The starter ensures the start of the power unit of the VAZ 2112 car. It rotates the crankshaft of the engine until the engine begins to work independently.

As a result of normal wear and tear or breakdown, the starter may fail. In this case, starting the car becomes difficult, and in some cases even impossible. Therefore, the unit should be given due attention and diagnosed at the first sign of a malfunction.

The process of replacing the starter on a VAZ-2112

Old and new starter

We will need the new starter itself, keys “13” and “15”; we can also use heads and ratchets for convenience.

- First of all, remove the negative terminal on the battery (this is necessary for safety, to avoid a short circuit).

Remove the terminal - Disconnect the wire at the traction relay.

- The next step is to unscrew the starter using a ratchet and a 15mm socket 2 fasteners (one from the bottom).

Unscrew the starter fasteners - After the above operations, you can safely remove the starter.

Installing the starter is done in the reverse order, but for simplicity, here is a small and clear diagram of the connection to the starter relay:

Connection diagram of the starter to the car relay

Or according to this scheme:

More details here

What is a starter for?

Let's introduce a little theory about the ignition system and the starter itself.

>

The ignition system is necessary to start the engine; the starter itself is designed to create a powerful current (by passing, so to speak, through the starter winding). This is done so that this energy turns the flywheel half a turn.

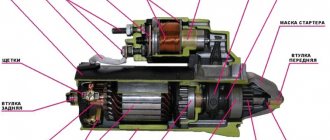

Main starter components:

You can see more details in the picture.

- Front cover with plain bearing.

- Bendix (engagement drive).

- Planetary reductor.

- Rotor with collector.

- Housing with stator.

- Solenoid relay.

- Brush unit.

- The back cover has a plain bearing. You can see more details in the picture.

Reasons why it is necessary to replace the starter

- The solenoid relay armature is broken.

- Broken wiring.

- Short circuit to negative.

Most of these reasons can be diagnosed if you try to start the engine by closing the contacts on the starter.

There are many reasons for the malfunction of the ignition system, and the starter is not always to blame, so before changing the part, make sure that it is definitely the problem. Check the relay and the presence of voltage at the starter terminals. More details in the material: why doesn’t the starter turn?

>

Installing an additional relay

If after 2-3 thousand kilometers a VAZ 2112 has a problem with the starter - it stops starting the overheated engine normally, rotates lazily and sluggishly - it is recommended to install an additional relay. It will save the contact group and increase the voltage to the solenoid relay. You can, of course, disassemble the device and reassemble it, thoroughly cleaning the contacts from oxides. You can also quickly start the engine with a long screwdriver by closing the bolts of the retractor relay. Or simply ask several people to push the car. But over time, the problem will make itself felt again.

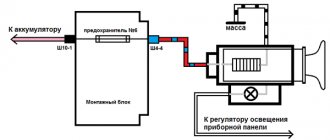

Below is a diagram of connecting a starter device with an additional relay:

- the positive impulse goes from the battery directly to the starter;

- the ignition key is connected to the positive terminal through an additional relay;

- a line is drawn from the relay not only to the starter, but also to the battery;

- minus or ground from the battery is shorted to the body.

In both options, the additional relay must be powered from a separate fuse. The latter can also be used as a variant of a kind of “secret”.

Now about what you will need:

- four-contact relay 98.3777-10 with an iron ear for 30 or 40 amperes;

- plugs: 2 ring plugs, 1 female relay plug, 5 standard female plugs and 1 standard male plug;

- new wiring.

Next we connect according to the following diagram.

Compactness - small weight and dimensions - are the advantages of the starter 12 of the VAZ model. On the other hand, this is the most loaded part in the entire electrical system. It is the starting device that must spin the heavy flywheel of a powerful engine. In addition, it is responsible for the rotation of the crankshaft with the connecting rod and piston group. For these reasons, the starter does not serve for a long time, failing after 5-6 years of continuous operation.

Reasons for replacing the starter

The required node is located in such a place that it is not always possible to examine it immediately.

