Description of design

The bottom of the VAZ 2110 has the same design for all cars in the line and is made of rolled steel with additional stiffening ribs. The metal frame of the car is a type of frameless body; the entire load from the mounted units falls on the floor and side members, which act as a frame and ensure the massiveness of the entire structure.

Repairing the underbody of a VAZ 2110 in 90% of cases begins with checking the side members and involves the use of welding. The welding points that hold the body structures together are torn apart by vibrations, bolted connections become loose, and the solidity of the structure weakens.

Causes of corrosion

The manufacturer does not pay enough attention to the anti-corrosion treatment of these machines (as well as sound insulation). This is evidenced by numerous reviews from owners. But if you can still put up with the noise in the cabin, then you can’t put up with the holes in the floor.

It's uncomfortable and unsafe. Accordingly, the question arises about repairing or replacing the bottom of a VAZ-2110. Experts identify several factors that significantly accelerate its wear:

- Weather. Metal rusts upon any contact with water, even if it was painted and treated at the factory. But rain is not the most destructive factor. More aggressive towards metal are the salt reagents that our road services use to sprinkle the asphalt in winter. If you don't frequently wash the underside of your car with high pressure, the salt will remain in the most hidden places. Further, rust will form in these areas, and after a year - through holes.

- Road accident. Even with a minor accident, the base layer of enamel and primer separates from the metal. If the painting was done by unqualified craftsmen, after 1-1.5 years rusty marks will form in the same place. The same problems occur if the surface was not properly prepared for painting and was poorly cleaned.

- Clogged drainage. Often, repairs to the underbody of a VAZ-2110 are required due to clogged drainage holes. Water eventually gets into the cabin and trunk. It has nowhere to go - it is absorbed into the factory carpet and soft soundproofing material. In addition to corrosion, it can cause a characteristic smell of mold and rot. Water also forms when using unsealed mats. Textile products are very popular now. But not every model retains moisture, which is why it is absorbed into the carpet and then onto the metal.

Thus, the bottom of the VAZ-2110 is exposed to negative effects from both sides. Plus, it is very difficult to find the source of the problem. Not everyone has a hole in their garage, and no one will disassemble the interior in order to identify “bugs.” They ride until the floor is soft like jelly.

Are there any differences between the bottom of 2110, 2111 and 2112

The wheelbase size for all cars in the generation is the same and is 2492 mm, while the cars have different lengths, heights and number of doors, depending on the model:

- Sedan (2110); dimensions 4265x1680x1420 mm.

- Coupe (21123); 4193x1680x1435 mm.

- Hatchback (2112); 4170x1680x1435 mm.

- Station wagon (2111); 4285x1680x1480 mm.

The body layout of each configuration has design differences, but these differences do not affect the central bottom. The bottom of the VAZ 2110 has average prices of 3,000 rubles. and is suitable for installation on the entire line. The part is made of ferrous or rolled metal, without protective galvanization, and therefore always needs to be treated with anti-corrosion agents.

When repairs are required

For all VAZ models, a mandatory condition is periodic inspection of the body for corrosion. Already from the factory, automotive hardware must be additionally protected from rust. The first VAZ 2110 began to become covered with corrosion from the area of the windshield frame. The paintwork peeled off quickly; after 6 months the first rusty plaques could be seen under the paint layer.

Cooking a rotten car body if the degree of metal destruction exceeds 70% is expensive and impractical. To protect the car from corrosion, once every 6 months it is necessary to carry out preventive maintenance and replace the old used metal.

The main reasons for rapid wear:

- The car is over 7 years old. The bottom is checked in the inspection hole: if there is minor corrosion, metal patches can be used.

- Accidents and driving on bad roads. Any deformation of the metal after an accident leads to the fact that the protective layer of anti-corrosion in places where it is broken is destroyed, and the metal begins to wear out faster. The same applies to frequent trips on bad roads.

- Car parking on the street. VAZ cars need a warm and dry garage. Considering that the car body is not treated with zinc, just one winter outside can cause corrosion of the sills and bottom. Moisture penetrates through the protective layer and destroys the metal of the seal, the outer part of the bottom.

