Someone needs to calculate the power of the engine unit in order to calculate the car tax. For some, it is important to independently calculate the power of the compressor engine. For some, it is important to know exactly the power of the machine in order to compare it with the one that was declared. In general, power calculation and engine selection are two inseparable processes.

These are not the only reasons why car enthusiasts try to independently calculate the engine power of their cars. This is quite difficult to do without the necessary formulas for calculation. They will be presented in this article so that every motorist can calculate for himself how much the real engine power of his car is.

You might be interested in: Expanding your vocabulary: a guest is...

Introduction

There are at least four common ways to calculate the power of an internal combustion engine. These methods use the following parameters of the propulsion unit:

- Revolutions.

- Volume.

- Torque.

- Effective pressure inside the combustion chamber.

- quality of the fuel mixture;

- combustion completeness;

- fuel losses.

For calculations, you need to know the weight of the car, as well as the acceleration time to 100 km/h.

Each of the following formulas for calculating engine power has some error and cannot give a 100% accurate result. This should always be taken into account when analyzing the data obtained.

If you calculate the power using all the formulas that will be described in the article, you can find out the average value of the actual engine power, and the discrepancy with the actual result will be no more than 10%.

You might be interested in: How to find the product of matrices. Matrix multiplication. Dot product of matrices. Product of three matrices

If we do not take into account various scientific subtleties associated with the definition of technical concepts, we can say that power is the energy generated by the motor unit and converted into torque on the shaft. In this case, power is not a constant quantity, and its maximum value is achieved at a certain shaft rotation speed (indicated in the passport data).

In modern internal combustion engines, maximum power is achieved at 5.5-6.6 thousand revolutions per minute. It is observed at the highest average effective pressure in the cylinders. The magnitude of this pressure depends on the following parameters:

Power, as a physical quantity, is measured in Watts, and in the automotive industry it is measured in horsepower. The calculations described in the methods below will give results in kilowatts, then they will need to be converted to horsepower using a special converter calculator.

Calculation of injector performance

Injectors are spray parts that supply fuel to the cylinders of the internal combustion engine. The nature of the injectors’ operation directly affects the engine’s operating format, so the engine power can be calculated based on the performance of the injectors.

The following complex formula is used for calculations:

M = (PF x CF x SC)/(CT x TD)

- PF is the performance of 1 injector. This parameter is usually indicated in the technical documentation for the engine (although in the case of a new car, this information can be found from the on-board computer).

- KF is the number of injectors. This parameter can also be found from the technical documentation or using the on-board computer.

- KZ - injector load factor. For most passenger cars this parameter is equal to 0,75-0,8.

- TT - type of fuel mixture. For highly purified gasoline, this coefficient is usually 12-13.

- TD is a type of engine. For an atmospheric engine this parameter is 0.4-0.5, for a turbo engine - 0.6-0.7.

This calculation method is quite inaccurate, since the formula contains many correction factors, many of which do not have an exact digital expression. Therefore, the real power may differ from the formula power by 10-15% (however, this is a small error).

Power via torque

You might be interested in: What does it mean to be stupefied? Definition and synonyms

One way to calculate power is to determine the dependence of motor torque on the number of revolutions.

Any moment in physics is the product of a force and the shoulder of its application. Torque is the product of the force that the engine can develop to overcome the resistance of the load and the shoulder of its application. It is this parameter that determines how quickly the motor reaches its maximum power.

Torque can be defined as the ratio of the product of the working volume and the average effective pressure in the combustion chamber to 0.12566 (constant):

- M = (Vworking * Peffective)/0.12566, where Vworking is the working volume of the engine [l], Peffective is the effective pressure in the combustion chamber [bar].

Engine speed characterizes the speed of rotation of the crankshaft.

Using the values of torque and engine speed, you can use the following formula to calculate engine power:

- P = (M * n)/9549, where M – torque [Nm], n – shaft rotation speed [rpm], 9549 – proportionality coefficient.