However, if you look from a certain angle, this element is quite easy to find. Every part in a car wears out over time, and the starter is no exception. The most common reason for replacement is the appearance of clicks when turning the key. This phenomenon does not allow the engine to start. Another reason could be poor scrolling. When trying to start the internal combustion engine, you can observe that the mechanism is turning, but very weakly. In this case, it would be useful to check the battery.

Unusual noises (such as crackling noises) may occur. Such situations are quite simply determined.

Diagnostics

The main symptoms of a damaged starter:

- the device does not work after trying to start the engine;

- the electric motor does not turn off after starting the engine, but continues to rotate;

- The starter turns normally, but does not turn the crankshaft.

In any case, competent diagnosis implies excluding from the search area all other possible causes of such symptoms. First of all, you should check the integrity of the wiring from the battery to the starter. Then turn on the optical lights and signal - this is how the battery is checked, which, if faulty, is simply unable to provide normal light and sound. Next, the ignition switch and solenoid relay are tested. If these parts are in order, the starter will have to be removed from the car for repair or replacement.

One of the main symptoms of a faulty battery: a voltage drop during rotation - usually accompanied by dimming of the lighting in the car interior.

How to replace the starter

The simplest job is to replace the electric motor. For this you need to prepare the following tools:

- 13 mm and 15 mm socket heads;

- handle equipped with a “ratchet”;

- extension.

First of all, you will need to disconnect the negative terminal of the battery. This is necessary to ensure that no power is supplied to the electric motor. For ease of operation, the air filter housing should be removed. Next, follow the instructions:

- It is necessary to disconnect the power wires from the solenoid relay: remove the red chip and unscrew the retaining nut. Move the wires to the side to give yourself room to manipulate.

- Locate the nuts where the starter attaches to the transmission housing. Unscrew them to remove the electric motor. Most often, car enthusiasts miss the top nut, do not forget about it.

- Once you remove the last nut, the starter can be removed with bare hands.

If you do not want to repair this unit, you can replace the removed electric motor with a new one. However, in order not to waste extra money, we recommend that you first inspect the starter and repair it, if possible.

Required Tools

In order to carry out repairs yourself and replace the starter on a VAZ 2112, you need the tools from the table below.

Table - Tools required to replace the front strut

| Name | Note |

| open-end wrench | "at 13" |

| Spanner | "at 13" |

| Head | "at 15" |

| Ratchet | With extension |

| Rags and wire brush | To clean dirt |

| Penetrating lubricant | For example, WD-40 |

Removing and replacing the starter tens

Such a repair operation associated with replacing the VAZ 2110 starter, the price of which is quite high, is carried out in the following order:

- The negative contact from the battery (the so-called “ground”) is removed.

- De-energize the wiring of the traction type relay.

- Using a wrench set to “13”, release the positive contact of the starter.

- Unscrew the starter fasteners to the motor clutch housing.

- We dismantle the starter.

- Using a “10” socket, it is necessary to remove the fasteners of the output section of the traction type relay.

- Release the tip of the electrical wire.

- Using a socket head at “8”, remove the relay fasteners.

- Remove the sealing gasket between the relay and the front cover of the electric machine.

- We remove the spring and relay armature from the front cover.

- Assembly is carried out in reverse order.

After disassembling the starter, we begin to inspect it. On the Internet you can watch a video on replacing a VAZ 2110 starter, where all operations are shown in practice. This process starts with the anchor. If the collector becomes dirty or traces of burning are detected, it must be sanded with fine (“velvet”) sandpaper. If there is increased roughness or mica traces between the lamellas, it is necessary to “groove” the collector and carry out the same grinding course.

The anchor is replaced in the following cases:

- if the core beat exceeds 0.08 mm;

- if there is a yellow coating on the anchor shaft from bearing wear, it should be removed with a rag;

- in the presence of burrs and other irregularities;

- inspect the winding at the ends of the armature, the diameter of which should be less than the armature iron package;

- when testing the “control” of the armature winding. The contacts must be connected to the collector plate and the armature core, and no voltage should be supplied. Otherwise, when the lamp lights up, the winding or collector plate may short-circuit to ground.

