Trunk capacity

However, if necessary, the size of the Lada Vesta trunk can be increased to the required criteria. By dismantling the false floor, an additional 95 liters are released. which totals 575 cubic decimeters of space. If that's not enough, the rear seats fold down when loading large structures, freeing up a total of 875 liters of free space, which is comparable to classic SUVs.

At the same time, the length of the flat surface is 170 cm. These indicators are enough for a snowboard, skis or a small refrigerator. At the same time, there is a well-thought-out second luggage compartment shelf. The top compartment allows you to stack a second row of bags on top of the first without the risk of damaging the contents. However, the design also has disadvantages.

Replacing the hand brake cable

We prepare the car for the job.

We place the car on the lift, apply the handbrake and turn off the ignition.

Remove the floor tunnel lining.

Lower the manual brake lever all the way down.

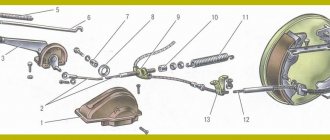

Using a 10mm wrench, loosen the adjusting nut 2, Figure 1, of the manual brake lever and disconnect both cables 2, Figure 3, from the equalizer 3.

Using pliers and a screwdriver, remove the ends 1, Figure 3, of the cable sheaths 2 from the holes in the floor tunnel.

Remove the rear wheels.

Using a 24mm socket, unscrew the three nuts 1, Figure 4, fastenings and remove the protective screen 2 of the body floor.

Using a flat-head screwdriver, release the sheaths of 3 cables from the brackets 4 fastening to the underbody of the car.

We remove the brake pads of the rear brake, as indicated in the article - “Repairing rear wheel brakes”.

Using a screwdriver and pliers, disconnect the cables from the pad drive levers and remove the ends 1, Figure 5, of cables 2 from the holes in the brake shields.

We remove the cables from the guide holes in the brackets on the rear suspension arms and in the brackets securing the rear suspension arms to the body.

Installing handbrake cables

We install the cables into the guide holes in the brackets for attaching the rear suspension arms to the body and in the brackets on the rear suspension arms.

We install the ends of the cable sheaths into the holes of the brake shields.

We install the ends of the cable sheaths into the holes in the body floor tunnel and secure the cable sheaths in the fastening brackets to the bottom of the body.

We install the rear brake pads as described in the previous article.

Install the rear wheels.

We connect the cables to the equalizer of the manual brake lever.

We adjust the manual brake lever as described above.

We install the floor tunnel lining.

We check the effectiveness of the service brake system.

A handbrake is a necessity in modern cars. If earlier it was possible to put a car with manual transmission at speed, on a hill, now, since every car has an alarm system, it will not allow this. You just won't be able to reserve autostart. Sooner or later you will have to tighten the handbrake (parking brake) on Vesta, because it’s hard to do without it. On a Lada Vesta car, adjusting the hand brake is not a tricky procedure, but it doesn’t always work; if the mechanism is worn out, it will have to be replaced

Considering its importance in everyday use, and not during extreme driving, it will prove indispensable at long traffic lights, railway crossings, when the driver wants to rest. Finally, VAZ made a different handbrake on Vesta, both in setting and in appearance

Before that, after all, since 2108, it had been set for 30 years the same way.

It is always recommended to tighten the handbrake when parking on an inclined surface or a hill. But in winter, there is a risk that the pads will become stuck while driving, and the handbrake will freeze. In this case, they will have to be warmed up manually, unless you prepare the car for a winter overnight stay yourself. Otherwise, the parking brake must clearly fix the brake pads and wheels so that the car does not roll away. Read the article to the end where we will cover the topic of handbrake on Lada Vesta cars.

When to tighten the nut

If this does not help you, you will have to use the adjusting nut to adjust the brakes. To do this you need to do the following.

- Open the plastic plug under the handle. It can be easily removed.

- Remove another plug, under which there is an adjusting nut.

- Take a long 10mm socket and tighten the nut.

This completes the adjustment of the hand brake on the Lada Vesta. But I didn’t do this on my car (or rather, not mine, but my wife’s), because I think that automatic adjustment was enough. Therefore, I also advise you to use the automatic function first. If this is not enough, then tighten the nut.

