Replacing silent blocks of the cross member of a VAZ 2110

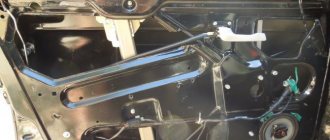

In this article we will talk about replacing the silent blocks of the cross member of the front suspension of the VAZ 2110. We will carry out the repair in the inspection pit without removing the cross member from the car. The first step is to remove the engine protection and brace. Then you need to find a bolt and suitable washers, as well as pipe sections in order to press the rubber silent block towards the front of the car.

If you can’t press it out, then cut off the rubber collar on the side with a smaller diameter. Next, you need to thoroughly clean the silent block seat from dirt and rust, then thoroughly lubricate the silent block and the socket with a soap solution to facilitate its pressing.

We will press in the same sections of pipes with a bolt and washers.

Pressing must be carried out carefully to avoid damage to the rubber silent block. We press in until the smaller flange completely comes out of the hole in the front cross member.

That's all, if you have questions, ask us in the comments, and also read other interesting articles about how to build a cramp yourself on our website and join our VKontakte group.

Diagnostics

To diagnose whether everything is in order with the suspension, you must first listen to how your VAZ 2110 behaves while driving. This doesn’t even require long distances – for an experienced driver, a couple of kilometers will be enough.

So, let's listen to the suspension:

- You can hear tires squeaking while driving. Moreover, the creaking may not be strong, but it still indicates that the suspension is not all right, and the main reason is that the silent blocks need to be replaced;

- When you hear a creak, be sure to inspect the silent blocks; you may notice cracks or even tears in the rubber;

- And if you hear not a creaking sound, but a knocking sound, it means that the silent blocks of your VAZ 2110 are already fairly worn out, and they simply need to be replaced. These heavily worn parts do not even have enough strength to spin, so instead of sliding, they “slip” and make knocking noises;

- Certain knocking noises can also be caused by the front beam with braces; axial play may occur in them. Such beams are subject to repair, and in particularly advanced cases, complete replacement is necessary.

Tools for replacement

On a VAZ-2106 it is almost impossible without the use of special pullers. This device is very simple in design - a metal cup, the diameter of which is equal to the size of the rubber-metal element, a washer and a bolt with a nut (their threads have a large pitch, since the requirement for it is to withstand heavy loads). In addition, you will need a few more special devices. It is better to purchase them in advance or borrow them from friends. Having all the tools makes repairs much easier.

Firstly, this is a spring puller - two pins, at the ends of which there are multi-faceted threads, with grips screwed onto it. Secondly, it is advisable to have a ball joint remover, because it is possible that during repairs you will decide to replace it. Thirdly, you definitely need a good tool - wrenches, screwdrivers, nuts. If you don’t have a puller, it will help. It is needed to burn the rubber out of the joint. In this way, you can quickly break the rubber-metal element to remove it from its seat.

Rear beam device

The metal rear beam, a photo of which is presented on our resource, is structurally represented by 2 longitudinal levers and connection elements, which are connected by welding through reinforcement components. At the rear of the product there are special holders with holes for mounting shock-absorbing elements. There are also flanges with holes for fastening the axles of the rear wheel pair together with the casings of the stern brake systems.

In the front part of the rear axle beam of the VAZ 2110 there are levers with welded bushings, in which rubber-metal type hinges are installed by pressing. The rear beam mounts pass through them, which connect the lever part of the stern suspension to stamped-welded type holders. Those, in turn, are mounted with welded bolts to the body side members.

The spring elements of the suspension rest with one plane on the support of the shock absorber strut, and with the other, through a rubber insulating gasket, into the welded support of the hidden arch of the body tail. The shock absorber strut of the rear suspension beam of the VAZ 2110 is a hydraulic telescopic system of a two-way operating principle.

Through fasteners in the form of a bolted connection, it is articulated with the holder of the longitudinal-type stern suspension arm. The upper fastener of the rack is made in the form of a pin connection, while the fastening of the rod to the upper support is made through rubber pads and a support washer.

