The clutch pedal is loose. How to fix it? Where to tighten it?

Comments 26

this is a design feature of the clutch pedal on Priors; I probably tried it on 8 Priors, including mine, the same pedal

I have the same thing, just as it came off the assembly line it hangs loose.

In short, can we forget about this?

Mine is hanging in exactly the same way, with a quick glance I realized that there was NO particular opportunity to tighten it, so I gave up on this matter. The main thing is that you can’t break it off with simple pressing, it’s clear that it’s made firmly and NOT CONVENIENT

The clutch is a unit that ensures smooth gear shifting while the car is moving. Incorrect operation of this unit will lead to jerking when driving and will reduce the overall driving comfort. In this article we will look at how to adjust the clutch on a Priora and in what cases it becomes necessary to do this.

When is tuning required?

How to configure it yourself

Video “How to properly remove the cable for replacement”

Comments and Reviews

Clutch pedal creaks - prerequisites and methods for solving the problem

Hi all. Not long ago I talked about the reasons for the failure of the clutch pedal, as well as methods for solving this phenomenon. Now I’ve decided to supplement the series of articles on the clutch with another, no less pressing topic - the creaking of the clutch pedal.

You will learn about the reasons why the clutch pedal squeaks and how to get rid of it.

I’ll say right away that the creaking of a pedal, whether it’s a clutch or a brake, almost always does not affect its functionality and, by and large, is an ordinary irritant that infuriates almost all motorists. The creaking or grinding of pedals occasionally indicates serious breakdowns, but before you give up on it with the words “I still have nerves of steel,” I recommend making sure that the problem is really not worth attention.

Step-by-step instruction

Now we will analyze the whole process step by step. Stock up on a caliper or at least a ruler in advance.

- Open the hood and disconnect the negative terminal on the battery. Now we need to remove the air filter, which hides the components we need

- We remove the mass air flow sensor connector, the adsorber coupler, the rubber supports and tilt the VF housing to the side

- Our clutch fork is located next to the crankcase. On some cars on the secondary market you can also find a sensor moved there by the driver

- Using a tool, say, pliers, we pull the tip towards ourselves in order to free up more space for work

- We take a caliper and measure the distance from the leash to the fork. According to Grant's technical documentation, it should be exactly 27 millimeters

- We adjust the leash according to the thread if the distance does not match

- Then we press the pedal a couple of times, look at the result, and repeat the setting

- Next is the travel of the pedal itself. It should be 14.6 centimeters (+ - centimeter). As already said, it is better if it is flush with the brake

- If even after several adjustments the pedal does not fall into place, then it would be logical to deal with the unit itself

Clutch pedal creaking - prerequisites

The main prerequisite in the vast majority of cases is the drive, which can be either mechanical or hydraulic. The force you exert on the pedals is transmitted to the clutch fork by means of a cable or hydraulic system. Despite the fact that hydraulic and mechanical drives have different designs, their creaking is monotonous. On models such as: VAZ 2110, 2112, 2114, 2115, a mechanical cable clutch is installed. In some models, in order to compensate for friction lining wear, the manufacturer installs a mechanism that does not require adjustment. This clutch is equipped with: Priora, Granta, and also Kalina.

When the driver notices that the clutch pedal is creaking, this already means that the problem has reached a certain point. Creaking is associated with excessive wear of working parts (for example, the fastening mechanism), water ingress on rubbing surfaces, and other reasons for which increased friction occurs. Often, pedal squeaking occurs due to the return mechanism.

Such sounds most often appear not when pressing, but when releasing the pedal, just at the moment when the clutch mechanism is released from overload. If we talk about the pedal assembly, then only mechanical connections and the return spring can creak there. The problem of the creaking itself is unpleasant because it is very difficult to get to the pedal block. Working in a confined space is not easy, because the work requires a lot of strength and patience.

The clutch pedal squeaks due to wear on the mounting mechanism. For most VAZ models, the pedals are mounted on hinged mounts and axles. Either a plastic bushing or lubricant is responsible for the pedal sliding on the axle. By and large, plastic bushings do not anticipate the presence of lubricant, but if you still add it, it won’t be worse. A squeaking clutch pedal can appear even on the newest cars, in which everything is working properly. You can remove creaking and grinding noises by applying lubricant or replacing the bushing and spring; the most important thing is to find where exactly the creaking is coming from. The lubrication itself is carried out after complete dismantling of the pedal block together with all mechanisms. The work is complicated by the fact that the dismantling process takes a lot of time and is considered very labor-intensive. If you don't want to remove all the pedals, you can try lubrication using a syringe. Apply oil to the rubbing parts, inside the bushings, and also where you think it is necessary. We remove the remaining lubricant with a rag, after which we check whether the clutch pedal squeaks or not.

If after lubrication nothing has changed, you can imagine that the reason is in the return spring. The spring may hit something or creak on its own. We lubricate the spring, if necessary, with silicone grease or WD-40, but the effect will most likely be short-term. Therefore, it is better to use the most severe lubricants such as graphite or CV joint lubricant.

The cable creaks. In some cases, creaking, grinding and clicking noises are associated with disturbances in the operation of the mechanical drive. The problem in this case is that the cable can creak both outside and inside the cabin. Full lubrication of the cable along its entire length will help correct this situation. The procedure is not difficult and does not take much time, so if this is the reason, then you can consider yourself lucky. For convenience, the cable is disconnected from the clutch fork, after which it is lubricated from the engine compartment. If the cable is old and shows signs of wear, lubrication is unlikely to be advisable, it would be better if you completely replace the clutch cable. Unprotected working surfaces of the cable that are outside the protective casing should be lubricated with waterproof grease.