The calculated power is measured in kilowatts. To convert the calculated value into horsepower, you need to multiply the result by a proportionality coefficient of 1.36.

This method of calculation consists of using only two elementary formulas, therefore it is considered one of the simplest. True, you can do it even simpler and use an online calculator, into which you need to enter certain data about the car and its engine unit.

It is worth noting that this formula for calculating engine power allows you to calculate only the power that is obtained at the output of the engine, and not that which actually reaches the wheels of the car. What is the difference? While the power (if you imagine it as a flow) reaches the wheels, it experiences losses in the transfer case, for example. Secondary consumers such as an air conditioner or generator also play a significant role. It is impossible not to mention the losses due to overcoming resistance to lifting, rolling, and aerodynamic resistance.

This disadvantage is partially compensated by the use of other calculation formulas.

What is the difference between the rated power of an electric generator and the maximum?

The power of an electric generating set is one of the main operational and technical characteristics that are of primary interest to the buyer. It is this that reflects the ability of this model of electric generator to provide power to electrical appliances in the required volume. However, in the technical documentation provided, manufacturers indicate two values related to the power of the equipment produced - nominal and maximum. How do they differ, and which one has the greatest practical value?

When choosing an electric generator, it is recommended to base it on the rated power indicator, since it is its value that is declared by the manufacturer as a design characteristic throughout the entire period of operation. Maximum power is the parameter allowed during peak loads, and continuous operation under such conditions leads to excessive wear on the equipment and its premature failure.

Determining the required power of an electric generator directly depends on the maximum total value of the corresponding parameters of each of the electrical appliances, the simultaneous inclusion of which is possible at a given time. And this figure should in no case exceed the rated power of the generator declared by the manufacturer. At the same time, when choosing an electric generator, you should also take into account the possibility of increasing the volume of electricity consumed in the future. This reserve will allow additional new devices to be connected to the existing network, powered by a proven and proven generator.

- Model: WELDARC 300 TDE XL C

- Power: 6 kW

- RUB 592,996

- Model: Weldarc 180 DE C

- Power: 3.6 kW

- RUB 330,524

- Model: WELDARC 200

- Power: 3.6 kW

- RUB 186,425

Selecting a generator by power

When choosing a generator, the consumer pays attention to various installation parameters - weight, service life, mobility, availability of additional functionality, price, etc. But first of all, you need to choose an installation based on its power. How to correctly calculate this indicator and what to pay attention to?

To make it clearer, let's look at this situation using a simple example. Let's say we have the following household appliances: a vacuum cleaner, a heater, a freezer. The power of these household appliances is 1 kW, 2 kW and 0.3 kW, respectively. It turns out that in order to ensure the operation of these devices, we need a generator with a power of at least 3 kW. To understand this, let's understand the concept of rated power of the generator.

The nominal, or, as it is also called, the real power of the installation, differs significantly from the maximum. In technical documentation, manufacturers most often indicate the maximum power ratings for a given generator model. It is worth noting that with such a load the installation can operate for a very short time without critical consequences - in some cases it is seconds, sometimes 1-2 minutes. At the same time, the real or rated power is slightly lower than the maximum. To calculate it, the power factor cos φ is required. This indicator is determined by the ratio of active power to total power.

Example

Let's say we have a generator with a power rating of 3 kVA and cos φ equal to 0.8. In this case, the rated power of this installation will be equal to:

3 kVA x 0.8=2.4 (kW)

Now you can understand why power can be indicated in certain units of measurement, in watts (W) or Volt Amperes (VA). Some manufacturers, in order to save the consumer from the need to carry out calculations, simply indicate in the accompanying documentation both power values - nominal and maximum. There are also options when the manufacturer indicates only one of the capacities and gives the value of the power factor. Some unscrupulous companies may hide the power factor from the consumer. This is done in order to pass off the generator as a more powerful unit than it actually is.

