Repair and restoration work

Regardless of the repair, adjustment or replacement of the link, the need to disassemble this unit does not disappear.

The parsing process includes the following procedure:

- First, you need to remove the casing from the gearshift lever, or, more precisely, from its handle.

- The front of the car needs to be raised with a jack or placed on a pit.

- Unscrew the mounting bolts that hold the front console, and then remove it.

- Now you need to unscrew the six bolts that hold the rocker and also remove it.

- When dismantling, you should be extremely careful, paying attention to the condition of each part and element, so that if their condition is unsatisfactory, replace it with a working analogue.

- To gain direct access to the cardan shaft, oil seal and support, you need to bend the boot.

Now let's get back to the repair itself. In fact, depending on the condition of the components and the unit itself, several recommendations can be made:

- It is practically impossible to do without a special repair kit for repairing the backstage, fortunately it is inexpensive.

- If the bushing is deformed during the repair work, it will have to be replaced with a new one.

- If the driveshaft is loose (which needs to be verified), then the matter will not be limited to just one repair kit, since you will have to dismantle and install a new rocker.

- The hole in the lever axis must be examined in detail, checking for wear.

- The rocker pad is one of the common reasons leading to random gear shifting and the appearance of extraneous noise and vibration. Replacing it is quite simple, so even a beginner can cope with this task.

Changing the oil seal

Many owners of a VAZ 2110 can often observe a situation where, after a long period of parking the car, traces of oil are found underneath it (on the ground). The problem has two causes: wear or damage to the oil filter, or wear to the oil seal.

Interestingly, when replacing the oil seal with a new one, owners will have the opportunity to completely replace the driveshaft, boot or cushion. Very comfortably.

However, before starting repairs, you need to objectively determine the cause of the oil leak. To do this, you need to carefully inspect the oil seal and filter for damage or wear. Once you are finally convinced that the oil seal is faulty, you should begin preparation and direct repair work.

If the filter is fully operational and not damaged, then in this case, you should put the car in a pit or find another way that will make it possible to get to the bottom.

It would be wise to watch videos dedicated to this type of repair, as well as view other useful materials, including information about repairing the VAZ 2110 backstage.

After that, you can get down to the most important thing:

- The boot should be studied in detail and inspected. If oil leaks from the gearbox, then traces of it will certainly remain on the surface of the boot.

- To get to the cardan, you will have to bend the boot. Afterwards, disconnect it, thereby gaining access to the cuff.

- Dismantling the cardan should begin by disconnecting the lever, and only then freeing it from the rocker.

- Let's move on to the oil seal.

- Before removing the cuff, you need to prepare the hook and awl in advance, since it can only be removed thanks to them.

- To install a new oil seal, craftsmen often resort to using a standard plastic bottle cap. This is quite convenient in practice.

- After successful installation, we assemble in the reverse order.

Replacing the gearbox seal on a VAZ-2110 (+ signs of wear)

An oil leak from a VAZ-2110 car is a serious cause for concern. It is especially dangerous when oil begins to leak from the gearbox. As a rule, this problem is associated with wear of the rocker seal. If this problem is discovered, repair work must be carried out immediately.

Two ways to replace the gearbox seal on a VAZ-2110

It is easier to change the oil seal with the gearbox removed.

Replacing an element that has become unusable can be done in two ways.

- The first of them is very labor-intensive , since it will be necessary to remove the gearbox. But replacing the oil seal will be much easier.

- The second method seems less time-consuming and labor-intensive , but in practice it is very difficult to carry out this procedure. Only experienced motorists who have repeatedly had to repair their cars can replace the oil seal directly on the car without removing the gearbox.

Troubleshooting

Experienced car owners know the visual reasons why they can determine the failure of the rocker seal. Naturally, for such reasons it is impossible to accurately determine the cause of the leak, but this gives a signal to carry out diagnostics, in which the cause of the oil leak can be accurately identified.

The most important sign is oil stains under the car, especially in the gearbox area.

An oily rubber boot indicates a malfunction of the rocker seal.

But these spots do not always indicate oil seal failure. It happens that this is due to the oil filter, which sometimes does not tighten properly. In any case, the driver is obliged to monitor for any oil leaks in the checkpoint area . To do this, you need to monitor the oil level. This is the only way to save the box from damage, which will certainly happen if it operates with a minimum amount of oil.

Another way that indicates the oil seal is worn out is a characteristic crunch that is heard when changing gears . But only an experienced VAZ-2110 owner can diagnose this crunch. In any case, if you hear unusual sounds when shifting into gear, it is better to diagnose the gearbox.

Set of tools required for replacement

A minimum set of tools for replacing the oil seal without removing the gearbox.

In order for the replacement of a part to take place without problems, you need to prepare the place and the necessary set of tools in advance. You will need:

- A set of keys and sockets, and for 13 you need two keys and there must be a key for 10. There must also be a socket head for 22.

- A chisel or screwdriver will be needed to knock out the oil seal.

