Many car enthusiasts interested in car modernization set out to install a turbocharger on their VAZ 2107. However, upon studying the topic in more detail, most VAZ 2107 owners come to the conclusion that installing a turbine on a carburetor is unsafe and too expensive.

That is why VAZ 2107 owners are faced with a choice - to refuse to install a turbine in favor of a compressor or to replace the carburetor with an injector. Let's look at the reasons why it is not recommended to install a turbocharger on a carburetor. The main reason is the danger of an explosion from the exhaust manifold caused by too high pressure generated by the turbine. The second important factor is the complexity of the installation, and therefore it is recommended to entrust this matter to professionals.

Having added up all the pros and cons, we will consider the option of installing a compressor on a VAZ 2107 carburetor as the most optimal. First of all, you need to purchase the compressor itself with a set of accessories for connecting to the engine. It looks something like the following photo.

The compressor is installed next to the distributor, in free space. The standard kit includes a special bracket for mounting the compressor on the front of the cylinder block. On the same bracket you can install additional tension rollers for the drive belt.

Once installed it will look like this:

Another significant modification is the installation of a special box on the carburetor instead of an air filter, which acts as an adapter for air injection.

This is one of the adapter options, the simplest and has a number of disadvantages. In particular, the efficiency of the pressurization system is reduced due to leaks in the carburetor itself. To eliminate these shortcomings, instead of the specified adapter, the carburetor can be placed in a completely sealed housing and air can be forced into it. There is already room here for the car owner’s flight of fancy.

All that remains is to connect the outlet nozzle of the compressor to the inlet of the carburetor with special pipelines, tighten the joints of the individual parts with special clamps to ensure tightness, and hermetically close the lid of the adapter box.

Since we had to remove the standard air filter during the modernization process, we should consider cleaning the air in another way. The simplest option is to install a special air filter on the suction pipe.

This element is characterized by increased quality and durability, so its use is preferable. After installing it, the engine with the compressor installed will look like this.

So, is it possible to install a turbocharger on a Zhiguli engine? And how to install a turbocharger on the engine of a Zhiguli car? Let's remember the technical specifications. Let's take, for example, a VAZ-2103 car: an engine with a displacement of 1458 cm3. The developed power will be 77 hp. With. at 5600 rpm The main goal of installing a turbocharger on a Zhiguli is to increase the maximum power of a serial carburetor engine by about 15-20%. At the same time, the reliability of the engine will not be reduced, and the serialization of the main parts and assemblies will not change. We also had the opportunity to estimate how much specific fuel consumption would be reduced with this change.

Installation of TKR turbocharger

As an experiment, we chose the smallest turbocompressor TKR-7, commercially produced in the Soviet Union in accordance with GOST 9658-66, which is equipped with a radial centripetal turbine. The diameter of the impellers is 74 mm, the pressure rise ratio Pk is 1.6, the air flow is 0.4 kg/s.

A significant increase in the pressure of the combustible mixture at the inlet can lead to early engine failure - the pistons will burn out very quickly, the exhaust valves will burn out, etc. That is why we decided to slightly limit the degree of pressure increase to 1.2. This made it possible to increase engine power by 15-20%. Next, we reduced the supply of exhaust gases to the turbocharger by installing a bypass pipe, which should divert some of the gases into the exhaust pipe past the turbine. In this case, replaceable throttling washers were used at the inlet to the TKR.

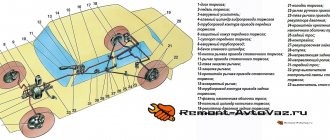

In order to test the layout of the TKR on a special stand that simulated the engine, a standard exhaust as well as engine intake manifolds were installed. The compressor and turbine sections of the TKR were connected to them, taking into account minimal pressure losses, as well as the strength of the structure and, accordingly, placement within the engine compartment of the VAZ-2107 car. A method was immediately determined for how to install the carburetor and air filter, as well as the configuration and fastening of the oil lines, and how to position thermocouples and pressure sensors.