Power via engine displacement

It is not always possible to determine the engine torque. Sometimes car owners do not even know the meaning of this parameter. In this case, the power of the engine unit can be determined using the engine volume.

To do this, you will need to multiply the volume of the unit by the crankshaft speed, as well as by the average effective pressure. The resulting value must be divided by 120:

- P = (V * n * Peffective)/120 where V – engine volume [cm3], n – crankshaft rotation speed [rpm], Peffective – average effective pressure [MPA], 120 – constant, proportionality coefficient.

This is how the power of a car engine is calculated using the volume of the unit.

Most often, the Peffective value in standard gasoline engines varies from 0.82 MPa to 0.85 MPa, in forced engines - 0.9 MPa, and in diesel units the pressure value ranges from 0.9 MPa to 2.5 MPa.

You will be interested: “Unexpected” - what is it? Meaning of the word

When using this formula to calculate the actual power of the motor, to convert kW to hp. s., it is necessary to divide the resulting value by a coefficient equal to 0.735.

This calculation method is also far from the most complicated and takes a minimum of time and effort.

Using this method, you can calculate the power of the pump motor.

How much horsepower is in a car?

These parameters differ for each car brand.

The difference between the indicators is quite significant. The passport of each car indicates the power in kilowatts. Power table of different cars

| Name | Engine capacity | Power in kW | Horsepower |

| Niva | 1.7 l. | 58 | 79 |

| Nissan micra | 1 l. | 48 | 65 |

| Volkswagen Golf | 2 l. | 155 | 210 |

Power via air flow

The power of the unit can also be determined by air flow. True, this calculation method is available only to those car owners who have an on-board computer installed, which allows them to record air consumption at 5.5 thousand revolutions in third gear.

To obtain the approximate engine power, it is necessary to divide the flow rate obtained under the conditions described above by three. The formula looks like this:

- P = G/3, where G is air flow.

This calculation characterizes engine operation under ideal conditions, that is, without taking into account losses on the transmission, third-party consumers and aerodynamic resistance. The actual power is 10 or even 20% lower than calculated.

Accordingly, the amount of air flow is determined in laboratory conditions on a special stand on which the car is installed.

The readings of on-board sensors are highly dependent on their contamination and calibration.

Therefore, calculating engine power based on air flow data is far from the most accurate and efficient, but it is quite suitable for obtaining approximate data.

Practical measurements

The most accessible way is to check the readings of your household electricity meter. First, you should turn off absolutely all household appliances and turn off the lights in all rooms, since even a burning 40W light bulb will distort the readings. Make sure that the counter does not spin or the indicator does not blink (depending on its model). You are lucky if you have a Mercury meter - it shows the load value in kW, so you only need to turn on the engine for 5 minutes at full power and check the readings.

Induction meters record in kW/h. Record the readings before turning on the engine, let it run for exactly 10 minutes (it is better to use a stopwatch). Take new meter readings and find out the difference by subtraction. Multiply this figure by 6. The resulting result displays the engine power in kW.

If the engine is low-power, calculating the parameters will be somewhat more difficult. Find out how many revolutions (or pulses) are equal to 1 kWh - you will find the information on the meter. Let's say it's 1600 rpm (or indicator flashes). If the meter makes 20 revolutions per minute when the engine is running, multiply this figure by 60 (the number of minutes in an hour). This turns out to be 1200 rpm. Divide 1600 by 1200 (1.3) - this is the engine power. The result is more accurate the longer you measure the readings, but a small error is still present.

Power through the mass of the car and acceleration time to “hundreds”

Calculation using the weight of the car and its acceleration speed to 100 km/h is one of the simplest methods for calculating the real engine power, because the weight of the car and the stated acceleration time to “hundreds” are the vehicle’s passport parameters.

This method is relevant for engines running on any type of fuel - gasoline, diesel fuel, gas - because it only takes into account the dynamics of acceleration.