- Water in the cabin. The liquid that has accumulated under the rubber mat quickly penetrates the bottom skin and contributes to the rapid rotting of the metal unprotected by anticorrosive.

A complete bottom repair will be required in the following cases:

- It is impossible to put the car on a jack; the jack falls through.

- It is clearly visible that the floor in the cabin has become uneven - the bottom is 60% rotten.

- It is impossible to adjust the driver's seat due to the skew of the bottom.

- Under the threshold, under a layer of putty, rust appeared. It is checked with an awl if the anticorrosive layer has peeled off.

- The appearance of rust on the inner surfaces of the sills in the interior and arches.

What's next?

Then we apply primer and paint. We treat the metal on both sides with bitumen mastic or gun lard. Due to their greasy consistency, these compounds will repel water and prevent it from penetrating inside the metal.

Additionally, you can apply an anti-gravel coating (if the metal is treated with mastic and not lard). After the composition has dried, we soundproof the interior. Sheets with vibroplast must be laid on a clean surface. It doesn't stick to dirt. But it will adhere fully to sticky mastic. Additionally, we roll the sheet with a special roller or with our hands through a rag. Then you can safely assemble the interior and install the seats.

Preparation for repair

When choosing to repair the bottom yourself, you need to prepare tools and materials. For experienced craftsmen, a complete replacement of a part takes at least 3-4 days; the cost of work at a service station averages 45–50 thousand rubles. To work you will need:

- Bulgarian. Using an angle grinder, the corrosion plaque is removed from the bottom, parts of the patches are adjusted, cut off, and welding seams are aligned.

- Welding machine. It is recommended to boil the iron body and bottom, in particular. Semi-automatic welding with wire and carbon dioxide is suitable. You can use gas welding and 3 mm electrodes, provided you are skilled in such work.

- Electric drill for drilling spot welds.

- It is not recommended to carry out underbody repairs in a pit - it is inconvenient; it is better to use stands, a lift or skids; in some cases, the car is turned over on its side.

- Sound insulation sheets.

- Anti-corrosion set: mastic, R-80 sandpaper, primer, auto enamel.

Preparatory work step by step:

- Disconnect the negative terminal from the battery or remove the battery.

- Drain the fuel from the tank.

- Disconnect the electrical wiring from the door power windows.

- Remove the doors, marking the fastener locations on the body.

Before dismantling the doors, it is necessary to insert iron spacers into the openings or weld a channel, this will ensure that the geometry of the body is preserved if the center pillar reinforcement is rotten and there is a possibility that the roof will fall or bend in half.

Dismantling the interior

Replacing the underbody involves work inside the cabin and under the car. Dismantling the interior is carried out in steps:

- Pull out the seats.

- Remove the interior trim by unscrewing the moldings.

- Pull out floor coverings and carpets.

- Remove air vents.

- Remove the sound insulation layer and additional anti-vibration pads.

- Disconnect all internal wiring, twist the cables into a bundle, and remove the fasteners.

- Remove the dashboard to open access to the engine compartment if you plan to completely replace the bottom.

If you are an inexperienced tinsmith and electrician, it is better to distribute all fasteners into separate packages and sign them. When installing the interior, this will help you avoid getting confused with the parts.

Complete replacement of the bottom

Before starting work, it is necessary to disassemble the elements of the exhaust system. From the point of view of the sequence of operations, a complete replacement is no different from a partial one.

Welding work

Welding will be required both to replace the entire floor and during repairs, when the rotten part of the bottom is cut out and a patch is welded. The iron for the patch is cut out in advance; the size of the patch should be 2 cm larger than the hole around the perimeter. There is an option to use the original part of the bottom instead of a patch, which is sold separately.

Replacement of car underbody elements

After the car interior is cleared, a full inspection of the underbody is carried out. In some cases, you can limit yourself to a partial replacement—boil only the corroded areas. Rotting of the floor begins from the thresholds of the car; these elements are inspected first. Replacing the body also begins with reinstalling the thresholds.

