The generator bearings ensure easy rotation of the rotor around its own axis. Since they have to constantly experience quite a lot of stress, they wear out over time. Which, in turn, will first lead to a hum, and then failure of the unit. In this case, they need to be replaced with new ones. Therefore, motorists have a question: “ What bearings are on the VAZ 2110 generator ?”

Choosing a generator bearing for a VAZ-2110 car

A generator for a car, of course, is not the “heart”, it is considered the engine, but without a generator you can’t go far - you can only get there. Driving without music is nothing, but without lighting, side lights and battery charging, it’s bad. Once you start the engine, the generator is responsible for powering all electrical appliances. The weakest point of a generator is often the bearings. They have quite a heavy load on them. If you hear an unusual noise when the engine is running, which increases as you increase speed, you can safely assume that the generator bearing has failed. Make sure that the source of the problem is the bearing, possibly even in an open field. If you have little skill, loosen the tension on the generator belt in order to free the generator pulley. If the extraneous noise disappears, the reason is clear: the bearing will have to be changed.

Select bearing

Structurally, a conventional generator has two bearings - front and rear.

The front one, as usual, is more powerful, since it remains under a relatively large load, which arises due to the influence of the tension of the generator belt. The integrity of the bearings should be checked by external inspection. Cracks in the races, the presence of rust or chipping of metal, etc. are unacceptable. The next step is to check the ease of rotation, the presence of play or extraneous noise. It is recommended to replace the front bearing together with the cover, since it is rolled into the generator cover, but it is cheaper, if the cost of repairs matters, to press it out and replace it separately from the cover. If you decide to carry out the repairs yourself, without resorting to the services of a specialist, this will allow you to save some money. You will only need to spend money on purchasing bearings.

During the repair process, you will need a set of tools, for example, a hydraulic press and various pullers, without which it will be quite difficult and you will need to use resourcefulness. Another very difficult step is the correct choice of bearing for the generator.

KATEK generators are routinely installed on dozens of them. With the digital designation 5102.3771 or 94.3701, the power of both is 80 amperes, voltage is 14 volts. Answer the question “What bearings are on the VAZ-2110 generator?” you can do this: if it is a standard KATEK generator, then this generator most often has two bearings. These are the front 6302 in older versions, or 6303, and the rear 6202, or, accordingly, in a more modern version 6203.

The dimensions of the front bearing (6303) are 17×47×14, the dimensions of the bearing (6302) are 15×42×13. Their domestic “twins” are designated as 180302 and, accordingly, 180303 and are called 303 closed, or 302 closed.

The dimensions of the rear bearing (6202) are 15×35×11, those of the bearing (6203) are 17×40×12. Domestic analogues are designated as 180202 and 180203.

Replacement

The procedure cannot be called complicated, but it is very important to strictly follow the instructions. Based on our recommendations, as well as video tutorials, you can carry out the replacement yourself without any problems.

You have already found out what bearings are on VAZ 2110 generators, purchased a set of new spare parts, so you can start repairing.

Dismantling works

Front bearing

- Slightly unscrew the mounting nut on the generator, and also loosen the adjusting bolt.

- Reset the alternator belt and start the engine. This will allow you to verify that the problem is with the generator.

- If the noise disappears, then we move on. There is still a lot of work ahead of you.

- Let's move on to the battery, from which the negative terminal should be removed. This is important from a safety point of view and protection against accidental short circuits during repairs.

- Once the terminal is removed, unscrew all the wires going to your generator.

- If you have a crankcase guard, unscrew the mounting bolts and remove it. This will allow you to reach the lower mount of the generator and remove the device. Remove the generator by pushing it through the engine compartment.

- Using a regular screwdriver or other handy tool, you need to block the generator rotor and then unscrew the pulley.

- The next step is to look for special latches. By pulling them to the side, you will be able to dismantle the device body.