When calculating, it is worth taking into account the weight of the vehicle along with the driver. Also, in order to bring the calculation result as close as possible to the actual one, it is worth taking into account the losses spent on braking, slipping, as well as the reaction speed of the gearbox. The type of drive also plays a role. For example, front-wheel drive cars lose about 0.5 seconds at the start, rear-wheel drive cars lose from 0.3 to 0.4 seconds.

All that remains is to find a calculator on the Internet to calculate the power of a car through acceleration speed, enter the necessary data and get an answer. There is no point in presenting the mathematical calculations that the calculator makes because of their complexity.

The result of the calculations will be one of the most accurate, close to the real one.

This method of calculating the real power of a car is considered by many to be the most convenient, because car owners will have to make a minimum of effort - to measure the acceleration speed of up to 100 km/h for the purity of the experiment and enter additional data into an automatic calculator.

Other engine types

It is no secret that engines are used not only in cars, but also in industry and even in everyday life. Motors of different sizes can be found in factories - driving shafts - and also in household appliances such as automatic meat grinders.

Sometimes it is necessary to calculate the real power of such engines. How to do this is described below.

It is worth immediately noting that the power of a 3-phase motor can be calculated as follows:

- P = Mtorque * n, where Mtorque is the torque and n is the shaft rotation speed.

Asynchronous motor

An asynchronous unit is a device whose peculiarity is that the rotational speed of the magnetic field created by its stator is always greater than the rotational speed of its rotor.

The operating principle of an asynchronous machine is similar to the operating principle of a transformer. The laws of electromagnetic induction are applied (the time-varying flux linkage of the winding induces an EMF in it) and Ampere (an electromagnetic force acts on a conductor of a certain length through which a current flows in a field with a certain induction value).

An asynchronous motor generally consists of a stator, rotor, shaft and support. The stator includes the following main components: winding, core, housing. The rotor consists of a core and a winding.

The main task of an asynchronous motor is to convert electrical energy, which is supplied to the stator winding, into mechanical energy, which can be removed from the rotating shaft.

Asynchronous motor power

In the technical field of science, there are three types of power:

- full (denoted by the letter S);

- active (denoted by the letter P);

- reactive (denoted by the letter Q).

The total power can be represented as a vector that has a real and an imaginary part (it is worth recalling the section of mathematics associated with complex numbers).

The real part represents the active power, which is expended to perform useful work such as rotating a shaft, as well as to generate heat.

The imaginary part is expressed by reactive power, which takes part in the creation of magnetic flux (denoted by the letter F).

It is the magnetic flux that underlies the operating principle of an asynchronous unit, a synchronous motor, a DC machine, and a transformer.

Reactive power is used to charge capacitors, creating a magnetic field around the chokes.

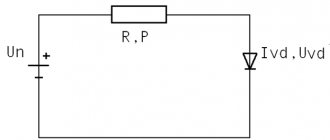

Active power is calculated as the product of current with voltage and power factor:

- P = I * U * cosφ.

Reactive power is calculated as the product of current with voltage and power factor, phase shifted by 90°. Otherwise you can write:

- Q = I * U * sinφ.

The value of the total power, if we remember that it can be represented as a vector, can be calculated using the Pythagorean theorem as the root of the sum of the squares of active and reactive power:

- S = (P2+Q2)1/2.

If we calculate the formula for total power in general form, it turns out that S is the product of current and voltage:

- S = I * U.

Power factor cosφ is a value numerically equal to the ratio of the active component to the total power. To find sinφ, knowing cosφ, you need to calculate the value of φ in degrees and find its sine.

This is a standard calculation of motor power by current and voltage.