The creaking of the compensatory mechanism. If the car has such a mechanism (it is located under the hood or near the pedal), the new cable can make unpleasant sounds and clicks, similar to squeaking or grinding. The problem in this situation is due to the fact that the mechanism is not worn in and requires lubrication of the compensation mechanism.

If the creaking of the VAZ clutch pedal is not associated with any of the problems listed above, there is a suspicion that unpleasant sounds are generated in the crankcase area. Such a squeak can be produced, for example, by the clutch fork. The difficulty in this situation is that it is possible to check whether the problem is or not only after completely dismantling the clutch. There are indeed some tricks like lubrication without removal, but they require certain skills and accuracy. The trick and dexterity lies in the ability to lubricate the fork with oil without removing the checkpoint (Checkpoint - a point designed to control passage (visit) and access to the territory of any facility)

. But if it is not the fork that is creaking, but another mechanism, the quickest way is to remove it.

The fork is lubricated as follows. We take out the rubber plug, then fill the syringe with lubricant and carefully apply a few drops to the clutch fork axle. For cars whose forks do not have an axle, lubrication occurs a little differently. Using a strong screwdriver or mounting tool, the fork is moved to the side, after which it is lubricated with a thick lubricant like “Litol” at the point of contact of the fork with the rod.

Source: vaz-remont.ru

Why does the brake pedal hit when braking?

The car's braking system is quite simple, and there are not many parts that can fail. Moreover, almost each of them can lead to the problem under consideration. If the brake pedal hits when braking, you need to check the following units:

- Brake pads. Severe wear on the brake pads can cause the brake pedal to squeal. It is necessary to check the pads for wear and determine their suitability. In this case, both front and rear pads should be diagnosed. If the thickness of the part does not meet the requirements of the brake system (or the pads have mechanical damage), it will need to be replaced. Do not forget that the pads must be changed in pairs on the same axis.

- Brake drum. When braking, the pads touch the drum. If it is damaged or deformed, vibration from their contact will be transmitted to the car body, including the brake pedal. Often the brake pads and brake drum on the rear axle of the car fail at the same time, and they will need to be replaced together to get rid of the problem.

- Brake discs. When operating a car, brake discs have to withstand severe loads associated not only with friction, but also with temperature changes. When driving in the city, you often need to press the brake pedal, which increases the temperature of the brake discs. If cold water (for example, snow) gets on them, they can become deformed under the influence of sudden temperature changes. A bent brake rotor will cause problems with braking and transmission of vibration into the pedal.

Please note: It is important to replace discs, like brake pads, in pairs on one axis. However, after replacing the disks, the problem may persist, even if all units are working properly. It is necessary to “break in” the new part a little so that the pads get used to it.

Brake cylinders. If the brake cylinders are deformed or malfunctioning, this can cause the brake pedal to wobble. In such a situation, it is recommended to inspect the cylinders for any distortions. If they are not detected, you need to lubricate them to be sure that there are no freezes.

It is important to inspect the entire braking system when looking for the cause of brake runout. Due to one faulty unit, other parts may become unusable.

Clutch pedal creaking on the latest Priora

Because you are not authorized on the website. To come in.

Because you are not a trusted user. How to become a trustee.

Because The topic is archived.

Because you are not authorized on the website. To come in.

Because you are not a trusted user (phone number not verified). Enter and confirm your phone number. Read more about trusts.

Because The topic is archived.

Because you are not authorized on the website. To come in.

Because you are not a trusted user (phone number not verified). Enter and confirm your phone number. Read more about trusts.

Because The topic is archived.

Because you are not authorized on the website. To come in.

Because you are not a trusted user (phone number not verified). Enter and confirm your phone number. Read more about trusts.

Because The topic is archived.

Because you are not authorized on the website. To come in.

Because you are not a trusted user (phone number not verified). Enter and confirm your phone number. Read more about trusts.

Because The topic is archived.

Because you are not authorized on the website. To come in.

Because you are not a trusted user (phone number not verified). Enter and confirm your phone number. Read more about trusts.

Because The topic is archived.

Because you are not authorized on the website. To come in.

Because you are not a trusted user (phone number not verified). Enter and confirm your phone number. Read more about trusts.

Because The topic is archived.

Because you are not authorized on the website. To come in.

Because you are not a trusted user (phone number not verified). Enter and confirm your phone number. Read more about trusts.

Because The topic is archived.

Because you are not authorized on the website. To come in.

Because you are not a trusted user (phone number not verified). Enter and confirm your phone number. Read more about trusts.

Because The topic is archived.

Because you are not authorized on the website. To come in.

Because you are not a trusted user (phone number not verified). Enter and confirm your phone number. Read more about trusts.

Because The topic is archived.

Because you are not authorized on the website. To come in.

Because you are not a trusted user (phone number not verified). Enter and confirm your phone number. Read more about trusts.

Because The topic is archived.

Because you are not authorized on the website. To come in.

