The engine is the main power unit of any car, on which both its power and dynamic characteristics depend. VAZ-2107 models are equipped with four-stroke engines, each cylinder of which has two valves. Older cars are equipped with a carburetor engine, and new ones are equipped with an injection engine.

Main characteristics of the model

In the large model range of Zhiguli cars, the VAZ-21074 stands apart. A powerful engine with a displacement of 1569 cm 3 gave it the right at that time to be considered the fastest rear-wheel drive sedan that rolled off the assembly line of the Volzhsky Automobile Plant.

On the first models of the 7th series, the engine was similar to the 5th model. Only a little later they began to install a more powerful engine from the no less popular VAZ-2106 car.

The vehicle's ground clearance is 17.5 cm. The installed tires have an outer radius of 165 mm. The volume of the luggage compartment is 355 liters. The total curb weight of the vehicle is 1430 kg. Maximum speed is 150 km/h. In 16 seconds the car accelerates to hundreds. A fuel tank of 39 liters allows you to store a fuel reserve of 400 km in urban mode.

The brake system did not change and was inherited from the prototype model - VAZ 2105. Initially, these cars were almost identical, but, nevertheless, they had certain distinctive features, namely:

- shape of the hood and trunk;

- radiator screen;

- rear lights;

- chrome bumper trims.

The car has proven itself to be unpretentious in operation, and the cost of spare parts is in an affordable price segment. This aspect is one of the main factors that positively influences the buyer’s choice (in favor of the VAZ-21074). We will consider the technical characteristics of components and assemblies in more detail below.

Engine number location

Regardless of the engine modification, its number can be located in one of three places:

- In the engine compartment on the air intake shelf on the starboard side.

- On the cylinder block on the left side.

- Near the oil filter.

To find the number, you need to flush the engine. The number is stamped in a special font.

The principle of operation of the injection engine is clearly shown in the attached video:

Salon VAZ-21074

The design of all modifications of the VAZ-2107 family (including the VAZ-21074 injector) provides for the arrangement of components and assemblies according to the so-called classical scheme, when the rear wheels are driven and the engine is shifted forward as much as possible, thereby ensuring optimal weight distribution along the axles and, as a result, improving vehicle stability. Thanks to this arrangement of the power unit, the interior turned out to be quite spacious and was located inside the wheelbase, i.e., in the zone of best ride smoothness, which could not but affect the comfort of the car.

The interior of the VAZ-21074 turned out to be quite spacious and comfortable

The interior trim is made of high-quality non-glare materials. The floor is covered with mats made of non-woven material on a polypropylene base. The body pillars and doors are upholstered in semi-rigid plastic, covered on the front side with caprovelor; velutin is used for seat upholstery. The ceiling is finished with polyvinyl chloride film with a duplicated foam pad, glued to a base formed from plastic. Through the use of various mastics, layered bitumen gaskets and felt inserts:

- heat and sound insulation of the interior is achieved;

- vibration is eliminated;

- Metal components are protected from corrosion.

Principle of operation

The internal combustion engine is designed to convert thermal energy into mechanical energy. The conversion process occurs in the cylinder block during combustion of the combustible composition. The preparation and delivery of a mixture of gasoline and air into the combustion chamber of the cylinder is carried out in different ways.

In an engine with external mixture formation, the mixture is prepared in the carburetor. The fuel is mixed with air and enters the combustion chamber through the suction manifold through the inlet valve. It is ignited by a spark plug and burns, expanding the gas, driving the piston.

In an engine with an injection system, the process occurs differently. The fuel-air mixture is prepared in the suction manifold just before entering the combustion chamber.

When the intake valve opens, the injector opens and sprays gasoline. It mixes with air, enters the combustion chamber and at a certain moment is ignited by a candle. From the generated heat, the gas expands and presses on the piston. A working process is taking place.

The VAZ 2107i was equipped with an engine with a distributed injection system, i.e. Each cylinder is supplied with fuel individually through its own injector. There are four injectors according to the number of cylinders.

The injectors, or rather the entire system, are controlled by an electronic control unit (ECU). Judging by its functionality and the amount of work performed, it can be called an on-board computer. All data from electronic and mechanical sensors enters the unit, is processed and commands the actuators to perform certain actions.

The operating principle is as follows. From the gas tank through the filter, the fuel pump supplies gasoline to the fuel rail, then to the injectors. Inside the ramp, a constant pressure of 300 mPa is maintained using a regulator. If the pressure rises, the excess fuel is dumped into the gas tank through a cutoff automatically.

The ECU sends a signal to open and close the injectors in the order in which the cylinders operate, while being guided by readings from the crankshaft position sensor.

The amount of fuel passing through the injector depends on the length of time it is open. The time is calculated by the control unit using information received from the mass fuel flow sensor and the throttle position sensor.

These are the fundamental parameters under which the engine can operate, but for the correct and smooth operation of the unit, the electronic control unit takes additional readings:

- from a coolant temperature sensor to regulate the combustion process of the fuel-air mixture;

- from a voltmeter to determine the voltage in order to clearly establish the start and end time of the injectors;

- from a tachometer to determine the crankshaft speed;

- from the catalyst to determine the composition of exhaust gases.