The turbocharger was placed on the side of the engine intake and exhaust manifolds. The axis was oriented parallel to the engine crankshaft. For smooth coupling, the turbine inlet pipe was connected to the exhaust manifold using a short tube. To remove exhaust gases from the TKR, the exhaust pipe of the muffler with a special pipe was modified.

Installation of VAZ turbocharger

To mount the turbocharger in the engine compartment of the VAZ-2107 car, it was necessary to remove the battery to the left side of the compartment. We had to remove the carburetor and air filter from the engine, and we installed an aluminum intake pipe onto the standard carburetor platform through a paronite gasket. For reliability, the structure was secured with bolts. At the same time, they did not forget to remove the standard exhaust pipe.

It is necessary to install and secure the gas supply pipe through the standard gasket onto the studs of the exhaust manifold. From below we introduce a modified exhaust pipe of the muffler. Next, through a copper gasket, it is necessary to connect this structure with the triangular flange of the bypass pipe of the gas distribution pipe. The TKR must be installed and secured to the horizontal flange of the pipe. Next, it is necessary to insert into the exhaust tract of the TKR the cylindrical end of the outlet pipe, which has an o-ring. After this, it is necessary to secure the rectangular flange of the pipe through a copper gasket on the receiving pipe of the TKR.

Between the TKR compressor pipe and the inlet and outlet pipes, a connecting pipe with a diameter of 50 mm is installed, which is secured with plastic clamps. We also install an aluminum pipe at the outlet of the TKR compressor, which we secure with tape clamps through a durite coupling. The carburetor is attached to the horizontal flange of the outlet pipe using standard studs and through a standard gasket.

Next, remove the second pressure plate on the right of the cylinder head cover and the standard throttle drive rods. In place of the pressure plate, a bracket for the throttle drive is mounted, to which the slides and long rods for the throttle drive are attached. The hydraulic vacuum booster pipeline is fixed to a special fitting of the inlet pipe, and we connect instrument indicators and sensors. Next, we install a standard air filter with a standard connection to the crankcase ventilation pipe.

To be able to compare engine performance before and after installation of the turbine, tests were carried out. The test program included throttle response tests, high-speed tests on an incline and on a horizontal section.

The temperature of the gases in front of the turbine was controlled using an aircraft thermometer with a scale of up to 950 degrees Celsius. The sensor was installed in the supply pipe of the TCR along the axis of the gas flow.

Results of the work.

Having analyzed the results of the work done, we can safely say that it is possible to place the TKR-7 in the engine compartment of any VAZ model, excluding 2108 and 2109, without changing the serial number of components. The Lada engine with installed TKR starts without difficulty and runs stably at all speed ranges. When reaching 4000 rpm, the boost pressure begins to exceed atmospheric pressure, that is, in this mode, afterburner is provided at the level of 20%, which, of course, has a positive effect on the dynamics of acceleration. The tested VAS-2107, when loaded with 4 people, reached 100 km/h in 18 seconds, while the car without TKR took 24 seconds.

The temperature of the engine with TKR did not differ from the serial one in all test modes. Taking oil for TKR lubrication showed a decrease in oil pressure in the line by 0.1-0.2 kgf/cm2. at a rotation speed of 4500 rpm, which is within acceptable limits.

Regarding engine efficiency, an engine equipped with TKR showed a reduction in specific fuel consumption by 15-20%.

Also, during the tests, shortcomings of the TKR installation were identified. For example, with an engine capacity of 1200-1500 cm3. It is advisable to use smaller TCRs.

In the described method of installing a turbocharger on an engine, the required charge air pressure (1.2 kgf/cm2) is achieved by selecting throttling washers, but this is labor-intensive and time-consuming. In the future, this problem will be solved by installing a valve in the gas conducting channel, which will operate when a certain pressure of the fuel-air mixture is reached.

From the moment of purchasing the first car and subsequently, when replacing vehicles, Russian car enthusiasts are constantly trying to improve both the interior of their car and its power characteristics. Therefore, as a modernization option, installing a turbine on a VAZ 2106 is used, as one of the ways to increase the dynamics of the power plant.

