The starter solenoid relay supplies current to the starter motor and also pushes out the bendix. This means that the moment the starter starts to rotate, its bendix is pushed out. In fact, understanding the operation of the starter is not difficult. Today we will help you understand how the solenoid relay works, how to check this element and repair it.

Solenoid relay design and operating principle

In the starter, the solenoid relay engages the flywheel crown with the bendix. All work is based on the principles of electromagnetism. The core, which is made as a hollow tube, inside which the armature is located, is equipped with a wire winding. The current in the coil creates an electromagnetic field, as a result of which the armature enters the core. After the current stops flowing, the armature can move freely.

The starter retractor relay includes: housing; magnet with windings; anchor; contacts; return spring. The magnet in the relay is made in the form of a pair of coils - retracting and holding. The relay retractor coil is connected to the electric motor and the control terminal, but the holding coil is connected to the control terminal and is in contact with the housing. When power is applied to the control contact, magnetic induction occurs in the coil, which leads to the appearance of a magnetic field. As a result, the armature compresses the return spring. At the same moment, the bendix rotates, which connects the starter to the car battery. At the time when the contacts close, the retractor winding receives power from the “+” terminal, the production of current in the coil stops, but the armature is affected by the field of the holding coil, so it remains inside. When the vehicle's power unit starts, the power is cut off, causing the armature to return to its original position under the action of the return spring. The contacts open, which can cause the bendix to disengage.

Common solenoid relay failures

The main reasons for failure of the starter solenoid relay are as follows: Physical wear. Burnout of contact plates. Destruction of components. Winding combustion. How to determine that the solenoid relay has failed:

The engine starts, but the starter does not want to turn off, constantly rotating. At this time you hear a characteristic buzzing sound. The starter rotates after starting, but cannot start the engine. When the key in the ignition switch is turned to its original position, the starter click is heard, but it does not want to rotate. How to check the starter solenoid relay As mentioned above, the operation of the solenoid relay, as well as the starter itself, is based on the principle of electromagnetism. When voltage is applied to the windings, the relay acts on the armature. This, in turn, changes the position of the Bendix gear so that it engages with the flywheel ring. At the same time, the contacts close, providing voltage to the starter windings. In order for the car engine to start, all this must happen very quickly. The article was published in the Machines public page. If at least one of the elements does not work correctly, you will not be able to start the car. To check the starter relay, you do not need to remove this element from the car. Experts advise closing the contact bolts located on the back of the relay using a piece of wire or metal. As a result of this, you will ensure the supply of current to the starter windings. If this caused the starter to rotate, you can conclude that the starter is working normally, and the problem lies in the relay itself. If the retractor clicks and the starter does not turn, this indicates that the relay is probably working, and the cause of the breakdown must be looked for directly in the starter.

Repair of starter retractor relay

If you have come to the conclusion that the starter traction relay has failed, you need to repair it. We would like to note right away that in most cases it is much easier to replace this element than to restore its functionality. Many manufacturers produce non-separable relays in order to make this unit the most reliable. In such situations, you will simply have to replace the solenoid relay with a new one. If the starter in your car is equipped with a detachable relay, you can repair it yourself. Often the relay does not work for the following reasons: the mechanical drive has worn out and failed; a short circuit has occurred in the winding; “nickels” or contacts were burnt. Each of the above faults can be determined after disassembly. vk.com/cars.best True, to determine the integrity of the windings you will have to use an ohmmeter. When measuring the resistance between the ends of the wire and the body, this indicator should be at least 10 kOhm. Otherwise, the windings have shorted, so you will need to go to the store for a new relay.

Installation of a new or restored relay is carried out in the reverse order of dismantling. Many car enthusiasts at this stage have a problem, which is how to connect the starter relay. In order to avoid such troubles, we recommend that you first mark the disconnected terminals. Before installing the relay, be sure to thoroughly clean the contacts and degrease them.

Replacing the starter relay

There are times when you try to start the engine, there is simply a click, but the starter does not turn.

Accordingly, it will not be possible to start Kalina in this case. This problem occurs in most cases due to a faulty solenoid relay. In order to replace it, it is not at all necessary to remove the starter from Kalina; all this can be done on site. You just need to free up access to the mechanism. To do this, you can remove the entire air filter housing so that it is out of the way. Read more about this in the first half of the article here.

And one more thing: initially disconnect the terminal from the battery.