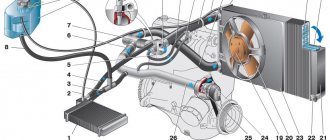

The bottom of the VAZ 2110 consists of the main elements:

- support platform;

- bottom panels;

- threshold extension;

- side member amplifier;

- crossbars;

- connectors.

It is necessary to check the condition of the panels under the driver's feet, side member reinforcements, jacks or support platforms. If the overall condition of the bottom is satisfactory, you can limit yourself to installing a patch on the damaged area or replacing the bottom element from the repair kit:

- A drill is used to drill the spot welding points with which the element is installed on the structure.

- The element is cut out with a grinder.

Under the bottom of the car on the driver's side there are tunnels for the fuel line and brake system. Removing the system on a VAZ 2110 is quite problematic; it is recommended to cut off the old lines and install new parts after repairing the bottom.

- A metal patch is cut out.

- The bottom is sanded and a patch is welded.

- Welding seams are cut off with a grinder and cleaned.

- The element is primed, sanded, and treated with anticorrosive.

Initial work before restoration

Primary work involves a number of sequential operations:

- mastic;.

- guide;.

- sandpaper;.

- protective enamel.

After disassembly, it will become clear whether the repair will consist of additional steel parts, or whether the entire VAZ 2112 base will need to be prepared.

- removal of seats, as well as interior leather;

- removal of moldings (if installed);.

- removal of air ducts;

- elimination of sound insulation, as well as exhaust gas insulation;.

- Getting rid of downloadable things.

In the case of the proposed replacement of the low station wagon with a VAZ 2112, it will certainly be necessary to get rid of the main passage from the dashboard. This will certainly facilitate access to the engine compartment.

Final processing

After welding work, it is necessary to clean the seams with a grinder, carry out anti-corrosion treatment, and install new sound insulation panels. The bottom of the VAZ 2110 must be treated with anti-corrosion agent both from the outside and from the inside. Bottom finishing:

- The welds are cleaned until they shine, a grinder is used, and at the final stage, sandpaper R-80 is used.

- The seams are covered with bitumen-based mastic.

- The bottom surface is primed outside and inside the cabin.

- An oil-based anti-corrosion agent is applied to the inner surface. The composition penetrates into all hidden grooves and pockets.

- The outer part of the body is treated with anti-gravel protection.

- Sound insulation panels are cut to the required size, heated with a hair dryer, and placed on the bottom inside the cabin.

- Doors are being installed.

The work on replacing the bottom is completed, all that remains is to mount the interior, install the trim elements, and connect the electrical wiring.

Replacement of structural elements

When performing work, keep in mind that the elements of the bottom are:

- help platform;

- composite panels;

- threshold extensions;

- side element supports and cross elements;

- adapters.

By assessing the problem, it becomes clear whether a specific aspect of the body can be fixed or whether the entire body will need to be replaced. For fragmentary repairs, it is necessary to drill holes in the places where the part is connected by welding. The body element itself will need to be removed using a bolt cutter.

To re-weld another area, the area must be prepared in advance. Additional work is performed in the following order:

- the area is sanded;

- the iron part is glued;

- welds are processed;

- the area is primed, sanded, and covered with an anti-corrosion structure.

A partial replacement is only possible in 1 case out of 10. A complete replacement of the bottom is carried out if the version of various aspects is not suitable.

How to extend the life of the bottom

The body on all VAZ models is not a high-strength unit. To maximize the life of the main part of the car, it is recommended to systematically carry out preventive maintenance. It is impossible to completely eliminate the aging process of metal, but every driver can increase the service life of a new underbody.

- Prevent water from entering the cabin through depressurized moldings on the windshield and side doors.

- Systematically remove the rubber mats under the driver's seat and check the floor for dryness. Systematically clean drains in thresholds and doors. Particular attention is paid to the area under the battery: under the influence of the electrolyte, the drainage holes on the platform become coked.