Practice shows that work on boosting the engine in combination with tuning the timing of the “six” does not produce the effect of significantly increasing the power of the vehicle, while the turbine shows excellent results in increasing the dynamic characteristics of the engine.

What is the problem with installing a turbine on a “six”? Because This car is not equipped with a turbocharger when it comes off the assembly line, then all work on the installation of this element must be carried out with the invitation of professional mechanics, or independently. However, it must be remembered that installing a VAZ 2106 turbine is a rather complex technological process, and without knowledge and skills in the automotive industry, it is extremely risky to undertake this set of measures.

The principle of operation of the VAZ 2106 with a turbine

The principle of operation of an engine enhanced by turbocharging is as follows: air, suitably processed and in a compressed state, is pumped into the combustion chamber, where it forms an air-fuel mixture, leading to an increase in the power characteristics of the engine. The turbine installed on the VAZ 2106 is usually placed between the air intake pipe and the intake manifold.

The freed gas flow from the combustion chambers of the cylinders gives the turbine connected to the compressor the necessary torque. The compressor directly supplies the air mixture under pressure to the engine cylinders. The efficiency of a VAZ 2106 with a turbine is directly proportional to the volume of burned fuel.

Correct installation of a turbine on a VAZ 2106 has the following advantages:

- the turbo component is lightweight and relatively small in size;

- the turbine can be adjusted to fit any brand of standard engine with an attached carburetor;

- the turbo nozzle can be mounted on a power plant that has been subjected to tuning;

- installing a turbine on a “six” is not an obstacle to subsequent modifications to the vehicle’s engine;

- The turbo element must be suitable for the “engine” of different volumetric values.

In practice, 2 types of turbines are used: a low-pressure device and a high-pressure device. The low-pressure device is considered less expensive to install, and no special improvements are made to the vehicle design. The high-pressure device requires modification of some key components of the car and this will require a large amount of money to modernize the design.

In order to solve the issue of how to install a turbine on your VAZ 2106 car, you will need to transform a number of vehicle systems: gas exhaust and fuel injection systems, as well as chip tuning of the power plant. After this, the vehicle acquires such qualities as sharpness of movement, throttle response and dynamism.

Principle of operation

Why is it that the turbine attracts vehicle owners to the injector? Everyone knows the fact that the volume of fuel that burns out in the cylinders is closely related to the amount of air absorbed into the middle of the engine when starting up by the injector. And the fulfillment of the mass ratio condition, numerically expressed as 1 kg of combustible mixture to 15 kg of air, is mandatory. After all, subsequent enrichment of the liquid implies a decrease in power. In order to remove this obstacle, the cylinder requires more air supply by pumping it into excess pressure. Thus, an increase in air pressure by 30% triggers an acceptable increase in power and acceleration dynamics.

The fundamental features of the operation of a gas turbine-type compressor on an injector are elementary. Its body is fixed to the exhaust manifold. In the middle of the unit itself there is a turbine wheel connected to a compressor wheel. The operation of the exhaust gas stream provokes the spinning of the turbine. Then, using the shaft, the torque is transferred to the impeller of the compressor sample, which sucks in air through an air-type filter and transfers it to the carburetor under pressure, thereby increasing the saturation of the cylinders.

Thus, the same volume of cylinders pumps a larger amount of working mixture. A regular VAZ 2107 engine is characterized by 25 percent combustion of the fuel pumped into the cylinder due to lack of oxygen.

An increase in air filling implies a uniform increase in fuel combustion. This factor affects the increase in engine efficiency. As a result, a gas turbine supercharger allows a larger volume of fuel to be pumped in the same period of time. Torque characteristics also increase, affecting acceleration dynamics.

Turbine installation

It is customary to install a turbine exclusively on engines with injection injection, but under certain conditions they mount a turbine on a VAZ 2106 carburetor model, which are prepared for such a technical action. It is known that the carburetor is not an ideal product from the point of view of supplying fuel for the operation of a turbo component for two reasons: the low level of supply and consumption of air masses to organize the interaction of these components and the lack of correspondence in the functionality of the turbo element with an intermediate cooler.