The ECU also controls the fuel pump, idle air control and ignition system.

Engine and transmission

The engine from the VAZ-2106 was installed on the VAZ-21074 model without any modifications. The technical characteristics of the engine made it possible to achieve a power of 74 hp. With. There are 2 valves per cylinder. The “five” had a belt drive of the camshaft, which made the engine less noisy. However, a belt is less reliable than a chain. Therefore, on a more powerful engine, it was decided to leave the timing chain transmission unchanged.

The gearbox compares favorably with its predecessors. It has a fifth speed, the gear ratio of which is 0.819. All other speeds have lower gear ratios compared to previous analogues. As a result, the gearbox operates more “softly”. The rear axle gearbox with self-locking differentials has 22 splines - it was borrowed from the VAZ-2106 model.

The suspension of the front pair of wheels is independent. The rear suspension has a rigid beam. This design significantly improved the car's stability when cornering.

What kind of engine can be installed on the “seven” instead of the standard one?

The driver begins to think about changing the engine when, for some reason, he is no longer satisfied with the operation of the standard equipment. In general, the 2107 model is excellent for various kinds of technical experiments and tuning, but the rational approach to choosing new equipment has not yet been canceled.

Therefore, before you even think about a new motor for your swallow, you need to weigh the pros and cons, namely:

Engines from other VAZ models

Naturally, engines from cars of the same family can be installed on the VAZ 2107i without significant modifications and loss of time. Experienced car enthusiasts advise taking a closer look at engines from:

These are more modern power units with an increased number of “horses”. In addition, the engine dimensions and connection connectors are almost identical to the standard equipment of the “Seven”.

Engines from foreign cars

Imported engines are rightfully considered more reliable and durable, so the idea of installing a foreign-made engine in a VAZ 2107i often excites the minds of drivers. It must be said that this idea is quite feasible if we take Nissan and Fiat models from 1975–1990 as donors.

The thing is that Fiat became the prototype of the domestic Zhiguli, so structurally they have a lot in common. And Nissan is also technically similar to Fiat. Therefore, without significant modifications, you can install engines from these foreign cars on the VAZ 2107.

Rotary power units

On "sevens" rotary engines are not that uncommon. In fact, due to the specifics of their work, rotor mechanisms can significantly optimize the operation of the VAZ 2107i and give the car acceleration and power.

An economical rotary engine ideal for the 2107 is a modification of the RPD 413i. The 1.3-liter unit develops power up to 245 horsepower. The only thing the driver should know about in advance is the drawback of the RPD 413i - a service life of 75 thousand kilometers.

Today, the VAZ 2107i is no longer produced. At one time it was a good car at an affordable cost for living and working. The injection modification of the “Seven” is considered to be maximally adapted to Russian operating conditions; moreover, the car is easily amenable to various kinds of under-hood upgrades and alterations.

Source

Design and construction

Compared to the basic “five”, the luxury version of the VAZ-2107 received a new and even daring front design, a different radiator grille, which was most often chrome-plated, plastic bumpers with chrome trims. To accommodate the new radiator grille with a larger area, the shape of the hood had to be changed. Less noticeable changes include slightly modified rear lights and a modified shape of the trunk lid; compared to the VAZ-2105, there were no stampings on it, but since 2008, due to unification, the shape of the lid has become the same as that of the “five”.

In the interior of the VAZ-2107, more comfortable front seats with integrated headrests were installed, and even more comfortable than those installed on some more modern VAZ-produced cars. For the first time, the rear sofa received a folding center armrest. Cold air deflectors appeared in the center of the dashboard, and a tachometer and oil pressure indicator appeared on the instrument panel. A new 4-spoke steering wheel was developed especially for the VAZ-2107. Some other interior details were also changed - door trim, beard, door lock buttons and gear shift lever.

As a power unit, the VAZ-2107 car received a more powerful 8-valve carburetor engine with a volume of 1.5 liters and a power of 77 horsepower, together with a manual 4-speed gearbox. But as expected, this engine was not the only one equipped with the VAZ-2107. By analogy with its predecessors, the “Seven” was equipped with a variety of engines with a volume of 1.3 to 1.7 liters and a power of 64 to 140 horsepower (with a rotary piston engine).

Since about the beginning of the 2000s, the VAZ-2107, along with other cars of the classic family, has increasingly been subject to tuning. Its low cost on the one hand and simply an incredible number of shortcomings on the other greatly contributed to this. Very often, the car was subjected to additional sound insulation, modifications to the engine to increase its power, and increase the overall level of comfort. This list can be continued endlessly.

What is the power of the VAZ-2107 engine and how many horsepower is it?

The engine is the main power unit of any car, on which both its power and dynamic characteristics depend. VAZ-2107 models are equipped with four-stroke engines, each cylinder of which has two valves. Older cars are equipped with a carburetor engine, and new ones are equipped with an injection engine.