- The hammer is small so you can get under it.

- Silicone sealant.

- Awl and hook.

Additional accessories

A regular self-tapping screw will allow you to do without a special puller.

For those who decide to replace the gearbox seal without removing it from the car, you will need additional equipment:

- Several long screws.

- A piece of pipe for pressing in a new oil seal.

It should be noted that the replacement process without removing the gearbox is much more complicated. In addition, there is a possibility of damaging the part being replaced during pressing.

What parts to choose for replacement

It is better to immediately change the boot along with the oil seal.

Before you begin repair work, you need to purchase the necessary parts for replacement.

As for the oil seal, Balakovo products are very popular. You need an oil seal with article number 2110–1701043 and 21100-1701043-00 .

Manufacturers offer two options for oil seals - simple and reinforced.

In addition, it is recommended to immediately purchase a cardan boot, as there is a high probability that it is also worn out. Even if this is not the case, it may break during the repair process. Therefore, it is better to spend a small amount on anther than to bother with disassembly again.

Recently, reinforced oil seals have appeared on sale, which are called that way. If you believe the assurances of sellers, their service life is significantly higher than that of standard products.

Process in detail (algorithm)

It is recommended to carry out replacement work in a pit. In this case, you must take care of safety. The car must be secured using a handbrake and wheel chocks, which must be installed on both sides of the rear wheels.

Having prepared a workplace and a set of tools, you can begin to work. To replace the gearbox seal, you need to do the following:

- Most often, the VAZ-2110 wing is closed with a rubber boot. If this part is covered in oil, this immediately indicates that the oil seal is really worn out. The boot needs to be bent. To do this, you just need to pull it by the wide part.

Oil leaking from under the “glass” - the rocker seal definitely needs to be changed.

Before loosening the clamp, you need to put a mark so that you don’t have to adjust the link later.

The oil seal is located deep in the bushing.

Only after this you need to press the new part into the rod. This procedure is quite complicated, since there should be no distortions. Many drivers use various homemade devices when pressing. When working, it is very important not to damage the new part, otherwise everything will have to be redone.

After the spare part is in its place, assembly is carried out in strictly the reverse order.

Conclusions (video)

If you are not confident in your abilities, you can watch a video that shows the entire replacement process in detail. Self-repair will guarantee that everything will be done efficiently, since the owner of the VAZ-2110 will control the process.

Adjusting the scenes of the VAZ 2110

It is preferable to carry out the adjustment together. The master with the tools is under the car, the assistant is in the cabin and performs the necessary actions behind the wheel.

- Try to install and hold the lever in first gear.

- Loosen the clamp on the control drive rod (stage).

- Move the lever to the far left position. Avoid switching to front and rear positions.

- Tighten the clamp.

- Assess the condition of the hinge switch cover. If damage is found, replace it.

- Carefully pull the boot towards the box. Inspect the cardan. Deviations from the norm are noticed - schedule a shift. Pull the protection back.

REPLACING THE INPUT SHAFT SEAL

To replace the gearbox seals, especially the input shaft, the gearbox must be removed from the engine. Having removed the gearbox, carefully inspect the installation locations of the cuffs. And first of all, you need to dismantle the release bearing and remove its guide. Under it you will find the input shaft oil seal.

To remove the seals we need a flat-head screwdriver. By prying it from the inside, you can remove the cuff from its seat. The input shaft oil seal has dimensions 25x45x9. Catalog number 2110-2301043Р. It is better to install it with sealant. The outer race of the oil seal must first be degreased, and then a thin layer of sealant must be applied.

When installing, you must ensure that the inner race of the oil seal does not turn outward and the cuff spring does not jump out of its place. We install it in its place and carefully, using a pipe, lightly tapping, hammer the cuff into place. In this case, it is necessary to ensure that the plane of the input shaft oil seal lies exactly in relation to its seat.

Then we install the release bearing guide in place. It is secured with three bolts, which should be tightened evenly so that it fits into place without distortion.

Next, we immediately install the release bearing. When installing it, you must immediately put on the wire springs, which are placed on the legs of the release bearing and fix it in place.

Now it's time for the drive seals. There are two of these seals, the left one is red and the right one is black. They also differ in the direction of rotation. This direction is shown by arrows on the seal housing. These arrows are located on the inside of the oil seals, on the right oil seal the arrow points to the left, and on the left oil seal the arrow points to the right. This can also be determined by the oil removal notches applied to the inside of the cuff.

They act to deflect oil away from the cuff. They are applied at opposite angles, in the direction of shaft rotation. Typically, the manufacturer labels it in three ways:

- Catalog numbers. The number of the right oil seal ends in an even number 2110-2301034Р, and the number of the left one ends in an odd number 2110-2301035Р.

- Arrows, left arrow on the right, right arrow on the left.

- Color. The left one is red. The right one is black.

REPLACING DRIVE SEALS

Video from YouTube channel: Engine repair and interesting!