- Next, the generator brushes are unscrewed, as well as the mounting bolts holding the halves of the generator assembly. There should be 4 of these bolts in total.

- We recommend marking both halves of the generator housing to avoid problems during reassembly.

- Use a flathead screwdriver to pry up the cover and remove it.

- Practice shows that it is more convenient to remove the rotor from the front cover bearing in the following way. Take a nut and screw it onto the rotor threads. Then hit it with a hammer, first placing a wooden block under it.

- Find a part whose diameter will coincide with the diameter of the bearing being removed. For example, a 27 millimeter head may be perfect.

- Gently start tapping the element so that the bearing comes out of its seat.

- Take the new bearing and prepare to reinstall it.

- The first step is to treat the new bearing with lubricant so that it lasts as long and reliably as possible.

- To install a new component, you will need the old bearing. Place it on top of the new device and lightly tap with a hammer to install.

That's it, the front bearing has been removed and replaced. Let's move on to the back.

Press-fitting

Rear bearing

- To remove the rear element, you will need a special puller;

- If you don't have a puller, you will have to knock out the component with a chisel. An alternative option is a metal rod and a powerful, strong screwdriver;

- The selected tool is used to strike the bearing with a hammer. Here you definitely need to move along the surface, moving in the opposite direction;

- Some people can easily cope with dismantling; they use a regular strong open-end wrench;

- Now take the socket that you used to remove the front bearing and the old generator element that was removed. With their help, a new bearing is driven into its seat;

- If you don't like this method, use a tubular wrench or a metal pipe whose diameter matches the diameter of the rear bearing.

Having finished the work, all you have to do is assemble the assembly, following the steps in reverse order. You should start with the front cover of the generator, followed by all other components of the assembly.

If you carefully study the instructions, watch training videos, understand the structure and operating principle of the generator, replacing its bearings will become a fairly simple repair job for you, which will take no more than an hour of your time.

After completing the replacement, be sure to check the machine for noise. If everything was done correctly, the next operation to change the bearings will not be required soon.

Replacing the generator bearing on a VAZ-2112 is quite simple with your own hands. However, to complete the process you will need some knowledge of car design and auto electrics. Particular attention should be paid to the quality of the part, since low-quality components fail much faster than more expensive high-quality ones.

Imported or domestic

Belarusian 90-amp BATE and Japanese Denso generators have bearings of the same size.

Imported analogues of bearings have a slightly different designation, namely:

Most 80-amp generators have bearings of similar sizes, at least this applies to domestic ones. If the generator has already been replaced before you, then you may be faced with the fact that a generator from a different manufacturer is installed and the bearings are of different sizes. Depending on the generator manufacturer, bearings of other sizes are sometimes found, for example, in the fairly common Bosch 14V 53-98A 0124 415 038 generator, bearings 6003-2RS (rear) are installed, the dimensions of which are 17 × 35 × 10 and 6303-2RS (front) , respectively, 15×35×14. The same bearings can be found in other imported generators. However, there are options where the rear bearing is designated as 6000-2RS, and the front bearing – 6203-2RS.

In order to accurately determine the dimensions of the bearing, it will have to be removed. If the markings on the bearing are not visible, then it is best to turn to professionals (you should not trust a caliper).

If you have decided on the size of the bearing, then to the repeated question “What bearings are on the VAZ-2110?” The answer suggests itself - original!

The quality of bearings varies from manufacturer to manufacturer; some prefer to install bearings from domestic manufacturers on their generators, while others prefer imported ones. When repairing a generator, everyone decides this issue for themselves, but after listening to numerous tips, some car enthusiasts are inclined to choose imported ones. If you focus on price-quality ratio, many experts recommend DAS LAGER Germany. But there are other suppliers of quality bearings: the French company SNR; FAG is one of the leading companies in Germany; NSK is another major bearing manufacturer from Japan; NTN – Japan; Kouo - part of the Toyota concern of Japan; Kraft or BOSCH.