The starter drive is replaced in the following cases:

- when the clutch is held, the gear receives free circular movement along the clock, and should not move against the clock;

- free movement of the drive along the splined grooves of the shaft;

- with significant wear of drive elements.

Timely replacement of the VAZ 2110 starter bushing will extend the time of effective operation of this electric unit. When inspecting the stator and detecting traces of the passage of the anchor element, it is necessary to change the feed cover and the intermediate type support.

general information

VAZ 2112 starter removal

As mentioned above, the starter provides current support due to permanent magnets. Producing a power of 1.55 kW, this element provides the starting frequency that is so necessary for the cylinders of the car’s power unit. Different motor types have different frequencies, but there is an average starting frequency. It is equal to 40-50 revolutions per minute, if we mean the operation of a gasoline engine, which is the VAZ 2112 engine.

Note. As a comparative example, diesel engines will require the starter to rev at 100-200 RPM.

Consists of the following components:

- Permanent magnets in the amount of 4 pieces. They are mounted inside the starter and perform one of the important missions.

- An anchor that rotates the flywheel, and with it the crankshaft of the car engine.

- Brush unit with 4 brushes. Two of the brushes are called positive, two are called negative. The brush assembly is designed to provide electrical connection.

Note. This assembly has been proven to be one of the least reliable parts of the starter. It is the brushes that are the first to be questioned when the stator is performing poorly and are subject to testing, followed by replacement.

- The planetary gearbox is the next component. It is also the most important element, as it is responsible for transmitting torque to the drive shaft. The gearbox itself consists of several gears that reliably perform their functions.

- A drive that is designed to insert the stator gear into connection with the engine flywheel. The mechanism of this drive is located on the armature shaft.

- Covers, front and back, which are cast mainly from aluminum, or rather from its alloy. The front cover is needed to mount the relay, which is connected to the drive through a plastic lever and ring. Brush holders are located on the back cover.

- Solenoid relay, also called traction relay. Thanks to this component, the drive gear meshes with the ring gear. As soon as the driver turns the key, voltage will not flow anywhere, but to the windings (holding/retracting) of this relay. As soon as the contact relay closes, the pull-in winding is switched off.

Note. It will be useful to know that 8V is the normal voltage of the traction relay, of course, if the ambient temperature is average. It is by this parameter that electricians determine the malfunction of this relay.

- Light weight and small dimensions, making it compact, are among the obvious advantages of this element.

- On the other hand, this is the most loaded part in the entire car system, because being small in size, it must spin the heavy flywheel of a strong car engine. In addition, the starter is also responsible for rotating the crankshaft along with connecting rods and pistons. Because of this drawback, the starter cannot serve for a long time and after a certain time (usually 5-6 years) fails.

Briefly, you can imagine the work of the starter. Through the ignition switch, power is supplied to the relay windings. The windings create an E.M.F. that is transmitted to the relay core. This, in turn, closes the power contacts, transferring power to the stator motor. At the same time, the relay influences the drive, which, with its gear, engages with the engine flywheel.

Note. To prevent reverse transmission of torque, the overrunning clutch disengages the rollers as soon as the machine's engine starts.

Replacing a starter in a VAZ 2112

The main symptoms of element malfunction are the following:

- The starter does not work (see VAZ starter repair - we do everything ourselves) after trying to start the power unit.

- The starter does not turn off when the engine has already started. It keeps spinning.

- The starter turns normally, but the engine does not start. The reason is that the crankshaft does not turn.

- While the car is moving, a characteristic noise and grinding noise is heard.

We make sure that the problem point in the car system is the starter:

- We check the reliability of the wires going from the battery to the starter. It is quite possible that they have a break or the contacts do not fit well.

- Turn on the signal and headlights if the wires are ok. The fact is that if the battery is weak and not fully charged, the problems described above with starting the engine may occur. If the headlights are dim and the signal is weak, then the battery is discharged.