The left and right drive seals are also removed using a screwdriver or a pry bar. There is no shaft on the right “black” oil seal (see video), so here you can insert a mounting bracket inside and remove it with a light blow. We also thoroughly clean the seat with a cloth.

Then, after degreasing the outer diameter, we apply sealant. After this, we install the cuff in place, and make sure that it sits evenly, without distortion, in its seat. Tapping with a flat object, we hammer it in until its outer plane is level with the body.

Then you need to insert a round block of suitable diameter into the hole; this is necessary to fix the satellites so that they do not move out of their places. You can also use a branch from a tree of a suitable diameter, sawing off a straight piece of the appropriate length, or a shaft from an old CV joint.

Next, place the gearbox vertically on the clutch housing.

We insert a flat mounting between the gearbox housing and the CV joint, or you can use a nail puller and, by hitting it, remove the CV joint from the gearbox. Next, using a powerful screwdriver or a flat mount, remove the “red” oil seal of the drive from the housing.

The new drive oil seal must also be checked for direction of rotation. The arrow on the inside should point to the right. Carefully install the new drive oil seal in its place, making sure that its plane is flush with the edge of the seat.

REPLACING THE GEAR SELECTION ROD SEAL

It's time to replace the gear selector rod oil seal, which is located under the boot. Catalog number 2108-1703042-01Р. Here you first need to remove the cross from the shaft. To do this, you need to move the rubber boot “glass” towards the gearbox housing, opening access to the crosspiece mounting bolt.

The bolt does not need to be completely unscrewed. Simply loosen it and the cross will be removed from the shaft. We remove the rubber boot and we will have access to the selector rod oil seal. We remove it, just like the others, by prying it off with a screwdriver.

The new oil seal, like the previous ones, covered with sealant, is driven into place using a pipe. Here you can use a spark plug wrench; it fits the diameter. We put the rubber boot in place, and then the cross, and that’s it!

The work on replacing the gearbox seals on a VAZ 2109 has been completed. With this, I finish the article and wish you, dear reader, success in operating the car!

Replacing the drawstring cuff

Replacing the backstage seals of a VAZ 2110

First you need to arm yourself with the necessary set of tools, which includes:

- Set of keys (10, 13);

- An ordinary awl or other sharp metal object;

- Screwdriver;

- Hook;

- Plastic stopper.

The oil seal must be replaced in a viewing pit or overpass. If this is not possible, then an option with a lift will do. In addition, there is another option, which involves placing two spare tires flat under the car, like stops. Two strong boards are placed on them, and the car drives onto a makeshift overpass. Simple and brilliant.

Advice. If a motorist drives into a hole or other device, he must take care of the safety rules. In particular, it is necessary to secure the vehicle using the parking brake and wheel chocks.

Replacing the gearbox seal of a VAZ 2110

- The slide on a vase is almost always covered with a special rubber boot. If the cuff is faulty, then this same boot will be covered in oil, which will once again indicate the need for replacement;

- We take the wide part of the anther and bend it;

- We see the cardan located at the bottom;

- We disconnect this same cardan from the rod and lever, thus gaining access to the cuff (we use a 13 key in our work);

- The nut is turned out completely, which allows you to loosen the connection between the cardan and the lever;

- The lever is removed from the cardan;

- First or third gear is engaged;

- The cardan is completely disconnected from the rocker;

- The cardan is removed;

- Now you should remove the rubber boot.

Replacing the rocker seal on a VAZ 2110 gearbox

We see the cuff itself, which is located in a certain recess. This is where the rocker seal fits into the gearbox and needs to be removed from this recess.

Note. It is almost impossible to remove the cuff from the rod without using a special tool. An awl and a special hook will help in the work.

- We insert the awl and the hook inside and thus remove the cuff (you can also use a self-tapping screw, which we screw inward, thereby uncorking the seal, like a corkscrew);

After removing the old cuff, you should begin replacing:

Advice. It is easier to replace the seal using a stopper from any plastic bottle. The new oil seal is inserted into the inside of the plug, which is cut out in advance. And then it is pressed in.

DEVICE OF BRAKE MECHANISMS

Many people wonder what is the difference between the brake mechanisms of the front wheels and the rear ones. The fact is that when braking, they are subject to different loads, and they do not operate synchronously. But this is not the main reason for the differences.

The front mechanisms consist of:

- Brake disc of classic design;

- Direction pads;

- Calipers;

- Directly the pads themselves;

- Cylinder;

- Piston;

- Seal rings;

- Protection casing;

- Direction finger;

- And its cover, which performs a protective function.

The design of the front brakes is a little simpler than the rear, however, this does not mean that they play a lesser role in braking. After all, these are the mechanisms that work first.

- Nuts that secure the hub;

- Actually, the hub itself;

- Tension springs (lower and upper);

- Brake pads;

- Directional springs;

- Wheel cylinder;

- Expansion bar;

- Handbrake lever finger;

- Handbrake lever;

- Mechanism casing.