VAZ-2107 engine design

Before we move on to describing the characteristics of the engine, we will talk in detail about all the elements of its design so that you can imagine exactly how the power unit works. Consists of the following main components:

- cylinder block. The heaviest component made from cast iron. This is where the cylinders are located, which are placed in one row. In addition, the block has passages for coolant, which prevents engine overheating during operation;

- the crankshaft, which transmits engine rotation to other components of the car. It also has quite a lot of weight. The crankshaft supports (cranks) are made of metal, which is hardened by high-frequency currents for maximum strength;

- connecting rods with piston pins made of forged steel. These elements are constantly subjected to high loads;

- pistons with compression and oil scraper rings;

- cylinder head. This part is made from a durable but very lightweight aluminum alloy. To prevent lubricant leakage, the cylinder head is equipped with a sealing gasket;

- a flywheel that is used to start an engine. It is in clutch with the starter, which responds to turning the key in the ignition;

- timing mechanism, which includes the camshaft and valve train.

The car engine is a perfect mechanism, in which the lubrication and cooling systems and supply of the air-fuel mixture are well thought out.

Characteristics of the VAZ-2107 engine

One of the main characteristics is the engine power of the VAZ-2107, which can vary depending on the modification of the car. For example, since its appearance on the domestic market (1976), three models with carburetor engines have been produced:

- VAZ-2107 1.5: engine capacity 1451 cm 3, power 72 kilowatts;

- VAZ-21072 1.3: volume 1290 cm 3, power 64 kilowatts;

- VAZ-21074 1.6 l. s: engine capacity 1569 cm 3, power 74 kilowatts.

In addition, the manufacturer has released two modifications of the car with an injection power unit - 2107i 1.6 (engine power 70 kilowatts) and 1.6MT (73 horsepower). It is impossible not to mention the 21073 1.7 model with central injection of the air-fuel mixture. This type of “seven” uses AI-95 gasoline as fuel (other models use AI-92), has an engine capacity of 1689 cm 3 and boasts the highest power of 76 horsepower.

Engine power directly depends on cylinder volume. Carburetor modifications of power units are still considered the most reliable and can be used for a long time without requiring complex maintenance and repairs. At the same time, injection engines are much more powerful, but they immediately require contacting a car service even when

the slightest failure or malfunction. In addition, engines equipped with an injector consume gasoline more economically, which is a very important selection criterion today.

It is very important to know that no car will be able to demonstrate the power declared by the manufacturer for a long time if the requirements for its operation are not fully complied with. Therefore, it is necessary to regularly replace the engine oil and oil filters, as well as the coolant. Severe overheating or lack of lubrication leads not only to a decrease in power, but also to serious damage to individual elements of the power unit.

The weight of VAZ-2107 car engines is on average 120 kilograms. This significantly complicates the work of dismantling or repairing them and requires the use of special equipment (beam crane).

Technical characteristics of Lada (VAZ) 21074

The VAZ-2107 sedan is the most comfortable model of rear-wheel drive VAZ cars. The car is distinguished by original anatomical front seats with a high back, a more modern instrument panel with a tachometer, and an original radiator grille. In general, the VAZ-2107 can rightfully be called the most advanced and comfortable rear-wheel drive domestic sedan.

The automobile catalog contains a description, technical characteristics and photographs of the Lada (VAZ) 21074 car.

Total information

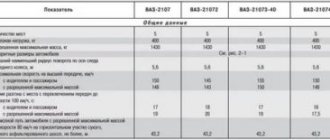

ParametersVAZ 2107VAZ 21074VAZ 2107-20VAZ 21074-20

| Weight of the equipped vehicle, kg | 1060 | 1060 | 1060 | 1060 |

| Payload, kg | 400 | 400 | 400 | 400 |

| Permitted maximum weight, kg | 1460 | 1460 | 1460 | 1460 |

| Ground clearance of a vehicle with a permissible maximum weight, with tires 175/70 R13, not less, mm: | ||||

| to the front suspension cross member | 162 | 162 | 162 | 159 |

| to the rear axle beam | 157 | 157 | 157 | 154 |

| Permissible weight of cargo on the additional (top) luggage rack, kg | 50 | 50 | 50 | 50 |

| Maximum speed, km/h: | ||||

| with permissible maximum weight | 148 | 148 | — | — |

| with driver and passenger | 150 | 150 | 150 | 150 |

| Acceleration time from standstill to 100 km/h, s: | ||||

| with driver and one passenger | 17 | 16 | 17 | 16 |

| with permissible maximum weight | 19 | 17,5 | — | — |

| Minimum turning radius along the track of the outer front wheel, m | 5,6 | 5,6 | 5,6 | 5,6 |

| The greatest rise overcome by a car with a permissible maximum weight without acceleration in first gear, % | 36 | 36 | 36 | 36 |

Chassis, steering and braking system

The front suspension of the VAZ 2107 has an independent double wishbone design with two shock absorbers and springs, as well as a stabilizer bar. The rear suspension is dependent with a rigid beam, which is connected to the body through one transverse and 4 longitudinal reaction rods. The suspension design is complemented by two hydraulic shock absorbers with coil springs.

wheels - 5Jxl3H2 (permissible offset 25-30 mm);

tires - 175/70R13 (165/70R13).

