According to the vehicle maintenance card, it is necessary to replace the front wheel bearings of the VAZ-2108. Their dimensions are larger than those of similar ones installed on the VAZ 2101-2107 model. Moreover, there are features of the replacement. The “classic” uses tapered bearings; it is imperative to observe the permissible force when tightening the hub nut. Otherwise, the bearing will fall apart and you will have to buy a new one. Eights use cylindrical bearings; when tightening the hub nut, you need to apply as much force as you can - just don’t break the thread.

Signs of a broken wheel bearing

As the vehicle is used, its components and assemblies wear out. Moreover, those that suffer the most are those that are constantly loaded - these are rubbing parts. The weight of the engine and the friction force act on the front hub bearing of the VAZ-2108. That's why its dimensions are so impressive - to cope with the load. But when an element fails, the following symptoms occur:

- In the early stages, a barely noticeable hum appears.

- Minor vibrations may be felt transmitted from the wheels to the body.

- As the bearing wears, the noise and vibration increase.

If you do not replace it in a timely manner, the bearing may jam. During operation, excessive heating of the hub will be observed - there is very little lubricant inside the bearing race, the metal elements rub against each other.

Instructions for replacing the VAZ 2115 wheel bearing at home

Replacing the VAZ 2115 wheel bearing with your own hands

Problems with the brake system or wheel bearing can be diagnosed by characteristic squeaks or knocks in the front part (wheel area). If the brake system is in order, you will need to diagnose the wheel bearing and replace it if necessary.

To check the wheel bearing, you need to compare the temperature of the wheel rim at the end of a long trip on the side where the squeaks and knocks are coming from. If the disc is too hot, it means the pads are sticking or the wheel bearing is faulty. The latter can lead to wheel misalignment, which usually leads to friction.

To check everything more thoroughly, you need to use a lift or jack.

Raise the tire that is causing some doubt with a jack and rock its lower part, holding it with both hands. If you feel play and a dull knock appears, the wheel bearing needs to be replaced.

Repair tool

To replace the front wheel bearing of a VAZ-2108, you will need a tool. All work must be carried out on a well secured vehicle. You will need the following tool:

- Set of keys and sockets.

- Mounting blade.

- Bearing puller.

- Gas-burner.

- Jack, wheel chocks and secure supports.

- A small piece of pipe with a diameter of 10 cm.

- Hammer and chisel.

- Pliers for removing retaining rings.

The procedure for carrying out work on the left and right wheels is the same. It is advisable to replace bearings on both sides at once. It is required to install elements from the same manufacturer, which are recommended by the factory.

Preparing for repairs

Now it's time to remove the old VAZ-2108 front wheel bearing. Its dimensions are indicated in the article below; when pressing out, you can use a clip from an old roller. Before starting work, do the following:

- Loosen the front hub nut.

- Using a 30mm wrench with a large lever, remove the nut.

- Install wheel chocks under the rear wheels.

- Remove the wheel bolts.

- Raise the side to be repaired with a jack.

- Place supports under the car.

- Remove the wheel and place it under the car engine.

That's all, now you can start dismantling the front wheel bearing of the VAZ-2108. The dimensions of the old and new must match. If the diameter is slightly larger or smaller, the bearing may not work properly.

How are alloy wheels tightened?

To perform such a scrupulous procedure, a special tool is used - a torque wrench. Mechanics also use pneumatic impact wrenches at service stations. And at home, drivers use a wheel wrench.

First of all, you should pay attention to the diameter of the wheel, its width, and then to the design

The number of holes along the rim is also important. They must necessarily have cone-shaped recesses, which are necessary for centering the disk on the hub with bolts and nuts

The number of such holes can be different - from 4 to 6. Some models have more than six

They must necessarily have cone-shaped recesses, which are necessary for centering the disk on the hub with bolts and nuts. The number of such holes can be different - from 4 to 6. Some models have more than six.

For different types of alloy wheels, the tightening of wheel fasteners is not the same. It differs in the sequence of actions. So, rims with 4 holes must be installed in the order 1-3-4-2, and rims with five bolts are secured in the order 1-4-2-5-3, but for rims with six nuts the option 1-4-5 is suitable -2-3-6.

Removing the front wheel hub

Now you need to remove the hub. To do this you will need:

- Mark the position of the hub on the strut using a marker. Be sure to clean the surface thoroughly before doing this.

- Using keys “17” and “19”, unscrew the nuts from the bolts securing the hub to the shock absorber strut.

- Using a “17” wrench, you need to unscrew the lower bolts securing the ball joint to the hub. This is a simple option when you do not need to replace the ball. But if you need to change it, then you need to use a “19” key to unscrew the nut from the ball pin and remove it using a puller.

- Completely unscrew the hub nut.

- Carefully push the front wheel hub off the CV joint.

That's all, now you need to completely disassemble the element and remove the front wheel hub bearing of the VAZ-2108.

Step by step replacement

1. Place the desired wheel on the jack and remove it.

2. Flare the hub nut.

3. Place the wheel and engage the gear. We take the head at thirty and tear off the hub nut.

4. Remove the wheel and completely unscrew the hub nut.

5. Unscrew the 2 bolts securing the brake caliper using a 17mm wrench.

The bolts are located at the rear of the caliper.

