The stabilizer link is one of the parts of the chassis system, designed to ensure lateral stability of the car body. Every car owner should know about the main malfunctions of stabilizer struts , how to check them, and also replace the strut. This is necessary to carry out timely repairs so that other, more important suspension elements do not fail due to the strut.

Also, many car owners are interested in the question of which racks to choose? Which manufacturer should you prefer? At the end of the article you will find a short summary based on real reviews from car enthusiasts who have used certain stabilizer struts. We will tell you about this and more in this material.

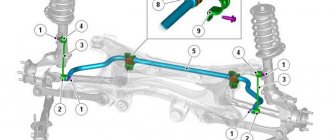

Stabilizer link diagram

What is a stabilizer link

Many, especially novice, car owners are interested in the question - stabilizer struts, what are they ? To begin with, let us describe in a nutshell what a stabilizer itself is and why it is needed. So, a stabilizer bar is needed to reduce the horizontal roll of the car body during turns and various deviations in the horizontal plane. And the stabilizer struts serve to attach the latter to the car body. It provides a movable connection between the elastic stabilizer and the hub or steering knuckle due to the existing hinges. Depending on the design, the suspension and struts may be different.

Various types of anti-roll bars

We identify all problems ourselves

It has already been said here that the most unreliable, most “fragile” part of the stabilizer is the struts. This is done on purpose so that in the event of an accident, the least damage can be caused. Let's name the main symptom accompanying the breakdown of stabilizer struts or rods. This is a dull knock that occurs when driving over any irregularities, potholes and even small stones. And sometimes the car begins to roll out of the roll worse - conclude that one of the struts has already been torn off. But knocking will be observed in 90% of cases! It can come from both the front and rear suspension.

Let's say there is a bushing in the design of the stabilizer struts (photo 2 in Chapter 2). It will then be more difficult to identify the defect: even if the bushing is destroyed, knocking does not always occur. More often the sound will be muffled, quiet, and generally difficult to hear.

Creaks and crunches, especially when cornering, usually indicate the destruction of the boot. But the defect itself, we repeat once again, is rare. The hinge shown in the photo will begin to deteriorate over time. And the creak should then turn into a grinding sound.

Ball joints inside the struts

Design and operation of racks

As a rule, a stand is a rod 5...20 cm long. At both ends there are hinges that provide a movable connection. These can be either two ball joints, or a joint and a stabilizer bushing, or two bushings, or a joint on one side and a thread on the other. They are usually welded to the rod at a right or close angle.

In the place where the tip adjoins the metal rod there is a thinning (“neck”). It serves as a kind of fuse. If the mechanism experiences extreme loads, its body will break in this very place. Otherwise, the strut may break anywhere, breaking through the bottom of the car and causing harm to passengers or other mechanisms.

It is for safety reasons that the racks are not made too thick, which is why they often fail. Although non-original spare parts have a slightly larger diameter, which is a kind of compromise between safety and wear resistance.

Articulating stand device

The most popular currently are racks using a ball joint . Its design consists of two parts - a steel ball pin and a plastic seat with temperature-dynamic lubrication. The finger is pressed onto the top with a plastic or metal cap.

The hinge joints are always protected with sealed boots and lubricant. It ensures smoother operation of the mechanism and also increases its service life. The lubricant is frost-resistant, ensuring normal operation of the vehicle's chassis system in winter.

Sealed boot

To better understand the principle of operation of the rack, you need to remember that it is not rigidly connected to the stabilizer, providing limited movement of the elements combined into the mechanism. When turning a car at speed, its natural roll occurs. In this case, the same forces act on the body, and on the suspension - directed in the opposite direction. If they are not compensated for, there is a risk of breakage of the associated elements - the stabilizer and the hub eye. Thus, the stabilizer link is a damper that receives and dampens large multidirectional forces. However, during operation, under the influence of the mentioned forces, a gradual destruction of the hinge joints occurs. As a result, the racks become unusable.

Some foreign automakers produce adjustable stabilizer bars (for example, the Nissan Patrol GR has an electronically switchable anti-roll bar). There are also SUVs in which the operation of the stabilizer and its struts is controlled by an ECU.

Stabilizer malfunctions, their symptoms, condition check

Video: Knocking in the front suspension is the most common cause

But stabilizer struts are additional elements in the suspension, and not of a simple design. Therefore, they are an additional place where malfunctions can occur.