- We remove the wires from the terminals of the ignition switch, if the battery is in order, and connect them together (these wires are marked on the car diagram with the numbers “30” and “50”). If the starter turns normally when the wires are briefly shorted, then the problem is in the ignition switch.

- If the lock is working properly and the starter still does not work, you can try connecting an additional wire to the relay plug and at the same time to the end of the battery positive wire. If the starter starts working, then there is clearly a malfunction in the circuit from the battery to the relay, which must be eliminated.

- If this does not help, you will have to remove the starter and check it.

So, the starter is not working well and you need to dismantle it to determine the severity of the malfunction with subsequent repair or replacement. Let's get started:

- Remove the negative wire from the battery.

- Now we disconnect the wire going to the traction relay.

- Using a 13mm wrench, unscrew the nut that holds the positive wire going from the battery to the starter.

VAZ 2112 remove starter

- The wire is removed.

- Now you need to unscrew the nuts that secure the starter to the clutch housing. To do this we use a key of 15.

- We remove the starter.

Replacing the starter on a VAZ 2112

Note. To avoid confusion when reinstalling the wires, it is recommended to mark them. For example, you can use separate pieces of wire of different colors for marking.

The starter has been removed. Now we need to disassemble it:

- Take a 10mm socket or wrench. Unscrew the nut on the relay and remove the wire going to the starter.

- We unscrew the relay bolts securing it to the starter with a wrench or a 8mm socket.

- Remove the starter relay.

- We see the gasket between the front cover and the relay, which we also remove.

- We dismantle the spring and armature.

- We dismantle the tie rod nuts.

- We remove the starter from the studs along with the anchor.

Where is the starter on a VAZ 2112 16 valves?

Dear visitors of the site “All about cars”! We will be very grateful to you for your comments on the video clip “Where is the starter on the VAZ 2112 16 valves”, registration is not required for this. We also ask you to let us know if you have any problems playing the video.

Well, what was the reason? Contact group or relay

What couldn’t be checked with a screwdriver? without removing the starter

the anchor burned out there after all, I still initially sinned on the solenoid relay

It would be useless, because I wouldn’t shoot another video because of this. It burned out completely.

The other day the starter also stopped working. VAZ 2114 was standard Belarusian. Didn't even bother with the repairs. I bought a new KOTEK for 3t. R. It starts with a click and buzzes like a bee. I advise everyone

I’m a teapot, where else can I put the air down if there’s no snowdrift nearby?

4. 28 than the reason

The battery must be disconnected before removing the air flow sensor chip, and not after. So you can burn it.

But I still didn’t take any risks and postponed the repairs until the winter, which I advise you to do as well.

The video needs to be renamed. The title does not match the content. How did you remove the bottom mount? The name of the video is repairing the starter or the reasons for the starter dying.

Before removing the MAF chip, you need to remove the terminal from the battery, otherwise you can then buy a new one.

Change the ignition switch, same thing happened.

Why show the left details, something like an air blower, it’s already clear to everyone what it looks like and how to shoot it….

What was the problem?

And I add. I plugged in the relay and everything worked for me. I connected the lamp to the red wire before - the current was flowing... But the current was weak. I still haven't found the ignition relay. Therefore, the most likely cause is the ignition switch. But this is a disease, as I understand it, in the tags. So it's better to add extra. relay. The current on the wires drops less and the chisel starts up faster now: There is really a possibility that the connector is simply stuck on the retractor. Emery solves this problem.

So what was the reason? What's next? -Egnition lock? -Wiring?

write why do you need to remove the hood lock wire? and how to unscrew the starter bolt from below if there is no pit, lift, or garage.

the importance is in the little things, but they are not there, what and how to unscrew is not said or shown, there is no point in the video, I filmed it for one, don’t make it accessible to everyone, there is so much garbage on the Internet

Starter device VAZ 2110 injector 8 valves

Lada 2110 8v tweet.

VAZ 2110 8 valve 2010.

VAZ 2110 engine injector for 14,500 rubles.