6. Separate the pads and remove the caliper. So as not to interfere, we tie it to the stand.

7. Unscrew the 2 bolts securing the brake disc and remove. Nuts for twelve.

8. Remove the 2 ball fastening bolts. Seventeen bolts.

After unscrewing the bolts, remove the ball pin from the hub.

9. Pull the hub towards you and remove the axle shaft from the hub.

10. Using pliers, remove the cotter pin and unscrew the nut securing the steering tip pin.

11. Using a puller, squeeze out the finger.

12. Turn the strut out and knock the hub out of the bearing. I took a nineteen head and used it as a guide. You can come up with something else.

13. Remove the retaining rings holding the bearing on both sides.

14. Install the puller and squeeze out the bearing. Instructions for using the puller are on the box.

The puller costs 1000 rubles.

15. We pick up and remove the boot from the hub.

16. Press out the bearing race that remains on the hub.

To make it easier to rotate, I placed the hub with the back side into the wheel. I aligned the holes and inserted a screwdriver to prevent it from turning.

17. Install the internal retaining ring.

18. Lubricate the bearing seat. This will make pressing easier.

19. We mount our bearing into the puller and press it in.

20. Install the external retaining ring.

21. Mount the hub boot.

22. We also press the hub into the bearing using a puller.

23. Putting everything back together. If you forgot what comes with what, watch the video.

Video lesson

Source

Bearing sizes

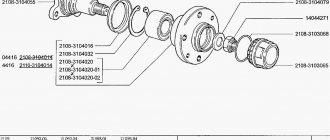

The article contains a photo of the VAZ-2108 front wheel bearings, as well as a drawing of a puller indicating all dimensions. Therefore, if you are in doubt whether you purchased the right roller, check the dimensions of the hub. The part number is 256907.

The dimensions of the element are:

- The outer diameter of the holder is 64 mm.

- Inner diameter – 34 mm.

- Weight – 445 g.

- Balls with a diameter of 9.525 mm are installed inside.

- The total number of balls is 28.

- The unit is designed to operate at rotation speeds above 6000 rpm.

In any car store, salespeople will be able to advise you on the best quality product.

Manufacturers

Many motorists do not know which VAZ-2108 front wheel bearing to choose for their car. Now you can find several manufacturers on the market:

- GPZ-23, Vologda, has the abbreviation VBF. The plant has earned the trust of motorists and is one of the best manufacturers of wheel bearings for domestic cars. Due to the relatively low cost, these parts are practically not counterfeited.

- SPZ, Saratov - according to many experts, the bearings of this manufacturer are the most reliable, durable and high quality. And most importantly - the very low cost of parts.

- GPZ-20, Kursk is no longer engaged in the production of wheel bearings, but you can find products in stores and warehouses.

- Experts do not speak very well of the Samara SPZ-3. The cost of the bearings is very low, but the quality is not great, the service life is very short.

Some auto stores try not to deal with little-known companies that produce low-quality products. Therefore, on the shelves you can only find bearings from Saratov and Vologda.

Who are packers?

Well, the guys have dealt with the monsters of the industry, but there are also so-called packagers - these are companies that do not have their own production facilities, but package “hubs” from third-party manufacturers.

A small list of well-known ones: 1) Ruville is one of the largest, but indiscriminate, it can pack both serious brands and outright fakes, mainly from Eastern Europe, Romania, Poland, etc.

2) Optimal – Polish packer, worked with IRB, SKF and FAG. However, now it has become an outsider, you can find fake China, Ukraine, etc. You need to look closely.

3) HK – used to belong to FAG, and accordingly only packaged its products, it’s worth taking a closer look.

4) QH - cheap Chinese brands, but not fakes. Medium quality.

5) Corteco - cheap brands are often from China, not worth buying.

Installing a new bearing

To simplify installation, you can do a little trick - warm up the hub a little and cool the bearing in the freezer. In the first case, the metal will expand, in the second, it will contract. Pressing will be much easier and faster. The main thing is not to overheat the hub, otherwise the seal on the bearing will melt and the lubricant will leak out. As a result, you will have to buy new spare parts and do the repairs again.

Lubricate the inner surface of the hub and install the retaining ring on one side. Carefully now you can begin to press in the wheel bearing of the VAZ-2108. If the dimensions are correct and there are no deviations in the geometry of the nodes, assembly will not take much time. When finished, install the second snap ring. Assemble the entire assembly and install it on the CV joint, tightening the bolts at the top and bottom. If necessary, replace the ball joint.

The hub nut is tightened with a “30” wrench with very high force after assembling the entire suspension and installing the car on the wheels. The entire assembly is carried out in reverse order, do not forget about the marks on the surface of the shock absorber strut. After all the work, make sure that there is no significant wear on the rubber - otherwise, do a wheel alignment.

Good day to all! The other day there was a very nasty squeak in the rear left wheel. I thought that the cylinder was a working brake, maybe because of it the pads were not moving well, but it turned out that the bearing itself was wedged. It was already unbearable to drive with a squeak and it was somehow unpleasant that everyone was paying attention to you because this creaking