The steering mechanism of the VAZ 2107 is a globoidal “worm” driven by a double-ridge roller (gear ratio 16.4). Drive – three-link (2 lateral symmetrical rods, middle symmetrical rod, pendulum arm, swing arm, bipod).

The VAZ 2107 brake system has a foot (foot) drive through a vacuum booster. Its design also includes an emergency sensor and a brake fluid pressure regulator in the rear wheel drive. The parking (hand) brake is activated by a cable that engages the rear wheel chocks. The rear wheels are equipped with a drum-type brake mechanism.

The brake mechanism of the front wheels has a classic disc design with automatic clearance adjustment.

Carburetor

The first cars in the series had a carburetor installed in the VAZ-21074. The technical characteristics of an engine with this type of fuel injection were as follows:

- fuel type - AI-95;

- engine power - 75 hp. With.;

- torque - 116 Nm (at 3750 rpm);

- fuel consumption (city) - 9.7 l/100 km;

- fuel consumption (highway) - 7.3 l/100 km;

- Acceleration time to 100 km/h - 15 seconds.

On the model with a vacuum corrector, a DAAZ 2107-1107010-20 carburetor was installed. Over the years of operation, this unit has proven its reliability and durability. Despite this, the carburetor system is very sensitive to fuel quality. Therefore, the manufacturer began installing a modern injection system on models of later years of production.

Injector

The first injection VAZ-21074 appeared only in 2006. Car enthusiasts were enthusiastic about the new product and preferred to buy cars with such an injection system.

Despite the fact that the cost of such a car was higher, the complexity of the equipment (the presence of a computer unit, a number of sensors) meant slightly higher operating costs, but at the same time a number of advantages appeared, namely:

- Lower fuel consumption compared to the carburetor model.

- Easy engine starting (especially in cold weather).

- The influence of fuel quality on the nature of engine operation was neutralized.

- Stable engine operation at idle speeds, which are much lower than those of carburetor models.

The installation of a modern injection system has opened up new opportunities for VAZ-21074 owners. The injector allows you to change the technical characteristics very quickly - reprogramming the control unit can make the engine more economical or, conversely, more powerful and responsive. There is no need to change the engine design in any way.

Ignition system VAZ 2107i (injector)

During the production of the seventh model Lada, three types of ignition systems were used.

- A contact ignition system with a breaker and distributor (distributor) was used on the first 7 models.

- A non-contact ignition system, where an electronic switch was used instead of a breaker.

- The electronic ignition system, controlled by the ECU, is developed and implemented together with the injection engine.

The ignition circuit used on the VAZ 2107i power plant is reliable and does not require constant maintenance. There is not a single moving part in it. The moment of supplying electricity to the spark plug to form a spark is determined by the ECU, focusing on sensor signals:

- crankshaft position;

- mass air flow;

- throttle position;

- determining the proportion of air in the exhaust gas.

The ignition circuit consists of an electronic board and two coils.

Operational features and popular love

There is no particular need to talk about any dynamic characteristics of the VAZ 21074 with a classic carburetor. Stock sevens could accelerate to hundreds in 16 seconds. During this time, a Volkswagen Golf of the same year of production could accelerate to 200 km/h, and a mid-range sports car could enter Earth orbit, but that was not why the seven was valued. And they appreciate it now.

They loved it for its unpretentiousness in repairs, ease of maintenance, and for the fact that in every village store you could buy at least a ball joint, a head gasket, or a carburetor repair kit. Moreover, all the repairs could be done with your own, even not very skillful, hands, and a good breakdown of a reliable Fiat engine happened extremely rarely, and even then due to the driver’s oversight. The Seven with the 2106 engine was loved for its timing chain drive. The fact is that on the five-wheel engines that were installed on version 21072, the timing drive was belt driven, which meant that if the belt breaks, bending of the valves and failure of the cylinder head is guaranteed unless pistons with special “five-point” grooves are installed. The engine made less noise, but was 3 horses weaker.

Problems

Cars with such engines under the hood have enough problems with frequent breakdowns. We must not forget that the engine was designed by Soviet engineers, so its vulnerabilities outnumber its positive qualities. The most common engine breakdowns are as follows:

- It often happens that the VAZ 2107 engine fails. This is a common breakdown that is associated with the fact that the batteries fail. Here it is worth paying attention not only to the ignition and its components, but also to look at the fuel pump.

- The power of the VAZ 2107 engine may drop significantly, and this is very noticeable, since the car stops accelerating normally. This is the first sign that the valves need to be adjusted, since there are no hydraulic compensators in the system.

- Often you have to add oil to the VAZ 2107 engine. Here everything looks much sadder, since this is a signal that the engine is gradually coming to an end. It is worth preparing mentally and financially for the fact that you will have to do major repairs.