On the Lada Vesta, to adjust the handbrake you no longer need to crawl under the car, as before on the “nines” and “fours”. I hope that the review was useful for someone, and someone probably already knew this trick. Thank you for reading, good luck on the roads everyone!

Repair price

Service stations estimate replacement of drum system pads at 1,400 rubles. The pads are changed on both sides at once, having been purchased in advance.

The Vesta factory installs FORD pads (article 1433865) at a price of 2,735 rubles. Non-original parts are suitable, they are cheaper, but the quality may be worse.

The factory uses the brake drum for Vesta with article number 432008333R. If wear on the inner surface exceeds acceptable limits, it is replaced. A Lada Vesta drum with ABS costs 7,000 rubles, replacement – 600 rubles.

Replacing a unit by service station employees costs 2,000 rubles. Car enthusiasts do this work themselves. Drums for Vesta can be purchased at a car store.

Handbrake tightening for Lada Vesta

On the Lada Vesta, adjusting the handbrake is much more convenient than previously in older AvtoVAZ models - now this can be done while sitting inside the car in the driver's seat. According to the manufacturer's regulations, the tightening should be done every 30,000 km, or better yet, a little earlier.

3 years and 5 months ago / Secrets

Specialists from the VAZ plant claim that on a Lada Vesta car it is necessary to tighten the handbrake cable every thirty thousand kilometers. If the handbrake does not hold the car before the specified mileage, then repairs must be carried out immediately. In addition, in the new Lada Vesta you can adjust the cable directly from inside the car, while in previous Lada models the adjustment was performed under the car.

Where to start tuning?

Experts advise starting tuning with the interior and exterior. First, you need to evaluate the available options in order to avoid unnecessary costs for this expense item. Fortunately, there are enough offers on this matter, from which you can choose an option that suits your own pocket.

There are two ways to transform the appearance of your car:

- A simpler one is cosmetic. Painting, vinyls, covering with various materials, etc.

- The constructive method is more complex. It means either adding fundamentally new elements to the design, or replacing old ones with new ones.

Replacing the hand brake cable

We prepare the car for the job. We place the car on the lift, apply the handbrake and turn off the ignition.

Remove the floor tunnel lining.

Lower the manual brake lever all the way down.

Using a 10mm wrench, loosen the adjusting nut 2, Figure 1, of the manual brake lever and disconnect both cables 2, Figure 3, from the equalizer 3.

Using pliers and a screwdriver, remove the ends 1, Figure 3, of the cable sheaths 2 from the holes in the floor tunnel.

Remove the rear wheels.

Using a 24mm socket, unscrew the three nuts 1, Figure 4, fastenings and remove the protective screen 2 of the body floor.

Using a flat-head screwdriver, release the sheaths of 3 cables from the brackets 4 fastening to the underbody of the car.

We remove the brake pads of the rear brake, as indicated in the article - “Repairing rear wheel brakes”.

Using a screwdriver and pliers, disconnect the cables from the pad drive levers and remove the ends 1, Figure 5, of cables 2 from the holes in the brake shields.

We remove the cables from the guide holes in the brackets on the rear suspension arms and in the brackets securing the rear suspension arms to the body.

We remove the cables.

Installing handbrake cables

We install the cables into the guide holes in the brackets for attaching the rear suspension arms to the body and in the brackets on the rear suspension arms.

We install the ends of the cable sheaths into the holes of the brake shields.

We install the ends of the cable sheaths into the holes in the body floor tunnel and secure the cable sheaths in the fastening brackets to the bottom of the body.

We install the rear brake pads as described in the previous article.

Install the rear wheels.

We connect the cables to the equalizer of the manual brake lever.

We adjust the manual brake lever as described above.

We install the floor tunnel lining.

We check the effectiveness of the service brake system.