The factory “tens” rear beam, the dimensions of which differ from the parameters of similar products, has the item number 2110-2914008, while the “eight” beam has the catalog number 2108-2914008-10.

Suspension design features

A feature of the suspension design is that many of its elements should not be rigidly connected, otherwise it will transfer all the vibration to the body.

How does the VAZ 2110 suspension work?

Therefore, some composite suspensions are connected by means of rubber bushings and rubber pads with metal bushings inside, i.e. silent blocks.

So, in the front independent suspension of the VAZ-2110 the following are connected to each other through silent blocks:

- Lower arm;

- Stretching;

- Anti-roll bar.

Each of these elements plays an important role in the suspension design.

The lower arm prevents lateral movement of the wheel, the extension prevents the wheel from moving longitudinally relative to the body, and the anti-roll bar prevents the body from swaying when performing maneuvers or when driving over uneven surfaces.

But the loads on these elements coming from the wheels are very large, so their displacement, although small, must be provided in order to partially absorb the loads and partially absorb them, and not transfer them to the body.

Beam structure

On the inside, brackets with special holes necessary for installing shock absorbers are attached to the suspension arms. There are also flanges located there, bolted to the axle of the rear wheels and shields located on the brake mechanism. Bushings are attached to the suspension arms on the front side. They are inserted into hinges made of a special rubber-metal material.

Bolts pass through them, connecting the suspension arms together with the stamped-welded brackets. They, in turn, are attached with bolts welded into the side member of the car. The springs of the rear beam of the VAZ 2110 are located in such a way that the first end rests against the recess of the shock absorber, and the second passes through a special gasket directly into the support area attached to the underside of the arch on the car body.

The gasket acts as an insulator and is made of rubber. The shock absorber mounted on the rear suspension is double-acting. It is attached with short bolts directly to a bracket located on the trailing arm in the rear suspension area. In the upper part, fastening is done using the rod method. The rod is fixed in the upper support directly on the suspension spring. The shock absorber is fixed through a protective rubber pad and a support washer.

A double row thrust bearing is located in the middle of the hub. Its structure is very similar to the bearing located in the hub of the front wheels, but it is much smaller in size.

Possible faults

One of the main and most common “symptoms” is knocking. Considering the number of parts and components that make up the suspension, there can be quite a few reasons. Perhaps there is some malfunction in the strut, which is the main element that ensures ride comfort. It consists of:

- springs;

- polyurethane buffer, which limits the compression stroke;

- top support;

- a bearing responsible for the ability to rotate the racks with wheels;

- shock absorber

Another reason for the knocking noise may be that the front suspension spring has failed or weakened. In any case, it requires replacement. It is also common for the cushion or brace located on the cross member to wear out. It happens that the bolts are simply loose. They must be checked to prevent more serious damage. The hinges may also wear out or the attachments to the body may become loose.

The knocking sound of the front suspension of the VAZ 2110 may be metallic in nature, which indicates the destruction of the rubber elements. Wheel imbalance may also be the cause. If any of the listed malfunctions occur, the VAZ 2110 suspension can be repaired without the help of a specialist.

If while driving the car constantly “pulls” to the side, it means:

- springs have different compression ratios;

- different tire pressures;

- one of the rubber elements collapsed;

- different wheel alignment angles;

What you need to prepare for self-repair of silent blocks

Replacing silent blocks or daisies is simply necessary, because this part is responsible for the operation of the car’s suspension. To carry out independent repairs, it is worth preparing a set of spanner wrenches, reliable socket wrenches, a standard vice (if you are used to working with them when pressing out small components), a chisel and a hammer, but this is in case the fasteners have soured and you will have to use force.

Set of tools

You will have a special silent block puller at the beginning of the repair, good, this will certainly make the work easier and speed up the replacement process. You will also have to purchase a new set of silent blocks for replacement in advance and decide how to change the daisies on a VAZ 2114.