There are 2 ways to install a turbine on a carburetor VAZ 2106, in which interaction between these mechanisms will occur. The first is to place the air supply system in front of the turbocharger and direct the air-fuel mixture through all elements of the created circuit. The second is to mount a complex for increasing the supply of air mixture by placing the carburetor after the air blower.

Both methods of turbine installation have their advantages and disadvantages. However, when installing a complex for increasing the air mixture supply, you need to know that the efficiency of the power plant will be optimal at above-zero air temperatures. A distinctive feature of installing a turbine on a VAZ “sixth model” from tuning individual parts is the radical improvement of the car’s “engine”.

A suitable turbine is mounted together with other additional components, for example, a cooler that cools the air mixture. It is believed that the installation of a turbine should be entrusted to specialists, because this work requires the selection and adjustment of parts and their configuration, which only professional car mechanics can do. A special place is occupied by setting up engine systems after completion of work. Although you can see all this in the video, you can’t do it without special knowledge.

If you want to install a turbine on a VAZ 2106, the price will be very high and can reach significant amounts. Therefore, it is necessary to weigh all the pros and cons for carrying out such a technological operation.

Any car enthusiast wants the engine of his car to be as powerful as possible. Owners of the VAZ 2106 are no exception in this sense. There are many different ways to increase engine power and make your car go faster. But in this case, we will try to figure out only one method, which is called a turbine.

Turbine for injection VAZ 2107

The turbine on the VAZ 2107 is considered exotic among car enthusiasts. And the power advantages of turbo engines over their factory counterparts are driving the proliferation of passenger cars equipped with turbines. And not only among foreign cars...

In theory, their main goal is to achieve maximum horsepower. For fans of fast driving, this is the main argument for sure. Given the same displacement, a turbocharged engine is characterized by almost double power with standard fuel consumption. In modern conditions, small-displacement turbo engines are very relevant.

Turbocharging VAZ 2107

The conventional division of the turbine provides for 2 groups:

- With low pressure up to approximately 0.2-0.4 bar.

- With high pressure up to 1 bar and above.

Installing a high-pressure turbine requires significant modifications to the engine, and when installing a low-pressure unit, almost all factory elements of the system can be preserved.

Purpose of the turbine

The technical characteristics of the VAZ 2106 engine cannot be called outstanding. For this reason, many car enthusiasts are beginning to modify the engines of their “sixes” on their own. Installing a turbine on a VAZ 2106 engine is the most radical, but also the most effective way to increase engine performance.

By installing a turbine, the driver receives several advantages at once:

- the acceleration time of the car from standstill to 100 km/h is almost halved;

- engine power and efficiency increase;

- Fuel consumption remains virtually unchanged.

How does a car turbine work?

In short, the point of operation of any turbocharging system is to increase the rate of supply of the fuel mixture to the combustion chambers of the engine. The turbine is connected to the exhaust system of the “six”. A powerful stream of exhaust gas hits the impeller in the turbine. The impeller blades rotate and create excess pressure, which is pumped into the fuel supply system.

As a result, the speed of movement of the fuel mixture increases, and this mixture begins to burn much more intensely. The standard six engine has a fuel combustion coefficient of 26–28%. After installing a turbocharging system, this coefficient can increase to 40%, which increases the initial engine efficiency by almost a third.

VAZ turbo: where to start, instructions for turbocharging

Turbocharging is the forced injection of air into the combustion chambers by creating a zone of high pressure at the inlet of the intake tract. When the driver of the car presses the pedal and the throttle valve opens, significantly more air will enter the intake manifold than if it were supplied at atmospheric pressure. As the amount of oxygen increases, the carburetor or injector also increases the amount of fuel. Because of this, the engine power increases.

Installing a turbo compressor has a lot of advantages. The mechanism is quite light in weight. Turbochargers are often universal - they can be adjusted to suit any engines, carburetors and other power systems. The kit can be installed on tuned engines, and the installation will not interfere with upcoming modifications. Engines of any size can be turbocharged.