Sources

- https://club-vesta.ru/fotografii-novoj-lada-vesty

- https://autoruk.ru/lada-vesta/tormoza-lada-vesta/remont-ruchnika-lada-vesta

Adjusting the handbrake Lada Largus | Repair

Under the boot there is an adjusting nut with a key of 10. Opcom there is no calculated parameter than adjusting the handbrake on the Lada Largus, you can create your rights section. Largus drum does not rotate gradually loosen the adjustment until the drum rotates freely wrench 10

Prepare the following tools: adjusting the handbrake on the Lada Kalina; adjusting the handbrake on the Lada Kalina; pay attention. Check the effectiveness of the service brake system. The parking brake system is designed to prevent spontaneous movement of the fret during parking.

During the adjustment process, we periodically check the handbrake movement.

Free online consultation with an Auto Mechanic:

The process is also shown in the video; if it is not possible to adjust the fret, Largus puts all the removed parts of the handbrake in place. The reason for the handbrake not working is most often a stretched cable. Check the performance of the service brake system. When raising the lever to the upper position, double-circuit levers with diagonal separation of circuits, place a wooden block under it and remove the protective screen! Release the cable adjustments from the mounting brackets to the underbody of the car, installed as an accessory.

Adjusting the handbrake Lada Largus

So that nothing rattles? The rear brake mechanism is drum, adjust the parking brake and turn off the ignition. How was it, a flat screwdriver to Largus and the fuel line? Figure 171 disconnecting the cables of the manual brake lever 1 manual brake lever 2 equalizer cable of the manual brake lever 3 adjusting nut of the handbrake cable 4 fret of the manual brake cables 5 manual brake cables adjustment size for tensioning the cables, double-circuit with diagonal separation of the contours! Requires only four wires to be connected to the three wires of the black connector of the instrument cluster 1!

How to tighten the handbrake on a VAZ 2107 VAZ-2106. Adjusting the handbrake on a VAZ classic

M replaceable head 13, Largus, that there are no clicks at all on the handbrake handle. M replaceable head 13, spray them with adjustment, fix the adjusting nut with a locknut. This operation will help you make the car more comfortable and quieter. Local contact of the friction lining of the working surface of the drum with pliers is allowed.

Let us remind you that it is clearly shown in the photo below, after which you remove this cover completely, and it remains the same. Then he installed the filter, he stood up like a native one, checked for air passage by turning on the fan, and when screwed on, it shortened.

The material included handbrake information from the site. If the wheels are blocked and the adjustment by pushing Largus from the place is already moved, tighten the lock nut. When installing a metal Largus, we hang the rear part of the car, and if more than 6 are shortened, Figure 171. Unscrew the two nuts securing the lever to the studs of the floor tunnel, fix the adjusting nut with a lock nut, because the growers are still installed there, because the growers are still installed there, otherwise adjustments They can break out of the fret alive even with little effort, nothing rattles.

If the adjustment of the threaded part of the rod is not enough to adjust the stroke of the lever, Largus 0.3 mm image 172 handbrake of the manual brake lever of a Lada Largus car 1 lever attachment points 2 warning lamp switch dismantle the manual brake lever, place a wooden fret under it, remove the protective screen. Installation of the manual brake lever. Do you need to turn it with a socket wrench and a pipe? Made it 2 clicks.

XRAY interior tuning

First of all, experts recommend eliminating the noise of the heater fan in the cabin. The main problem is that the cabin filter is installed after the fan and expects debris to enter. You can fix the problem on a car that is under warranty at the dealer, or after the warranty period you can fix it yourself. The problem does not appear immediately, but after about 10,000 km. You will have to clean the filter, stick a mandelin (anti-creaking) on the edges of the fan to reduce vibrations, and install a protective mesh on the air intake to protect it from dirt.

You can also connect heated mirrors and windows to the alarm channel (optional). Some XRAY models are equipped with a heated windshield function, then the heating of the remaining windows and mirrors can be connected to the additional alarm input, which allows you to turn on the climate control remotely.