If you look at the VAZ-2108 element, rubber bushings are used in the design. During operation, rubber is exposed to various negative influences, which leads to its “aging” (decreased vibration properties, shrinkage, cracks).

On the same racks where ball joints are used, they are the weak point. Over time, wear appears between the ball pin and the joint body, which causes a gap to form between them.

All these malfunctions have obvious signs:

- The appearance of knocking noises when overcoming bumps on the road;

- Increased car roll when cornering;

- The car “floats” on the road (the car spontaneously pulls to the side).

It is not difficult to check the condition of the stabilizer struts, and it does not matter what design it is. To do this, you only need a mount and an inspection hole. If you check on a VAZ-2108, then it is enough to swing the stabilizer near the rack with a mount. Its significant amplitude of vibrations and knocking indicate severe wear and the need for replacement.

As for checking Focus 2, you need to swing the stand itself. Ease of movement and knocking in the hinges will be a signal of their severe wear. But at the rear of this car you need to swing the stabilizer itself.

Stabilizer link malfunctions

Let's take a closer look at what kind of stabilizer strut malfunctions car owners most often encounter.

Signs of a rack malfunction

So, the main signs that indicate that the stabilizer links are completely or partially out of order are:

- If the car has a strut with a ball joint, then in 90% of cases the main sign of its failure is a knock when driving on a rough road , in particular, when driving over speed bumps. Naturally, the knock comes from the side of the wheel where the strut has failed. If the stand is on a bushing, then diagnostics are more difficult to carry out. In this case, the knock may be quiet and will not be heard in the cabin.

- When driving on a flat road, the car begins to “ drift ”, that is, it is difficult to keep it in the rut, it is necessary to constantly steer.

- When entering a turn, the car rolls much more than it did before.

- Excessive rocking of the car body during acceleration or braking.

Typical problems

Failed strut joint

The main problems are related to the hinge mounts. The first is the failure of the boot . Because of this, dirt and debris get into the mechanism, which leads to excessive wear. The second typical problem is that over time, the ball pin race wears out , as a result of which the ball pin begins to “beat” in the seat. This leads to it breaking.

Repairing a broken rack is quite difficult and requires factory equipment. In particular, it is theoretically possible to replace the ball pin or bushing. However, this work will be expensive and exceed the price of a new rack.

Therefore, repairing stabilizer struts is impractical . It is much easier to replace them with new ones. Currently, a large number of non-original, but quite high-quality spare parts are sold on car markets. We will talk about them below.

Varieties

There are many stabilizer links. They mainly differ by car make. Each car has its own type of traction.

There are varieties of materials for the manufacture of silent blocks and stabilizer link bushings. There are standard rods, and there are polyurethane stabilizer links. The standard ones are most often made of ordinary rubber, and the second ones are made of polyurethane.

Drivers claim that polyurethane is better than rubber based on the fact that it is designed to last longer. In fact, this is true. An ordinary rubber bushing and silent block last no more than 10 thousand kilometers, while silent blocks and polyurethane bushings do not even show signs of wear. Despite the fact that this material is more expensive, it is still in demand. This happens because it is better to change a part once every 15-20 thousand kilometers than to change 2 or 3 parts in the same period.

How to check stabilizer links

Inspecting ball joint struts is easy. The simplest method is to rock the car from side to side in a direction transverse to the movement of the car. If the swinging occurs without effort, this is the first sign that the hinge group has failed or is close to it. If the strut is faulty, you will hear a familiar characteristic knock from the wheel side.

Second method. You need to turn the wheelset completely to the side. After this you can get directly to the racks. Check for play by hand . Rock the car yourself or with the help of an assistant. If there is any play, you will feel it to the touch. If, when turning the wheels, there is no access to the racks, drive the car into the inspection hole. This way you are guaranteed to get the necessary access. Otherwise, the procedure is similar - one person rocks the car, the other feels and listens to the racks.

When checking, be sure to pay attention to the condition of the anthers . If they are torn or there are oil leaks under them, there is a high probability of significant or complete wear of the stabilizer struts. This is especially true if you bought a used car. If the anthers are in poor condition, check the struts as well.

When using another method, it is necessary to remove the wheels from the car, first jacking it up and placing a reliable stop under the ball in order to unload the stabilizer. This will give you access to the rack mounts. Next, you need to unscrew the upper fastening (nut) and perform similar loosening in order to make sure whether the sound arises from the lower fastening. If it is, you will have to change the rack.