About the choice of turbocharging systems

Currently, car enthusiasts do not need to design turbines themselves, since a wide range of ready-made systems are available on the aftermarket. But with such abundance, the question will inevitably arise: which system to choose? To answer this question, the driver must decide how much he is going to modify the engine, i.e. how deep the modernization will be. Having decided on the degree of intervention in the engine, you can move on to turbines, which come in two types:

- reduced power turbines. These devices rarely generate pressure above 0.6 bar. Most often it varies from 0.3 to 0.5 bar. Installing a low-power turbine does not involve serious intervention in the engine design. But they also provide an insignificant increase in productivity - 15–18%.

- powerful turbocharging systems. Such a system is capable of creating a pressure of 1.2 bar or more. To install it in the engine, the driver will have to seriously upgrade the engine. In this case, the engine parameters may change, and not necessarily for the better (this especially applies to the CO level in the exhaust gas). However, engine power can increase by a third.

What is meant by modernization

Before it comes to installing the turbine, the driver will have to carry out a number of preparatory procedures:

- cooler installation. This is a device for cooling air. Since the turbocharging system runs on hot exhaust gas, it gradually heats up. Its temperature can reach 800°C. If the turbine is not cooled in a timely manner, it will simply burn out. In addition, the engine may also be damaged. So you can’t do without an additional cooling system;

- The carburetor “six” will have to be converted into an injection engine. The intake manifolds of the old carburetor “sixes” were never particularly durable. After installing the turbine, the pressure in such a manifold increases approximately five times, after which it ruptures.

All of the above points indicate that installing a turbine on an old carburetor six is, to put it mildly, a questionable decision. It would be much more advisable for the owner of such a car to install a turbocharger on it.

This solution has several advantages:

- the driver will no longer worry about the problem of high pressure in the intake manifold;

- there is no need to install additional cooling systems;

- there will be no need to redo the fuel supply system;

- installing a compressor costs half as much as installing a full-fledged turbine;

- Motor power will increase by 30%.

What's better?

The answer to this question can only be given by the owner of the VAZ 2107. A cheaper option would be to install a conventional compressor. It won't take much time or money.

But if you want your car to “fly”, then you need to install a turbine.

As stated above, this is a more complex procedure in which you will need to change some components of the car and invest a lot of money in such tuning. But you will definitely be pleased with the result.

Installation of a turbocharging system

There are two methods for installing turbines on the “six”:

- connection to the collector;

- connection to the carburetor;

The vast majority of drivers are inclined towards the second option, since there is less hassle with it. In addition, in the case of a carburetor connection, the fuel mixture is formed directly, bypassing the manifold. To establish this connection, you will need the following things:

- spanners included;

- flat screwdriver;

- two empty containers for draining antifreeze and lubricant.

Sequence of connecting a full-fledged turbine

First of all, it should be said that a turbine is a rather large device. Therefore, it will require space in the engine compartment. Since space is limited, many 6 owners install turbines where the battery is installed. The battery itself is removed from under the hood and installed in the trunk. It should be noted here that the sequence of connecting the turbocharging system depends on what type of engine is installed on the “six”. If the car owner has the earliest version of the “six”, then a new intake manifold will have to be installed on it, since the standard one will not be able to work with the turbine. Only after these preparatory operations can you proceed directly to installing the turbocharging system.

- First, the additional intake duct is installed.

- The exhaust manifold is removed. A small section of air pipe is installed in its place.

Video: connecting the turbine to the “classic”

Compressor connection sequence

It was mentioned above that connecting a full-fledged turbocharging system to an old “six” may not always be justified, and that installing a conventional compressor may be a more acceptable option for many drivers. So it makes sense to analyze the installation sequence of this device.

- The old air filter is removed from the inlet air pipe. A new one is installed in its place; the resistance of this filter should be zero.

- Now take a piece of special wire (it usually comes with the compressor). One end of this wire is screwed to the fitting on the carburetor, the other end is attached to the air outlet pipe on the compressor. Steel clamps from the kit are usually used as fasteners.