You might be interested in: Knowledge Engineering. Artificial intelligence. Machine learning

What are kilowatts (kW)

Watt is the SI unit of power, named after the inventor J. Watt, who created the universal steam engine. The watt was adopted as a unit of power during the 2nd Congress of the Scientific Association of Great Britain in 1889. Previously, horsepower, which was introduced by J. Watt, was mainly used for calculations, less often - foot-pounds/min. The 19th General Conference of Measures in 1960 decided to include Watt in the SI.

One of the main parameters of any electrical device is the power it consumes. For this reason, on each electrical device (or in the instructions supplied with it) you can read data on the number of watts that are required for the operation of the device.

1 Watt is a unit of power that allows you to perform 1 J of work within 1 second.

It is not just mechanical power that is distinguished. Thermal and electrical power are also known. 1 Watt of heat flow is equivalent to 1 Watt of mechanical power. 1 Watt for electrical power is equivalent to 1 Watt for mechanical power and is essentially the power of a direct electric current of 1 A, which does work at a voltage of 1 V.

Calculation of the power of a 3-phase asynchronous unit

To calculate the net power on the stator winding of an asynchronous 3-phase motor, you should multiply the phase voltage by the phase current and by the power factor, and multiply the resulting power value by three (by the number of phases):

- Pstator = 3 * Uph * Iph * cosφ.

Electric power calculation engine, which is active in nature, that is, the power that is removed from the engine shaft is produced as follows:

- Poutput = Pstator – Ploss.

The following losses occur in an asynchronous motor:

- electrical in the stator winding;

- in the steel of the stator core;

- electrical in the rotor winding;

- mechanical;

- additional.

To calculate the power of a three-phase motor in the stator winding, which is reactive in nature, it is necessary to add up three components of this type of power, namely:

- reactive power consumed to create stator winding leakage flux;

- reactive power consumed to create leakage flux in the rotor winding;

- reactive power consumed to create the main flow.

Reactive power in an asynchronous motor is mainly spent on creating an alternating electromagnetic field, but part of the power is spent on creating leakage fluxes. Leakage fluxes weaken the main magnetic flux and reduce the efficiency of the asynchronous unit.

Power by current

Calculation of the power of an asynchronous motor can be done using current data. To do this, follow these steps:

Power can always be calculated as the product of current and voltage. In this case, it is important to know which values of U and I should be taken. In this case, U is the supply voltage, it is a constant value, and I can vary depending on which winding (stator or rotor) the current is measured, so it is necessary to select its average value.

How to determine the power of an electric motor?

If there is no technical certificate or tag on the engine, the question arises: how to find out the power of an electric motor without a plate or technical documentation? The most common and fastest methods, which we will discuss in the article:

- According to shaft diameter and length

- By dimensions and mounting dimensions

- By winding resistance

- By no-load current

- By current in the terminal box

- Using an induction meter (for household electric motors)

Determining engine power by shaft diameter and length

The simplest ways to determine the power and brand of an engine are the overall dimensions - shaft or mounting holes. The table shows the lengths and diameters of the shafts (D1) and length (L1) for each model of an asynchronous industrial three-phase motor. Go to detailed overall dimensions of AIR electric motors