What are the bearing numbers on the VAZ 2110 generator?

The voltage source in cars of the “tenth” family is the VAZ generator; bearings numbers 6203 and 6303 are used as supporting elements of the rotor shaft. It is well known that these parts do not last forever, although they are quite reliable. Generator bearings in models 2110 can operate for 150 thousand or more kilometers without problems. But there comes a time when, due to mechanical wear, they need to be replaced. In order to save his own money, the owner of the “Ten” can do this with his own hands, having carried out a preliminary diagnosis of the malfunction.

Methods for checking the unit

For timely detection of bearing failures, there is no better way than a preventive inspection and checking the rotation of the rotor shaft. To do this, it is not necessary to specially disassemble the unit if you periodically replace the generator drive belt with your own hands. During this replacement, shaft rotation is checked in the following ways:

- grab the pulley with your hand and try to swing it perpendicular to the axis to determine the play;

- actively rotate the pulley in different directions.

If you feel play by hand or the shaft rotates with jamming and noise, then replacing the bearings of the VAZ-2110 generator is inevitable. Another sign of wear on parts is the appearance of noise in the form of a humming sound coming from the unit when the engine is running. In this case, it is necessary to localize the malfunction, since a rotating element of another unit located nearby may be humming: a pump or a timing belt tension roller.

It is not difficult to determine where the noise originates: you need to remove the generator drive belt and start the engine for a couple of minutes. If the hum disappears when idling, it means that its source was the elements of the VAZ-2112 generator, and the pump and roller are in good condition. In the same way, the operation of the bearing of the VAZ-2114 generator and any other model of the “tenth” family is checked.

Pullers for standard parts

It is enough to simply knock the front bearing out of the cover with a hammer, even if there is a flange, so in 99% of cases only a puller for the rear bearings of the generator of two types is used:

- with two legs;

- with three legs;

Moreover, the device can be made independently; the most popular are two designs:

- the lower part of the split bushing is put on the outer race of the bearing, a bolt passes through the upper part, the halves of the bushing are pulled together by a tubular casing, a cover made of thick-walled metal is put on the bolt under the nut;

- in a square pipe, cuts are made from below, into which, after being placed on the outer race of the bearing, steel plates are inserted; a nut is welded to the top of the pipe, into which a bolt of sufficient length is screwed.

With homemade devices, replacing a generator bearing is both faster and cheaper. However, they will take some time to produce.

Parts Specifications

To purchase new parts, you need to know which bearings are specifically installed in your unit in order to avoid mistakes. The VAZ-2110 generator has 2 supporting elements: front and rear. Their markings vary depending on the year of manufacture:

- in units produced in recent years, the rear part is marked 6203, the front - 6303;

- in older versions the number is slightly different - 6202 and 6302, respectively.

The bearing cages are sealed on both sides with plastic caps, which can be removed to add lubricant if necessary. The overall and internal dimensions of the rotating parts are the same for any marking; their exact values are indicated in the table.

| Bearing size | width, mm | by outer diameter, mm | by internal diameter, mm | Catalog number |

| Front | 14 | 47 | 17 | 180202 |

| Rear | 11 | 35 | 15 | 24940220 |

As a lubricating filler for cages, you can use thick lubricant “Litol-24” or another intended for rolling bearings. It is easy to identify the manufacturer by the additional symbols on the labeling.

The most popular parts of Russian production are from the following enterprises:

- Samara plant, marking - SPZ-4;

- Vologda plant - 23GPZ;

- Saratov plant - 3GPP.

Also, quite often, motorists install 2110 generator bearings from the Koyo, Kraft and LSA brands.

It is strictly not recommended to install elements without inscriptions and markings, manufactured in an unknown location, most often in China.

You may run into trouble with such parts quite soon due to the poor quality of the products.