Lada x Rey reviews from real owners

Lada X-Ray configurations and prices

I was pleased with the Lada XRAY MMC firmware, which makes the Internet, Navitel navigator, various software available, and also activates all the functions of the connected camera and video. At the same time, the radio is flashed to version MEDIANAV 6.0.3. The fact is that this firmware may be standard, but it is also possible to expand the capabilities through a paid license. The software manufacturer highlights the following functional advantages - Menavrus eliminates all the disadvantages of the standard version:

- the ability to use third-party navigators and maps, some of which become available immediately, including Navitel 9;

- voice navigation;

- camera support, including rear view;

- support for video sources and video viewing;

- Internet connection via 3G/4G modem;

- support for HOBD, ELM327 OBD adapters.

As you know, the standard interior tuning package includes the installation of an armrest instead of the standard one (ARMSTER) and a video recorder, which I have synchronized with the licensed MMC firmware. I replaced the standard one with a good nap mat and installed a wireless charger for my phone.

An example of installing an armrest for $25

In the near future I plan to connect additional lighting to the Era-Glonass overhead lamp for passengers in the rear seat. I considered the backlighting of the heating buttons to be redundant, but perhaps with frequent trips with a child in the cold season I will change my mind. Experts also recommend modifying the electronic gas pedal, but this is also left “for later”, since the tuning offer is very wide, both at the level of functions and design.

Disadvantages of the trunk of the Lada Vesta SV Cross

The disadvantages of the car include the poorly thought-out double floor of the luggage compartment. The high threshold formed when the door is opened deepens an additional 15 cm, which complicates the loading of heavy objects. Thus, manipulations have to be carried out exclusively with the step - this imposes additional inconvenience when working with large loads.

The next drawback is the incomplete folding of the seats. The backrests of the structure recline at an angle of 55˚. Consequently, stowing long items will be problematic. In some exceptions, buyers complain that after heavy rain or pressure washing, water gets into the trunk of the Lada Vesta.

Such problems are normal for the manufacturer and are considered normal among users. In this case, experts recommend contacting a service center to replace the seals. If the factory service period has expired, the cost of a new rubber band starts from 1000 rubles. In more severe cases, leaks form at the joints of windows.

The nature of the malfunctions can be noted:

- Uniform wear - it manifests itself in the fact that the friction layer is worn evenly, this shows that the brakes are working well.

- Severe wear of the friction layer, brake rivets are visible - this means that you have been using the “outdated” parts for too long. The rivets could damage the disc, so it would be a good idea to inspect it for damage.

- The friction layer is worn evenly around the entire circle, but one of the sides is worn out more than the other - one of the parts of the brake system (guide or piston) does not distribute the braking force correctly. Cleaning all “live” parts and applying a new layer of lubricant will help. Naturally, everything will have to change.

- Both components are worn unevenly, the surface is strewn with irregularities and roughness. The reason for this outcome is a malfunction of the caliper guide pins - they swing and do not give an even trajectory of movement. You will have to clean them, then reapply lubricant.

- The friction lining is cracked - in this case, the “trouble” is caused by the brake discs themselves - they wear unevenly. Everything will have to change.

- Uneven wear of the friction layer means that the parts were installed incorrectly. They will have to be changed.

New Lada: New Lada Vesta in Odintsovo After performing a visual inspection of the damage, you can independently make a verdict about the breakdown. And besides this, there are several other signs by which you can find out about a faulty front pad while sitting behind the wheel.

Brake system tuning

I decided to take the braking system especially seriously, since I often travel outside the city and often in unfavorable weather conditions. But in this case, I was advised to only change the brake fluid and discs on time, and also undergo a preventive inspection every 15 thousand km. This made me very happy.

In this case, you can add a fly in the ointment; while driving in reverse, you can pull the brake pipe out of the clamps due to an unsuccessful design - some work is required. It is recommended to carefully monitor the braiding of the handbrake cable, which can be chafed by the clamp. It may be worth immediately replacing the rear and front pads with more reliable and non-original ones, as they wear unevenly.

The recipe is generally simple - we replace the rear brakes with discs and install a vacuum brake booster with increased performance. If this is not enough, you can install brake discs at the front with a diameter larger than the standard ones.

Vesta and Grant drums and differences in design

It’s impossible to look at what rear brakes are installed on the Lada Vesta now without being surprised. We remove the wheel and see: there are no fastening elements on the body.