As we can see, this difference in design is caused by the presence of parking brake elements in the rear mechanism. Therefore, the part itself looks much more massive. The operating principle of the hydraulic part is the same as in the front. The only difference between the rear brakes is this.

A simple diagram of the VAZ 2114 brake system allows you to easily carry out any repairs yourself. Spare parts for domestic cars are inexpensive and quite common, which greatly simplifies operation and repair work. This is why VAZ cars are in such demand and provide good competition to foreign cars.

How to repair a car

Replacing the drive seal of VAZ 2109, VAZ 2110, VAZ 2112, VAZ 2114, VAZ 2115

You can replace the drive seal of a VAZ 2109, VAZ 2110, VAZ 2112, VAZ 2114, VAZ 2115 car with your own hands, in a garage. Now we will look at how to replace the drive seal of a VAZ 2109, VAZ 2110, VAZ 2112, VAZ 2114, VAZ 2115 car yourself. When should you change the seal?

We are all fans of driving cars; we often forget about such an event as replacing the drive seal, or rather the internal grenade seal. Let's remember what signs indicate the need to replace the drive seal?

— oil leakage from the gearbox (formation of an oily film on the gearbox); If you notice an oil film, be aware that over time, more oil will ooze out, even to the point of forming oil droplets on the asphalt under the car.

Do not forget! Oil seals are left and right, and they should not be confused. The left and right drive seals are different in color. The left oil seal of a VAZ is usually brown and is installed on the driver’s side, while the right oil seal is black and is installed on the passenger’s side.

Tool for replacing the drive seal of a VAZ 2109, VAZ 2110, VAZ 2112, VAZ 2114, VAZ 2115:

- Wrench 17;

- 30mm socket wrench;

- Mount ;

- Screwdriver;

- Hammer ;

- Mandrel for pressing the oil seal;

- Container for draining oil.

- Pipe of suitable diameter.

How to buy a VAZ drive oil seal?

Before you run out to buy a drive seal, decide which drive seal you need (left or right). You can buy a drive oil seal at any VAZ auto store or at the car market.

What is the difference between the left and right drive oil seal?

The left-hand drive oil seal differs from the right-hand drive oil seal of the car in that it has oil drainage grooves in different directions.

The main differences between the left and right drive oil seal.

- Different directions of arrows on the inside of the seals;

- The numbering of the right oil seal has an even number at the end, and the left one has an uneven number.

- The color of the left oil seal is brown, and the color of the right one is black.

How to replace the drive seal of a VAZ 2109, VAZ 2110, VAZ 2112, VAZ 2114, VAZ 2115 car yourself?

- Drain the oil from the vehicle's gearbox.

- Loosen the wheel bolts and unscrew the VAZ front wheel bearing nut.

- Using a jack, raise the car and remove the ball joint from the steering knuckle by unscrewing the bolts.

- Using a pry bar, push the lower arm down and pull one end of the drive out of the hub.

- Then we push the drive out of the gearbox (for this we drained the oil from the gearbox))) so that it doesn’t drip into the eyes.

- Using a screwdriver, remove the drive seal from the gearbox.

- Press in a new oil seal. The oil seal should fit freely.

When and how to replace the oil seal on a VAZ 2110 gearbox?

The VAZ 2110 gearbox is manual. To extend its service life, it is advisable to use original transmission oils. It should be noted that the VAZ 2110 is equipped with injection engines.

When does it become necessary to replace the VAZ 2110 gearbox oil seal?

The VAZ 2110 transmission system includes reliable components that, when interacting, ensure smooth running and decent power performance of the vehicle. Among the consumables that periodically have to be changed on a car are oil seals. These components are located on the front wheel drives and the gearbox input shaft. Among the reasons for their deformation are:

- natural wear and tear;

- factory defect of the product;

- mechanical damage as a result of external influence.

The result of this is an oil leak from the gearbox. The failure of a spare part can be indicated by the presence of an oil slick under the car or the appearance of a characteristic crunch when changing gears. An independent inspection often reveals fuel leaks at the junction of the gearbox and the power unit. In case of these manifestations, vehicles must be sent for diagnostics.

What tools are needed to replace consumables? To carry out this procedure, you need a set of keys and heads, a chisel (punch punch), and a hammer. The sooner a breakdown is detected, the less damage will be caused to the automotive system.

How to replace the gearbox drive oil seal, the input shaft of the VAZ 2110 gearbox?

When servicing a car's gearbox, the driver often needs to change the rod seals along with the seals on the manual transmission. If these elements have lost their physical properties, then the owner of the VAZ 2110 will face a problem such as oil leakage in the gearbox. To fix the problem, you need to replace the seals, seals and sealants.

The drive seal (left or right) is changed as follows:

- The driver must provide access to the checkpoint.

- It is necessary to drain the transmission oil from the car into a previously prepared container.

- The drive is removed.

- The old oil seal is removed and a new one is installed.

In this case, there is no need to disassemble or remove the gearbox from its original location.