- If the first rust is found on the bottom of the interior, clean it, fill it with epoxy resin, and treat it with an anti-corrosive agent with the effect of preserving corrosion areas.

- Clean chips and renew the paintwork on the sills immediately after detection: the sills and fenders begin to rot first.

- It is necessary to lift the car with a jack only with the doors closed.

How to find rust on the bottom

A prerequisite for trouble-free operation of the 12th family hatchback is periodic inspection of the car for corrosion from below. Even cars from recent years of production need additional processing.

It is better to carry out a comprehensive inspection of the bottom. Among the main detected defects are:

- peeling of the anti-corrosion composition;

- the appearance of local foci of corrosion (jack attachment points, thresholds);

- presence of fires on the interior side.

You should not delay diagnostics, since if the iron is damaged by 70% of its thickness, restorative repairs are difficult to carry out. It is more convenient to do diagnostics when lifting the car on a lift or driving into an inspection hole. It would be a good idea to look under the upholstery and from the interior.

How to choose a part: average prices

To weld the bottom of a car at a car service center, the minimum price is 25,000 rubles. This applies to minor floor defects in all customer materials. A complete overhaul and update can cost up to half the cost of a car. Considering that the price of a VAZ is minimal, such repairs are not profitable for most drivers.

Many people prefer to carry out repairs and replacements on their own, buying a solid bottom. The repair kit is produced by AvtoVAZ, the element is suitable for models 2110, 2111, 2112, 2170, 2171, 2172. The cost does not exceed 4,000 rubles. Cold-rolled steel 0.8 mm thick is used in production.

There are options on the market to buy bottom elements: panels, amplifiers, connectors and cross members. The cost of each element is from 900 rubles. Parts of the bottom are chosen instead of metal patches if local repairs are necessary without welding out the entire bottom.

Replacement of car underbody elements

Most often, when replacing individual parts of the bottom or installing patches, welding is used; a semi-automatic welding machine is best suited for such repairs. If an entire separate part is being changed, for example a cross member, you can drill out the rivets and dismantle the element without welding.

When the bottom and sills are changed at the same time, the latter are removed from the car first, and when replacing sills it is important to control the geometry of the body. When replacing floor panels, the bottom parts are always mounted from below, then welded or riveted. When there are many holes and pockets of corrosion in the floor of the body, it is better to replace the entire bottom, especially since it is relatively inexpensive when assembled for the “Ten”.

Self-repair of the underbody of a VAZ 2110

The current condition of the car can largely be assessed by analyzing the body.

If all kinds of consumables need to be replaced, you can even rebuild the suspension yourself and even install a new engine, then restoring a completely rusted body is expensive and pointless. No one will tune, modify, or invest a lot of money in a car if its body is already in its last years. This significantly reduces the cost of the car, even if the engine is in perfect condition.

Therefore, if you want to maintain the attractive appearance of your VAZ 2110, extend its service life, and, if necessary, sell it for good money, keep an eye on the body and periodically carry out repair or preventative body work aimed at combating corrosion.

Replacement of thresholds VAZ 2110, 2111, 2112

By examining the condition of the thresholds and bottom of the VAZ 2110, you can easily determine the age of the car. It should be recognized that the factory anti-corrosion treatment is not of very good quality and without proper care, after 7-10 years, through holes may appear on the thresholds as a result of corrosion.

In this article, we will analyze the process of replacing VAZ 2110 thresholds, list the tools and materials for the work, and also talk about why thresholds rust and how to extend their life when there is no severe corrosion yet.

Why do the thresholds of the VAZ 2110 rust?

There are several reasons:

- Irregular anti-corrosion treatment. On vehicles of the VAZ family, preventive treatments must be carried out before each winter season of vehicle operation.

- The car was damaged in the threshold area and poorly repaired. In this case, corrosion develops very quickly and after 2-3 years through holes may appear.

- Winter operation on roads where a lot of reagents are used. Salts settle on the thresholds of the car and after a short period of time “break through” the external anti-corrosion treatment, starting the corrosion process. If you operate a car in such conditions, you need to wash it once a month and preferably with warm water.