Symptoms of malfunction, diagnostics, solutions

| Sign | Cause and remedy |

| Short pedal stroke | Adjust the length of the cable. Check the integrity of metal fibers. Most likely delamination or bending. |

| The clutch drags at speed, it is difficult to shift into higher gears. | The flywheel is bent or damaged. The gripper teeth are worn. Replacing the flywheel and related consumables. |

| Slipping when activating first gear and increasing speed with the accelerator pedal. | Replace friction linings, disk, clean the drive from old grease |

| Sharp jerks when turning on / changing gears. | The pressure plate is damaged, replace the basket. |

| Whistle when activating first and subsequent speeds | Install a new release bearing |

| Crackling, knocking, crunching noise when shifting into up/down gears | Wear out the damper spring, replace it with a new one, lubricate the entire drive mechanism. |

| The lever falls, falls, rattles | Excessive stretch of tensioner. Replace with a new one, install bushings. |

Video: CREAKS, CLICKS, ETC. (Clutch pedal) | VAZ PRIORA, GRANTA, KALINA

Why do cables squeak?

Another nuisance is the appearance of squeaks and clicks that occur when the clutch is disengaged with mechanical drives located in the area of the cable. Understanding this problem is much more difficult, because the cable can creak both under the hood and inside the car.

In these cases, it is better to coat the cable completely; besides, it will not take much time.

If the cable is not too old, there is no point in completely removing it. It can be coated with engine oil using a syringe, carefully pushing it under the cable casing.

The areas where the cable exits from under the casing should be coated with a water-repellent lubricant, such as Litol 24, for example.

Not only the cable rubbing against the casing, but also the compensating mechanism can make a creaking noise. In some cars it is mounted under the hood next to the clutch, and in some on the opposite side, near the pedal. While the cable is new, it creaks and clicks. This cannot be avoided, but it is still necessary to lubricate it.

It is better to lubricate the compensation mechanism even when installing the cable. But, if you missed the moment, then you will have to practice acrobatic sketches in a car showroom. Using the same syringe, get to the compensation mechanism and sprinkle a couple of drops on it. The squeaks will disappear.

Save aerosols with magical properties for other occasions.

Advertisements on NN.RU – Auto

Extend the chassis (frame) on Gazelle Next, Gazelle peasant under a body of 4.2 m, 5.1 m and 6.2 m. Extend the frame on Gazelle Next, Gazelle Gas 3302. Cost: 25,000 rubles.

The company allows you to upgrade the Fiat Ducato Fiat Ducato basic version for a solution.

A wide selection of hydraulic pumps and hydraulic motors of all series: spline hydraulic pump of right rotation. It is used in road construction and... Cost: 1,000 rub.

The broken-type towing platform produced in our company has the highest design reliability, which is confirmed by its longevity.

Source: www.nn.ru

Why do clutch problems occur?

This unit is designed for a mileage of about 150,000–300,000 km. Vibration of the clutch pedal when pressed and a reduction in its service life as a whole is possible due to:

- a car driving style in which the driver sharply squeezes and throws the pedal, since in this case the lining wears out faster;

- increased loads on the vehicle (relevant for trucks);

- towing a vehicle with a larger weight can cause the clutch to burn out (if you smell a burning smell, you must stop immediately).

- holding the unit pedal half-pressed unless absolutely necessary.

Diagnosing and eliminating squeaking clutch pedal

The clutch is one of the most important devices in a car. This mechanism ensures the transmission of the torque of the car's engine to the driven disk through the clutch basket. The clutch disc is in constant contact with the flywheel using a spring mechanism. It is subject to the action of a release bearing, the function of which is to disconnect the torque of the motor from the driven disk when you press the pedal. Like all vehicle elements, the clutch is subject to wear and various types of problems.

Car owners often do not take into account the existing creaking of the clutch pedal. In fact, this may indicate a number of severe defects. Photo: autoskipper.ru

Advice!

Struts and shock absorbers ss20 for the front and rear suspension of VAZ 2108-2110, Lada Priora, Lada Kalina, Lada Granta

The clutch pedal should be installed at the level of the other two, otherwise there is a chance that the reverse gear simply will not engage.

If all the manipulations to lubricate all rubbing parts and mechanisms did not help you, and the problem remains unresolved, then in such a situation the best option would be to contact a specialized service center for diagnostic analysis.

Because solving problems with the gearbox and clutch in advance can prevent you from unexpected breakdowns and further expensive repairs.

- For lubricants in hard-to-reach areas, it is best to use WD-40 or a silicone lubricant in spray form. Thus, the material will be better distributed on the surface and will reach all places that are difficult to reach manually.

- It is recommended to lubricate the clutch pedal and fork cable fastenings with graphite lubricant, which has a beneficial effect on such mechanisms and holds well on devices subject to constant load.

Causes of a squeaking clutch pedal

The source of pedal squeaking is the clutch drive. On the most expensive car models, the clutch drive is hydraulic. In Russian-made cars, a mechanical drive is installed. The difference between the devices is that in the first type, the force transmitted from the pedal to the clutch fork is carried out through a hydraulic system, which is supplemented by an amplifier. The operation of the mechanical drive is ensured by a cable mechanism and a compensation mechanism.

There are two types of defects associated with clutch squeaking:

- Insignificant creak. It occurs when you press and release the clutch pedal. This type of appearance of third-party sounds does not pose any threat to either punishment or the safety of the driver and passengers. The only thing that is possible is boredom from the constant nasty sound and irritation of the nervous system of the owner of the car. The consequence of this type of clutch squeaking can be severe winter weather conditions, characterized by severe frosts. But the creaking has a fickle temperament. When the engine and interior of the car warm up, the pedal and the entire clutch mechanism come into a smooth, serviceable state.

- The malfunction is accompanied by a hard and loud squeaking sound from the clutch during operation. The clutch pedal is pressed tightly and turns jerkily or very slowly. Such a malfunction carries the risk of breaking the clutch cable or damaging its fork. If you experience these symptoms, you should immediately contact a service station to have the problem diagnosed and repaired by highly qualified auto mechanics.