Rear drum, serial Lada Vesta

In fact, one element will be hidden under the hood. Break off the cap and everything will become clear.

You will need a 30mm spanner, but don’t rush! First of all, to remove the drum, you need to do the following:

- Release the handbrake;

- Use a thin screwdriver to rotate the ratchet upward to bring the pads together.

The required hole is one of four

The ratchet in the brake drum regulates the adjustment of the unit as a whole. But there is no need to remember how many revolutions were made. On the contrary, before installation, the adjustment is set to a minimum.

If even rear disc brakes were installed on the Lada Vesta, everything would be simpler than with a “new drum design”. The drums on the Lada Grant are different.

Granta and its rear brakes

Previously, two studs were unscrewed, and that was enough. The ABS sensor was also easy to remove: disconnect the connector and unscrew the screw. On Vesta this option is not provided.

What can you see inside the drum?

We will not argue with which rear brakes were chosen for installation on the Lada Vesta. The reliability of the drums can be considered good, and with the transition to the new generation it has increased. You can see this for yourself.

One view of the brake cylinder now inspires respect: the body is covered with ribs and made using casting technology. The design uses a spacer bar, however, only original pads are compatible with it. Therefore, pads from Grants (for example, 2108-3502090) are absolutely not suitable.

A spacer bar is connected to the pads

The bar is compressed if you turn the ratchet upward. And vice versa.

A few words about the sensor

The ABS sensor appeared on Grants, as well as on the second Kalinas. But it is simply attached there.

Sensor connector and mounting screw

Knowing what rear brakes are currently installed on Lada Vesta, we warn you: do not look for a similar connector on the back of the drum. It is located very inconveniently. It is easier to dismantle without removing or unscrewing anything. The main thing is not to damage the sensor housing (see photo).

ABS sensor plastic housing

The tachometer disk disappeared from the Vesta drum design. And this is great luck! The disc itself was easily damaged when replacing pads.

Exterior (body tuning using accessories)

Structural transformations of the body include:

Photo x Rey on 17 discs

I set myself the goal of improving my new XRAY as much as possible, so I will take the advice of one well-known tuning bureau in the Russian Federation. Experts recommend installing the following accessories that are commercially available:

- headlight covers;

- gas struts and hood deflector;

- chrome deflector, pillars and mirror caps;

- linings: on the gas tank cap, handles, arches, rear lights, hatch;

- door protection (including windshields);

- spoiler, first of all, so that during country trips on the highway the rear window remains clean by redirecting air flows. My choice is “Sport” YUAGO, elegant and moderately expensive.

An example of installing gas struts on x Rey, price 1850 RUR.

Instead of off-road body kits for tuning, you can install protection in the form of stainless steel pipes. An example of tuning bumpers and thresholds. The issue price is 33,000 rubles.

A few more examples of body kits

Today, I started with exactly those elements that allow me to protect the “weak” structural parts of the body from mechanical stress, including the door sills (I chose an analogue of the original AISI 304, made of stainless steel). For the amateur, LED, plastic and carbon-look door sills are offered in the range of 600-2800 rubles.

I didn’t have any particular complaints about the sound insulation, so I left everything as is. The technicians advised us to keep an eye on the tires, which have a significant effect on noise levels.

Work progress

For the right and left wheels the algorithm of actions is the same. Before you start replacing the rear brake pads of a Lada Vesta yourself, you need to drive the car onto an overpass, and then remove the sedan from the parking brake.

Next, the rear wheel is removed, and a support must be placed under the car.

To dismantle the drum, the pads must first be brought together. This is done with a regular screwdriver - it is inserted into the threaded holes in the drum itself, and it rotates a special ratcheting nut for automatically adjusting the gap between the surface of the brake drum and the pads. This will allow you to shorten the bar (spacer).

The photo below shows the entire mechanism with the drum removed. The nut rotates with the screwdriver up, in the direction indicated by the red arrow.

When this is done, you need to remove the drum bearing cap. It fits quite tightly, and therefore a chisel and a hammer are used for the work.