Important! When installing a new oil seal, it is necessary to lubricate it and use a special seal.

Removal of the gearbox is required if the input shaft oil seal is worn out. This accessory part changes as follows:

- Removing clutch parts from the housing.

- Using a special tool, you must carefully pierce the oil seal.

- To remove the oil seal, use pliers.

- A new part is being installed.

How often do you have to replace? This indicator is influenced by driving style. On average, a spare part is replaced every three years. As a rule, after replacing this component, the car restores its driving properties.

Thus, it is possible to replace the oil seal on a VAZ 2110 gearbox yourself using special tools. This transmission consumable cannot be restored. Its price remains affordable. To keep vehicles in working condition, it is worth undergoing maintenance every 15,000 km.

Replacing differential VAZ 2114

Due to the fact that the drive of the VAZ car of the fourteenth model is the front one, the unit of interest to us is located in the gearbox. Therefore, to remove and replace the differential itself, you will need to dismantle the gearbox itself. We will not describe in great detail all the nuances of the process of removing the box, but will focus only on the main stages.

So, the steps to remove the gearbox are:

- We place the car on the lift.

- Using a screwdriver, hammer and a special wrench, unscrew (loosen) the hub nuts on the two front wheels;

- We raise the car to the height required for work;

- If the crankcase protection is installed, then remove it.

- Drain the oil from the box. If you do not plan to change it, then pour it into a clean container for reuse;

- Remove the flywheel protection;

- Loosen the clamp and unscrew the fastening of the gear shift lever;

- Now you need to disconnect the drive. To do this, on one side, with a sharp movement using a long lever with a flat end, we tear off the joint from the drive. As a result, a small gap should form.

- The second wheel will require similar steps. The only difference is that you will have to disassemble the suspension so that nothing interferes with dismantling (remove the wheel, ball joint, unscrew the stabilizer link, unscrew the lever). Afterwards, we pull out the fastener.

- Before unscrewing all the bolts and removing the box itself, place a stand under it, this way you will avoid falling and damaging the unit.

- Don't forget to disconnect the connector from the speed sensor and the wire to the tail lights, otherwise you will tear them off. In the engine compartment, remove one of the battery terminals. Disconnect the terminals from the starter. From the ignition module, unscrew the bolt that connects it to the box. Release the clutch cable (disconnect it).

- We unscrew all the bolts securing the box and mounting pad.

- Carefully remove the box from the block.

Now all the preparatory conditions have been met, and you can begin to directly disassemble the gearbox itself and replace the differential.

Further steps are shown in this video:

You can pay for your purchase in any convenient way:

- VISA, MasterCard (no commission)

- Receipt for payment

- Sberbank Online

We deliver goods throughout Russia and Kazakhstan

We can send your purchase to you by transport company:

- home

- Catalog

- Transmission

- Blocking

Conclusions (video)

If you are not confident in your abilities, you can watch a video that shows the entire replacement process in detail. Self-repair will guarantee that everything will be done efficiently, since the owner of the VAZ-2110 will control the process.

VAZ 2110 backstage and oil seal replacement

It is noteworthy that on the VAZ 2110 the rocker seal must be replaced when there is an oil leak from the gearbox. Replacing the VAZ 2110 rocker seal can be done in two ways, which will be discussed in this article. One of the ways to replace the cuff cuff involves dismantling the gearbox. The second method is not so cumbersome and is carried out directly on the car without removing the box. Needless to say, this method requires knowledge of certain secrets and skills.

There is no fundamental difference between the two types of units. The advantage of a short-throw is that it provides faster gear changes for a fraction of a second.

Do not believe those who claim that a short walk has a positive effect on dynamics. There is no connection between the rocker and the dynamics of the car. But the short walk has its advantages.

Replacement kit

Diagnostics

Replacing the rocker seal on a VAZ 2110

What symptoms indicate that it is time to change the cuff or gearbox rod? Most often, oil stains and marks remaining on asphalt or other surfaces after the car has been stopped for a long time are the very signs. An experienced driver is obliged to notice them in time and draw the appropriate conclusions. But such spots do not always indicate a problem with the cuff of the drawstring. Often the reason for oil loss is the oil filter, which needs to be checked to avoid errors. Often this same filter is poorly screwed in, resulting in leakage.

Note. Needless to say, noticing an oil leak from the gearbox in a timely manner is an opportunity to save an important vehicle mechanism. Otherwise, the danger associated with the complete loss of oil from the gearbox and the replacement of the gearbox, as a consequence, cannot be avoided.

Replacing the oil seal on the wing of a VAZ 2110

Regular checking will help avoid problems with oil leakage from the gearbox. The gearbox oil level should be easily visible, and a faulty oil seal makes itself felt by a characteristic crunch that occurs when changing gears.

Process in detail (algorithm)

It is recommended to carry out replacement work in a pit. In this case, you must take care of safety. The car must be secured using a handbrake and wheel chocks, which must be installed on both sides of the rear wheels.