Parameters and design

The basis of the operation of each car, along with the power plant, is an alternating current generator. Like any other automotive equipment, this unit has its own characteristics, functions and features. An installation for generating electricity is one of the most reliable devices, especially considering the quality of components and assembly of domestic cars. The generator is able to withstand constant vibrations from the engine, sudden temperature changes and the ingress of moisture and dirt without any consequences, because protection is not always effective. The electric current at the output always remains constant - regardless of what modes the power complex operates in and at what speed.

The generator set has general requirements. The vehicle's on-board network is provided with a stable electrical voltage, regardless of the conditions under which the power unit operates. In this case, the battery must not be discharged. On the contrary, simultaneously with the power supply to the on-board network, the battery is recharged.

Insufficient electric current or its unstable generation will lead to constant undercharging of the battery and, as a result, difficult starting of the engine, especially at low temperatures. Excessively high voltage generated by the generator also does not bring anything good, causing premature failure of the battery.

Principle of operation

The generator is not the most complex mechanism; everything about its functioning is quite simple. After turning the key in the ignition switch, the following processes occur.

- An electrical impulse is received at the contacts and then transmitted through an assembly with graphite brushes to the armature winding (rotor).

- The rotor shaft begins to rotate synchronously with the crankshaft, a magnetic field is formed in the windings, which is transmitted to the stator winding. As a result of this process, an alternating current voltage appears at the stator output contacts.

- After reaching the optimal rotation speed, the self-excitation phase of the generator begins. This means that electric current begins to flow to the rotor winding from the generator set.

- Passing through the rectifier block (diode bridge), the alternating current is converted into direct current. This voltage can already be used to recharge the battery and power the energy consumers of the vehicle’s on-board network.

The voltage regulator does not start working immediately, but after the vehicle starts moving, i.e., when the speed and load on the device becomes unstable. The regulator's task is to turn on the excitation of the rotor winding at a certain moment when it is required. The excitation switching time depends on external loads and on changes in rotor rotation, i.e., when these parameters decrease, the time decreases, and when these parameters increase, the time increases.

There are cases when the energy consumption of the on-board network exceeds the capabilities of the generator set (connecting a powerful speaker system, lighting, etc.). In this case, with a working generator, the battery begins to supply the missing voltage, which inevitably leads to chronic undercharging and rapid failure of the battery.

The functionality of the device is indicated by a special lamp on the instrument panel. If there are problems with charging, the lit icon will notify you in time.

How the unit works

The rated voltage of the car's electrical network is 12 V. At the same time, the rated current of a standard VAZ 2110 generator is 80 A, and the rotor speed is 6000 rpm. The standard device is compact in size, which is not surprising given the low current.

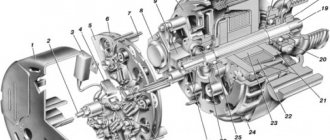

Structurally, the device consists of several main parts

| Parts | Characteristics |

| Rotor. | This component, more often called an armature, is a rotating shaft with an excitation winding, which, when rotated, creates a magnetic field. Power is supplied from slip rings on the armature shaft. There is also a wire from the winding, a fan (impeller), bearings and a belt drive pulley. |

| Stator. | The part of the generator that does not move when the crankshaft rotates. There are 3 windings (three phases) on it, creating an alternating current. Each winding is connected to all the others in two types of ways: star and triangle. |

| Frame. | Made of aluminum alloy. Consists of a front and rear cover, which are connected to the body using bolted fasteners. In front of the front cover there is a drive pulley, in front of the rear cover there is an impeller and slip rings. |

| Fasteners | The VAZ 2110 uses a bracket for upper mounting with two bolts. A single bolt is used to secure the bottom bracket. Thanks to these fasteners, the generator is securely fixed in its position. |

| Brush unit. | Graphite brushes, which are pressed against the rotor contact assembly by special springs, are fixed in brush holders. |

| Voltage regulator. | A non-separable (most often) unit with two graphite brushes, thanks to which the output voltage is regulated depending on the load on the rotor. |

| Rectifier block. Another name is diode bridge. | It consists of six diodes that transform alternating current generated by the magnetic field of the rotor and stator windings into direct current. It is subsequently used to power all electrical equipment of the car. |

| Drive pulley. | Serves to connect the rotating rotor shaft to the crankshaft using a belt drive. For these purposes, use a belt with 5 or 6 rivets. |

Most generator sets have such a device, regardless of how many amperes they are rated for. Differences may be in fastening methods, pulleys, and covers. Otherwise, all models are identical.

