The robotic gearbox of the Lada Vesta has two actuators in its design: gear shift and clutch. If there are no problems with the first device in principle, then the clutch actuator is a headache for many Lada Vesta owners. The fact is that after a certain time it begins to creak, and other related problems arise. When contacting an official dealer with this problem, the owner will be in for another surprise. The unit is not repairable, but must be replaced as an assembly; if the warranty on the Lada Vesta has already expired, you will have to pay for the spare part out of your own pocket, the amount is about 16 thousand rubles.

Car enthusiasts who are not ready to pay that kind of money to replace a unit resolve the issue by repairing the old vehicle. It is worth understanding that it is unlikely that it will be possible to carry out a full repair. The fact is that the company that produces actuators installed on Lada Vesta cars does not supply repair kits for its products, and there are simply no suitable analogues.

How to lubricate the AMT clutch actuator and get rid of squeaking on a LADA

Owners of Lada Vesta, XRAY, Granta, Priora and Kalina cars with an automated transmission (AMT or “robot”) may encounter a creaking actuator (especially in hot weather) that presses the clutch fork. The problem can be solved by lubricating it. We'll tell you how to perform this procedure yourself.

How to detect a creaking AMT actuator

:

- turn on the ignition;

- turn on the gear;

- press and release the brake pedal;

- If there is a squeak, then it is the actuator.

The process is also shown in the video:

Procedure

:

- Remove the clutch actuator (see these instructions).

- Remove the actuator cover by unscrewing the fastening bolts.

- Lubricate all load points and hinges with special lubricant (for example, Liqui Moly 3352 or LIQUI MOLY Thermoflex Spezialfett)

The process is also shown in the video:

To lubricate the actuator, there is no need to disassemble the mechanism itself, therefore, after reinstalling the actuator, its adaptation (training) is not required. The whole process will take no more than 3 hours. By the way, actuator lubrication is done at a service station, the price of the service is about 2,000 rubles.

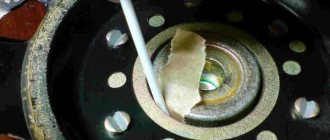

Another reason for a squeaking clutch may be a rusty release lever stop. Lubricate it with Bechem High-lub L2 MO (photo by premoy).

Let us remind you that we previously told you how to check the technical condition of the AMT box in case of problems.

Categories of products that may be of interest to you based on the article “How to lubricate the AMT clutch actuator and get rid of squeaking on a LADA”:

Third option

It consists of unscrewing the bracket itself from the gearbox. To do this, you need to unscrew 4 bolts - 2 at the bottom, 2 at the top.

All that remains is to remove the actuator wire connector. You need to pull the yellow lock towards you, press on the sides and pull it out.

Now the device is in our hands and available for use. I disconnected it from the bracket. The screws are easy to remove. This is a cover with a gasket.

Inside the case, wear on the hinge or darkening of the lubricant is visible.

You can also see some wear on parts and metal shavings on the spring. Although the grease is also visible.

Lada X Ray Cross automatic - new equipment

Lada Vesta repair books

Products from the Dustershop77 range on the topic of the article:

| Name | Manufacturer | Price | Availability | Add to cart |

| DC952-7703062062 | Gasket for gearbox drain plug, transfer case Renault Duster / Terrano / Captur original 7703062062 | Original | 200 / 100 rub. Discount: 80 rub. | >10 |

| DC1560-8200884113 | Drive oil seal original Renault 8200884113 left | Original | 1000 / 800 rub. Discount: 700 rub. | 2 |

| DC1667 | Clutch kit Vesta (1.6l 21129 + manual transmission VAZ / AMT) LUK | Analogue | 5500 / 4600 rub. Discount: 4400 rub. | 2 |

| DC524-302054100R | Clutch kit for 1.6 (H4M) 4×2 gearbox JR5 (5-speed) original art. 302054100R | Original | 8000 / 7400 rub. Discount: 7000 rub. | 1 |

| DC1630-7703075180 | Filler plug for gearbox / transfer case original 7703075180 | Original | 200 / 150 rub. Discount: 100 rub. | 4 |

| DC422-510009710 | Release bearing H4M 4×2 JR5/JH3 5-speed. LUK 510009710 306200650R 7701478631 8200046103 8200764613 8200990502 306205482R 306205482R 306206219R 306201586R | Analogue | 4500 / 3900 rub. Discount: 3500 rub. | 2 |

| DC383-ASAM-30799 | Gear shift lever bushing ASAM-SA 30799 original art. 7700732903 | Analogue | 400 / 150 rub. Discount: 100 rub. | 2 |

| DC440-8200410813 | Drive shaft retaining ring original art. 8200410813 | Original | 500 / 300 rub. Discount: 250 rub. | 3 |

| DC1631-8200201381 | Transmission/transfer case filler plug gaskets original 8200201381 | Original | 500 / 350 rub. Discount: 300 rub. | 3 |

| DC950-321031MG0B | Rear gearbox filler plug Renault Duster / Captur / Nissan Terrano 4x4 321031MG0B | Original | 1500 / 1200 rub. Discount: 1100 rub. | 4 |