Advertisement for the sale of 8 valve engine VAZ 2110 / 2111 / 2112 in Saratov…

Logbook Lada 2110 is no longer stock). I decided to change the engine)

The ignition system of the 2110 engine is an injector.

Turbo VAZ 2110 8 valves.

VAZ 2110, 2002, 72 thousand km, 5500 USD

Buy injectors for VAZ 2110 8 valves.

The engine is in perfect condition, mileage after replacing rings and consumables is 234...

Lada 2110 8 valve.

VAZ 2110 2001 buy in Stavropol.

...VAZ 2109 Mechanical 2000 95000 km 1499 l 68/5600 Avito buy engine...

Buy VAZ 2110 1.6 8-valve Price 6300 USD

VAZ 2110 engine.

Control points of the VAZ 2110 body.

Photo VAZ 2110 8th grade.. engineer.

Selling very urgently VAZ 2110 16-cl injector overhaul of the engine in... mechanical...

Repair of VAZ 2110 8 valve engine with your own.

Selling VAZ 2110 1.5 engine 8 cl.

Repair of VAZ 2110 8 valve engine with your own.

VAZ 2110 8 class. 2005.

Replacement of valve oil seals for VAZ-2110, -2111 engines.

Do-it-yourself VAZ 2110 engine repair 8 valves injector video.

Selling a VAZ 2110 Injector, 8 valve in good condition.

Lada 2110 8 valves.

How to remove the ceiling trim on a VAZ 2110.

The VAZ 2110 engine is in excellent condition.

Original parts and their analogues: which is better

Despite the fact that this vehicle model ceased production more than 10 years ago, it is not difficult to purchase original starters made by AvtoVAZ. Moreover, their quality is not always higher than their analogues. Original part:

| Manufacturer's name | vendor code | Options | Cost, rubles |

| AvtoVAZ | 2112-3708010. | 9 bendix teeth 3 mounting bolts | From 4 000 |

There are many analogues on sale from a variety of manufacturers. The cost fluctuates quite significantly. The following manufacturers have proven themselves to be good:

| Manufacturer's name | vendor code | Options | Cost, rubles |

| StartVolt | 2110-3708010-00 | 1.5 kW | From 2 800 |

| KENO | KNV-3708010-31 | 2 kW | From 3 000 |

| ELPROM ELHOVO | ST2110E | 1.5 kW | From 3 100 |

Bosch starters have proven themselves to be good. This manufacturer carries out quality control. There is no chance of purchasing a product that does not work. It should also be noted that different manufacturers may produce parts of different sizes.

For example, the Bosch starter is slightly larger than the KEHO starter. The price of the part will vary significantly depending on the manufacturer. The difference between the dimensions can be seen in the photo. Larger parts will be difficult to install.

The principle of operation of the starter and its main elements

With the help of the starter, the primary rotation of the engine crankshaft begins until the power unit starts up due to the ignition of the oxygen-gasoline mixture. This electric machine is a constant current EDC with 4 brushes of a four-pole type, which initiates the excitation moment using permanently installed magnetic elements, so replacing the VAZ 2110 starter is necessary in case of its failure.

It includes a freely rotating roller-type clutch, a traction relay with 2 windings, and a planetary gearbox. The traction relay with 2 windings is the most significant element of the starter. With its help, the drive gear is brought into engagement with the rim of the motor flywheel. In addition, it determines how the starter motor receives power.

What is a starter

The VAZ-2110 is equipped with a starter with a gearbox, which has one advantage - it consumes less current. It is capable of ensuring rotation of the crankshaft even with a weak battery charge. Thanks to this feature, your car will start even in conditions where other models refuse to work. However, with prolonged use, the electric motor with gearbox may fail for no apparent reason. In this regard, starters without gearboxes are more advanced - they are easy to repair due to the simplicity of their design.

The electric motor on the VAZ-2110 consists of several elements:

- drive shaft;

- gear with inner ring;

- shaft support equipped with a liner;

- relay armature and its components (for example, core);

- winding;

- brushes;

- magnet.