The resource of the standard VAZ 2110 generator is declared by the manufacturer to be at least 10 thousand kilometers.

This equates to 10 years of operation, provided that the rules of use of the device are followed according to the manual. When choosing an alternative option, you should take into account the number and power of energy consumers in the on-board network. So, for a standard set, 80 A will be enough, but when using, for example, powerful acoustics, it is better to pay attention to 120 A.

Installing new items

Before replacing worn VAZ-2110 bearings on your own, it doesn’t hurt to check the presence of lubricant in the newly purchased parts. To do this, you need to pry up and remove one of the plastic protective covers of the separator with a sharp object. If necessary, add lubricant and replace the cover. Then you can start replacing, for which you will need a standard set of keys and tools available to every business car enthusiast.

It is most convenient to dismantle the rear bearing of the generator using a puller, but if this is not available, a regular open-end wrench measuring 22-27 mm will do.

It is better to remove the generator from the car from the inspection ditch in the following sequence:

- Disconnect the battery and disconnect the wires from the contacts of the unit by unscrewing the fastening nuts with a 10 mm wrench.

- Unscrew the belt tensioner bolt, loosen it and remove it from the generator pulley. Remove the tensioner bar.

- Using a 13 mm wrench, loosen and unscrew the nut of the lower support of the unit. Remove the bolt and remove the generator from the car.

According to the manufacturer’s recommendation, replacing the VAZ-Ten generator bearing located at the front should be carried out together with the cover into which it is pressed. But there is no point in changing the cover if it is in good condition, which should be ensured before disassembling. And such a replacement will cost more.

The main thing that needs to be done carefully when performing further work is to remove the old bearings. The procedure is as follows:

- Place marks on the body and covers of the unit to indicate the relative positions of the parts. Unscrew the bolts holding the covers together with the body (4 pcs.).

- Use a flat-head screwdriver to separate the housing parts. Remove the back cover along with the winding.

- The front bearing is knocked out of the cover through a round insert. This must be done carefully so that the lid does not crack, otherwise it will have to be replaced.

- Remove the rear bearing using a puller or an open-end wrench inserted vertically at one end between the part and the rotor. Tapping the key with a hammer and moving it around the axis, gradually knock down the bearing.

New elements are pressed into place with a hammer using old bearings as guides. Then the unit is assembled and installed on the car.

Source

Ways to solve the problem

If such a malfunction occurs, you need to solve the problem as quickly as possible. Basically, there are three main ways to do this.

- Seek assistance from specialists at the nearest service station.

- Replace the complete prefabricated generator, rather than trying to solve the issue with a more budget-friendly method.

- Purchase a new bearing for the generator and replace it yourself.

What nuances does one or another method presented above have?

- The first option is reliable, but requires costs not only for the part itself, but also for the expensive services of craftsmen.

- The second option is more financially accessible, but you will have to do quite difficult work.

- Option number three is the most difficult from the point of view of independent execution, but is the most budget-friendly. Consequently, you will be able to save an impressive amount of money.

So, you have decided to purchase new bearings and follow a difficult but fairly economical path. For cars like the VAZ 2114, self-repair is a common thing. Such work, even in the absence of impressive experience and knowledge, is not difficult to do. Simple follow the instructions.

- Disconnect the generator from the battery to deprive it of power.

- Remove the timing belt.

- Using wrenches of the appropriate size, remove the fastening nuts.

- The film is removed, after which the sleeve is removed.