The starter relay is located in the mounting block

Gained access to the fuse box

Finding the starter relay is very simple; it is located in the mounting fuse block on the left side of the steering column, on the cover of which the controls for the instrument panel illumination and the direction of the headlight beam are mounted.

Before starting work, disconnect the negative terminal from the battery.

- In order to dismantle it, carefully lift the edge of the lid with your hand and release it down.

- On the inside of the cover there is a diagram of the location and purpose of the relays themselves.

- In the photo, a red marker indicates the location of the starter relay in place of K3.

Replace the non-working relay with a new one

When installing a new relay, make sure it matches the current ratings indicated on the relay body.

Guide to replacing the retractor on Kalina

Once access is free and nothing interferes with work, you can disconnect all terminals and power plugs. One wire can be easily removed - you just need to pull it to the side. But the other two are fastened with nuts:

We release one using a 10mm socket with a ratchet, as is clearly shown in the photo below:

And the second one as usual at 13:

Next, you can begin to unscrew the two bolts securing the retractor relay itself. Doing this is extremely inconvenient, so it’s unlikely to do without a ratchet and a thin-walled socket 8 - especially for the bottom bolt:

The upper bolt is unscrewed without an extension, using a wrench:

After this, you can remove the solenoid relay. Most likely it can be removed without an anchor, since it is hooked to the drive lever:

But then you can release the anchor, moving it a little in the right direction to remove it from the lever, and pull it back.

Now we take a new retractor and replace it. Installation is carried out in the reverse order and will not cause much trouble. It is worth noting that you will first need to insert and hook the retractor armature to the lever, and then put on the spring and insert the relay body itself.

The price of this part is about 500 rubles on average across all car dealerships.

Source

What's the result?

As you can see, the starter circuit involves two types of relays: a solenoid relay and a relay in the control circuit. With all this, it is easier to start checking with the relay in the circuit, after which the traction relay is then checked. In any case, comprehensive diagnosis (the process of establishing a diagnosis, that is, a conclusion about the nature of the disease and the patient’s condition)

allows you to find the faulty element, after which you can easily remove the damage.

This approach will allow the fault to be localized more quickly and often simplifies repairs. By the way, usually the relay is not repaired, but replaced immediately, because in the case of the VAZ, the cost of similar parts is completely affordable. As for the replacement itself, usually, even car enthusiasts without much experience are fully capable of changing the starter relay in the circuit or the starter solenoid relay with their own hands in the conditions of an ordinary garage.

Source: krutimotor.ru

VAZ Kalina starter retractor relay

CHECKING THE STARTER CIRCUIT OF LADA KALINA (VAZ 11173 11183 11193)

If the starter does not work when the ignition key is turned to position “II,” there may be a malfunction of both the starter itself and its activation circuit.

To check, turn off the ignition and disconnect the wire block from the terminal of the starter traction relay windings.

When carrying out this operation, care must be taken, since sparking is possible in the area where the terminals are closed.

Do not connect the screwdriver to ground while closing the terminals! If the crankshaft rotates, then the starter is working, and the cause of the malfunction is a violation in its activation circuit. Otherwise, the starter or its traction relay is faulty. If it is not possible to eliminate the malfunction in the activation circuit of a working starter, then, if necessary, in this way (by turning on the ignition and closing the terminals), you can start the engine and drive to the repair site.

A malfunction in the starter switching circuit can be caused by damage to: the starter relay, the power circuit or relay control circuit, the ignition switch contact group. To troubleshoot the starter circuit.

. remove the starter relay from the mounting block.

To check the starter relay, install a known-good relay type 902.3747-11 in its place. To do this, you can use the adjacent power window relay. If the starter turns on with the newly installed relay, then the starter relay has failed and must be replaced. If not, check the power circuit and starter relay control circuit.

To check the power circuit, remove the starter relay from the mounting block.

In this case, the second (“negative”) probe of the tester can be connected to the bolt securing the door opening limiter.

If voltage is supplied to socket “30”, use a tester to check the integrity of the circuit from socket “87” of the starter relay to the tip of the starter traction relay control wire. If voltage is not supplied to socket “30”, check the circuit from terminal “50” of the ignition switch to socket “30” of the relay. If the circuit is in good condition, it is necessary to replace the ignition switch contact group.