| DC956-7700102458 | Automatic transmission filter DP2 original 7700102458 | Original | 900 / 600 rub. Discount: 500 rub. | 1 |

| DC1964-21102301034 | Right drive oil seal Vesta, Largus, X-Ray article 21102301034 (black 35x57x9) | Original | 200 / 150 rub. Discount: 110 rub. | 4 |

| DC1316-8201630012 | Guide (tool) for centering the clutch and release (H4M-JR5/JH3) original 8201630012 | Original | 2000 / 1800 rub. Discount: 1600 rub. | 1 |

| DC1818-7701209239 | Boot of outer CV joint Duster, Terrano, Captur 1.6 / 1.5 4×4 manual transmission 7701209239 original | Original | 3200 / 2500 rub. Discount: 1900 rub. | 1 |

| DC2046-8200544206 | Gearbox input shaft oil seal TL4/TL8/JR5 8200544206 | Original | 1200 / 800 rub. Discount: 600 rub. | 2 |

| DC2245-7703065290 | O-ring, oil pump oil seal, automatic transmission original 7703065290 | Original | 800 / 700 rub. Discount: 500 rub. | 2 |

| DC1956-21820160121100 | Clutch fork boot Grant, Vesta, X-Ray 21820160121100 | Original | 150 / 100 rub. Discount: 70 rub. | 1 |

| DC2159-6001548446 | Clutch master cylinder Duster and others original 6001548446 | Original | 4600 / 4200 rub. Discount: 3900 rub. | 1 |

| DC2163 | Clutch basket Vesta, X-Ray 1.8 21179 JR5 original 21179-1601085-10 | Original | 7300 / 6500 rub. Discount: 6100 rub. | 1 |

| DC2164 | Clutch disc Vesta, X-Ray 1.8 21179 JR5 original 21179-1601130-11 | Original | 6400 / 5300 rub. Discount: 4900 rub. | 1 |

| DC2374-35025 | Repair book for VAZ LADA Vesta | 1700 / 1400 rub. Discount: 1300 rub. | 0 | |

| DC2373-35026 | Repair book for VAZ LADA Xray | 1900 / 1600 rub. Discount: 1400 rub. | 0 | |

| DC1963-21102301035 | Left drive oil seal Vesta, Largus, X-Ray article 21102301035 (red 35x57x9) | Original | 200 / 120 rub. Discount: 90 rub. | 0 |

Automated transmission design

The main difference from a manual transmission is the replacement of the clutch pedal and gear shift knob with corresponding electromechanical type switches. To manage them, the following have been additionally implemented:

- Control block.

- Shaft speed sensor.

- Fork position sensor.

- Interior gear selector position lock.

AMT has one significant disadvantage of the operational plan: the electromechanical drive processes commands with a delay. A hydraulic alternative, unfortunately, is not available due to its high cost.

Reliability and operating features of the robot box in the Lada Grant

The design of a robotic gearbox is simpler than an automatic one with a torque converter: the cost is lower. Therefore, AMT began to be actively installed on inexpensive car models.

A robotic gearbox is a kind of compromise between a manual and an automatic transmission. The Lada Granta is equipped with a VAZ-2182 manual transmission. AMT (Automated Manual/Mechanical Transmission) is equipped only with cars with a 16-valve engine. How long the robot can walk on the Grant largely depends on its driving style.

Possible malfunctions of the robot box

The most common malfunctions are of two types - mechanical and caused by electronic failure. They say about a breakdown in the Lada Granta robotic box:

- indicator lights on the instrument panel;

- howling or buzzing when moving;

- lack of response to an increase in speed - the speed does not increase;

- leakage of liquid from the box;

- stopping the operation of the unit and stopping the machine.

Mechanical failures are caused by worn or damaged parts. In this case, replacement is required. The most common malfunctions are wear of the gear selection fork and rolling bearings.

The most common failures of electronic components are:

- burnout of contacts of electric drives - requires replacement at a service center;

- breakdown of switching drives;

- burnout or contamination of the brushes of the electric motor responsible for operating the shift levers.

Source

A few words about regular MMT

Toyota Corolla 150, 2007, 2008 cars are equipped with MMT 89530-12290. This device has a number of imperfections and shortcomings, which, by the way, was recognized by the automobile concern.

In order to find out which actuator is installed on the car, it is necessary to remove the lower glove compartment cover, and from the driver's seat on the car body you can find the number of the MMT installed on the vehicle.

When should adaptation be made?

Adaptation of AMT should be done in the following situations:

You have a pre-production car, and you need to update the settings to more recent and correct ones.

The fact remains that the first cars turned out to be a little damp and there’s nowhere without it, but fortunately AvtoVAZ quickly solves the problem, as it has already done with bushings and stabilizer struts, with the clutch.

When replacing the clutch

It turned out that the Turkish Valeo clutch, which was installed on the first cars, is not suitable for the weight of the car. As a result, the owners of the first West felt the clutch slipping, felt that the car was moving poorly and needed to increase the speed. When replacing the clutch with a new one, adaptation is carried out. If for some reason you changed the clutch not from an official dealer but on your own, do not be afraid to move on the new clutch without adaptation as necessary. But it will need to be done.