Having prepared a workplace and a set of tools, you can begin to work. To replace the gearbox seal, you need to do the following:

- Most often, the VAZ-2110 wing is closed with a rubber boot. If this part is covered in oil, this immediately indicates that the oil seal is really worn out. The boot needs to be bent. To do this, you just need to pull it by the wide part.

Procedure

On Renault Logan cars, the weak point is the left inner boot. It often leaks and quickly loses its protective qualities. Replacing the left CV joint boot on a Logan is carried out in the following order:

- Unclench and remove the retaining ring from the rear end of the drive shaft;

- with the help of light progressive blows we knock down the tripoid;

- we bite off the clamp, remove the used cover;

- install a new dirt cover and tighten the clamp.

Replacing the right boot of Logan is carried out by analogy with the left one. The difference is that the three-stud cage is removed first.

Procedure:

- We cut the large clamp with a hacksaw and remove it; we will install a new one in its place;

- pull the part off the holder;

- remove the stopper, knock down the tripod and install a new dirt cover.

Assembly is carried out in reverse order. After washing all the parts, apply lubricant.

Important! The stopper has to be knocked down with a hammer. It is better to do this through a wooden block, which must be installed on the inside of the body, so as not to damage the grenade balls. Make sure the retaining ring is not damaged when knocked out

Otherwise, you will have to change both the stopper itself and the CV joint. The problem occurs quite rarely, but there is a risk

Make sure the retaining ring is not damaged when knocked out. Otherwise, you will have to change both the stopper itself and the CV joint. The problem occurs quite rarely, but there is a risk.

Replacing the front-wheel drive oil seal on VAZ-2108, VAZ-2109, VAZ-2110, VAZ-2115 cars

Is the front wheel drive seal leaking?

Thoughts like: How expensive is it to replace an oil seal? Is it possible to replace the oil seal with your own hands? And how difficult is it to replace it? Yes!? Then you have come to the right place... I can say for sure that it is not difficult, and you can easily carry out the work yourself. Of course, only if you have the desire, the necessary tools and precise instructions for correctly replacing the front wheel drive oil seal on VAZ-2108, VAZ-2109, VAZ-2110, VAZ-2115 from the Auto Repair School website! ))) Well, as they say, from words to deeds! Let's move on to the description of the main thing - a list of tools, purchasing spare parts and the process of replacing the drive oil seal with photographs. It will be useful. Replacing a Volvo XC90 automatic transmission with your own hands Tools: 17mm wrench, 30mm socket wrench with a long knob, pry bar, screwdriver, oil drain container, a hammer and a mandrel for carefully pressing the oil seal. You can also use an old oil seal to mount the drive seal. But this is not very convenient. It’s easier, after all, to buy an oil seal and select a piece of pipe of a suitable diameter for it.

Spare parts: when purchasing a drive oil seal, you must know exactly which side you need it for. Since the oil seals of the left and right drives differ in the direction of the oil drainage notches. There are three main differences from each other. First, the direction of the arrows on the inside of the seals. On the right oil seal, the arrow indicates movement to the left, and on the left, to the right. The second difference is the numbers at the end of the catalog number. The number on the right oil seal ends in an even number (4), on the left oil seal - in an odd number (5). And the third, exactly applies to Balakovo-made oil seals, is the color of the oil seal itself. Right black, left brown (photos 1 and 2).

Let's move on to the description of the process of replacing the front wheel drive oil seal on VAZ-2108, VAZ-2109, VAZ-2110, VAZ-2115:

We drive the car into a pit or overpass and drain the oil from the gearbox. You don't have to drain everything. It will be enough to drain about one liter. Loosen the wheel bolts and unscrew the front hub bearing nut (photo 3).

We jack up the car and unscrew the two bolts securing the lower ball joint to the steering knuckle (photo 4). Having installed the pry bar between the body and the anti-roll bar, push the lower arm down. And pull out the end of the drive from the hub.

We unscrew the bolts securing the lower ball joint from the steering knuckle of the VAZ-2109. After that, we climb under the car and, using a pry bar or mounting blade, leaning on the boss on the gearbox housing, push the drive out of the gearbox (photo 5). At this moment, if you forgot to drain the oil from the box, the fun will begin))).

Using the same pry bar or screwdriver, we pull out the oil seal from the gearbox (photo 6).

AND …. We can press in a new oil seal (photo 7). We do not press the oil seal all the way, namely as shown in photo 8.

How to correctly install the front wheel drive oil seal on a VAZ-2110 car. We carry out the assembly in the reverse order. Don't forget to fill the gearbox with oil!

If you find an error, please select a piece of text and press Ctrl+Enter.

VAZ-2110: do it yourself to replace the CV joint and boot yourself

Reasons for failure and number of gearbox seals

Among the most common reasons:

- The service period has expired.

- Factory defect.

- Structural features of the car.