If the starter power circuit is working properly, check the starter relay control circuit. To do this, insert the tester probe into socket “86” of the starter relay, the second tester probe

. Is there ground in socket “85” of the relay?

. connected to pin “50” of the controller.

Otherwise, we check the integrity of the starter relay control circuits: from the main relay of the control system and output “50” of the controller - respectively to sockets “86” and “85” of the starter relay.

1200 rub. for the photo report

We pay for photo reports on car repairs. Earnings from 10,000 rubles/month.

Write:

The starter solenoid relay is an electromagnet that performs two functions in the ignition system. The first is to bring the Bendix starter gear to the flywheel ring gear. The second is its return to its original position after starting the engine. A breakdown of the solenoid relay may result in the engine simply not starting . There are not many reasons for relay failure. In this material we will try to describe the signs and causes of failure, as well as diagnostic and repair methods.

Solenoid relay with core

Starter relay Kalina: checking the circuit yourself

The car starter is a fundamental unit because it is responsible for starting the unit. With all this, it is the starter that consumes the largest amount of electronic current coming from the battery. Of course, in order to avoid problems with the battery, as well as with the start-up of the internal combustion engine, it is necessary to check and revise the starter from time to time.

But most often breakdowns occur on economical foreign cars and Russian cars. Next we will look at what to do if the Kalina starter does not work, as well as how to check the starter relay, power circuit, etc. on a VAZ Kalina.

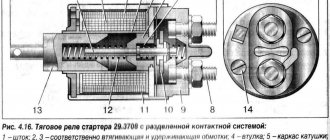

Starter solenoid relay diagram

Solenoid relay circuit

In addition to the previous point, we present to your attention a diagram of the starter retractor relay . With its help, it will be easier for you to understand the principle of operation of the device.

The solenoid coil of the relay is always connected to the negative side through the starter. And the holding winding goes directly to the battery. When the relay core presses the working plate against the bolts, and “plus” is supplied to the starter from the battery, then a similar “plus” is supplied to the “minus” output of the retractor winding. Because of this, it turns off, and the current continues to flow only through the holding winding . It is weaker than the retractor, but has sufficient strength to constantly hold the core inside the housing, which ensures continuous operation of the motor. The use of two windings allows you to significantly save battery energy when starting the engine.

Why doesn't the starter turn or click the solenoid relay?

In practice, most of the problems and malfunctions when the starter operates are problems with the electrical part. Mechanical failures are less common. Problems with starting the vehicle's power unit, which are caused by electrical faults.

If you cannot start the car, you need to check its battery for functionality, since the starter is powered from it. If the power supply is insufficiently charged, the characteristic sounds of the engine starting system may be completely absent. You can measure the battery charge using a voltmeter. If it is less than 9V, it is necessary to recharge the battery, otherwise further loss of capacity may negatively affect its operation. If there is no tester, you can determine how charged the battery is by the brightness of the headlights, although this requires some experience. If, when the high beam is on and the ignition key is turned in the lock, the headlights begin to shine weaker, it means that the battery charge has decreased significantly. If you suspect that a charged battery is not powering the car's electrical system, it is necessary to clean its terminals to remove the oxide film from them, which is causing poor contact.

If the starter clicks but cannot turn the engine, you need to test the solenoid relay. In addition to the failure of this part, problems may arise with the power cable. To determine the functionality of the relay, it is recommended to connect it directly to the battery terminals. If the traction works with such a connection, the cause of the problem must be sought in the power system (damage to the wires, burnt relay contacts, a malfunction in the ignition switch). After troubleshooting, the engine starting system will function properly.

Insufficient contact or its absence leads to a loss of current in the vehicle's electrical network, which is why its consumers function incorrectly. Therefore, it is necessary to periodically pay attention to all connections in the on-board network. For normal functioning of the starter, a current of approximately 200A is required. At a lower starting current, only the pull-in winding of the relay is activated. However, the power unit cannot start.

Repair of starter retractor relay

Worn relay contact plates

On many modern cars, the solenoid relay is made in a non-separable form. This is done for two reasons. First, this increases the reliability of the mechanism and its durability due to mechanical protection from external factors. The second is that automakers want to make more profit from the sale of their components. If your car has just such a relay, then the best solution in this case is to replace it. Write down the brand of the relay, its technical parameters, or better yet, take it with you and go to the nearest store or car market for a similar new one.