- Damage to the external protection of the threshold and its untimely restoration.

- Blockage of drainage elements in thresholds. Drains should be checked once a year throughout the entire body.

Threshold selection

The threshold consists of three parts:

- External lining.

- Amplifier inside.

- Connector.

Thresholds can corrode in different ways, but generally, if there are through holes, you will need to purchase the entire three-piece threshold kit.

Threshold article number for the right side is 21100-5401060-00, for the left side 21100-5401061-00. Ask for connectors and amplifiers in stores; they are not available for order according to factory articles.

Tools and materials for work

Step-by-step replacement process

- First, remove the doors, seats, bumper and front fenders. Also remove carpets, seat belts and sound insulation.

Use a grinder to cut through the previously marked areas.

We core all the contact welding points along the edges at the top and bottom of the threshold. Next, we drill out the points, and then use a body knife to separate the metals from each other.

After you have separated the threshold, remove it and evaluate the condition of the bottom, amplifiers and connectors. If necessary, cut off rotten parts of amplifiers, connectors, or remove them entirely.

We clean all welds, grind the threshold with abrasive and apply epoxy primer.

The process of replacing thresholds for VAZ 2110, 2111, 2112 is clearly shown in this video:

Let's summarize

To replace VAZ 2110 thresholds with your own hands, you need to have many specific tools and skills. If you are not ready to learn bodywork and invest money in tools, trust the replacement of the threshold to professionals. The price of replacing a threshold with painting and anti-corrosion treatment is from 7,000 to 12,000 rubles.

Causes of rust and preventive measures

The first versions of the VAZ 2110 were characterized by the fact that their paintwork began to peel off in the area of the windshield frame. The problem began to develop from the seal and gradually spread to the entire body element.

Soon the manufacturer changed the painting and installation technology, but still the problem of a body that was not resistant to corrosion could not be completely overcome.

We will look at the main reasons for the probable appearance of rust on the sills, bottom, arches, and side members. We will also give some tips on how to deal with them.

| Causes | Prevention measures |

| Age | After 5-7 years, traces of corrosion may appear on the body and bottom. There are no remedies against age, so listen to the following protective measures |

| Accidents and accidents | It is easy to advise avoiding accidents. In this case this is the only recommendation |

| Poor quality repairs | Do not try to save money on body repairs, since an unqualified specialist will not really do anything, but will only waste your time and money. Choose experienced, proven craftsmen and service stations |

| Weather | The worst thing is snow and rain. Try to knock down and wash away the snow stuck under the bottom. Especially if you often drive on roads sprinkled with salt or snow and ice melters. |

| Humidity in the garage | Think about the issues of moisture protection of the room; in winter, periodically turn on the heater or heat fan in the garage in order to at least partially combat the high level of rust |

| Driving on gravel | Small stones destroy the anti-gravel coating within a year, after which corrosion begins to appear. Avoid such roads, carry out periodic preventive maintenance |

| Moisture in the cabin | It gets through wet shoes and snow brought into the cabin. As a result, the bottom begins to rot from the inside. Be sure to lay down rubber mats with sides in winter; be careful that water does not get inside the cabin during rain or car wash. |

To increase the service life of the underbody of your own car, periodically perform anti-corrosion treatment. Pay special attention to the hidden cavities of the side members and sills.

Rusted thresholds

Problem Definition

It is not difficult to determine the presence of rust on the bottom. Although if you bought the car second-hand, these problems can be carefully disguised.

- Be sure to inspect the body from below. Traces of corrosion may be hidden behind a layer of anti-gravel coating or putty. Use a hammer or awl to hit these areas lightly. If rust is present, you will see it.

- Check the condition of the body along the thresholds, in the cabin at the feet of the driver and front passenger. It is these places that are quite weak in the case of the VAZ 2110.

- If the bottom is rotten, you can notice this by the sagging of the floor under your feet under load.