Many drivers assume that replacing one oil seal can eliminate the problem, which is not entirely correct. There are three cuffs that are installed in the car. Consequently, it is necessary to carry out three operations:

- Replacing the VAZ 2110 gearbox seals located on the front wheel drives.

- Replacing the VAZ 2110 gearbox seal located on the input shaft.

- Replacing the gear selector rod cuff.

It would seem that such a simple mechanism as a box, but it has three different oil seals that need to be replaced. After replacing the seals, the car starts to work much better. This affects the quality of gear shifting, and subsequently the handling of the car.

When does it become necessary to replace the VAZ 2110 gearbox oil seal?

The VAZ 2110 transmission system includes reliable components that, when interacting, ensure smooth running and decent power performance of the vehicle. Among the consumables that periodically have to be changed on a car are oil seals. These components are located on the front wheel drives and the gearbox input shaft. Among the reasons for their deformation are:

- natural wear and tear;

- factory defect of the product;

- mechanical damage as a result of external influence.

The result of this is an oil leak from the gearbox. The failure of a spare part can be indicated by the presence of an oil slick under the car or the appearance of a characteristic crunch when changing gears. An independent inspection often reveals fuel leaks at the junction of the gearbox and the power unit. In case of these manifestations, vehicles must be sent for diagnostics.

What tools are needed to replace consumables? To carry out this procedure, you need a set of keys and heads, a chisel (punch punch), and a hammer. The sooner a breakdown is detected, the less damage will be caused to the automotive system.

Replacing the cuff

Replacing gearbox seals on a VAZ 2110

In order to replace the front wheel drive seal, you must be able to do the job correctly. When it is not possible to replace it yourself, you need to contact special workshops. The local specialists will do this work in a matter of hours, or maybe even less.

Removing the drive seal

Replacing the gearbox cuff

So, to replace the front wheel drive seals, you need to do the following:

Note: When replacing seals, there is no need to remove and disassemble the entire gearbox. The oil seals for the right and left drives are not interchangeable.

- The first step is to drain the oil from the gearbox.

- Once the oil is in the container, remove the drive.

- After opening access to the oil seal, it is necessary to carefully remove the damaged or worn-out oil seal with a sharp tool, taking the utmost care.

Installing a new cuff

The oil seal removal process is completed. But, it is necessary to install a new part in place of the damaged one. To perform these actions, several simple rules are used:

- The oil seal surface is lubricated with special transmission oil.

- To install a new oil seal, it is necessary to apply a used cuff to its surface (from the inside).

- By lightly tapping the used oil seal with a hammer, we place the second new one in its original place.

- We assemble the mechanism.

The oil seal installation work has been completed. Assembly steps must be performed in exactly the opposite order. The left drive oil seal is replaced using the same technology as for the right one.

Input shaft cuff and its replacement

The input shaft seal may need to be replaced. The job won't seem too difficult if you do specific steps in a specific order:

- The gearbox is removed.

- The crankcase has several clutch parts. They must be carefully removed.

- The oil seal is pierced with a special tool. The center punch is ideal. The work should be carried out very carefully, since damage to the input shaft of the gearbox is unacceptable.

- Using thin-nose pliers, the old oil seal is removed and a new one is installed in its place.

How to change the oil seal on a VAZ 2110

- The working surface of the new oil seal must be lubricated with transmission oil.

- The old seal is installed on the outer surface of the new seal and, with careful blows of a hammer, the new seal is installed in place of the old one.

Replacing the outer CV joint

If you only plan to replace the boot of the outer CV joint of a VAZ 2109, then at the last stage you just need to tighten it and cut off the old one. But if you need to replace the entire hinge, then follow the same procedure as in the previous paragraph. Clamp the drive tightly in a vice and use a hammer to knock the CV joint off it. You shouldn’t feel sorry for it, because the new one will serve you for many years if your driving style is not very aggressive.

As in the previous point, first thoroughly wash the axle shaft, wipe it dry, and then install all the elements. First the boot, then the ring, drive the CV joint onto the splines. That's all, all that remains is to squeeze out all the grease under the boot and put it on, tightening it with clamps

Please note that worm-type clamps cannot be used, they will rest against the hub

What parts to choose for replacement

It is better to immediately change the boot along with the oil seal.

Before you begin repair work, you need to purchase the necessary parts for replacement.

As for the oil seal, Balakovo products are very popular. You need an oil seal with article number 2110–1701043 and 21100-1701043-00 .

Manufacturers offer two options for oil seals - simple and reinforced.

In addition, it is recommended to immediately purchase a cardan boot, as there is a high probability that it is also worn out. Even if this is not the case, it may break during the repair process. Therefore, it is better to spend a small amount on anther than to bother with disassembly again.

Recently, reinforced oil seals have appeared on sale, which are called that way. If you believe the assurances of sellers, their service life is significantly higher than that of standard products.

Replacing the gearbox seal of a VAZ 2114

The gearbox makes it possible to change the acceleration rate of the car, increase the speed at different speeds, rotate the wheels at different speeds, etc. During operation, the gearbox may fail, which will require repair of the gearbox on the VAZ 2114.