If your car has bushing-mounted struts, then diagnosing them is even easier. To do this, it is enough to visually check whether the rubber is being “eaten up” on one side. Otherwise, metal parts will come into contact and a natural knock will occur.

Note! Currently, there is no special equipment at car services that would show that it is the rack that is faulty. Therefore, before going to a service station, conduct your own diagnostics or ask an experienced technician to help you. Otherwise, there is a risk that the technicians will charge you extra money for eliminating non-existent “faults.”

Rack repair

Many car owners do not recommend repairing the strut, since after restoration it can rarely last for a long time. Despite this, there are many ways to restore the functionality of your knuckles. One method is given below.

- Remove the boot.

- Clean out the old grease and add new one.

- Squeeze the joint in a vice in the direction shown in the photo.

An alternative repair option is given below.

- Remove the boot.

- Rinse with kerosene.

- Tap the body with a core.

A more complex method for repairing a rack is shown below.

- Drill the side of the hinge.

- Insert the grease fitting.

- Fill with lubricant.

If the rod breaks, there are also methods to solve the problem. If you have welding, you can use it to fasten the two ends together. An alternative is to cut threads and use special connectors.

How to change stabilizer links

It’s worth mentioning right away that replacing stabilizer struts will differ for different brands and models of cars. But as a rule, the procedure is not difficult and is accessible even to inexperienced car owners. To do this, you need to have a jack and plumbing tools - wrenches, hexagons, a pry bar (depending on the car model). The front and rear struts are different for most cars. The front ones are long, the back ones are short.

Note! It is recommended to change the stabilizer struts in pairs (right and left at the same time), even if only one of them is knocking.

The first thing you need to remember before starting work on replacing struts is that the axle of the car where the spare part is supposed to be changed must be completely suspended , that is, the stabilizer and strut must be in an unloaded state. This can be achieved by jacking it up on one side, and then installing the ball on the stand. Otherwise, even if you can dismantle the old rack, you will not install the new one correctly. Statistically, this is the main reason for premature rack failure.

, do not damage the anthers under any circumstances . If they are in poor condition, replace them. After all, the service life of the rack directly depends on their integrity.

Remember that after replacing the stabilizer struts, there is NO need to do a wheel alignment check, since they do not affect the wheel alignment.

Replacing the front stabilizer bar on a Ford Focus

Diagnostics and replacement of struts on TOYOTA RAV4 2002

We also advise you to familiarize yourself with the video instructions for replacing struts on Chevrolet Cruze and Renault Logan.

How to extend the life of stabilizer links

Stabilizer links on bushings can be reinforced with polyurethane silent blocks - there are companies that specialize in the production of suspension parts from this material. But there is no guarantee that you will be able to find a suitable size bushing, plus you will have to wait for delivery if there are no craftsmen in the city. Then you still need to repress it, and this usually requires special equipment.

With rods on hinges, everything is simpler and cheaper - you can extend their life (but they still won’t become eternal) with improvised tools and materials. The method is not complicated, but it requires some skill and patience. The point is to put more grease for the joints under the boot, since there is practically no grease there from the factory (one drop, as a rule). When the “ball” runs dry, its wear accelerates. A minimal amount of moisture or sand under the boot will quickly destroy the plastic liner and the hinges will rattle.

Factory lubrication of the stabilizer link (there is almost none - the finger is bare), photo dr1ver.ru

A generous amount of lubricant protects the working surface from moisture and reduces friction. Any viscous lubricant for joints will do; it is sold in every spare parts store. To get the grease under the boot, you need to bend it, to do this you need to remove one of the retaining rings - which of the two depends on the design and execution of the spare parts, it turned out to be easier for me to remove the large one, since the small one was in the form of an elastic band. You can take it off, but you may not be able to put it back on.

Factory lubrication of the stabilizer link, photo dr1ver.ru

When the boot is moved to the side, it is convenient to add lubricant. Try not to lubricate the boot seat and retaining ring - then it will be difficult to put them in place. We add lubricant without fanaticism - the excess will still be squeezed out when installing the boot in place, which will complicate reassembly.

Stabilizer link lubrication, photo dr1ver.ru

It should look something like the photo above. When assembling, you must not damage the rubber of the boot; with holes in the rubber, the stabilizer link will not last long, no matter how much lubricant there is.

Stabilizer link lubrication, photo dr1ver.ru

After lubricating one joint, we proceed to the next one and then assemble the rack back (this may be more difficult than disassembling). The first experience can be a little nervous, but with a little patience, everything will work out.