However, some car owners repair it themselves. But at the same time you need to know how to disassemble the starter solenoid relay . If the relay is collapsible, then it can be repaired. In the case of non-dismountable parts, repairs are also possible, but to a small extent. In particular, when burning “nickels”, improving and cleaning the contact. If one of the windings burns out or short-circuits, then such relays, as a rule, cannot be repaired.

For further work you will need a flat blade screwdriver, as well as a soldering iron, tin and rosin. Disassembling the relay begins with the fact that it is necessary to remove the core from it. After this, two are unscrewed that hold the top cover where the coil contacts are located. However, before removing it, it is necessary to unsolder the mentioned contacts. In this case, it is not necessary to solder both contacts . Usually, to get to the “nickels”, it is enough to unsolder only one contact and lift the cover on one side.

Disassembly and repair of the solenoid relay

Repair of the retractor relay VAZ 2104

Next, you need to unscrew the bolts holding the “nickels” from the top side and remove them. If necessary, they need to be reviewed. That is, clean them with sandpaper in order to get rid of carbon deposits. A similar procedure must be performed with their seats. Using a plumbing tool (it is best to use a flat blade screwdriver), clean the seat, removing dirt and carbon deposits. Reassembling the relay housing occurs in the reverse order.

Disassembly and assembly of a collapsible relay occurs in the same way. To do this, you need to unscrew the stud bolts and disassemble its body. This will give you access to the internal elements of the device. The audit work is carried out similarly to the above algorithm.

Checking with the starter removed using a multimeter

This test of the solenoid relay allows you to very accurately perform internal diagnostics and determine the condition of the windings and contacts.

Dismantling the starter, depending on the make of the car, is carried out in various ways. For VAZ 2110, this procedure is carried out from below from the pit. Before unscrewing the fasteners, remove the wires (it is better to mark the terminals so as not to confuse them during assembly); you may need to remove the crankcase protection.

To begin with, voltage is applied from the battery to the body and terminals of the relay; operation is accompanied by a characteristic click and visible movement of the rod.

Further checks are carried out using a multimeter, which is switched to resistance measurement mode and the range of 200 Ohms is selected.

Video: Checking the starter removed from the car

First, check the serviceability of the retractor and retention coils. To do this, one of the probes is connected to ground, the second touches the contacts in succession. The device readings are 2 ohms. Deviation of the device readings from the specified value is a sign of a break or short circuit. To check the power contacts, remove the core from the relay body and remove the return spring, after which the core is inserted back. The core rod is pressed against the table with a certain force and the resistance between the contacts is replaced. The resistance is approximately 1.5 ohms.

Types of solenoid relays and their manufacturers

Let's briefly touch on the solenoid relays used on VAZ cars. They are divided into four types:

In addition, as mentioned above, they are divided into collapsible and non-collapsible. Older models are collapsible. New and old are interchangeable .

For VAZ cars, solenoid relays are produced by the following companies:

When choosing a particular manufacturer, it is necessary to take into account that the highest quality and most common brands are “KATEK” and “KZATE”. Also remember that if an AZD starter is installed on your car, then “native” relays manufactured at the same enterprise are suitable for them. That is, they are not compatible .

Results

The starter retractor relay is a simple device. However, its failure is critical , as it will not allow the engine to start. Even an inexperienced car owner with basic plumbing skills can check and repair the relay. The main thing is to have the appropriate tools at hand. If the relay is not removable, we still advise you to replace it, since, according to statistics, after repairs are completed, its service life will be short. Therefore, if the solenoid relay does not work in your car, buy a similar device and replace it.

Lada Kalina: starter and traction relay

Diagnostics (the process of establishing a diagnosis, that is, a conclusion about the nature of the disease and the patient’s condition)

, discussed above, allows you to determine whether the starter needs to be replaced on Kalina or whether there is a problem in the power and control circuits. But that is not all. In addition to circuits and power relays, there is also a so-called starter traction relay, which can fail.

Another designated relay supplies the Bendix gear to the teeth on the flywheel crown. After the engine starts, the relay moves the Bendix gear to its original position. For this reason, the starter traction relay is often called a solenoid relay.

- As for defects, the starter relay operates with high voltage, which sooner or later causes it to fail. The contacts of the starter relay burn out, the holding or retracting winding may break, the return spring is deformed, a short circuit occurs in the windings, mechanical damage occurs, etc.