- The generator itself is carefully removed from its seat.

Subsequent work is more subtle and complex. After all, you have to disassemble the generator in order to get to the bearings. The task is not an easy one, but you can handle it yourself.

- There are nuts on the generator housing that need to be unscrewed;

- Remove the cover and remove the regulator from under it. This element is responsible for brushes and tension;

- Disconnect the stator from the cover. This operation should be done as carefully as possible so as not to damage the copper winding;

- Sometimes the housing can become rusty, making the stator difficult or even impossible to remove. In such a situation, arm yourself with a hammer and an impact screwdriver. With the help of these tools it is necessary to deliver the most accurate blows. This way you will be able to divide the element into blocks;

- Separating the generator from the stator, you will see both bearings - front and rear;

- Remove the damaged component and install a new alternator bearing in its place. Don't forget that there are two of them. For prevention, you can replace both at once, even if one of them is in completely good condition;

- Assembly is performed strictly in reverse order.

Important Tips

There are several questions that you should know the answers to before you begin the job of replacing alternator bearings.

- Installation must be carried out using a special press. Theoretically, it is possible to install a new element in place of the damaged one with an ordinary hammer, applying directed blows to the bearing. But this way you can damage the new spare part, plus additional damage to neighboring elements.

- Make sure the new element is firmly in place. Only after this proceed with installing the pulley and impeller.

- When purchasing a part, ask the seller what kind of vehicle this particular bearing is designed for. These parts differ in size.

- During the replacement process, be sure to check the tension of the timing belt. If the tension is not strong enough, voltage sag may occur.

If the above operations do not produce results, you should look for other potential problems with the generator.

Consequences of a malfunction

A faulty bearing, like any other failure associated with generator components, leads to its malfunction. It is impossible to predict the consequences of such a breakdown.

Let’s just say that both an inadequate and an excessive charge pose a potential threat.

- If the alternator does not provide sufficient charge, the battery will quickly discharge, so you will not be able to start the car or go anywhere.

- If a charge is too powerful, the consequences are even sadder, since this puts the entire electrical circuit of your VAZ 2114 at risk.

Problems and solutions

There are several common generator problems that are more than possible to repair. Here you just need to follow certain recommendations and rules.

We invite you to familiarize yourself with the malfunctions and methods for solving them in the corresponding table.

Generator bearing VAZ 2110

Current to power conversion calculator

Convert how many amperes a kW has online. Calculator for converting current amperes to power watts

The generator bearings ensure easy rotation of the rotor around its own axis. Since they have to constantly experience quite a lot of stress, they wear out over time. Which, in turn, will first lead to a hum, and then failure of the unit. In this case, they need to be replaced with new ones. Therefore, motorists have a question: “ What bearings are on the VAZ 2110 generator ?”

What bearings are on the VAZ 2110 generator?

The “tens” generator has two bearings – a larger front one and a smaller rear one. In this case, it is the front one that most often requires replacement, since it experiences more significant loads. But, over time, you also have to change the rear one, although it is better if you change it, then both at once. They can be sold as a set or separately. New bearings are selected depending on its size.

Bearing sizes for generator

The bearings of the VAZ 2110 generator have different sizes depending on the year of manufacture of the car, as well as whether it is carburetor or injection. They differ in diameter for the landing shaft.

| Dimensions of original VAZ 2110 bearings | ||||

| Year of manufacture of the car | Bearing | vendor code | Catalog number | Dimensions, internal diameter / external diameter / width, mm |

| Before 2001, carburetor | Front | 180303 | 6302 | 15×42×13 |

| Rear | 80202 | 6202 | 15×35×11 | |

| After 2001, injector | Front | 180302 | 6303 | 17×47×14 |

| Rear | 80203 | 6203 | 17×40×12 | |

Sedans of the first years ( before 2001 ), which are most often equipped with a carburetor, have old-style generators. In such a generator, the front bearing has dimensions of 15×42×13 mm, and the rear bearing – 15×35×11 mm. The first has catalog number 6302 and original article number 180303, the second has number 6202 and factory article 80202. Foreign-made parts will be marked 6302-2RS and 6202-2RS, respectively.