- When the driver's seat comes off or cannot be moved, a rotten body may also be the cause.

- One of the most unpleasant situations is rotten thrust pads designed for lifting a car on a jack. But this way you will immediately determine that there are problems and they need to be solved.

Boil the bottom of the VAZ 2110

I have a typewriter. It’s old, but it’s dear to me—I build on it. It still starts in any frost, drives and doesn’t break down. But it has one problem - it has begun to rust. It’s still too early to cook the body, but the bottom and bottom of the trunk—things have already begun to fall out. The holes are big, in short.

I would like to digest it, cover it with an anti-corrosion coating so that rust does not appear on it until at least another three years.

What can you recommend? How much could it cost?

Best regards, Sergey Tikhomirov.

Bottom repair Hello!

Disassembly/assembly of the interior, welding of the bottom and trunk, anti-corrosion treatment - RUB 30,000. I think it can be done.

The condition of the car largely depends on the body. The suspension can be “rebuilt” by replacing worn and faulty parts. The engine's attachments are also repaired or replaced; in severe cases, major repairs or complete replacement are performed. Body work determines the appearance of the car and, in many ways, its service life.

New VAZ 2110 from the showroom with an ideal body

When is repair required?

The first copies of the tenth family had a characteristic feature - the paintwork on the windshield frame peeled off at the top, starting from under the seal. Then this disease was overcome by changing technology, but the weaknesses remained.

Already on five- to seven-year-old cars, corrosion on the sills is very likely, and ten-year-old cars necessarily require monitoring of the bottom, arches, and side members.

They accelerate the appearance of rust and through corrosion, damage in road accidents followed by incomplete or unqualified repairs, difficult operating conditions on bad roads in winter and in bad weather, storage in conditions of high humidity.

Regular anti-corrosion treatment done at a service center or with your own hands will help extend the life of body parts; it is especially necessary for the hidden cavities of the sills and side members, this power “skeleton” of the car.

The bottom is corroded on both sides. From below he is attacked by dirt and water from the road. If the anti-gravel coating is damaged, the first spots appear literally within a year; after 2–3 years, with intensive use, corrosion becomes through.

Through corrosion of the bottom

In the cabin there is a carpet on the floor, under which there are layers of vibration-insulating and noise-absorbing materials. If water or snow gets into the bottom trough, for example from shoes, the coating gets wet and does not dry well. Increased constant humidity leads to corrosion of the bottom from the inside of the cabin and the need for repairs. To prevent this, use rubber mats with sides, and make sure that no water gets into the interior during rain or when washing.

Corrosion due to moisture under soundproofing material

A rotten bottom is revealed when viewed from below; under a layer of putty or anti-gravel, the holes may not be visually noticeable, but light blows with a hammer or pricks with an awl will immediately reveal the defect. Corrosion most often appears along the sills and in the driver's and front passenger's feet.

In the cabin, poor condition of the bottom will be indicated by sagging of the floor under your feet under load, in extreme cases, the breakdown or impossibility of fixing the driver's seat. And, of course, there is a frequently encountered situation when, when lifting a car on a jack, the special thrust pads for the jack break due to corrosion.

Preparation for repair

Bottom repair can be done with your own hands, but this requires a good tool, a suitable room, free time, skills and desire.

When working with metal, you cannot do without welding. It is optimal to use a semi-automatic welding machine with wire and carbon dioxide; compared to gas and electrodes, it is much simpler, more convenient and of better quality. An angle grinder will be needed when removing rotten floor fragments, for fitting parts and patches during welding work, and for cleaning seams and surfaces before processing and assembly.

Semiautomatic welding machine with wire for welding with carbon dioxide

You also need stands for the car, for example, four pieces of the “diamond” type. The rest of the tool is standard and more common. The materials you will need are welding wire, joint mastic, anticorrosive, sandpaper, primer, paint, soundproofing sheets.

For repairs, the car is driven indoors and placed on stands. It must be possible to work comfortably and safely from below the bottom. The battery and electronic control unit are turned off to prevent damage during welding. The doors are removed; to maintain the rigidity and geometry of the body, spacers in the doorways are very desirable.