Clutch device

On the Lada Vesta, as well as on all its modifications, including the X-RAY crossover and Cross versions, a standard unit with one disk is installed. The contact of the friction and drive disk occurs under the action of a spring. The main difference between the Vesta clutch and other AvtoVAZ models is the drive.

Structurally, the Vesta clutch is designed according to the standard type and consists of a pressure and driven disc that interact with each other. A pressure disk is installed in the basket; the basket itself is a steel body. The pressure plate in the basket is pressed using a special device in the form of a spring. The clutch basket is installed directly on the flywheel of the power unit and is firmly attached to bolted connections.

A disc with friction linings is placed between the flywheel and the drive disc. The driven clutch disc is also called a friction disc due to special linings attached to both sides. A damper with springs is installed in the center of the hole, designed to eliminate vibrations when the clutch is engaged. The friction disc is mounted through the hub onto the engine input shaft.

Features of the Vesta clutch hydraulic drive

The hydraulic drive consists of pipelines and two cylinders (worker and main). From the master cylinder, the pressure from the rod is transferred to the working one. This, in turn, exerts an influence on the clamping device through pipelines. The working cylinder is a module where the release bearing is also located. All this is mounted in the clutch housing.

Brake fluid performs the functions of working fluid. To ensure the reliability and performance of the hydraulic drive, it is necessary to promptly change the working fluid in accordance with the regulations. Problems with the hydraulic drive most often result from air in the system. In advanced cases, it will simply be impossible to change gears on the car.

Features of the electric clutch drive on Vesta

The electric drive, unlike the hydraulic one, is designed slightly differently; it acts directly on the clutch fork. When the fork is turned, the force puts pressure on the release bearing, which, in turn, presses on the petals of the pressure plate spring. The release bearing is reinforced and is constantly in operation, and the spring is always pressed against the coupling due to the absence of any gaps.

The release bearing does not require periodic maintenance, i.e. no lubrication is needed, the manufacturer took care of this too. The bearing lasts a long time and is simply replaced if it fails. You can recognize this by the characteristic noise. The release plate must also be replaced when replacing the driven or pressure disks, regardless of whether the bearing is in good condition or not.

Malfunctions in the operation of the hydraulic drive can be easily eliminated with your own hands; often it is enough to bleed the system and get rid of the air. But with an electromechanical drive, troubleshooting is much more complicated. A similar procedure on automatic and robotic gearboxes is called adaptation, and it is impossible to perform it without knowledge, skills and equipment. In such cases, the only correct decision is to contact an official dealer.

Today, the AvtoVAZ plant is actively introducing modern technologies into its cars, this also applies to clutches. Nowadays, structural elements that meet international quality standards are used for this. Friction linings and springs are much more reliable and durable.

Replacing the clutch cable

To replace the clutch cable, you will need to perform the following manipulations sequentially:

- unscrew the nut that secures the cable to the pedal assembly (it is located under the panel);

- remove the stopper from the braid pin;

- then use pliers to remove the locking clip;

- then remove the pedal axle;

- remove the pedal bracket spring;

- Use pliers to remove the tip stop;

- release the pedal from the cable end;

- Next, you need to remove the cable sheath seal from the engine compartment;

- pull the end of the cable connected to the fork towards you, and then remove it;

- dismantle the tip driver;

- dismantle the guide bushing;

- to complete the work, it will be necessary to pull the cable through the hole located between

- engine compartment and car showroom.

Before installing the cable, it is lubricated, and a small amount of machine oil is poured between its shell and itself. Install the cable, carrying out actions similar to its removal in the sequence directly opposite to dismantling.

AMT management

During operation, the “robot” is much simpler than automatic transmission and classic “mechanics”. The electronic selector allows you to use 4 operating modes:

- neutral - N;

- automatic - A;

- reverse - R;

- manual control - M.

Before you start driving, you need to set the selector lever to position “A”, then press the brake pedal and only then put your foot on the gas pedal.

Attention! The engine of a LADA Granta (sedan, liftback) equipped with a “robot” will not start if you forget to press the brake pedal. The car's acceleration time to a speed of 100 km/h is 12.5 seconds, which is 1.6 seconds inferior to models with a manual transmission (10.9 seconds), but 0.8 seconds better than the LADA Granta with automatic transmission (13. 3 sec.)

In this case, gear shifting occurs at 5000 rpm with an aggressive driving style or 2500 rpm with a quiet mode

The car's acceleration time to a speed of 100 km/h is 12.5 seconds, which is 1.6 seconds inferior to models with a manual transmission (10.9 seconds), but 0.8 seconds better than the LADA Granta with automatic transmission (13. 3 sec.). In this case, gear shifting occurs at 5000 rpm for aggressive driving or 2500 rpm for quiet driving.

The time to switch from one gear to another in automatic mode is no more than 2 seconds. Because of this, AMT may seem “thoughtful” to some drivers, but when switching to manual control mode, the gear shift speed is comparable to the speed of a manual transmission.