If the car is fuel-injected and manufactured after 2001 , then these parameters will be different. The front bearing of the VAZ 2110 generator (number - 6303, article - 180302) has dimensions - 17 × 47 × 14 mm. And the rear bearing with number 6203 and article 80203 is 17x40x12 mm. Their foreign analogues are marked: front - 6303-2RS and rear - 6203-2RS.

Size and catalog numbers

These parameters of the ball bearing are necessary for purchase, since without these numbers it is very difficult to buy the right part suitable for your car.

The dimensions of the bearings varied depending on the year of manufacture of the car, so the selection of a bearing can be carried out based on the year of manufacture. auto.

Cars manufactured before 2001 with carburetor engines they have bearings of type 6302 front and 6202 rear.

Cars produced after 2001 with injection engines, have bearings type 6303 front and 6203 rear.

Catalog numbers (articles) and external dimensions

To replace it, you will need to remove the generator from the car and some plumbing tools. It would also be a good idea to have a generator bearing puller. Having all the necessary tools, you can handle the job with basic mechanical knowledge.

The puller greatly facilitates bearing replacement work, saving time, effort and nerves. This device is a faithful assistant not only when working with a generator, but also with other car parts.

It consists of claws and a thrust bolt. There are a large number of different pullers, they are: two-jaw and three-jaw. In our case, when working with a VAZ 2110 generator, it is best to use a two-jaw one; it is the most compact and convenient to dismantle the bearing.

Its cost varies from 200 to 1000 rubles, depending on the quality of the part.

Necessary tool

The tools you will need to complete the work are presented below:

- Ratchet;

- 13mm, 10mm key;

- 21mm head;

- 8 mm hexagon;

- Gas key;

- Powerful screwdriver “+”;

- Hammer;

- Puller;

- Punch;

- WD-40 (lubricant)

- Rags;

- Marker;

Stages of work

1. Disconnect the negative terminal from the battery. We unscrew the wires on the generator with a 10mm wrench and remove the generator excitation chip.

2. Remove the generator from the car. To do this, unscrew the generator belt tension bolt and remove the belt, unscrew the generator from the mounts and remove it from the car. Be careful not to lose the rubber bushing and washers when removing the lower mounting bolt.

3. Let's start disassembling. Remove the plastic cover of the diode bridge by bending the three latches. Unscrew the two screws securing the brushes to the body and disconnect the connector from the brushes. We mark the alignment of the covers with a marker so that in the future we can assemble everything correctly.

4. Using a screwdriver, unscrew the screws of the ends of the generator winding from the diode bridge and bend them. Unscrew the screw securing the capacitor and separate the diode bridge from the generator.

5. Unscrew the generator pulley with a 21 mm socket, holding it with a gas wrench and holding the rotor shaft with an 8 mm hexagon. We take out the generator pulley and thrust washer.

6. Unscrew the 4 bolts of the cover and remove it along with the stator winding.

7. Remove the back cover by pressing the manifold with your fingers and pull the cover towards you, remove the plastic bearing bushing.

8. Remove the bearings using a puller.

We assemble the generator in the reverse order.

Which bearings are better to install?

As a rule, KATEK brand generators were installed on cars of this model from the factory. It may also be suitable for spare parts from some other domestic and foreign manufacturers. It is not recommended to use original bearings from the Samara and Volzhsky plants (VBF and VPZ), as well as Chinese ones, due to poor lubrication and short service life. Products from German brands DAS LAGER Germany and FAG, French brands SNR, Japanese brands NSK, NTN and Kouo, as well as Polish Craft are considered to be of good quality.