This sequence is the simplest and at the same time the most effective when installing a turbocharger on all VAZ “classics”. While installing this system, the driver himself can look for new ways to improve the tightness of the box and pipe connections. Many people use regular high-temperature sealant for this, which can be found at any auto parts store.

Visual installation

A sample with a low-pressure turbine and a VAZ 2107 engine with distributed injection involves the use of the following factory parts: cylinder block, crankshaft, connecting rods, camshaft and valves. The difference in additional components is associated only with the pistons and cylinder head due to the need to reduce the compression ratio during installation. This functional feature is achieved by enlarging the combustion chamber or special pistons. However, there is a theory that the pistons can be factory pistons and you can limit yourself to replacing the head.

The injector output also differs. The turbine fills the space between the exhaust pipe and the exhaust manifold. The factory model remains the resonator and muffler. If you need to obtain more power, still use the recommendations for installing a direct-flow exhaust. Injection requires an enlarged receiver and a non-standard control program. The lubrication system also undergoes minor changes. Summarizing the above, we can conclude that the turbine itself will be the most expensive and scarce part.

How is oil supplied to the turbine?

A complete turbocharging system cannot function without oil. So the driver who decides to install a turbine will have to solve this problem. When the turbine is installed, a special adapter is screwed to it (such adapters usually come complete with turbines). A heat dissipation shield is then installed on the intake manifold. Oil is supplied to the turbine through an adapter onto which a silicone tube is first placed. In addition, the turbine must be equipped with a cooler and an air tube through which air will flow into the manifold. Only in this way can an acceptable temperature of the oil supplied to the turbine be achieved. It should also be said here that sets of tubes and clamps for supplying oil to turbocharging systems can be found in spare parts stores.

This set costs from 1200 rubles. Despite the clearly inflated price, such a purchase will save the car owner a lot of time, since he will not have to bother with cutting and adjusting silicone tubes.

About the pipes

Pipes are needed not only for supplying oil. Exhaust gases from the turbine also need to be removed. To remove excess gas not used by the turbine, a massive silicone pipe on steel clamps is used. In some cases, a whole system of silicone pipes is used to remove the exhaust (their number is determined by the design of the turbine). Usually there are two of them, in some cases - four. Before installation, the pipes are carefully inspected for internal contamination. Any, even the smallest, speck that gets into the turbine can cause a breakdown. It is for this reason that each pipe is thoroughly wiped from the inside with a cloth soaked in kerosene.

When choosing clamps for pipes, you should remember: silicone is not a very durable material. And if, when installing the pipe, you tighten the steel clamp too much, it can simply cut the pipe. For this reason, experienced motorists recommend not using steel clamps at all, but instead using clamps made of special high-temperature plastic. It provides reliable fastening and does not cut the silicone.

How is the turbine connected to the carburetor?

If the driver decides to connect the turbocharging system directly through the carburetor, then he must be prepared for a number of problems that will have to be solved. Firstly, with this connection method, air consumption will increase significantly. Secondly, the turbine will have to be installed near the carburetor, and there is very little space there. That is why the driver should think twice before using such a technical solution. On the other hand, if the turbine can still be placed next to the carburetor, it will work very efficiently, since it will not have to waste energy supplying air flow through a long system of air ducts.

Fuel consumption in old carburetors on “sixes” is regulated by three jets. In addition, there are several fuel channels. When the carburetor is operating normally, the pressure in these channels does not rise above 1.8 bar, so these channels perform their functions perfectly. But after installing the turbine, the situation changes. There are two ways to connect the turbocharging system.

- Installation behind the carburetor. When the turbine is installed like this, the fuel mixture has to pass through the entire system.

- Installation in front of the carburetor. In this case, the turbine will pump air in the opposite direction, and the fuel mixture will not flow through the turbine.