- The temperature of the VAZ 2107 engine may not reach operating parameters or the car begins to quickly overheat. Everything is simple here - as a rule, the reason for this phenomenon is that the thermostat gets stuck in a large or small circle, respectively.

Review of the VAZ-21074 injector model

The beginning of serial production of VAZ-21074 cars dates back to 1982, when the first copies of this model rolled off the assembly line of the Volzhsky Automobile Plant. At that time, the car was equipped with a carburetor power system: the injector on the VAZ-21074 appeared only in 2006. The advantages of the injection method of fuel supply are no longer a revelation to anyone, and after this system was implemented on the VAZ-21074:

- the engine began to start better in conditions of negative temperatures, without requiring prolonged warm-up;

- at idle speed the engine began to operate more smoothly and quietly;

- fuel consumption has decreased.

The injection version of the VAZ-21074 replaced the carburetor version in 2006.

The disadvantages of the VAZ-21074 include:

- low location of the exhaust pipe catalyst, which increases the risk of damage to this expensive part;

- inaccessibility of some parts and sensors, which was a consequence of the fact that the old type of body was not designed for an injection system - in the carburetor version there is much more space under the hood;

- low level of noise insulation, which reduces the level of comfort of the car.

The presence of a computer control unit allows you to respond in a timely manner to the occurrence of malfunctions, since a signal about a breakdown is immediately sent to the instrument panel. The control circuit for the operation of the engine and its systems used in the VAZ-21074 allows you to control the composition of the fuel mixture, turn the fuel pump on and off using electronics, and continuously monitor all components and mechanisms.

The control circuit of the VAZ-21074 allows you to respond in a timely manner to malfunctions of systems and mechanisms

The control scheme includes:

- Motor diagnostic block;

- Tachometer;

- Control system fault monitoring lamp;

- Throttle sensor;

- Throttle valve;

- Radiator cooling fan;

- Fan relay;

- Control block;

- Ignition coil;

- Speed sensor;

- Ignition section;

- Temperature sensor;

- Crankshaft sensor;

- Fuel pump relay;

- Fuel tank;

- Gasoline pump;

- Bypass valve;

- Safety valve;

- Gravity valve;

- Fuel filter;

- Canister purge valve;

- Reception pipe;

- Oxygen sensor;

- Battery;

- Egnition lock;

- Main relay;

- Nozzle;

- Fuel pressure control;

- Idle air control;

- Air filter;

- Air flow sensor.

A plate with identification data of the VAZ-21074 car can be found on the bottom shelf of the air intake box, which is located under the hood near the windshield, closer to the passenger seat. Next to the plate (1) is stamped VIN (2) - the vehicle identification number.

The plate with the identification data of the VAZ-21074 car can be found on the bottom shelf of the air intake box

The passport data on the plate is:

- Parts number;

- Manufacturing plant;

- Indication of conformity and vehicle type approval number;

- An identification number;

- Power unit model;

- Maximum permissible force on the front axle;

- Maximum permissible load on the rear axle;

- Version and equipment;

- Maximum permitted vehicle weight;

- Maximum permitted weight with trailer.

The alphanumeric characters on the VIN number mean:

- the first three digits are the manufacturing plant code (in accordance with international standards);

- the next 6 digits are the VAZ model;

- Latin letter (or number) - year of manufacture of the model;

- the last 7 digits are the body number.

The VIN number can also be seen in the trunk on the left rear wheel arch connector.

The VIN number can also be seen in the trunk on the left rear wheel arch connector

I drove it for two years, and during that time I only changed consumables and one ball joint. But then one winter an emergency happened. I went to visit the village, and it was incredibly cold outside, about -35. While we were sitting at the table, a short circuit occurred and the wiring began to melt. It’s good that someone looked out the window and sounded the alarm, and they eliminated this incident with snow and hands. The car stopped driving and a tow truck brought it to the house. Having seen all the consequences in the garage, I thought that not everything was as scary as it seemed at first glance, although the wiring, all the sensors and some parts had to be disposed of. Well, in short, I decided to restore it and called a friend who was famous among his friends as a good mechanic. After a short search for spare parts, it became clear that it would be problematic to restore the injector, since not all of the required components were in stock, and the price tag for them was outrageous. As a result, we threw out the idea of fixing the injector, deciding to make a carburetor.

Features of operation and maintenance

- Fuel selection

It was said earlier that many drivers cannot decide on the type of fuel used for their engine on the VAZ 2107. And if with AI-92 everything is simple, since its composition is very similar to AI-93, then with AI-95 everything is not so smooth.

Increasing the octane number leads to an increased risk of valve burnout, but gives a small increase in power. The engine begins to run smoother and more stable.

But the designers still took into account the possibility of using AI-95 gasoline. You just need to correctly set the ignition timing on your car (if you have a conventional carburetor engine) or reflash the engine control unit (if your VAZ 2107 engine is fuel-injected). But usually even this is not required. Engines of this brand are very durable and not picky about the type of fuel (within reasonable measures).