The most worn element is the brushes. During operation, they wear out, which is why they need to be replaced. Brushes are sold separately.

Recommendations for “extending the life” of the trigger mechanism

Above, we studied the structure of the electric motor and the starting relay, and also answered the question of how to remove the starter on a VAZ 2110 with your own hands. Let's add to all this a number of recommendations for careful handling of this element - this will reduce the likelihood of part failure:

- Never spin the engine for more than 7-8 seconds.

- Wait at least 1 minute between attempts to start the engine.

- Always depress the clutch before starting - this will eliminate additional stress in the form of the clutch and the transmission input shaft.

- Fill the engine with engine oil appropriate for the season of operation - thick oil greatly increases the load on the starting mechanism.

If signs of a malfunction nevertheless appear, the first thing to do is stop trying to start the engine and figure out the cause, otherwise there is a high probability of complete failure of the mechanism. In such a case, it is better to spend time starting the car “from the pusher”.

VAZ 2110 starter repair

Having disassembled the starter, we begin an external inspection of the product. All repair actions begin with an inspection of the anchor, which, if dirt and traces of combustion get on it, requires cleaning and grinding with fine-grained sandpaper. If there is large scuffing of the armature surface or traces of mica in the interturn spaces, it is necessary to “grind” the collector and grind it.

The starter armature is replaced in the following cases:

- when the longitudinal runout of the core is more than 0.08 mm.

- If there are yellow crystals on the armature axis due to increased bearing wear, they must be removed with a rag.

- if irregularities and large roughness are identified.

- with a reduced diameter of the end armature winding identified during external inspection.

- when voltage is applied to the armature winding when checking with a “control” light bulb, which is connected to the collector plate and the armature core. It should not come, because... may cause a short circuit in the winding or commutator plate.

The starter drive is replaced in the following cases:

1. When holding the clutch, the gear receives free circular movement along the clock, and should not move against the clock. 2. Free movement of the drive along the splined grooves of the shaft. 3. If there is a lot of wear on the drive elements.

A timely replacement of the VAZ 2110 starter bushing will prolong the service life of this part and the entire electric machine as a whole. When diagnosing the starter visually and finding traces of the armature touching, you need to replace the rear starter casing and the intermediate support of the product.

The planned replacement of VAZ 2110 starter brushes is associated with wear of these parts when there are gaps of less than 3.5 mm between the final and operational surfaces. They must move without interference along the path of rotation.

When diagnosing the drive shaft, the operating part should not have a worn surface and no roughness. Traces of use of copper bushings should not be present, because Dust can cause the drive shaft to malfunction. The VAZ 2110 starter bendix, which engages with the engine flywheel and needs to be replaced if it rotates in two directions, is an important element of the electric machine that causes the flywheel of a gasoline engine to rotate.

Timely replacement of the starter relay is a guarantee of reliable operation of the vehicle's starting system, which can also be subject to repair work. When carrying out repairs, you should unscrew the housing fasteners and unsolder the relay winding leads, then remove the casing and use fine-grained sandpaper to process the contacts of the product and the front parts of the bolts.

If the surface of the bolts is severely burnt, you should turn them to a full angle, and then assemble the product. Installation of the starter should be carried out in the reverse order, lubricating all elements.

Bendix repair

Do-it-yourself Bendix starter repair is possible if the rollers are worn out first, or the source of the problem is contamination or frozen lubricant.

The Bendix is assembled by rolling, and the outer race of the clutch is made of durable metal. It is difficult to flare it, so the fastest way is to carefully cut through the clip with a grinder.

Having knocked the weakened clip off the Bendix, we remove the gear, rollers and springs from it. After washing the insides, we check the absence of deep nicks in the grooves of the coupling and on the gear shank.

We inspect the rollers: the surface should be cylindrical, without signs of wear. A replacement for the rollers can be found by disassembling a roller bearing of a suitable size (bearing parameters can be found in reference books). We stretch the weakened springs a couple of millimeters or select new ones.