Price of bearings for VAZ 2110 generator

The price of a VAZ 2110 generator bearing is very low. It starts from about 100 rubles for the rear and from 150 rubles for the front. Here a lot depends on the manufacturer of the parts. Russian-made spare parts are considered the cheapest. Products of foreign brands are more expensive, sometimes twice as expensive.

Additional recommendations for replacing rotor ball bearings

- Reasons for ball bearing failure (for subsequent replacement):

- Wear of parts to failure (service life from 100,000 km);

- Ingress of dirt, abrasive particles, moisture;

- Damage to sealing protective washers, separator;

- Drying of the lubricant, insufficient quantity;

- Development of landing surfaces;

- Corrosion on rings;

- Low-quality steel (non-metallic inclusions, inconsistency in hardening, hardness);

- Inconsistency in the processing accuracy of rings, micro-geometry of raceways, balls;

- Before reassembling, check the condition of the internal elements of the mechanism (brushes, contacts); they should be changed at the same time;

- Additionally, it is recommended to check the condition of the clutch release ball bearing and the hub bearings on the VAZ.

- If, when unscrewing the pulley nut, it turns, insert a screwdriver into the groove of the cover, thereby stopping the rotor.

- When tightening bolts, lubricate them with graphite lubricant.

- Be sure to watch useful videos on how to correctly change bearings on a Lada model fourteen, as well as how to improve and strengthen the generator.

Improving the VAZ generator

Replacing generator bearings 2114

Articles on your car from an expert:

Best on the site:

Save it for yourself, it will come in handy!

Signs of bearing failure and diagnosis

You can understand that the bearing in the generator has failed by the following characteristic signs:

- when the engine is running, a hum, whistle or grinding noise is heard from under the hood;

- the generator is hot to the touch when the engine is running or immediately after stopping it;

- The device pulley rotates.

In addition, some other symptoms may indicate this problem. And the ones mentioned above do not always indicate a bearing malfunction.

Comparison of worn bearings (left) with new ones (right)

The bearings in the generator can wear out due to time, lack of lubrication or poor quality, and also due to too much belt tension. The latter is usually typical for front bearings.

In order to accurately verify the failure of this element, you need to carry out simple diagnostics. Simply remove the alternator belt and start the engine.

If the extraneous sounds disappear, it means that the bearing is faulty. With the engine off, you can slightly shake the generator up and down by grabbing its pulley. In this case, no backlash should be felt. You can find out which bearing should be replaced after disassembling and inspecting all the elements. It's often better to buy a kit right away just in case.

Recommendations and tips for repairing a generator

1.Before assembling the mechanism, check the condition of the brushes. These should be replaced immediately so as not to remove or disassemble the structure again. You will also need to replace the body bolts, if their edges are “licked”, be sure to check the condition of the rotor. 2. To make disassembling the case easier, moisten the fasteners, nuts and other threaded connections with WD-40 penetrating lubricant. 3. If you cannot remove the pulley with a hexagon, try fixing the rotor with a screwdriver inserted into the holes of the case. 4. When removing the product from the front cover, make sure that it has not fallen apart, otherwise it will become more difficult to remove. 5. Use an impact screwdriver when disassembling the housing so that the nut and bolt heads are not deformed. 6. When repairing the generator or replacing elements in it, be careful with the stator winding and the housing, as it is made made of brittle duralumin aluminum. 7. Carefully watch the video on how to replace a bearing in a generator.

Some novice motorists are sure that the source of energy in a car is exclusively the battery. But this is not so. The battery's job is to supply the necessary current to start the engine and provide power to the starter so that it turns the crankshaft.

The engine starts, and at this moment the electrical equipment begins to be powered by the generator. The quality of operation of electrically dependent equipment and timely recharging of the battery depend on the generator. If the generator breaks down, the entire load goes to the battery. Once it runs out of power, the entire car will be left without power.

In almost 90% of cases, generator failure is associated with its bearings. That’s why we’ll talk about them in more detail today.

Element appearance