A prerequisite for the appearance of squeaks when operating the clutch pedal can also be an insufficient amount of lubricants on all surfaces of the working parts moving and rubbing against each other. Photo: avtodelkino.ru

Eliminating a squeaking clutch pedal

First, to eliminate the creaking of the clutch pedal, you need to carry out a number of measures related to the lubrication of the entire pedal assembly of the car. Any car owner can do them. When lubricating the pedal assembly, you need to pay attention to the clutch bushings. Motor oil is dripped into them using a syringe. In addition, it is necessary to pay attention to the return spring. The popular WD-40 is perfect for lubricating it. The second option, not the worst, is a lubricant created for the CV joint (constant velocity joint).

You will learn more about the news from Mitsubishi – Eclipse Cross – in this material.

Also here you will find a video of the KIA Mohave test drive.

For the most confident car enthusiasts who have extensive experience in repairing cars, it is recommended to disassemble the entire pedal assembly and get to the clutch release fork. It needs to be inspected for flaws. If they are identified, then the plug must be replaced with a new one. In addition, it is necessary to lubricate the cable, which is located under the rubber gasket, having previously cleared it of accumulated debris. This becomes especially important if the cable is outdated. The newest cable, which is in good condition, does not require lubricants. In order to lubricate the cable, various water-repellent consistencies, namely lithium, are ideal.

There are two points of view regarding the operation of the clutch cable. Some car owners believe that when the clutch pedal squeaks, you just need to change the cable to a new one. But they forget that it must be lubricated before installation. Other drivers say that clutch cables should not be lubricated under any circumstances. They argue this by saying that over time, a layer of dust and sand appears on the cable, which destroys it. Despite these statements, in practice a cable that is lubricated serves for a long time and without failure.

It is necessary to inspect the clutch fork boot and change it if necessary. Photo: blogspot.com

In addition, it is necessary to inspect the clutch fork for the presence of vertical movements, which are explained by a design flaw in the mechanism. The consequence of such a problem will be a downward displacement of the fork, due to which the bearing will begin to wear out, the friction of which will occur on the input shaft. This problem can be solved by installing the fork in space using round spacers.

If, after lubricating the cable and repairing the clutch release fork, the squeaking noise during pedal operation is not eliminated, then the compensation mechanism should be examined. It can be placed either next to the clutch (under the hood) or near the pedal. It depends on the car model. Using a syringe, apply a few drops to the compensatory mechanism.

Inattentive operation of the vehicle, namely ignoring such a malfunction as the squeaking of the clutch pedal, is an absolute threat to the driver and passengers. Therefore, it is necessary to take timely measures to identify the circumstances and carry out repairs. Thus, a faulty fork leads to failure of the entire clutch mechanism. The friction linings that are located on the clutch disc will wear out quickly over time. If the linings are completely worn out, the car simply will not be able to move. The same applies to the clutch cable. If you do not take timely care of the clutch mechanism, in an instant when changing gears from one to another, the clutch cable may break. In this case, the clutch pedal itself falls to the floor, and the driver may lose control of the uncontrollable car.

You will find one of the options for eliminating the squeaking clutch pedal in this video:

The clutch is an important part of the car, without which its real functioning is impossible. Any signs of problems in it should immediately attract the attention of the car owner. Creaking when the clutch pedal operates may indicate wear on the cable, the need to lubricate the pedal assembly, or a malfunction of the clutch release fork.

Source: procrossover.ru

Lada Kalina sedan 2009, engine Gasoline 1.6 liter., 84 hp, Front drive, Manual — tuning

Comments 15

There are clicks on the new viburnum too. This is normal, since this indicates that the mechanism for adjusting the length of the cable is activated (1 - bushing; 2 - leash; 3 - toothed (upper) cable tip; 4 - cable tip clamps; 5 - bracket (with limiter). Manual: yadi .sk/i/T39rNo48bhgn5, page 90-92. On page 92, pay attention to: "Pulling the tip, stretch the clutch cable as much as possible and use a caliper to measure the distance between the driver and the fork lever. If the distance is not equal to 27 mm, turn the driver along the thread on the end of the cable, achieving the recommended value.”

I did everything exactly the same) my friend’s Kalina 2 also clicks, but it annoys me

Well, at least withstand the tension of 27 mm. Write a letter to AvtoVAZ - I wonder why they didn’t leave it like on the 2110 and put in a mechanism for adjusting the length of the cable - this is not economical on their part)))?

I’m not a fool, I stood it) MB it was a cable issue, who knows, it doesn’t matter) Well, in foreign cars this mechanism works great) but ours somehow didn’t hold up

I remember driving to work. The clutch cable broke. I put it in 2nd gear and started the internal combustion engine, got there in 2nd gear, put in a new cable, and it also clicks. Colleagues also click on grate-sport.

There are clicks on the new viburnum too. This is normal, since this indicates that the mechanism for adjusting the length of the cable is activated (1 - bushing; 2 - leash; 3 - toothed (upper) cable tip; 4 - cable tip clamps; 5 - bracket (with limiter). Manual: yadi .sk/i/T39rNo48bhgn5, page 90-92. On page 92, pay attention to: "Pulling the tip, stretch the clutch cable as much as possible and use a caliper to measure the distance between the driver and the fork lever. If the distance is not equal to 27 mm, turn the driver along the thread on the end of the cable, achieving the recommended value.”