To quickly check this relay, you need to know that normally a click is heard when the armature is pulled inward. So, after turning the key in the lock, you need to listen for a click. If the starter clicks then the relay is good. If there is no click, the relay is not receiving power or the relay itself is faulty.

It also happens that the relay is working, but the starter does not turn. In this situation, the relay contacts may burn out. Again, to check, the contacts are closed using the method discussed above. If after a short circuit the starter turns, the problem is in the contacts. If the starter fails to engage, the problem is not in the protruding contacts, but in the starter.

If the resistance is less, there may be space for a short circuit inside the winding. At the same time, the highest resistance indicates poor contact with ground, terminals, etc.

If there is reason to believe that a winding break has occurred, the test is carried out with a test lamp connected to the winding (when the lamp is on, the winding is normal, if not, then the possibility of a break is high). Naturally, this method does not allow you to find a short circuit, because fluctuations in resistance do not change the brightness of the light bulb. With all this, the method is still effective in terms of quick diagnostics.

Possible starter malfunctions

If the Lada Kalina does not start, the following typical malfunctions are possible:

If after starting the engine all the instruments go out, this means that there is no power supply. You should check the terminals and state of charge of the battery. If after starting the starter does not work, then you need to check its serviceability (the author of the video is Expert R).

It is better to start troubleshooting without removing the device from the car. First, use a screwdriver to connect the solenoid relay bolts at the top and bottom. As a result, the electric motor should start working, but without rotating the crankshaft. It should rotate freely, and there should be no extraneous sounds or noises.

After checking the electric motor, you need to remove the wire from the control terminal of the traction relay and bridge it and the upper bolt with a screwdriver. After switching on, the engine crankshaft should begin to rotate. If everything works fine, you need to look for the fault in the retractor circuit.

First you need to check the trigger relay located in the mounting block, replacing it with a known good element. If the starting device works, then you need to replace the faulty relay. Otherwise, you need to check the power circuit. To do this, insert a jumper into sockets 87 and 30.

Mounting block Kalina

When you turn the key ZZ, the engine should start, otherwise you should check with a test light whether 12V voltage is supplied to socket 30. One end of the test light should be touched to terminal 30, and the other should be connected to ground. The light should be on. Otherwise, damage to the current-carrying path may occur.

If the circuit is not damaged, we check the contact group 33 by connecting the ends of the test lamp to connectors 85 and 86. If, when starting the engine, the light comes on, this indicates that everything is in order with the contact group. Otherwise, it will need to be repaired.

Replacing the traction relay

The retractor is checked for serviceability by connecting its bolt located on top to the control terminal. When closed, the relay should operate. Otherwise, check the battery charging and the condition of its terminals. If the traction relay is broken, it should be dismantled and check whether the windings are working properly. If the relay is in working condition, you need to check the wear of the brushes.

If after starting the starter does not turn and the engine does not start the first time, then the traction relay needs to be replaced. It is possible that the reason is burnt contacts on the electric motor. If the device turns on but rotates slowly, you should check the voltage at the battery terminals with an ohmmeter. For successful startup, the voltage should not be lower than 9V. Otherwise, repairs are needed. The cause of the problem may be bushings, brushes, or the stator magnet may have fallen off.

If the starter spins but the crankshaft does not rotate, then the device requires repair. In this case, the following malfunctions are possible: the bendix rotates, the flywheel crown is weakened, the textolite gear of the gearbox is broken.

The starter relay clicks, but it doesn't turn over.

If, when you turn the ignition key, clicks are heard from the starter relay, but the unit itself does not spin, then the problem may be associated with a malfunction of the control cable that powers the relay, or with a problem in the performance of the relay itself.

In such a situation, the car can be started if you short-circuit the “plus” from the battery to the positive control terminal from the ignition switch (the smallest wire of the three is connected to it). If, with such a connection, the starter starts to spin, then the malfunction is definitely not related to the battery, and the problem should be looked for in the relay, ignition switch or wiring.

Solenoid relay diagnostics

If the starter does not turn when the engine starts, but clicks are heard, the first step is to diagnose the relay itself. It connects to the battery and ignition switch via 2 cables. One of them (thick section) comes from the positive terminal of the battery, and the second (thin section) goes from the positive control terminal of the ignition switch. The relay also has a third terminal (thick section), which connects it to the starter motor.