| R, kW | 3000 rpm Min | 1500 rpm min | 1000 rpm min | 750 rpm min | ||||

| D1, mm | L1, mm | D1, mm | L1, mm | D1, mm | L1, mm | D1, mm | L1, mm | |

| 1,5 | 22 | 50 | 22 | 50 | 24 | 50 | 28 | 60 |

| 2,2 | 24 | 28 | 60 | 32 | 80 | |||

| 3 | 24 | 32 | 80 | |||||

| 4 | 28 | 60 | 28 | 60 | 38 | |||

| 5,5 | 32 | 80 | 38 | |||||

| 7,5 | 32 | 80 | 38 | 48 | 110 | |||

| 11 | 38 | 48 | 110 | |||||

| 15 | 42 | 110 | 48 | 110 | 55 | |||

| 18,5 | 55 | 60 | 140 | |||||

| 22 | 48 | 55 | 60 | 140 | ||||

| 30 | 65 | |||||||

| 37 | 55 | 60 | 140 | 65 | 75 | |||

| 45 | 75 | 75 | ||||||

| 55 | 65 | 80 | 170 | |||||

| 75 | 65 | 140 | 75 | 80 | 170 | |||

| 90 | 90 | |||||||

| 110 | 70 | 80 | 170 | 90 | ||||

| 132 | 100 | 210 | ||||||

| 160 | 75 | 90 | 100 | 210 | ||||

| 200 | ||||||||

| 250 | 85 | 170 | 100 | 210 | ||||

| 315 | — | — |

Check power by dimensions and mounting dimensions

Table for selecting engine power based on mounting holes on the feet (L10 and B10):

| R, kW | 3000 rpm | 1500 rpm | 1000 rpm | 750 rpm | ||||

| L10, mm | B10, mm | L10, mm | B10, mm | L10, mm | B10, mm | L10, mm | B10, mm | |

| 1,5 | 100 | 125 | 100 | 125 | 125 | 140 | 140 | 160 |

| 2,2 | 125 | 140 | 140 | 160 | 190 | |||

| 3 | 125 | 140 | 112 | 160 | 190 | |||

| 4 | 112 | 160 | 140 | 216 | ||||

| 5,5 | 140 | 190 | 216 | 178 | ||||

| 7,5 | 190 | 216 | 178 | 254 | ||||

| 11 | 178 | 216 | 178 | 254 | 210 | |||

| 15 | 254 | 254 | 210 | 241 | 279 | |||

| 18,5 | 210 | 210 | 241 | 279 | 267 | 318 | ||

| 22 | 203 | 279 | 203 | 279 | 267 | 318 | 310 | |

| 30 | 241 | 241 | 310 | 311 | 356 | |||

| 37 | 267 | 318 | 267 | 318 | 311 | 356 | 406 | |

| 45 | 310 | 310 | 406 | 349 | ||||

| 75 | 311 | 406 | 311 | 406 | 368 | 457 | 419 | 457 |

| 90 | 349 | 349 | 419 | 406 | 508 | |||

| 110 | 368 | 457 | 368 | 457 | 406 | 508 | 547 | |

| 132 | 419 | 419 | 457 | 610 | 355 | |||

| 160 | 406 | 508 | 406 | 508 | 610 | 355 | ||

| 200 | 457 | 457 | 560 | 610 | ||||

| 250 | 610 | 355 | 610 | 355 | 560 | 610 | ||

| 315 | 630/800 | 686/630 | — | — |

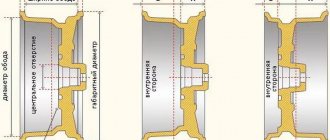

For flanged motors

Table for selecting electric motor power by flange diameter (D20) and flange mounting hole diameter (D22)

| P, kW | 3000 rpm | 1500 rpm | 1000 rpm | 750 rpm | ||||

| D20, mm | D22, mm | D20, mm | D22, mm | D20, mm | D22, mm | D20, mm | D22, mm | |

| 1,5 | 165 | 11 | 165 | 11 | 215 | 14 | 215 | 14 |

| 2,2 | 215 | 14 | 265 | |||||

| 3 | 215 | 14 | 365 | |||||

| 4 | 265 | 300 | 19 | |||||

| 5,5 | 265 | 300 | 19 | |||||

| 7,5 | 265 | 300 | 19 | |||||

| 11 | 300 | 19 | ||||||

| 15 | 350 | |||||||

| 18,5 | 350 | 400 | ||||||

| 22 | 350 | 350 | 400 | |||||

| 30 | 500 | |||||||

| 37 | 400 | 400 | 500 | |||||

| 45 | 400 | |||||||

| 55 | 500 | 500 | 550 | 24 | ||||

| 75 | 500 | 550 | 24 | |||||

| 90 | 500 | 28 | ||||||

| 110 | 550 | 24 | 550 | 24 | 28 | |||

| 132 | 550 | 680 | ||||||

| 160 | 550 | 28 | 28 | 680 | ||||

| 200 | 550 | 740 | 24 | |||||

| 250 | 680 | 680 | 740 | 24 | — | |||

| 315 | 680 | — |

Current calculation

The electric motor is connected to the network and the voltage is measured. Using an ammeter, we alternately measure the current in the circuit of each of the stator windings. We multiply the sum of consumed currents by a fixed voltage. The resulting number is the power of the electric motor in watts.