- Change of oil

Changing the oil on any engine must be approached with the utmost seriousness. Poor quality oil can lead to not very pleasant consequences, such as accelerated wear of main components and assemblies.

The ability to select oil is a real skill. Taking well-known brands is not always safe, since you are very likely to come across a counterfeit from dishonest companies. At best, you will not receive the positive qualities that this company has. At worst, you will have to carry out major repairs.

You shouldn't buy unknown brands either. In this case, you are buying a pig in a poke. You can buy oil that is of a quality that is not inferior to expensive analogues, or you can end up with expensive repairs. It is best to buy oil in specialized stores, where you can get at least some explanation and compensation.

Another important parameter is the oil class according to the international nomenclature. True, everything is simpler here. You just need to take the oil that the manufacturer himself recommends.

The manufacturer (AvtoVAZ) for VAZ 2107 engines and other models with this type of engine recommends:

- 5W-30;

- 5W-40;

- 10W-40;

- 15W-40.

You need to take about 4 liters of oil. When changing 3.5 liters of oil is usually enough. It’s better to carry the rest with you in the trunk, since oil consumption in this engine leaves much to be desired.

- Changing the oil in the VAZ 2107 engine

The procedure itself is quite simple and should not raise any questions. It is better to change the oil on a VAZ 2107 in the warm season.

- First you need to start the car and warm it up to operating temperature. Then turn it off and let the oil fall back into the crankcase. This will take about half an hour. During this time, we prepare a receiving container with a volume of 4-5 liters, as well as new oil, a watering can and a hose.

- Use a special wrench to unscrew the plug on the crankcase and wait for the old oil to drain out.

- If you change the type of oil or brand, you must also take flushing oil, which will clean the engine of the remnants of the old one. We pour it in the same way.

- Then we tighten the crankcase cover and fill in new oil through the neck on the cylinder head. We measure the level with a dipstick. It should be somewhere between the MIN and MAX marks. Please note that oil is not water and it cannot quickly sink into the crankcase, and therefore after a short stop the oil level in the crankcase will rise a little more.

Usually, along with changing the oil, the oil filter is also changed. It's even simpler here:

- We unscrew the old one using a special tool (you can also use an ordinary rope), lubricate the o-ring of the new filter with oil and screw it in place of the old one.

- Adjustment of valves

Adjusting valves is a rather complicated process and requires certain skills and tools. Actually, it is advisable to entrust the valve adjustment itself to competent specialists, but if you want to do everything yourself, then this video is for you:

Major repairs and maintenance

If valve adjustment can be done at home, then major engine repairs should only be entrusted to specialists.

During a major overhaul, all components and assemblies of the VAZ 2107 engine are checked for serviceability. They will check for you:

- Valve condition, adjustment;

- Chain, chain tension;

- Condition of oil seals, valve stem seals;

- Geometry of the cylinder block;

- Condition of the pistons, crankshaft, pins, connecting rods;

- Wear of compression rings;

- Condition of the oil pump and coolant pump.

If damaged, the part will be replaced. The cylinder block will be bored out, which will increase the combustion chamber and working volume. After this procedure, the car will be run-in for several thousand kilometers.

Typically, running-in lasts 5-10 thousand km. At this time, it is not advisable to give the engine heavy loads. After completing this procedure, your engine will make you happy.

Malfunctions

1. Engine won't start

| Cause of failure | Elimination method |

| No fuel in carburetor | |

| Fuel line clogged | Blow out the fuel line, flush the fuel tank |

| Carburetor and fuel pump filters are clogged | Wash filters and replace if necessary |

| Ignition system is faulty | Check the ignition system, replace broken parts |

| The carburetor air damper does not open at the first flashes in the cylinders | Eliminate leaks in the carburetor starting device |

| The carburetor solenoid valve does not open when the ignition is turned on: | |

| break in the wire going to the valve | Check the wire and its connections, replace the damaged wire |

| solenoid valve faulty | Replace valve |

2. Knock of the crankshaft main bearings.

Usually a dull, metallic knock. It is detected when the throttle valves are opened sharply at idle. Its frequency increases with increasing crankshaft speed. Excessive axial clearance of the crankshaft causes a sharper knock with uneven intervals, especially noticeable with a gradual increase and decrease in the crankshaft speed.

| Cause of malfunction | Elimination method |

| Ignition too early | Adjust the ignition timing |

| Insufficient oil pressure | Check oil pressure |

| Flywheel mounting bolts are loose | Tighten the bolts to the recommended torque |

| Increased clearance between journals and main bearing shells | Sand the journals and replace the bearings |

| Increased clearance between thrust rings and crankshaft | Replace thrust half-rings with new ones or thicker ones |

Engine tuning

The most popular types of tuning for engines of this type are increasing the displacement, replacing the camshaft, installing a zero-resistance filter and direct-flow exhaust.

The most effective way (and the most expensive) is to install a turbo kit.

- Increase in working volume

The design of the VAZ 2103 engine allows for a good increase in displacement, since its cylinder block is almost identical to the VAZ 2106 engine block. And when this block is bored, it can be made to fit the piston and rings of the VAZ 2106 engine.