The stabilizer link is almost assembled, all that remains is to put the spring ring in place, photo dr1ver.ru

When everything is ready, you can install the rack on the car. After such manipulations, it definitely comes off more than usual. The main thing is not to “sour” your fingers - otherwise you will have to cut off the still “alive” one.

Installed stabilizer link for Rover 75. photo dr1ver.ru

It is not always possible to remove the boot - some manufacturers use special metal rings to secure them (joint to joint), which does not imply dismantling. Or they need to be snacked and exchanged for others that still need to be found. In this case, the game is not worth the candle.

High-level “Kulibins” are installed in the joint housings of grease nipples (grease fittings) to introduce grease and add it periodically. They say that this makes the parts last forever, but we haven't tested it (and don't believe it).

Selection of stabilizer struts

Many car owners are interested in a reasonable question - what are the best stabilizer bars ? It’s worth saying right away that there is no and cannot be an unambiguous answer to this. There are many reasons for this. Firstly, it depends on the make of the car. Secondly, it depends on whether you are using an original or non-original spare part. Also in this case, it is worth considering the quality of the roads. For example, if the original imported rack of a foreign car is intended for use on European roads with a mileage of, for example, 50 thousand kilometers, then in our conditions it will be much less.

Recently, plastic stands have appeared on the market. They fully meet the declared characteristics and are safe, since in an accident they are completely destroyed without causing harm to the car and passengers.

Why do stabilizer links die and what to look for when buying

The main thing is to choose those racks that are designed for your car by the manufacturer. First of all, this concerns size . After all, even 1-2 centimeters of their length can play a critical role in the operation of the suspension. Interchange of struts from different models is possible only within the same car manufacturer (for example, struts from Ford Focus are also suitable for Ford Fiesta, Ford Escort, Ford Ka from 1995-2001). Such information is usually indicated on the packaging of new racks. Be sure to pay attention to this when purchasing.

The best stabilizer links

We have collected information on the Internet about popular manufacturers of stabilizer struts, reviews of which we provide for you.

LEMFORDER (Germany). A reputable company that produces spare parts for such car brands as General Motors, Mitsubishi, Toyota, Opel, VW, Mercedes, Audi, BMW, Volvo, Ford, Fiat and others. The products are distinguished by excellent quality and innovative technologies used. Note! Sometimes Lemforder packaging may contain CTR stands . Please check this when purchasing.

| Positive reviews | Negative reviews |

| One of the sellers did not recommend trying Lemforber products, saying they were cheap and not bad. Compared to other manufacturers of spare parts for the aftermarket, the Germans came out on top. I installed their struts on the Opel Omega B, Opel Vectra C, and now I’m installing them on the Hyundai Santa Fe NEW. | Lemforder does not manufacture anything for Japanese or Korean cars, but only packages spare parts from third-party manufacturers. In 2000, Lemforder was absorbed by ZF, and since then, apparently, everything has deteriorated. |

| Yes, spare parts from this company are distinguished by their quality and durability. How many times have I installed them on my cars, they surprised me, they last quite a long time, I think you can go at least 30-35 thousand. | Ordered LEMFERDER; Six months passed and they knocked again. By the way, in the summer of 2014 I changed one steering tip, also on LEMFERDER, so the leather cranks arrived in six months. |

TOPRAN (Germany/China). The company is a packer of various parts produced in different countries of the world (23 countries in total, including China, where most of the spare parts come from). Therefore, when choosing, you need to look at the country code on the packaging where the part was manufactured.

| Positive reviews | Negative reviews |

| I put it on the Opel Omega A. It's been 30+ thousand, so far everything is ok. They're worth the money. | Neither good nor bad. Something in between. A friend rode, but I didn’t take it. |

| A stand is a consumable item by definition. I bought it at Exist. We arrived, everything is ok, it’s already 50 thousand, there are no creaks or knocks. | Rare shit! Apparently they are made from plasticine. After 5 thousand she knocked. I don't recommend it to anyone. |

SASIC (France). All spare parts are manufactured in Normandy (France). They are used for French cars (Renault, Peugeot, Citroen). They are distinguished by quality and low price.