The next stage will be lengthy and responsible - disassembling the interior. Here you need to dismantle the seats, remove the floor tunnel lining, air ducts, remove the carpet, move the wiring harnesses aside, scrape off or beat off the noise. If it becomes necessary to change the entire bottom or weld in a floor panel, then you need to remove the torpedo and the beard - access to the engine shield must be open. It is recommended that all fasteners be carefully assembled, packaged and labeled to facilitate assembly work.

Welding work

When the floor is completely visible, you can decide on the scope of repairs. At best, you can do without replacing parts. All areas of corrosion must be thoroughly cleaned down to “healthy” metal and, if necessary, reinforced with patches. But usually this option is unlikely.

If there are through holes or loss of rigidity, the corresponding body part must be replaced. For VAZ models of the tenth family, the body floor consists of:

- floor panels;

- threshold extensions;

- front spar extensions;

- support platforms;

- connectors;

- cross members.

To replace, the old part is drilled out at the welding points or cut off with a grinder. Remember that there are fuel and brake lines running underneath the underbody on the driver's side. Disassembling them on similar machines is problematic; it is easier to cut them off and replace them with new ones during installation.

If the floor panel of the VAZ 2110 is in very poor condition, then the entire bottom assembly is replaced, in which case additional dismantling of the exhaust system will be required. If it is necessary to replace the thresholds at the same time, then they are changed one at a time with geometry control, and only then the floor is re-welded.

Marking, cutting out the old, fitting the new requires attention and accuracy, and the welding itself also requires an assistant. The bottom is started from below, tacked, the main welding is not done with a continuous seam, but in increments of 4–5 cm.

Final processing

After welding is completed, the seams must be protected from corrosion.

The metal is cleaned from scale to a shine and coated with joint mastic. All surfaces are primed, then painted in the main color, without selecting paint. The selection of quality materials and careful processing will guarantee successful corrosion resistance.

A layer of mastic and anti-gravel coating is applied on the outside. From the inside, after adjusting to size using scissors and heating the bitumen layer with an industrial hair dryer, sheet sound insulation is glued.

Now all that remains is to assemble the interior using the fasteners packaged and signed during disassembly.

Repairing or replacing the underbody with your own hands is within the capabilities of most car enthusiasts. If you want to save money, feel confident, learn new skills, and maybe hang out with friends in the garage and take a break from family worries, then go for it. Do-it-yourself car repair is necessary, useful, and affordable.

VAZ-2110 is a very cheap and easy to maintain car. But one of its main “sores” is the body. Unfortunately, it is poorly protected from corrosion. After only two years of operation, “bugs” form on it. If you continue to ignore the problem, through holes will appear. Rust forms everywhere: on the arches, fenders, and at the bottom of the doors. But the most vulnerable spot of the VAZ-2110 is the bottom. See photos and description of the repair process later in the article.

Preparatory activities

To repair the bottom with your own hands, you first need to prepare in a certain way. You will need a set of tools, premises, a lot of time, experience and desire to do such things.

Of the tools, it is especially important to prepare the following components:

- Welding machine. In the case of repairing the underbody of a car, it is better to use a semi-automatic machine with wire and carbon dioxide. It is better, more efficient and more reliable than gas and electrodes;

- Angle grinder. It will be useful, if necessary, to remove rust from the floor, to adjust elements and patches, to clean seams and surfaces;

- Car stands. Here you can use various items. So look for what you have;

- The rest of the kit is standard and includes such components as anti-corrosion solution, mastic for seams, welding wire, sandpaper, primer, soundproofing sheets, paint, etc.

Now you need to drive the car into the garage or other equipment room and put it on stands.

The machine should be positioned in such a way that it is comfortable and safe to work under it.

Disconnect the battery, then remove the doors. In this case, experts advise providing spacers for doorways in order to maintain body rigidity and the necessary geometry.