I changed it after denver02, because I also encountered this problem, not only were there clicks, there were also creaks, although they removed the cable, and poured oil into it, and sprayed silicone on the clutch fork, it helped, but for a couple of weeks, then everything again , I installed a cable from 10 with a minimum of modifications and everything is quiet and comfortable, and by the way, regarding the rigidity of pressing, again lubricate the fork and the cable itself and everything will be easy to press! They changed it for me at the service center because I’m dragging myself around during the replacement process and there’s no garage; it’s not on the street to change it! I paid 500 rubles for everything including installation and finishing touches.

Source

Individuality of the Lada Priora clutch

Any motorist who is interested in how to adjust the clutch on a Priora should know about the presence of the drive cable auto-adjustment function. In other words, VAZ designers took care of the owner and freed him from the need to constantly adjust the clutch drive mechanism during use. The same ratchet-type system is installed on Kalina , but both there and on Priora it is impossible to do without repeated adjustments. This factor has been confirmed by practice and pages of forum discussions.

Features of the VAZ 2112 clutch

The machine is equipped with a dry-type single-plate friction clutch with a central pressure spring. adjusting the clutch on Kalina any motorist must take into account that the control pedal is connected to the disc via a cable with a special ratcheting mechanism.

How does automatic cable tightening work?

As a result of intensive use, the friction linings of the disc gradually wear out. The ratcheting mechanism built into the drive design allows you to compensate for wear for a certain period of time - it gradually tightens the cable. During operation of the device, the fork rotates and the bushing spring is gradually compressed. As a result, the cable end clamps are compressed, after which the latter is released and tensions the cable.

The purpose of this design is to facilitate the maintenance process. According to the plans of VAZ engineers, the mechanism should save the owner from the need to make adjustments himself. But this is all only in theory, but in practice it turns out that you cannot do without adjusting the clutch.

When should adjustments be made?

Before adjusting the clutch on a Kalina car, you need to determine the moment when the automatic cable locking no longer functions. This is not difficult, especially since the machine itself signals problems:

- Loss of traction, friction clutch does not provide a reliable connection between the flywheel and the disk. The consequence of such a defect will be the loss of a significant part of the torque force.

- The clutch control pedal does not return to its initial position, which, in fact, is a consequence of the first point.

- Poor clutch disengagement - the pedal is not pressed all the way, which makes changing gears difficult.

When is adjustment of the clutch drive mechanism necessary?

Despite the presence of innovative ideas in the field of gearbox control, Togliatti automakers still advise inspecting the condition of the ratchet mechanism during any maintenance. In addition, it would not be superfluous to pay attention to the signs that indicate problems in the clutch control system:

- Loss of traction due to unreliable connection between the flywheel and the disk.

- “Sagging” of the clutch pedal.

- Difficulty changing gears.

- Extraneous sounds when using the clutch pedal.

Symptoms (Symptom from Greek - case, coincidence, sign - one separate sign, frequent manifestation of any disease, pathological condition or disorder of any vital process)

are generally similar to when you need

to adjust the drive on a VAZ 2110 , i.e. their identification should not cause any problems. With all this, we must not forget that the automatic tensioner has its own compensation limits. The working stroke of 27 mm is the stroke of the compensator.

In other words, during the process of using the disc, the fork moves specifically to this length. Therefore, the problem of how to adjust the clutch on a Priora car is actually solved trivially. Even if you want to, you won’t be able to “overload” the release bearing.

How to check the characteristics of the VAZ 2170 clutch drive?

A few common steps will help you verify that the drive option is necessary:

- Open the engine compartment hood.

- Disconnect the MAF sensor and remove the air filter.

- Just below the battery, find a cable with a plastic clip.

- Pull the mechanism clamp forward in the direction of travel.

- Holding the tip in an extended position, measure the distance L (in the photo), the norm corresponds to 27 mm.

Correcting the mechanism

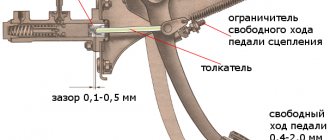

If various extraneous sounds appear when the clutch is disengaged during vehicle operation, you need to check the gap on the drive fork and, if necessary, adjust it. Clutch cable adjustment is performed in the following order:

- Remove the air filter and pull out the cable by the tip to its maximum length.

- Using a caliper, measure the distance between the tip and the fork. Normally, this distance should not deviate from 2.7 mm.

- If discrepancies are found, turn the driver on the thread until the desired value is established. Release the end of the cable: it should press tightly against the fork.

- Press the clutch pedal 3-4 times to activate automatic cable length correction, measure again.

When re-measuring, a deviation from the value of 2.7 mm may again be detected. In this case, you need to repeat the described steps to adjust the cable length.

The clutch on Kalina may make squeaks and noises even after adjustment. They can be caused by the tip driver rubbing against the fork. The noise in this case comes from the engine side and is eliminated by applying lubricant to the contact point between the cable tip nut and the fork. Other possible causes - pedal creaking, cable grinding when rubbing against the casing - can be eliminated by applying lubricant. In some cases, the source of the noise may be the clutch pedal sensor.

For once: how to correctly adjust the clutch on a Priora without the help of others?

If the numbers do not correspond to the norm, then you need to set the appropriate size by rotating the leash. After each option, press and release the clutch pedal three or four times for the auto-adjustment mechanism to work.