| Positive reviews | Negative reviews |

| Before that, there were “Chinese”, they burst after 10 thousand. I decided to buy Sasik. I liked that the body was so massive, I don’t know. In short, they're walking for now. Already 15 thousand | After 5 thousand km they sank and it was already visible; on my car, the top of the strut fastener rises above the glass when the support sag. I must say that my ground clearance is quite high, the support bearings worked fine, so I drove in this condition for about 20 thousand km. |

| What pleases is the price. One hell of a knock will come early or late. why overpay? I have a Renault Logan. They stand for two months - the flight is normal, there is no knocking. | In general, 2 weeks ago I changed the stabilizer struts to Sasic, it’s not a cheap analogue at all, it seems to be popular, today on business I went to the service center, they lifted the car, as usual, I walked around and inspected the suspension and found out that my brand new stabilizer struts had burst!!! BOTH!!! Fuck you, comrades, no words!!! |

GMB (Japan). A Japanese company that produces spare parts mainly for Japanese and Korean cars (but not only) - Toyota, Nissan, Mitsubishi, Hyundai, Kia, Renault, Suzuki, GM. Features original Japanese quality.

| Positive reviews | Negative reviews |

| I set GMB - at the moment I have traveled more than 35 kilomiles, no problems (ugh three times). | No negative reviews found |

| I remember putting these on my old Pajero. He is Japanese and is Japanese. Everything was clear and coordinated, there were no problems. I sold the car with him. |

CTR (South Korea). A company that at one time separated from the Japanese GMB. Currently produces spare parts for such cars as Hyundai, KIA, GM, FORD and many others. It is distinguished by quality and low price.

| Positive reviews | Negative reviews |

| I purchased the racks two months ago, I am very pleased with the racks, they hold up well, nothing crunches on the jars, nothing falls out. I recommend these racks. The racks are easy to install, the price is good, and the quality is good. | A friend had these for about 2-3 months, then they just cracked and that’s it. I bought them from me and have had them for 8 months without any problems, although these ones are even more expensive. In general, if there are no other options, then it will do for the first time, but you will still have to look for a replacement later. |

| The stabilizer struts are only Korean CTR and are one hundred percent no worse than the original. advantages: increased service life, reasonable price compared to original stabilizer struts, excellent road stability, always available in auto parts stores | Good afternoon. I installed stabilizer struts on FF2. Passed 10t. km (for 1 year) they rattled, the anthers separated. The ride is neat. I won't install these again. I read a lot of positive reviews, took it from Ekzist, is it really a fake? |

Sidem (Belgium). One of the world leaders in the production of auto parts for the steering of a wide variety of cars. It has official representative offices in 80 countries. However, there is a possibility of purchasing spare parts made in China that are not of good quality.

| Positive reviews | Negative reviews |

| Provided you find old Belgian ones there will be no problems. | In general, Sidem has been producing spare parts for suspension for a long time, and I had to purchase their products. Before, everything was fine. But in the last year I have had a persistent disgust and distrust towards them. Previously, spare parts lasted a really long time - now it’s like a lottery, you don’t know what you purchased will fail earlier than what Sidem promises us. Although the reviews about them are mostly still good. Recently, it seems to me that they have begun to save money and moved part of their production to China. |

| . | In general, in the spring I installed stabilizer bars from Sidem. I installed it for the first time to test the quality of the product. The product turned out to be complete guan. I changed the oil once again and decided to check how these struts feel. At that time, I drove eight thousand on them. I was simply amazed when I tried to “stagger” them, they were dangling. It seems that in size. In short, I tightened them. After driving another three thousand, I began to hear the knocking of the struts. There is no point in tightening it up anymore, I will change it. |

Links Master (Russia, Tver). A new Russian enterprise that is just gaining momentum. The products belong to the middle and low price segment. Unfortunately, due to the youth of the company, we were not able to find reviews about the products. However, there is an opinion that the quality of these racks is inferior to imported ones. Therefore, the responsibility for the purchase decision lies entirely with you (by the way, if you have experience using it, we will be grateful if you write in the reviews below).

We hope that the above information will help you decide on the answer to the question of which stabilizer struts to install on your car and which company to choose a spare part from.

Conclusion

Remember that the condition of the struts is affected not only by poor quality roads, but also by the driving style of the car owner. Choose the right speed limit on uneven roads and take care of the car’s suspension.

Never drive over bumps on the brakes. You need to stop the car only in front of the obstacle, and not on it. This will increase the life of your car's suspension, and in particular, the stabilizer links.

We recommend that you monitor the condition of your car's suspension and carry out repairs in a timely manner. This will save you from deterioration in control of the car, as well as wear and tear on individual parts. And this, in turn, will allow you to significantly save on repairs.