Each method has both advantages and disadvantages:

- the first method is much simpler. Yes, the air pressure in the system will not be too high. But the carburetor will not have to be seriously upgraded, installing an additional valve for the compressor and additional coolers;

- the second method is much more complicated. The overall pressure in the system will be much higher. At the same time, the CO content in the car exhaust will be lower, and in addition, it will be easier to start a cold engine. But it is more difficult to implement such a connection, since it will be necessary to upgrade the carburetor, as mentioned above.

About connecting turbines to the injector

It is much more expedient to install a turbocharging system on an injection engine than on a carburetor one. Fuel consumption becomes lower and engine performance improves. This primarily relates to environmental parameters. They improve because about a quarter of the exhaust is not released into the environment. In addition, motor vibration will be reduced. The sequence of connecting the turbine to injection engines has already been described in detail above, so there is no point in repeating it. But something still needs to be added. Some owners of injection cars try to further increase the turbo boost. To achieve this, they disassemble the turbine, find a so-called actuator in it and install a reinforced spring under it instead of the standard one. Several tubes are connected to the solenoids in the turbine. These tubes are silenced, but the solenoid remains connected to its connector. All these measures lead to an increase in the pressure created by the turbine by 15–20%.

Is the installation justified?

Tuning a VAZ 2107 carburetor in the form of installing a turbine requires a balanced decision. Do not forget that the VAZ 2107 is an outdated passenger car in all respects. For an adequate owner, modification of the engine with a gas turbine supercharger is purely theoretical. In practice, this is a series of problems unworthy of attention.

The seventh model of Zhiguli does not itself provide for the use of a turbine as such. The manufacturer did not provide for the possibility of introducing such a unit at the design stage. For stubborn amateurs who have installed a turbine on an injection-type engine, there is no problem with the injector itself.

From a technical point of view, such an installation on the VAZ 2107 is acceptable. However, it is impossible to escape without consequences:

- A passenger car is not designed to withstand the loads that a suddenly stronger engine will impose on it.

- In addition to the suspension, other components may be damaged.

- The exhaust manifold, for example, may simply not withstand the gas pressure that the turbine will supply to it.

Installing a turbine on a VAZ requires a special base. Amateur replacement carries certain risks. For example, the exhaust manifold may not withstand the high pressure created by the turbine. People are adults - the consequences are clear to everyone. Such engine modernization can be done by professional service center workers.

How is a turbine checked?

Before installing the turbine, it is strongly recommended to change the oil. In addition, the oil and air filters must be replaced. The sequence for checking the turbocharging system is as follows:

- the turbine should be inspected for oil leaks (this applies to both the part through which oil is supplied and the part through which it drains from the turbine);

- All air ducts are also carefully inspected. None of them should contain dirt or foreign objects;

- if the machine is equipped with a catalyst, then it should also be checked for wear (excessive exhaust from a worn-out catalyst can significantly worsen the operation of the turbine; it simply cannot cope with the large volume of incoming gas);

So, installing a turbine on a VAZ 2106 is a long and painstaking process. In some situations, instead of a full-fledged turbine, you can think about installing a turbocharger. This is the least expensive and simplest option. Well, if the car owner has firmly decided to install a turbine on his “six”, then he should prepare for a serious modernization of the engine and serious financial expenses.

Turbine check

Before installing the turbocharger, it is recommended to change the oil, as well as the air and oil filters. The turbine is checked in the following order:

- the oil drain and supply parts of the compressor are inspected for the presence of foreign impurities;

- the catalyst is checked (excess exhaust gases will negatively affect the operation of the compressor);

- all air supply channels are inspected for dirt and blockages;

- The rotor rotation speed is checked.

In other words, checking a turbocharger comes down to:

- control of the quality and quantity of gases released from the collector;

- checking the quality of fresh air supply to the compressor;

- checking the output of hot gases from the turbine;

- checking the compressed air output from the compressor.

Video: testing a tractor turbine on a VAZ 2107

Thus, installing a turbocharger on a VAZ 2107 is quite complicated and expensive. Therefore, it is easier to immediately turn to professionals. However, before this, it is necessary to carefully evaluate the feasibility of such tuning.

Source