Garage or service station

All car owners can be divided into two categories:

- Those who carry out most of the repairs themselves in their garage, and only in emergency cases turn to a car service;

- Those who prefer not to touch anything with their own hands, but completely entrust repairs and maintenance to the masters of service stations.

Each of them is right in their own way. Therefore, we have no right to reproach those who do not want to carry out repairs themselves. After all, garage and professional repair of silent blocks, like other components, has its advantages.

STO has the following advantages:

- A high-quality, responsible car service provides a guarantee for repairs performed;

- In the event of a repeated breakdown covered by the warranty, repairs will be carried out free of charge;

- Professionals are professionals; they have extensive experience and knowledge, which allows them to competently perform their work.

But first you need to find such a car service, which, alas, is not an easy matter. Many provide a guarantee, but when you re-apply, they do everything possible to prove that the breakdown does not comply with the terms of the guarantee. A banal trick.

Repairing your garage will provide the following advantages:

- Significant financial savings, since you only have to spend money on consumables;

- The quality of the work performed by a master is always in doubt if you do not know this person personally. So self-repair may be much better than at a service station;

- You purchase the silent block, and the master only installs it. Why pay money for work that you can do yourself?!;

- Guarantee that a new one will be installed instead of the old silent block. Questionable service stations can easily install an old, more or less usable silent block instead of the one you gave them. You know what the result is.

Replacing lower arm joints

When you're done with the top one, you can start with the bottom one. His fastening is done a little differently. And the replacement of VAZ-2106 silent blocks is carried out without removing the suspension arm. You just need to unscrew the nut, which, by the way, needs to be replaced with a new one during assembly. And remove the washer. That's all, now use the hollow bolt of the puller to press out the hinge. The second one is extracted using the same exact technology.

Installation of new hinges is done by pressing. To do this, a silent block is inserted into the hole by hand. Then, using a stand, carefully strike with a hammer. You don’t need to hit with all your might, a sharp but weak blow is enough. But this is if there is no puller, and if there is one, then the task is simplified many times - place it on the hinge and slowly, avoiding distortions, screw in the bolt. After pressing, check that there is no gap. When finished, screw in a new nut, not forgetting the washer. That's all, the replacement of the VAZ-2106 silent blocks is completed, you can put the upper arm in place.

The silent block is an important part of the suspension, which ensures the mobility of the elements relative to each other, and also eliminates friction from metal parts. If so, it needs to be changed. On all VAZ classic models (2101, 2102, 2103, 2104, 2105, 2106 and 2107), the silent blocks of the front levers change in the same way. The procedure for replacing the silent block of the VAZ upper arm is as follows: 1. Jack up the car and remove the front wheel.2. Unscrew the nut on the axis of the upper arm (you need a 24mm wrench).

Replacing daisies. — logbook Lada 2112 2007 on DRIVE2

After replacing the supports, stabilizer struts and tips, the knocking still did not go away, I read on the drive and somewhere else that it might be daisies, they just looked tired to me, well, I think they were, I took them all apart, they really died, I pressed out the old ones , I stuck the new ones in and put them on one side for now, at least to check whether they were there or not, I took it for a ride, it felt a little rougher, maybe because I pulled everything together well, at first I was glad that the knocking had disappeared, but that was not the case, I drove up to the house, everything was smooth when braking and starting, but much quieter, tomorrow I'll change the right side and look at the caliper, most likely there's nothing more wrong with it, so tomorrow I'll look on the right side to see if the caliper is hanging there and then I'll think further, but the problem is almost gone :)

Replacing the silent blocks of the upper arm

That's all, now you have the upper lever in your hands, you need to knock out the hinges from it. But, of course, you shouldn’t hit it hard, since the rubber reflects the blow, so you can hit yourself in the eye with a hammer if you swing it well. It is best to use a puller for this purpose. If you are repairing a car, then you should have tools available. In particular, a good vice will not be superfluous. Now begins the replacement of the silent blocks of the VAZ-2106 lever, which you have been looking for for so long.