How to check the power of an electric motor by no-load current

You can check the power by no-load current using the table.

| Engine P, kW | No-load current (% of rated) | ||||

| Engine speed, rpm | |||||

| 600 | 750 | 1000 | 1500 | 3000 | |

| 0,75-1,5 | 85 | 80 | 75 | 70 | 50 |

| 1,5-5,5 | 80 | 75 | 70 | 65 | 45 |

| 5,5-11 | 75 | 70 | 65 | 60 | 40 |

| 15-22,5 | 70 | 65 | 60 | 55 | 30 |

| 22,5-55 | 65 | 60 | 55 | 50 | 20 |

| 55-110 | 55 | 50 | 45 | 40 | 20 |

Calculation based on winding resistance

Star connection.

We measure the resistance between the terminals (1-2, 2-3, 3-1). Divide by 2 - we get the resistance of one winding. The power of one winding is calculated as follows: P=(220V*220V)/R. We multiply the figure by 3 (the number of windings) - we get the engine power.

Delta connection.

We measure the resistance at the beginning and end of each winding. Using the same formula, we determine the power and multiply by 6.

Article about diagrams for connecting electric motors to the network

If it is not possible to determine the engine power yourself

We still recommend entrusting the determination of electric motor power or selection to professionals. This will significantly save your time and allow you to avoid annoying mistakes in operating the equipment. Service - professional selection of motors, troubleshooting, major and current repairs and rewinding of electric motors of any type and any power. Trust the professionals.

Source: https://slemz.com.ua/news/kak-opredelit-moshchnost-elektrodvigatelya

Power by size

The stator has many different components, one of which is the core. To calculate engine power using dimensions, follow these steps:

It is better to carry out all measurements and calculations with maximum accuracy so that the calculation of the power of the electric drive motor is as close to reality as possible.

Table for translation l. With. in kW

To calculate the motor power in kW, you need to use the proportion 1 kW = 1.3596 hp. With . Its reverse form: 1 l. With. = 0.73549875 kW. This is how these two units are mutually converted into each other.

| kW | hp | kW | hp | kW | hp | kW | hp | kW | hp | kW | hp | kW | hp |

| 1 | 1.36 | 30 | 40.79 | 58 | 78.86 | 87 | 118.29 | 115 | 156.36 | 143 | 194.43 | 171 | 232.50 |

| 2 | 2.72 | 31 | 42.15 | 59 | 80.22 | 88 | 119.65 | 116 | 157.72 | 144 | 195.79 | 172 | 233.86 |

| 3 | 4.08 | 32 | 43.51 | 60 | 81.58 | 89 | 121.01 | 117 | 160.44 | 145 | 197.15 | 173 | 235.21 |

| 4 | 5.44 | 33 | 44.87 | 61 | 82.94 | 90 | 122.37 | 118 | 160.44 | 146 | 198.50 | 174 | 236.57 |

| 5 | 6.80 | 34 | 46.23 | 62 | 84.30 | 91 | 123.73 | 119 | 161.79 | 147 | 199.86 | 175 | 237.93 |

| 6 | 8.16 | 35 | 47.59 | 63 | 85.66 | 92 | 125.09 | 120 | 163.15 | 148 | 201.22 | 176 | 239.29 |

| 7 | 9.52 | 36 | 48.95 | 64 | 87.02 | 93 | 126.44 | 121 | 164.51 | 149 | 202.58 | 177 | 240.65 |