Thus, we get an increase in displacement, which increases fuel consumption and power. If even this is not enough, then they sharpen the pistons on the valve side and install a crankshaft from the Niva, which also increases the working volume. Presumably after these operations you can get an engine with a displacement of 1.7 liters, sometimes 1.8 liters.

- Installing a new camshaft

This modification does not increase engine power, but changes the nature of its operation. In most cases, they try to install a camshaft that will transfer maximum torque to as low a speed as possible. This makes the engine more responsive at lower speeds, which has a very good effect when driving at low engine speeds. The best option for such a modification is a camshaft from Niva 21213.

- Installation of direct-flow exhaust and zero-resistance filter

The most popular modification. First of all, it's pretty cheap. Secondly, it allows the car owner to show off to neighbors in the garages. In fact, it does not have any practical benefit for the stock engine. Allows you to feel a slight increase in power only at high speeds.

It is quite effective when installing Turbo, since it does not put pressure on the engine, which is now capable of developing enormous power. Direct-flow exhaust is not convenient due to increased exhaust sound. It is dangerous to use the filter in wet weather, as it can let water into the engine, causing water hammer.

- Installation of turbocharging

The most expensive and effective way to increase engine power, while its resource sharply drops by 2-3, sometimes 4-5 times.

Requires deep exhaust tuning:

- Installing T-Valves

- Imported rings and forged pistons

- Lightened crank feces

- Intercooler and much more.

It is also necessary that your VAZ 2107 engine be fuel-injected. The carburetor can simply burst due to such high pressure. This article will not describe the procedure for installing Turbo on a VAZ 2107. There is enough such information on the World Wide Web. Here we will simply indicate a price of approximately 15% of the cost of the car. If you are ready to spend your money on this, go for it.

Modifications of VAZ 2107

It turns out that the seven had a lot of modifications, which sometimes even the workers of the plant in Tolyatti are not aware of. And we know and willingly share this information with fans of VAZ retro. The technical characteristics of the VAZ 21074 (shown in the table) are actually no different from other Ladas with a six-wheel engine, with the exception of some nuances that could not be noticed at all, but respecting the traditions of the plant, they are worth emphasizing.

So, the “pure” seven, 2107, came only with a four-speed manual transmission and a three-liter one and a half liter engine with a carburetor power system. But today we are not talking about it, but about its first modification, the seven with an engine from the VAZ 2106, which received the factory index 21074.

How does the VAZ 21074 injector control circuit work?

VAZ 21074 with an injection type engine has its own characteristics. Firstly, there is electronic control of the engine. This system clearly controls the composition of the fuel mixture. The fuel pump is also controlled and turned on and off electronically. This control is exercised over all parts of the engine.

The VAZ 21074 injector circuit consists of the following main components: an electronic unit, several sensors, connecting wires. There is a warning lamp on the dashboard that lights up in the event of malfunctions in the operation of system elements. When the car starts to operate and the engine starts, checking its operation begins. The warning light first turns on and then, if everything is OK, goes out. If the lamp lights up while the car is running, this indicates possible malfunctions in the engine.

The VAZ 21074 injector generator has a three-phase alternating current. It has a built-in rectifier unit and voltage regulator.

The most important element of the electronic circuit is the control unit. It is he who is responsible for generating signals to control engine operation and processing coming from sensors of performance indicators of parts of the system. The unit has a built-in memory, in which data is stored even in the absence of power.

Sensors are used to generate signals about the operation of, for example, the crankshaft and other things, which allows you to synchronize the operation of system elements with each other.

In general, proper operation of the VAZ 21074 injector allows you to pay a minimum of attention to the car and periodically check it using special diagnostic equipment. But a carburetor engine is more demanding and will require more attention, since it will have to be periodically cleaned, adjusted and tuned. For example, very often they do tuning of a VAZ 2109 (carburetor).

It is also worth noting that the VAZ 21074 (injector) has an affordable price (on average about $4,000, if you look, you can find it for $2,000, but you still have to tinker with it), which, of course, is an additional advantage along with efficiency and reliability of the car.

And finally, a video about how the VAZ 21074 injector accelerates to 150 km/h:

How many horsepower does a VAZ 2107 carburetor have?

The engine is the main power unit of any car, on which both its power and dynamic characteristics depend. VAZ-2107 models are equipped with four-stroke engines, each cylinder of which has two valves. Older cars are equipped with a carburetor engine, and new ones are equipped with an injection engine.

VAZ-2107 engine design

Before we move on to describing the characteristics of the engine, we will talk in detail about all the elements of its design so that you can imagine exactly how the power unit works. Consists of the following main components:

- cylinder block. The heaviest component made from cast iron. This is where the cylinders are located, which are placed in one row. In addition, the block has passages for coolant, which prevents engine overheating during operation;

- the crankshaft, which transmits engine rotation to other components of the car. It also has quite a lot of weight. The crankshaft supports (cranks) are made of metal, which is hardened by high-frequency currents for maximum strength;

- connecting rods with piston pins made of forged steel. These elements are constantly subjected to high loads;

- pistons with compression and oil scraper rings;

- cylinder head. This part is made from a durable but very lightweight aluminum alloy. To prevent lubricant leakage, the cylinder head is equipped with a sealing gasket;

- a flywheel that is used to start an engine. It is in clutch with the starter, which responds to turning the key in the ignition;

- timing mechanism, which includes the camshaft and valve train.