In addition, it is necessary to check the full pedal stroke, which should be at the level of 135-145 mm , but not more than 160 mm . Measurements are taken using a ruler, tape measure or caliper. When installing the tip driver back onto the fork, the contact area should be treated with Litol-24 lubricant.

What to do with a faulty clutch

If you notice vibration of the clutch pedal when pressed, you need to contact a service center as soon as possible, because if you ignore the first signs of a malfunction of the mechanism, then in the near future you will face serious problems and expensive repairs.

Vibration and unit failure may be caused by a malfunction of the driven disk. To solve the problem, it is necessary to remove the mechanism and inspect it, paying attention to existing damage, deformations and defects. If they are present, the unit needs to be replaced.

If the vibration is caused by a malfunction of the clutch hydraulic system, a thorough check of the pipelines, master and slave cylinders is necessary. The reason may also be air trapped in the hydraulics. In this case, it is enough to remove it, and the pedal will work flawlessly when pressed.

Please note that you can save time and avoid unnecessary disassembly of the clutch mechanism by first making sure that the pedal travel is sufficiently free. This is done by measuring the free play of the pedal thrust pad (in domestic cars it should vary between 20–30 mm).

You can get acquainted with information about the free travel of the pedal when pressing it in the car’s service book or on the website of the automaker.

If the free play is within normal limits, but the clutch pedal continues to vibrate when pressed, you should contact a car service center as soon as possible. You should not disassemble and reassemble the clutch mechanism yourself, especially if you have no experience in this area, since the consequences for the car can be disastrous.

It wouldn't hurt to know

What do most owners of the newest Lada Priora do? Naturally, they treat the body with Movil or something similar against corrosion; they have no more problems at the initial level. But it didn’t work out without complaints about a squeak when pressing the clutch pedal; from time to time it was when the engine was heating up, from time to time only when it was cool - the essence of the problem was that there was a problem.

Of course, anyone immediately starts reading the “primer book” on how to properly adjust the clutch on your own Priora, which helps from time to time, but the fact of the matter is that from time to time. After this, owners can try several more methods, after which the creaking may disappear:

- Change the drive cable, some drivers praise the “tenth”.

- Check the presence of a spring in the automatic tension mechanism; sometimes the effect can be achieved after replacing the standard part with a spring with greater elasticity.

- A certain percentage of car enthusiasts get rid of the crackling noise by lubricating the fork and the plastic cable nut.

- Lubricate the installation space of the plastic bushing on the pedal bracket with lithol.

- Remove the boot from the fork lever and lubricate the box input shaft with graphite grease from a can.

It is worth considering another effective method, shown in the video, which is used by experienced car enthusiasts. Its essence is as follows:

- Disconnect the mass air flow sensor and remove the air filter.

- Remove the clutch release rod plug.

- Release the cable from the clutch fork.

- Pour 30-40 ml of gear oil from a syringe.

- Move the fork back and forth 10-15 times.

- Install the cable, plugs and filter into the space.

Using the example of part 2 of the article, it becomes clear that adjusting the clutch drive does not always bring the desired effect in the fight for acoustic convenience. Although, from a technical point of view, the procedure is necessary, as it ensures productive operation of the vehicle.

Hello everyone! Maybe someone can give me a hint. When you press and release the clutch pedal, you hear a creaking sound, the pedal feels like it is jerking to the touch. The cable is alive, it has been lubricated. I recently changed the release bearing. What options might there be? And also, there is a creaking noise both when the engine is running and when the engine is turned off. Pedal The Priora clutch creaks.

Similar articles

20 comments on “The Priora clutch pedal creaks. There is a squeaking sound when pressing and releasing the clutch pedal.”

Or the cunt clutch circle, or the fork

the fastest cable is an old one. When you press the pedal, it stretches and therefore creaks.

Spring on the pedal itself

Stanislav, I already installed a new cable. Nothing has changed

Baizet, the spring is alive

Kolya, then maybe a fork

I took off the box. Everything is in place, everything is method. Only on the petals is the development in steps at the point of contact between the release lever and the petals

I guess I'll have to change it

This is the norm. The clutch fork needs to be changed, it’s the same garbage, it just creaks not right away, but after a while, that’s why the clutch fork is needed, the parts cost pennies, but the work itself costs from 3000

Denis, damn I’ll do it myself) since I removed everything myself and took it apart

Well done then, I would like to see how it’s done and the result of the work

If I don't forget I'll take a couple of photos

Kolya, it was like this, look at the clutch pedal console, there is a bushing where the clutch cable is called, this bushing for us should have a plastic bushing so that the cable does not warp and it does not creak, it often wears out from friction, plastic costs 50 rubles together with an iron bushing ...I just changed the plastic

Diman, the plastic is ok)

Diman, the pedal moves smoothly without distortions or squeaks

Then something deeper)

The top plug of the fork, which is on the box, can also creak at the bottom, then we carefully drip oil onto the fork, and it runs down.

When you release the clutch pedal, a small squeak is made, what can you use to lubricate it and do you need to go a little far?

How to eliminate clutch squeaking in Renault Logan/Sandero?

The clutch is a highly loaded unit in a car! As a result of constant work, the mechanisms wear out and may produce extraneous sounds. If you hear squeaks or the pedal becomes too hard to press, then you need to inspect the clutch mechanism.

What could be the reasons for a squeaking clutch?