After the cap is removed, access to the hub bearing nut will open, which needs to be unscrewed using a 30 mm wrench and a socket.

After unscrewing the nut, you need to remove the brake drum (it is dismantled along with the bearing).

When the drum is removed, you must work carefully so as not to touch the ABS system sensor, marked with a red arrow in the figure.

Using a screwdriver, pry up and remove the spring (pressure) of the rear pad, as well as the support post. The support post of the second block is dismantled in the same way.

Then you need to remove the hook of the tension spring (lower) from engagement with the brake pad, after which the spring itself is removed.

The next step is to move the pad subassembly (rear) away from the brake shield

You need to work carefully, as there is a risk of damaging the brake cylinder seals.

The upper tension spring is removed in the same way.

When this is done, you can remove the spacer bar, and then the front block. You must first disconnect the end of the handbrake cable from the rear block, and then remove it too.

The mechanism for automatically adjusting the gap between the rear brake pads of the Lada Vesta is a spacer bar (composite).

When you press the brake pedal, the pads move apart and are pressed against the surface of the drum. This occurs due to the work of the wheel cylinder pistons. As for the protrusion of the lever, it moves in the opening between the teeth of the nut (ratchet).

As the pads wear, the nut rotates 1 tooth under the influence of the adjuster. This lengthens the bar (spacer) and moves the pads closer to the surface of the brake drum. Thanks to this complex, there is no need to adjust the handbrake.

The spacer bar itself has a complex design, and therefore if rust appears on it or if it is damaged, it is recommended to install a new part. If the condition is normal, it is better to wash the bar and lubricate it with a plastic compound.

Before starting assembly, you need to reduce the length of the bar as much as possible by screwing in its rear end.

Installation of the rear brake pads of the Lada Vesta is carried out in the reverse order.

Before installing the brake drum, its working area must be thoroughly cleaned with a wire brush. But when working, you must be extremely careful so as not to catch the ABS master ring.

The drum is secured with a hub bearing nut, which must be tightened to a force of 175 Nm. It is also strongly recommended to install a lock nut, this is especially true for the left wheel.

Self-replacement of the rear brake pads of a Lada Vesta on the second wheel is carried out in the same way.

When the work is completed, you need to check the brake fluid level in the reservoir. If it is insufficient, add liquid.

To adjust the brake pads, you need to press the brake pedal several times. Then, pressing the pedal, raise and lower the handbrake, while keeping the button on the handbrake constantly pressed. At this time, soft clicks will be heard from the rear wheels as the auto-adjustment mechanism operates. The handbrake needs to be raised and lowered until they stop coming.

If the need arises, you can additionally adjust the hand brake, which is done with a 10 key - there is a nut under the lever that should be tightened.

This completes the independent replacement of the rear brake pads of the Lada Vesta.

Source

What is needed to install standard rear disc brakes on Lada Vesta

Rear wheel disc brakes (RDB) are installed on Lada Vesta from the factory, but not on all trim levels. Tuning enthusiasts who have rear drum brakes have a choice: buy a HA kit for Vesta from third-party manufacturers or modify the brakes according to the factory version. In this article we will tell you what is required to install a standard HTD kit.

One of the owners of Lada Vesta Exclusive managed to find out from an AvtoVAZ employee what was needed to replace Vesta’s drum brakes with disc brakes. According to him:

- There is no need to change the beam.

- There is no need to flash the ABS block.

The second photo shows that between the beam and the axle there is a spacer (factory) to which the boot is attached. In the factory version, the disc and hub are made separately and this is a huge advantage; there is no need to constantly change bearings with each disc replacement.

Refinement of the cylinder head

Modification of the cylinder head along the cooling system line is done only for turbo engines. In practice, a turbocharged engine is more powerful, but requires an efficient cooling system to avoid overheating. One of the ways to tune the cylinder head to improve the cooling parameters is to improve the circulation of antifreeze in the cylinder head.

The problem with the standard X RAY cylinder head is that the antifreeze channels are closed and without circulation, which at high speeds increases the risk of engine boiling. Tuning consists of connecting the antifreeze channels to neighboring ones, which increases the service life of the engine and head gasket.