The car engine is a perfect mechanism, in which the lubrication and cooling systems and supply of the air-fuel mixture are well thought out.

Characteristics of the VAZ-2107 engine

One of the main characteristics is the engine power of the VAZ-2107, which can vary depending on the modification of the car. For example, since its appearance on the domestic market (1976), three models with carburetor engines have been produced:

- VAZ-2107 1.5: engine capacity 1451 cm 3, power 72 kilowatts;

- VAZ-21072 1.3: volume 1290 cm 3, power 64 kilowatts;

- VAZ-21074 1.6 l. s: engine capacity 1569 cm 3, power 74 kilowatts.

In addition, the manufacturer has released two modifications of the car with an injection power unit - 2107i 1.6 (engine power 70 kilowatts) and 1.6MT (73 horsepower). It is impossible not to mention the 21073 1.7 model with central injection of the air-fuel mixture. This type of “seven” uses AI-95 gasoline as fuel (other models use AI-92), has an engine capacity of 1689 cm 3 and boasts the highest power of 76 horsepower.

Engine power directly depends on cylinder volume. Carburetor modifications of power units are still considered the most reliable and can be used for a long time without requiring complex maintenance and repairs. At the same time, injection engines are much more powerful, but they immediately require contacting a car service even when

the slightest failure or malfunction. In addition, engines equipped with an injector consume gasoline more economically, which is a very important selection criterion today.

How is 21074 different?

The main and, perhaps, the only difference from the beds of other sevens of various modifications is in the engine. This is a 1.6-liter (more precisely, 1,569 cc) engine with a cast-iron Fiat block and an aluminum head. Initially, the engine ran only on 93-octane gasoline, but later the compression ratio was lowered to allow the vehicle to be operated on lower grades of fuel. Since the power system still remained carburetor, there was not much difference. The seven happily consumed about 10 liters of fuel in mixed mode.

Seventy-five power and 116 Nm of torque look helpless by modern standards, but then for the country that built communism, it was proletarian chic. Even the Volga was more powerful by only a dozen forces. Toward the end of its career, 21074 still received distributed injection, although it was a different modification, 21074-10, which met Euro2 standards, and the next year an even more advanced seven 21074-20 with an injector appeared, which could meet Euro3 standards. But the injection versions of the six engine completely abandoned 92 gasoline and required only high-octane 95 gasoline.

Sources

- https://aprilvlad.ru/avto-opyt/moshchnost-2107.html

- https://RussoAuto.ru/auto/vaz/vaz-2107

- https://uhta-trans.ru/remont/vaz-2174.html

- https://old-vaz.ru/texnicheskie-xarakteristiki-vaz-2107.html

- https://ladamaster.com/tekhnicheskie-kharakteristiki-vaz-21074

- https://avto-all.com/rossiyskie-avtomobili/vaz-21074-inzhektor-mozhno-smelo-nazvat-obnovlennoy-semerkoy

[collapse]

Engine VAZ 2103

Specifications

The main characteristics of the engine are presented in the table below:

Download .xls file

xls

Download picture

Send by email

| OPTIONS | MEANING |

| Year of production of engines of this type | 1972 – our time |

| Supply system | Injector/carburetor |

| engine's type | Row |

| Number of pistons | 4 |

| Cylinder block material | cast iron |

| Cylinder head material | aluminum |

| Number of valves per cylinder | 2 |

| Piston stroke | 80 mm |

| Cylinder diameter | 76 mm |

| Engine capacity | 1452 cm 3 |

| Power | 71 l. With. at 5600 rpm. |

| Maximum torque | 104 Nm at 3600 rpm. |

| Compression ratio | 8.5 units |

| Oil volume in crankcase | 3.74 l |

This engine uses AI-93 fuel. In practice, motorists can fill in completely different fuels. The most common deviations from the norm are the flooding of AI-92 and AI-95. You can read more about this below.

- According to available data, fuel consumption in urban conditions is 9.4 liters per 100 km.

- On a flat road at cruising speed it will already be 6.9 liters per 100 km.

- In mixed mode, consumption will be from 8 to 9 liters per 100 km. Such figures do not allow us to call this engine economical, but in this case a lot depends on the driver himself.

- Another parameter that depends on the driver is oil consumption per 100 km. For the average driver of a car with this engine, it is 700 g per 100 km. This, of course, is not small, but with careful driving you can reduce this consumption down to 450-500 g/100 km.

- The weight of the 2103 engine when fully assembled is 121 kg.

Its dimensions (characteristics are indicated in millimeters):

| Height | Width | Length |

| 665 | 541 | 565 |