The clutch in Renault Logan and Sandero cars may make extraneous sounds for the following reasons:

- worn clutch cable

- clutch fork stop dirty

- Worn release bearing/clutch disc/clutch basket

First of all, determine by ear where the sound is coming from. If the sound comes from the pedal assembly, check the clutch cable for breaks or wear. Cable wear is one of the most common problems that lead to tight clutch release or squeaking in the pedal area. It happens that the cable itself begins to move along with the braid jacket and when it jams, a squeaking sound results. I recommend that at the first sign of tight squeezing or squeaking, immediately replace the clutch cable.

If the script is heard from the engine compartment and after replacing the cable the clutch is still pressed tightly with a squeak, then dirt has probably gotten onto the clutch fork stop. If so, then you can get away with simple cleaning and lubrication:

- Remove the clutch cable from the fork

- Remove the rubber boot from the clutch fork base

- Move the clutch fork to the left until there is space between it and the stop

- Clean the stop with a screwdriver and lubricate it with Litol or CV joint-24 lubricant.

Be careful: never lubricate the shaft on which the release bearing runs. It must be dry. Otherwise, clutch waste products (ferodo) will stick to the lubricant and act as an abrasive, wearing out the clutch.

To eliminate the creaking of the clutch fork, remove the protective boot and clean and lubricate the stop.

If, after replacing the clutch cable and cleaning the fork stop, the sound continues to annoy you, then it is likely that the release bearing is jammed or the release plate and clutch basket are worn out. In this case, only replacing or repairing the clutch mechanism will help.

FakeHeader

Comments 15

on the priors there is a rubber seal, at least lubricate the tensioning mechanism or not, the output will click one cable from the 10th family

I poured WD 40 where the pedal is, under the boot on the cable where it clings to the fork, and under the fork boot in the box

you need to lubricate the cable... and everything will go away + see the tension

There was also a problem a month after the purchase)) and this is a new machine)) there was a creaking from the mechanism, I spilled a lot of VD)) for six months nothing arose.

Specifically, in the priorotros there is a spring in the mechanism that tensions the mechanism, preventing it from creaking. Maybe someone doesn’t have a spring, then you can see how I fixed it, creaking in the sense

Source: l2rv.ru

How to change and adjust the cable yourself?

We figured out why the pedal creaks, now let's talk about adjusting the clutch on the VAZ 2114.

When there are problems in the functioning of the system, they must be eliminated. One of the most common problems is a broken cable. Therefore, if the pedal fails, then before properly adjusting and tightening the cable, it must be changed.

If you are experiencing problems with your pedal squeaking, check out the video that demonstrates the procedure for lubricating the device. Filmed by VikiNow.

Required Tools

To adjust the tension and replace the cable, you will need the following devices and tools:

- the cable itself;

- Litol lubricant;

- set of open-end wrenches;

- ruler;

- pliers.

How to replace it correctly?

To repair the cable, you need an assistant:

- Open the hood of the car and remove the bolts securing the battery terminals.

- You need to disconnect the connected cable from the pedal itself. Using a 17mm wrench, unscrew the nuts securing the bottom of the product. Then remove it from the retainer and remove it from the plug installed in the engine compartment.

- Further steps are carried out in the car interior. Move the carpet away from the driver's seat. There is carpet under the pedals, it needs to be removed. This will allow you to find the place where the cable is attached to the pedal; the clamp must be disconnected from it. There will be no problems, since this element is simply removed from the hook.

- After which the cable itself is removed from the seat. To do this, the device must be pushed away from you towards the engine compartment. When the product is difficult to push out, most likely its fastening has soured. Then lubricate the retainer with WD-40 and work it out a little, moving it in different directions. If you have an assistant, while you are developing the cable, he can pull it from the side of the engine compartment, this will speed up the procedure.

- After dismantling the product, a new one is installed. Before this, the bushing that secures the cable is removed from the clutch pedal. If its condition is poor, it is worn out, it is advisable to replace the bushing. The retainer itself is lubricated with Litol before installation.

How to adjust free play?

After repairs, the cable is adjusted in height. If you do not adjust the stroke adjustment and adjust it, you will have difficulty changing gears. Before tensioning and adjusting the cable, it is recommended to test drive the machine. It will allow you to figure out how to properly tighten the pedal - raise or lower it.

Position tension diagram:

- If the car begins to move at the end of the pedal stroke, open the hood and locate the cable attachment location. There are two nuts here that can be unscrewed with a 17mm wrench. To reduce the free play of the pedal, that is, lower it, the bolt located inside the bracket is unscrewed. The outer screw must be tightened with a wrench.

- If, when starting to move, you realized that the free play should be increased, that is, raise the pedal, then the inner screw on the metal clamp should be tightened, and the outer one should be loosened. If there is rust on the free play adjustment nuts, it must be removed using WD-40. If there is no fluid, motor oil or brake fluid is used.

- If the adjustment is successful, check the free play with a ruler. If the actions are performed correctly, its length will be from 12.5 to 13.5 cm. This distance will be directly from the pedal itself in the car to the floor.

The VikiNow channel published a video showing the process of changing the cable and further adjusting its free play.

Checking work

If everything was done correctly, then you should make sure that the task was completed correctly. To do this, you need to press the pedal all the way several times, then measure the free play again. After pressing, it may go astray. If this happens, adjust the stroke again. Ideally, the clutch should engage in the middle.

How to check whether all actions were performed correctly:

- The VAZ 2114 car is installed on a flat horizontal surface.

- The handbrake lever is activated.

- The machine engine starts, the shift lever is moved to the first gear position.

- Try to start, but don't press the pedal. When all the setup steps have been completed correctly, the machine’s engine will stall. If the car starts to move, the mechanism needs to be re-adjusted. In this case, all the steps described above are performed again.