The lever is securely fixed in a vice. You put the puller on the hinge and, screwing in its nut, begin to press out the silent block. Before repairs, it is recommended to treat all components with penetrating lubricant - hinges. And if you do not want to suffer with the puller, then your only helper is fire. Just warm up the silent block under an open fire. All the rubber burns out, leaving only the metal part of the hinge, which is easily knocked out of the lever with one blow. Of course, this method can be called barbaric, but on the VAZ-2106, silent blocks can be replaced with its help. Especially in cases where the puller fails to remove the hinge.

Replacing front arm silent blocks on VAZ-2110 cars

- Remove the engine splash guard.

- Remove and disconnect it from the lever.

- Holding the extension with a 24mm spanner, use a spanner of the same size to unscrew the extension nut.

- Using two 17" wrenches, unscrew the nut of the bolt securing the transverse stability to the lever. Use a soft metal drift to knock out and remove the bolt.

- Using two 19mm wrenches, unscrew the nut of the bolt securing the lever to the body. We remove (or knock out) the bolt and remove the lever from the bracket.

- Remove the washer and lever from the stretcher. On the extension behind the large washer there are washers for adjusting the pitch angle of the steering axis.

- To remove the brace from the cross member of the front suspension, use two 24mm wrenches to unscrew the nut, remove the washer and remove the brace from the silent block.

- To replace the silent block of the lever, press it out in a vice with suitable pieces of pipe (or use a puller).

- We wet the new silent block with soapy water and press it into the lever.

- We knock down the silent block of the guy wire with a chisel. Having removed one, we similarly dismantle the second. We pre-press the new silent block in a vice and finally press it by striking a drift with a diameter of 8 mm through three windows in the rubber layer.

To replace the front arm silent blocks on VAZ-2110 cars you will need:

- new silent blocks VAZ 2110;

- liquid soap (can be replaced with detergent or soapy water);

- standard set of wrenches (both socket and socket) for 24, 17 and 19;

- chisel and hammer;

- penetrating fluid WD-40;

- a universal cup puller or a piece of pipe, the diameter of which allows for free entry of the silent block;

- metal brush;

- knife and screwdriver (with a blunt end);

- inspection hole and jack;

- vice;

- gas burner or blowtorch.

Everyone knows that it is with the help of silent blocks that the angles of the car's wheels are influenced.

Therefore, it is very important to ensure that they are always in good condition. Replacing the front silent blocks of the VAZ 2110 in some cases is simply necessary. And it’s worth noting that replacing the front silent blocks on a VAZ 2110 can easily be done with your own hands

Removing the rear block

Replacement of the rear beam is carried out after transporting the car to an inspection ditch or lift. To begin, remove the brake pads located at the rear of the VAZ 2110. Disconnect the steel ropes that secure the parking brake to the underside of the beam attached to the rear of the bracket.

Now disconnect the thin brake hoses leading to the brake cylinders located at the rear of the car. Disconnect the brake pipes attached to the beam. In addition, you will need to disconnect the elastic lever from the beam, which is located on the drive responsible for regulating the pressure.

Using a size 17 wrench, unscrew the 4 mounting bolts holding the hub axle together with the rear suspension beam. Remove the axle itself along with the brake mechanism shield and, if necessary, separate them by unscrewing the two fastening screws using a Phillips screwdriver. Bend the bracket and remove the brake pipe.

It is necessary to disconnect the lower ends of the shock absorbers and the nuts attaching the beams to the brackets from the beam

After this, you need to remove the bolts from the beam and carefully remove it. Using a size 17 socket, remove the 3 nuts securing the bracket to the body

Rear suspension structure: 1 — rubber-metal hinge; 2 — suspension arm mounting bracket; 3 — shock absorber casing; 4 — compression stroke buffer; 5 — casing cover; 6 — support washer; 7 — shock absorber cushion; 8 — spacer sleeve; 9 — shock absorber; 10 - insulating gasket; 11 — rear suspension spring; 12 — lever connector; 13 — rear suspension beam arm; 14 — shock absorber mounting bracket; 15 - flange; 16 — lever bushing