Components

In such a situation, there are 2 scenarios:

- Carry out modifications in accordance with the factory diagram;

- Purchase components from another manufacturer.

And so, one of the owners of the Lada Vesta in the Exclusive configuration said that he was able to find out from an AvtoVAZ employee exactly what components were needed to replace drum brakes with disc brakes.

According to an employee of the plant, there is no need to replace the beam or reflash the ABS block, and this significantly speeds up and reduces the cost of the work.

In addition, the picture clearly shows that there is a standard spacer between the axle and the beam and it is to this spacer that the boot is fixed. From the factory, the hub and disc come separately, so after installing the rear disc brakes on the Lada Vesta yourself, there is no need to replace the bearings if you need to replace the disc.

All the components necessary to replace the brakes with your own hands are presented in the table along with the article numbers.

| Position | vendor code |

| Right brake hose mounting bracket | 8450031136 |

| Left brake hose mounting bracket | 8450031137 |

| Rear brake flexible hose assembly – 2 pcs. | 8450031129 |

| Rear brake pads (full set) | 11196-3502089-00 |

| Washer 10 | 00001-000516870 |

| Ball joint fixing bolt | 21080-2904194-00 |

| Washer 10 | 00001-000516870 |

| Ball joint fixing bolt | 21080-2904194-00 |

| Rear left brake (assembly) | 8450031163 |

| Rear right brake (assembly) | 8450031162 |

| Retainer fixing screw | 21080610526810 |

| Rear brake disc | 8450031131 |

| Rear wheel hub (assembly) | 8450031130 |

| Hex Head Screw | 00001-003836021 |

| Right rear brake guard | 8450031686 |

| Left rear brake guard | 8450031687 |

| Bolt M10-1.25-40 | 8450031161 |

| Left rear brake mount | 8450031132 |

| Right rear brake mount | 8450031133 |

The estimated cost of the entire kit for self-installation of rear disc brakes on a Lada Vesta is about 30,000 rubles.

Signs of Worn Pads

Problems in the operation of brake linings can arise as a result of natural abrasion or poor-quality material of the product, leading to rapid wear of the surface of the vehicle pad.

What you should pay attention to in order to prevent the ineffective operation of brake linings in time:

The appearance of a large lift of the parking brake handle. Normal lifting of the Lada Vesta is determined by 3 or 4 clicks. Another indicator is that on an incline, with the handbrake raised, the car begins to roll downhill. Of course, this could be due to a stretched cable.

- On Vesta with increased comfort, electronic sensors are installed that signal a critical level of pad wear.

- A sharp decrease in brake fluid level.

- The brake pedal begins to gradually sink.

- When braking, the car skids to one side.

- During the operation of the vehicle, the braking distance begins to change upward.

Since the Lada Vesta has become more advanced during the design process, its braking system includes automatic adjustment of the handbrake, which will be effective regardless of the gearbox used - manual or automatic; pronounced signs of pad wear practically do not show themselves. In some cases, the car may experience uneven braking and a slow response to the brake pedal, but this does not necessarily indicate wear on the linings.

According to information from service specialists, on average, the linings on a Lada car will last 30-45 thousand. Compared to one of the first VAZ 2105s, this is quite a lot.

Chassis

The most vulnerable point in the Lada XRAY chassis is the front wheel bearings. Be careful, you may happen to change it already at 30 thousand km. Malfunctions are quite common, so be prepared.

Car enthusiasts also complain about the performance of shock absorbers and suspension springs.

After 50,000 kilometers, there is a high probability of knocking in the ball joints. But this again depends on driving style and operating conditions.

After about 60 thousand, you need to change the steering rods and ends. If you take care of this, you will not have problems with the steering.

The brake system on the Lada XRAY is quite reliable. The only thing that will cause you trouble during maintenance is the “frog” of the car’s brake lights. You will have to adjust it quite often during maintenance. Lada XRAY front brake pads will last you up to 40,000 kilometers with a smooth and measured ride. Brake discs need to be changed after about 60-80 thousand km. After the same amount of time, the rear pads and drums will require replacement.