What to do if the clutch pedal on a VAZ squeaks

| The VAZ clutch pedal of the tenth family cannot be called tight, even when the fork shaft turns sour over time and the grease on the release bearing clutch thickens, you can still press the pedal. In this article, we will find out how to make the clutch release easy without disassembling the checkpoint (Checkpoint - a point designed to control passage (visit) and access to the territory of any facility) , and also get rid of squeaks. |

When you drive Russian cars for a long time, you get used to their typical comfort and it seems that everything is not so bad. But once you change to a good foreign car, then you immediately realize that you were mistaken.

Modification of the VAZ clutch pedal consists of drilling a hole approximately 6 mm in diameter in the plastic bushing into which the fork shaft fits. More precisely, before this you should first select a suitable plug, and then create a hole according to its size.

| Before drilling a hole in the bushing, select a suitable plug to seal it later. | |

| Flowing down the shaft, the oil lubricates the upper support, and then gets onto the lower one. | A few drops and ease of clutch release is restored. |

Clutch faults Lada Kalina

Long-term use leaves its mark on the clutch mechanism; the driven disc linings wear out and become thinner. In order to compensate for this wear, the ratchet mechanism, as we have already said, automatically compensates for the degree of wear and tightens the cable. This is done by turning the release fork, causing the spring, which is located in the bushing of the adjustment mechanism, to compress. The spring, in turn, compresses the clamps of the toothed tip of the cable, after which the tip is released and tightens the cable.

Stories from our readers

“Fucking basin. “

Hi all! My name is Misha, for now I’ll tell you the story of how I managed to exchange my two-wheeler for a 2010 Camry. It all started with the fact that I began to be wildly irritated by the breakdowns of the two-wheeler, it seemed like nothing serious was breaking, but damn it, there were so many little things that really started to irritate me. This is where the idea arose that it was time to change the car to a foreign car. The choice fell on the melting Camry of the 10s.

Yes, I had matured morally, but financially I just couldn’t handle it. I’ll say right away that I am against loans and taking a car, especially not the latest one, on credit is unreasonable. My salary is 24k per month, so collecting 600-700 thousand is virtually impossible for me. I started finding different methods of making money on the Internet. You can’t imagine how many scams there are out there, what I’ve just tried: sports betting, network marketing, and even the Vulcan casino, where I successfully lost about 10 thousand ((The only direction in which it seemed to me that you could make money was currency trading on the stock exchange, they call it Forex. But when I started to delve into it, I realized that it was very difficult for me. I continued to dig further and came across binary options. The essence is the same as in Forex, but it’s much easier to understand. I started reading forums, learning trading strategies. I tried it on a demo account, later I opened a real account. To be honest, I didn’t manage to start making money right away, until I figured out all the mechanics of options, I lost about 3,000 rubles, but as it turns out, it was a precious experience. At the moment, I’m earning 5-7 thousand rubles a day. I managed to buy a car after half a year, but as for me this is a good result, well, it’s not about the car, my life has changed, I naturally quit my job, I have more free time for myself and my family. You’ll laugh, but I work directly on the phone) ) If you want to change your life like me, then here’s what I advise you to create right now: 1. Register on the website 2. Practice on a Demo account (it’s free). 3. As soon as something works out on the Demo account, top up your REAL ACCOUNT and go to REAL MONEY! I also advise you to download the application to your phone, it’s much more convenient to work from your phone. Download here.

Over the course of several days, pour 5–10 drops of motor oil into the hole formed and close it with a stopper. In this way, the oil will penetrate into the gap between the bushing and the fork shaft, flow down the shaft and lubricate the lower support. The clutch pedal will be soft without repairing the checkpoint (Checkpoint - a point designed to control passage (visit) and access to the territory of any facility)

. Lubrication will also eliminate clutch pedal squeaks. A similar modification is suitable not only for the VAZ 2110, but also for the VAZ 2109, because The boxes of these cars are of the same type.

By the way, if the car is old, then the clutch drive already has wear, distortions and, as a result, difficult movement of the clutch. Repair the checkpoint (Checkpoint - a point designed to control passage (visit) and access to the territory of any facility)

For the sake of such a little thing it’s unlikely to be purposeful. To compensate for losses in the drive, you can install a spring on the fork lever (with a force of 1 kgf). You should not use an excessively hard spring; it will only interfere with full activation.

Was it easier to create a clutch pedal using the method from the article?

Source: xn--2111-43da1a8c.xn--p1ai

Other causes of squeaking

What causes a hard clutch pedal?

tight clutch pedal: causes of malfunction tight prior clutch causes If everything is perfect in the calculations, and the unpleasant sound does not leave you behind, then you need to look for other culprits:

- Plastic pedal bushing. It can “get used” to the bracket and make squeaks. Everything is quite simple here, we are looking for the attachment point, it is probably loose. Let's pull it up. Then be sure to repeat the procedure with the cable

- Tip lead. You will notice this at the first stage. If it squeaks, then it needs to be changed. Fortunately, there are plenty of such parts on sale, and the replacement process itself is not difficult. Unscrewed the old one and screwed on the new one. Then again measure and adjust according to the instructions above

- Loss of input shaft lubrication. This is already a problem with the box itself. Here the solution is clear: lubricant.

If you have carried out all these repairs, but still haven’t gotten rid of the problem, then the best advice would be to visit a car service center or an official dealer. Tell the technician what you tried to fix on your own, but did not achieve results. Then he will immediately look in other places and will not spend much time on repairs.