To diagnose a possible malfunction in the solenoid relay, you need to use a jumper to connect two terminals to which thick wires are suitable. To connect them to each other, you can use a regular screwdriver, wrench or other available tools. Grasp the insulated surface of such a tool and use it to connect the two large terminals (it is important that the “jumper” does not touch any other metal parts under the hood).

If the result of shorting the terminals is the rotation of the starter, then the problem is related to the contact pads in the relay, which could be burned due to the high current supply. In such a situation, it is necessary to replace the relay, since the procedure for cleaning the contacts will take a lot of time, but due to the lack of an alloy of non-ferrous metals on them, which is applied at the factory, they will not work for long.

Diagnostics of wiring and contacts

If the starter clicks but does not turn, poor contacts or wiring problems may be to blame. Most often, a malfunction occurs along the path of current transmission from the positive terminal of the battery to the solenoid relay. The starter requires about 200 Amps to start, but if there are problems in the wiring and contacts, much less current can reach it. This leads to the fact that it is possible to power the solenoid relay (which requires 10 Amps), but there is not enough current to spin up the starter itself.

With such a malfunction, clicks may be heard in series or stop from time to time. If there is such a problem, you need to check the wiring, make sure there is no oxidation on the pads and that they are tightened enough to fully transfer current.

Summarizing

It is advisable that the starter spins the engine crankshaft during an attempt to start it for no more than 10 seconds, then the device must be given a minute pause. Failure to comply with this rule will, at best, lead to a discharge of the power source, and at worst, it will completely disable the starter. Only replacing it can save the situation, since not every auto electrician will undertake the task of rewinding burnt windings, since it is not always possible to perform this procedure efficiently. In addition, the cost of this service is comparable to the cost of a new element.

The wiring diagram for hatchbacks 2112 is a unique thing in itself. In order for voltage to appear on the solenoid relay, the following parts must be in good working order: the ignition switch, the ECU unit and two more relays - the main and additional ones. Some cars do not have an additional relay, which can be considered good luck. But, if when you turn the key on a VAZ-2112 the starter does not turn, then the fault must be looked for in the wiring. A broken immobilizer code can also cause problems. The last malfunction can be cured by replacing the ECU or disabling the immobilizer. Well, let's look at something simpler.

Car battery is faulty

The simplest and most common problem that causes the starter to click but not turn when you turn the ignition key is a low battery charge. If the car's power supply is discharged or simply damaged, similar "symptoms" will be observed.

The engine starting system will behave as follows if the required current does not flow to the starter from the battery when the ignition key is turned:

Nothing happens - there are no sounds, clicks or attempts by the starter to spin up. In such a situation, it is necessary to diagnose the health of the battery by turning on any consumer - radio, headlights or others;

- The dashboard lights go out and the starter solenoid relay clicks. In such a situation, the battery is almost certainly to blame;

- The starter makes a series of clicking sounds, and the lights on the car's dashboard dim slightly.

In all three cases, be sure to check the battery charge level using a multimeter or load plug. If the battery is faulty or discharged, it should be replaced or charged. When, as a result of the check, it turns out that there are no problems with the battery, it is necessary to move on to the following possible reasons for the appearance of clicks from under the hood when starting the engine.

Operating principle and types of starters

When this mechanism operates, battery electricity is converted into mechanical energy. When the microcontacts of the electric ignition are closed, the starter relay contacts the clutch of the traction relay winding. When the anchor moves into the retractor housing, the bendix pushes out from there, and engagement occurs with the gear at the end of the flywheel.

The armature moves to the end where the contacts close, electricity goes to the starter motor winding. The self-start shaft begins to rotate, the car starts. The faster the flywheel rotates, the sooner the bendix disengages from the ring, and the return spring sets it in place.

As soon as the key in the ignition switch returns to its original position, the current stops flowing to the starter and the car stalls.

Malfunctions and their features

During operation of the power unit starting device, the entire load is transferred to its solenoid relay. Therefore, to the question: why does the starter click, we can answer that the relay begins to function, making characteristic sounds. This indicates a malfunction, since the starter does not work at this moment and does not turn the crankshaft of the car engine. The occurrence of such symptoms is typical for the following situations:

- short circuit or burning of the turns of the rotor or stator windings;

- deterioration of the bushings, which caused the motor shaft to jam;

- breakdown of the rotor to ground.

Without removing the device from the car and completely disassembling it, it will not be possible to detect such malfunctions.