After assembling the Bendix dry, we check its operation by turning the gear in the direction of jamming: the rollers should block the Bendix, after turning in the opposite direction, immediately release the gear.

Before assembly, add a medium-viscosity grease to the Bendix so that it does not thicken excessively in the cold. Moreover, there should be a minimum of lubrication: its task is to protect the insides of the coupling from corrosion; excessive lubrication only gets in the way.

Having put the clip in place, we fix the edges of the cut with spot welding. In this case, you cannot overheat the bendix; it is better to use a semi-automatic machine. We clean off the protruding weld so that it does not interfere with the movement of the bendix in the starter housing.

Operation of the VAZ 2110 family starter, faults and solutions Autosite

Technical characteristics of the starter for cars of the VAZ 2110 family Rated power, kW…………………………………………………………………………………..1.55 Current consumption at maximum power, no more , A………….375 Consumed

Technical characteristics of the starter for cars of the VAZ 2110 family Rated power, kW…………………………………………………………………………………..1.55 Current consumption at maximum power, no more than, A ………….375Current consumption in a braked state, no more than, A…………..700Current consumption at idle, no more, A…………………………….80

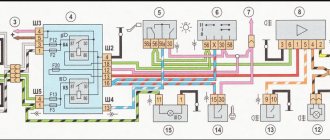

Features of the starter device type 57.3708 The starter type 57.3708 installed on VAZ 2110, VAZ 2111, VAZ 2112 cars (Fig. 7-15) is a direct current electric motor with excitation from permanent magnets, with a planetary gearbox and an electromagnetic two-winding traction relay. Covers 2, 6 and stator housing 3 are tightened with two studs. The armature shaft 23 rotates in two metal-ceramic liners installed in the cover 2 and support 21. Four permanent magnets 22 are fixed in the stator housing.

Rotation from the armature shaft 23 is transmitted to the drive shaft 14 through a planetary gearbox, which consists of a central gear 20, three planetary gears 10, a carrier 19 and an internal gear 18. Planetary gears rotate on needle bearings. The starter connection diagram type 57.3708 for VAZ 2110, VAZ 2111, VAZ 2112 cars is shown in Fig. 7-16. When the starter is turned on, the voltage from the battery is supplied through the ignition switch to both windings of the starter traction relay (retractor II and retainer I).

general information

VAZ 2112 starter removal

As mentioned above, the starter provides current support due to permanent magnets. Producing a power of 1.55 kW, this element provides the starting frequency that is so necessary for the cylinders of the car’s power unit. Different motor types have different frequencies, but there is an average starting frequency. It is equal to 40-50 revolutions per minute, if we mean the operation of a gasoline engine, which is the VAZ 2112 engine.

Note. As a comparative example, diesel engines will require the starter to rev at 100-200 RPM.

Consists of the following components:

- Permanent magnets in the amount of 4 pieces. They are mounted inside the starter and perform one of the important missions.

- An anchor that rotates the flywheel, and with it the crankshaft of the car engine.

- Brush unit with 4 brushes. Two of the brushes are called positive, two are called negative. The brush assembly is designed to provide electrical connection.

Note. This assembly has been proven to be one of the least reliable parts of the starter. It is the brushes that are the first to be questioned when the stator is performing poorly and are subject to testing, followed by replacement.

- The planetary gearbox is the next component. It is also the most important element, as it is responsible for transmitting torque to the drive shaft. The gearbox itself consists of several gears that reliably perform their functions.

- A drive that is designed to insert the stator gear into connection with the engine flywheel. The mechanism of this drive is located on the armature shaft.

- Covers, front and back, which are cast mainly from aluminum, or rather from its alloy. The front cover is needed to mount the relay, which is connected to the drive through a plastic lever and ring. Brush holders are located on the back cover.

- Solenoid relay, also called traction relay. Thanks to this component, the drive gear meshes with the ring gear. As soon as the driver turns the key, voltage will not flow anywhere, but to the windings (holding/retracting) of this relay. As soon as the contact relay closes, the pull-in winding is switched off.