before cleaning the probe, inspect it carefully. If there is damage or the structure is deformed, then the malfunction is unlikely to be related to contamination. If there is no damage, you can clean it.

- You will need orthophosphoric acid, which effectively corrodes scale and removes soot. Do not use mechanical cleaning tools: iron brush, sandpaper, needle file, etc. You will damage the precious metal layer and the sensor will become unusable. Remove the oxygen sensor from the car and place it in acid. To speed up the process, take a soft brush and apply the liquid evenly over the entire surface.

- Phosphoric acid cleans the lambda probe in 15–25 minutes. Afterwards, rinse the device with warm water and dry thoroughly.

Unfortunately, cleaning does not always help.

If orthophosphorus baths do not bring results, the oxygen sensor should be replaced or disabled by software.

Varieties of hand-made trompe l'oeil

A decoy, also known as an emulator, is a device that does not determine the oxygen content in gases. It only serves to fool the car's electronic control unit.

Changed controller firmware

You can reflash it yourself by downloading the software and instructions on how to do it. It's better to give it to a specialist. In electronic mode, the oxygen sensor is turned off through a certain program. In fact, it should turn out that the ECU will receive only the most correct value from the catalyst and there will be no errors on the instrument panel.

Reflashing the controller

Some particularly sophisticated car owners decide to reflash the control unit, which blocks the processing of signals from the second oxygen sensor. However, it must be taken into account that any changes to the system operation algorithm can lead to irreversible consequences, since returning the factory settings will be almost impossible and costly. Therefore, it is not recommended to perform such manipulations yourself. The same applies to ready-made firmware that is sold on the Internet.

Healthy! When flashing the lambda probes, they are removed.

If you still want to flash the system, then contact a competent specialist who can disable receiving DC data using specialized equipment.

It is also worth considering that almost any intervention in the operation of systems can lead to not the most pleasant consequences.

Buy a lambda probe decoy

The easiest and most effective way in terms of installation and saving time is to purchase a ready-made oxygen sensor.

In Moscow, a lambda probe blende can be purchased in 2022 for:

- 1500 rubles is for a catalyst emulator (electronic blende). Installation will cost about 500 rubles.

- Up to 1400 rubles - this is for the corner version of the blende.

- Up to 1200 rubles - this is for the second lambda sensor with a metal minicatalyst. Suitable for vehicles with Euro 4 engines.

- 500 rubles is for the most common option, a mechanical blende manufactured by Fort Luft. It does not contain a microcatalyst. Installed on cars up to 2001.

Which lambda decoy is better?

Unambiguously answer the question “Which lambda decoy is better?” impossible. Each device has its own pros and cons, and different compatibility with certain models. Which lambda probe decoy is best installed depends on the purpose of this manipulation and specific conditions:

- mechanical blende operate only in conjunction with a working oxygen sensor;

- To simulate the normal operation of an oxygen sensor on an old gas equipment, only electronic fakes with a microcontroller (pulse generator) are suitable;

- on old cars of a class no higher than Euro-3, it is better to install a screw-in screw - cheap and reliable;

- on more modern cars (Euro-4 and higher) it is better to use mini-catalysts;

- the option with a resistor and capacitor is a cheaper, but less reliable type of blende for new cars;

- An emulator of a second lambda probe on a microcontroller, powered by the first one, is the best option for a car with a failed or removed second oxygen sensor.

Generally speaking, a mini-catalyst is the best option for a working DC, because it highly reliably imitates the operation of a standard converter. A microcontroller is a more complex and expensive option, and therefore is only appropriate when there is no standard sensor at all or it needs to be tricked to drive on gas.

Possible consequences

This method of fooling a car computer is a risky endeavor. The following may happen:

- Failure of all sensors without the right to restoration.

- Many different errors can appear in the on-board computer.

- Wiring problems.

- The engine may malfunction because when the computer should give a signal - to supply a rich mixture or, conversely, a lean mixture, but it will not do this, because the snag shows that everything is normal.

What are the risks of intervention?

The installation of decoys for LZ is not provided by car manufacturers. Motorists have to deceive the control system, risking the correct operation of a variety of vehicle systems.

If errors are made during installation, problems may arise:

- If the car's computer stops regulating the injection process, problems with the engine may occur.

- If the circuit is soldered incorrectly, the electrical wiring may be damaged.

- During installation of decoys, sensors are sometimes damaged. Moreover, the car owner does not even suspect this, since the system already contains a decoy.

- Installing a fake, as well as flashing it, can lead to a malfunction of the computer.

If your area of interest does not include “communication” with a lathe or soldering iron, any type of blende can be purchased at an auto store. Even novice motorists will not have any problems installing them.