Checkpoint disassembled

The best way to prevent breakdowns is to take preventive measures. Unfortunately, even the most careful care is not able to protect the box from the occurrence of certain malfunctions.

Manual transmission

Today, all cars are equipped with one of three types of gearboxes.

- Mechanical. Speed shifting is done manually using a special lever.

- Automatic. No external influence is required to change gears. Switching is carried out depending on the degree of pressure on the brake and gas pedals. In this case, reverse gear is engaged manually.

- CVTs. This is a mixed type of gearbox, where the bulk of the work is performed automatically, but if necessary, the gearbox is switched to manual mode.

Do-it-yourself oil seal replacement

https://youtube.com/watch?v=WS6G9UZEIhY

The complexity of the procedure depends on the design of the drives. If the internal CV joint grenade has a flange connection, it will be enough to just unscrew the drive and move it to the side. All work is performed on the flange. But most often on compact front-wheel drive cars, a floating spline connection is used on both sides of the drive. In this case, replacing the CV joint seals entails dismantling the wheel knuckle.

We jack up the car body, allowing the suspension arms of the front wheel (on which the repair is being carried out) to move freely; After removing the wheel, unscrew the brake caliper and hang it on a wire; We unscrew the stabilizer links (if necessary, we change them, since we disassembled the suspension anyway); We release the steering knuckle from the steering rod, unscrew the CV joint hub nut; We remove the hub with the steering knuckle, disengaging the splined connection of the outer grenade. Check the instructions to see if the transmission oil needs to be drained. If the seal leaks, dirt and moisture can get inside. Therefore, it is advisable to replace the fluid in any case;

We pry up the inner grenade with a puller (with a pry bar or a nail puller, if there is no puller), and with a sharp movement we pull out the splined joint, overcoming the resistance of the locking ring; We remove the damaged oil seal and thoroughly clean all surfaces of dirt and old oil. There are special pullers, you can use a wide flat screwdriver

Important! Before changing the oil seal, it is necessary to wash the adjacent surface with any means. We start work only after the unit has dried;

Inspect the oil seal

If there are no signs of wear, then there is another reason for the leaks. Often the ventilation breather on the gearbox or transfer case becomes clogged. The heated air squeezes the oil through a working oil seal. Therefore, check the fitting and breather tube. If this is the reason, you will still have to replace the oil seal; it is not recommended to reinstall it; Install a new oil seal, first moistening the installation site with lubricant. Shrinkage is carried out using a mandrel, which you can make yourself from a pipe of a suitable diameter; Carefully insert the splined connection of the inner CV joint into the gearbox (transfer case); Check the free longitudinal movement and rotation of the shaft in the oil seal; Place the outer axle shaft into the hub and assemble the steering knuckle in reverse order; Fill the gearbox with oil and test drive; Check for oil seal leaks.

This procedure is performed by one driver within several hours. Whether to entrust the work to a service or to save on paying for standard hours is up to the owner of the car to decide. But in any case, you should not delay the replacement. Today you leak a couple of drops overnight, and tomorrow on the road you can be left without any oil at all and hello to replacing the unit.

Gearbox device

General view of the gearbox

Before proceeding directly to the process of replacing the oil seal, it is necessary to consider the structure of one of the main elements of the car - the gearbox. So, what parts does the unit consist of:

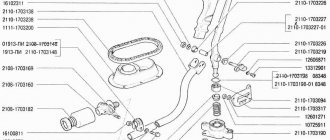

Transmission device diagram

Gearbox: 1 – clutch release bearing; 2 – guide sleeve; 3 – input shaft; 4 – roller bearing of the secondary shaft; 5 – secondary shaft; 6 – retaining ring; 7 – satellite axis; 8 – speedometer drive drive gear; 9 – transport plug; 10 – wheel drive oil seal; 11 – tapered roller bearing of the differential; 12 – axle gear; 13 – satellite; 14 – differential box; 15 – clutch housing; 16 – driven gear of the main gear; 17 – drain plug; 18 – adjusting ring; 19 – driven gear of the 1st gear of the secondary shaft; 20 – synchronizer for 1st and 2nd gears; 21 – driven gear of the second gear of the secondary shaft; 22 – retaining ring; 23 – persistent half ring; 24 – driven gear of the third gear of the secondary shaft; 25 – synchronizer for 3rd and 4th gears; 26 – driven gear of the fourth gear of the secondary shaft; 27 – needle bearing of the secondary shaft gears; 28 – ball bearing of the secondary shaft; 29 – thrust plate; 30 – driven gear V of the secondary shaft transmission; 31 – 5th gear synchronizer assembly; 32 – nut; 33 – thrust washer; 34 – drive gear V of the input shaft; 35 – rear cover of the gearbox housing; 36 – ball bearing of the input shaft; 37 – gearbox housing; 38 – roller bearing of the input shaft; 39 – breather; 40 – input shaft oil seal