Dismantling the interior

Since you need to repair the underbody not only under the car, but also from the inside, you will have to completely disassemble the interior. This is a difficult task that will take a lot of time. Be psychologically prepared for this.

You will have to dismantle:

- Armchairs;

- Floor tunnel lining;

- Carpeting;

- Air ducts;

- Soundproofing layer.

Carefully collect all the wiring, combine it into bundles if they are not collected, so that later there will be no problems with assembly. Collect all fasteners, distribute them into boxes or bags, and label them. This is extremely important because you may face serious problems later.

If you plan to completely replace the bottom or weld a panel to the floor, then the dashboard and beard will have to be removed to create open access to the engine shield.

Lifting a car

Welding

So, you have disassembled your VAZ 2110, so now you can really assess the condition of the bottom, as well as analyze the required amount of work. The most optimal situation is one that does not require replacement of elements. The rust spots are cleaned until high-quality metal is obtained, after which they are strengthened by patches. But not everyone manages to face such a situation.

If the holes in the bottom turn out to be through, this will lead to a loss of body rigidity, therefore it is strongly recommended to replace the element completely.

In the case of the VAZ 2110, the following body elements are distinguished:

- Floor panels;

- Support platforms;

- Threshold extensions;

- Spar extensions;

- Crossbar;

- Connectors.

Now let's discuss a few basic nuances of welding.

- To replace a part that has “slipped” due to corrosion, it must be drilled out at the welded points or simply cut off using a grinder.

- Do not forget that the brake and fuel system pipelines pass under the bottom. It is extremely difficult to dismantle them, so the easiest way is to cut them off and install new pipeline elements during reassembly.

- If the floor panels are in critical condition, the entire bottom assembly should be replaced. But in this case, be sure to dismantle the exhaust system.

- If it is necessary to change the thresholds, they are dismantled and new ones are installed one by one. It is important to control the geometry.

- If the floor and thresholds are being replaced at the same time, the thresholds are replaced first, and only then the floor panels.

- Carefully mark the elements for welding. The old components must strictly correspond to the new ones being cut out.

- You cannot do without an assistant, so agree in advance with someone who can help you.

- Always start the bottom from the bottom, then grab it.

- Do not make the main weld using a continuous weld. Maintain a step of approximately 4-5 centimeters.

When welding work is completed, be sure to carry out anti-corrosion treatment.

How to properly replace the underbody of a car?

- Log in to reply to this topic

#1 Maler

- Top

- Insert nickname

#2 Vladimir from Kamyshin

- Top

- Insert nickname

#3 Peacemaker

- Administrator

- Messages: 7,037

- City: Irkutsk. Alexander, can you please

Can anyone tell me how to replace it correctly and reliably? I looked for smart welders in the area, but couldn’t find them. Seeing the work of some craftsmen, it became simply creepy (I don’t give a shit either). I would be grateful for your advice.

Attached images

- 4

- Top

- Insert nickname

#4 MIHA75

- City: N. Tagil

- Top

- Insert nickname

#5 Maler

thank you. The car was bought by my sister and who knows. It turned out to be a bit broken. It’s a pity to sell. I changed a lot of things with my own hands (debut). The bottom is rotten. Apparently it was without treatment. I’ll be honest, I don’t know about the thresholds and the above. I don’t even know such words))) that’s why I’m looking for a person who will do it conscientiously. They suggested taking it to a service center to measure and level the geometry (visually the left gap on the trunk is a little larger. I think a stretcher and a properly tightened lid will correct the situation). In general, they don’t take on small rust, they offer to paint everything at once, with welding work the price becomes huge. Don’t laugh, but if I had the extra 100 thousand they ask for at the service center, they wouldn’t take the ’04 VAZ. I cooked it myself, without experience. I've been working recently. and not particularly neat. You still have years of training to reach your level. in general, I’m afraid myself. If I looked at how it’s done, maybe I could learn. In welding, I mastered what I can with the help of your forum and by trial and error. I would have practiced on some Cossack, but not))) inner voice yells - don't poke your nose in) sorry for the many letters)