The traction clicks due to the fact that its core moves between the retracting and fixing windings, and if the voltage on the latter is insufficient, it cannot hold on and returns to its original position. The presence of clicks is evidence of unsuccessful attempts by the core to stay in the required position. It will not be possible to start the engine and start moving, because the starter stops turning, and the retractor relay clicks, which does not allow the bendix and flywheel to engage.

Note that if it was not possible to start the vehicle engine the first time, this is not at all evidence of a faulty starter. It is likely that most systems have not yet started working; to do this, you need to turn the ignition key again.

In addition to the solenoid relay, burnt contacts (this is accompanied by a characteristic burning smell and, in some cases, smoke), lack of ground, disruption of the integrity of the electrical network, or a discharged power source can cause problems with the engine starting system. Elimination of these faults is carried out on an individual basis.

ZZ malfunctions

Most often, damage to the Kalina ignition switch is associated with its mechanical part. In this case, it is impossible to turn the key to the desired position. A malfunction does not arise, as they say, out of the blue. As a rule, frequent jamming of the key is observed over the course of several months, which is eliminated by rocking it in the cylinder.

Rarely, there are cases of failure of the electrical component of the Lada-Kalina ignition switch. Basically they come down to a lack of contact when turned on. This is typical only for locks with a long service life. True, there is another common reason for burnt contacts - the car owner himself.

Clicking sounds are heard, but the starter does not turn due to the windings or brush assembly

If the battery, ignition switch, contacts, wiring and starter relay are checked, but it still does not rotate when you turn the ignition key, then the problem is directly in the starter. In such a situation, you will have to completely remove it from the car, disassemble it and evaluate the possibility of repairs. You can also simply replace the starter with a new one.

If you decide to repair the starter yourself, know that the problem with it refusing to rotate under load may be due to:

A faulty brush assembly, the wear of which is easily determined visually.

Starters are rarely repaired, and such a step should only be taken as a last resort. If it is possible to replace the starter, then it is better to do this than to bother with repairing the winding or brush assembly.

Source

DIY mechanism repair

If the mechanism does not work, it must be removed. To do this, you need an open-end wrench set to “13”.

1. The process of unscrewing the fastening bolts 2. Dismantling the mechanism from the car 3. New mechanism for replacement

The removal procedure consists of the following steps:

- First, remove the negative terminal from the battery.

- Then we dismantle the air filter.

- Next, disconnect the traction relay control wire.

- Now you need to disconnect the power cable. To do this, move away the protective rubber cap, under which there is a positive wire.

- Then unscrew the nut that secures the power cable.

- Disconnect this wire, as well as the wire located nearby.

- Next, unscrew the nuts with a “13” wrench that secure the starter. Two are located on top, and the third can be felt with your hand below.

- After unscrewing all the nuts, you can remove the device from the studs.

Further actions depend on the condition of the starter. It is either repaired or replaced. Repairs will require disassembling the device. If a replacement is needed, a new part is purchased. Installation is in the reverse order.

How to start a car without a starter

If the starter on your car is faulty or the battery is dead, then the car can be started in other ways.

You can try to start the car from a tow, from a hill, etc. turning on the ignition and second gear, this method is relevant for both a dead battery and a broken starter. These manipulations can only be performed with a manual transmission.

If the starter rotates but does not turn the engine, then the solenoid relay is most likely faulty. With such a malfunction, the engine can be started quite simply, just turn on the ignition and bridge the contacts on the solenoid relay, as shown in the picture, and the engine will start.

Price

Prices for the original Lada Kalina starter can reach or even exceed 4,000 rubles. There are a large number of analogues on the market at prices starting from 2000 rubles, but the quality of such parts leaves much to be desired.

Replacement

To replace the starter, you need to prepare a special tool that will be needed during the work process.

Required tool:

- Screwdrivers, flat and Phillips;

- Ratchet with heads for “13” and “15” mm;

- Open-end wrenches for “10” and “13” mm;

Step-by-step replacement instructions

- Remove the negative terminal from the battery, remove the air filter housing and take it out.

- We turn off the power from the solenoid relay; to do this, unscrew the power cable with a key and disconnect the connector.

- Using a ratchet and an extension, unscrew the bolts securing the starter to the gearbox housing.

- We remove the starter from the engine compartment.

We perform assembly in reverse order.