| 8 | 10.88 | 37 | 50.31 | 65 | 88.38 | 94 | 127.80 | 122 | 165.87 | 150 | 203.94 | 178 | 242.01 |

| 9 | 12.24 | 38 | 51.67 | 66 | 89.79 | 95 | 129.16 | 123 | 167.23 | 151 | 205.30 | 179 | 243.37 |

| 10 | 13.60 | 39 | 53.03 | 67 | 91.09 | 96 | 130.52 | 124 | 168.59 | 152 | 206.66 | 180 | 144.73 |

| 11 | 14.96 | 40 | 54.38 | 68 | 92.45 | 97 | 131.88 | 125 | 169.95 | 153 | 208.02 | 181 | 246.09 |

| 12 | 16.32 | 41 | 55.74 | 69 | 93.81 | 98 | 133.24 | 126 | 171.31 | 154 | 209.38 | 182 | 247.45 |

| 13 | 17.67 | 42 | 57.10 | 70 | 95.17 | 99 | 134.60 | 127 | 172.67 | 155 | 210.74 | 183 | 248.81 |

| 14 | 19.03 | 43 | 58.46 | 71 | 96.53 | 100 | 135.96 | 128 | 174.03 | 156 | 212.10 | 184 | 250.17 |

| 15 | 20.39 | 44 | 59.82 | 72 | 97.89 | 101 | 137.32 | 129 | 175.39 | 157 | 213.46 | 185 | 251.53 |

| 16 | 21.75 | 45 | 61.18 | 73 | 99.25 | 102 | 138.68 | 130 | 176.75 | 158 | 214.82 | 186 | 252.89 |

| 17 | 23.9 | 46 | 62.54 | 74 | 100.61 | 103 | 140.04 | 131 | 178.9 | 159 | 216.18 | 187 | 254.25 |

| 18 | 24.47 | 47 | 63.90 | 75 | 101.97 | 104 | 141.40 | 132 | 179.42 | 160 | 217.54 | 188 | 255.61 |

| 19 | 25.83 | 48 | 65.26 | 76 | 103.33 | 105 | 142.76 | 133 | 180.83 | 161 | 218.90 | 189 | 256.97 |

| 20 | 27.19 | 49 | 66.62 | 78 | 106.05 | 106 | 144.12 | 134 | 182.19 | 162 | 220.26 | 190 | 258.33 |

| 21 | 28.55 | 50 | 67.98 | 79 | 107.41 | 107 | 145.48 | 135 | 183.55 | 163 | 221.62 | 191 | 259.69 |

| 22 | 29.91 | 51 | 69.34 | 80 | 108.77 | 108 | 146.84 | 136 | 184.91 | 164 | 222.98 | 192 | 261.05 |

| 23 | 31.27 | 52 | 70.70 | 81 | 110.13 | 109 | 148.20 | 137 | 186.27 | 165 | 224.34 | 193 | 262.41 |

| 24 | 32.63 | 53 | 72.06 | 82 | 111.49 | 110 | 149.56 | 138 | 187.63 | 166 | 225.70 | 194 | 263.77 |

| 25 | 33.99 | 54 | 73.42 | 83 | 112.85 | 111 | 150.92 | 139 | 188.99 | 167 | 227.06 | 195 | 265.13 |

| 26 | 35.35 | 55 | 74.78 | 84 | 114.21 | 112 | 152.28 | 140 | 190.35 | 168 | 228.42 | 196 | 266.49 |

| 27 | 36.71 | 56 | 76.14 | 85 | 115.57 | 113 | 153.64 | 141 | 191.71 | 169 | 229.78 | 197 | 267.85 |

| 28 | 38.07 | 57 | 77.50 | 86 | 116.93 | 114 | 155.00 | 142 | 193.07 | 170 | 231.14 | 198 | 269.56 |