The stabilizer link is one of the parts of the chassis system, designed to ensure lateral stability of the car body. Every car owner should know about the main malfunctions of stabilizer struts , how to check them, and also replace the strut. This is necessary to carry out timely repairs so that other, more important suspension elements do not fail due to the strut.

Also, many car owners are interested in the question of which racks to choose? Which manufacturer should you prefer? At the end of the article you will find a short summary based on real reviews from car enthusiasts who have used certain stabilizer struts. We will tell you about this and more in this material.

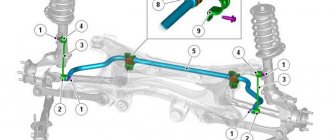

Stabilizer link diagram

Design and principle of operation

The stand is a rod with a length of 5 to 20 centimeters. The rod has hinges at both ends for mobility. The following options can be installed as hinge joints:

- two ball joints;

- stabilizer joint and bushing;

- two bushings;

- on one side there is a hinge, and on the other there is a thread.

As a rule, hinge parts are welded to the rod at a right angle (90 degrees). At the point where the tip attaches to the metal rod, it has a neck (thin end). This was done on purpose, that is, they weakened the structures in this particular place, so that if the permissible maximum loads were exceeded, the device stand would break in exactly the thinned place. This method can be called a mechanical fuse. If the strut had broken in any other place, it could have pierced the bottom of the car, causing harm to the driver or passengers.

This thoughtful design of the racks allows you to protect yourself from unnecessary problems. There is no need to complain that the racks often fail; they are specially made not too thick. Non-original racks are often larger in diameter than the original ones. They will last longer, but safety in this case is reduced.

The most popular type of racks are racks with ball joints. A device of this type of rack includes a steel ball pin and a plastic seat with a lubricant that has special temperature and dynamic characteristics. A metal or plastic cap is pressed onto the top of the finger.

To protect against dust getting into the hinge joints, sealed rubber boots with lubricant are always installed. Such a simple part as a boot significantly increases the service life of the device and the moving mechanism protects against loss and contamination of lubricant. The main property of the lubricant for the hinges under the boot is frost resistance so that it does not thicken in severe frosts.

To better understand how stabilizer struts work, you need to understand that the struts are not rigidly connected to the stabilizers, that is, they have some mobility relative to each other. During a turn, the car begins to tilt (natural roll), and at this time only forces act on the car body, and forces act on the suspension, which try to straighten the body. If the roll force is much greater, then there is a risk of breaking the associated parts: the stabilizer and the hub eye. It turns out that the stabilizer link is a damper that equalizes oppositely directed forces. But, since the force that wants to overturn the car (during a sharp turn) and the force that is against it, both put pressure on the stabilizer bar, which is why the hinge joints of the strut are gradually destroyed.

There are manufacturers who make stabilizer struts with self-adjustment. For example, on the Nissan Patrol GR (Nissan Patrol GI ER) an electronic anti-roll bar is installed, that is, the electronics can turn off the stabilizer.

There are also cars, often SUVs, in which the operation of the stabilizers is regulated by an electronic control unit (ECU).

What is the danger

Knowing how the knocking of stabilizer struts manifests itself, it is logical to ask what to do next.

It even happens that a new rack knocks, literally after replacement. This can be explained by incorrect installation, a problem in other components, or a banal factory defect.

It cannot be said that knocking struts is a characteristic problem of exclusively inexpensive cars such as Lada Vesta, Chevrolet Lacetti, Polo Sedan, etc. This happens on any car, since we are talking about consumables. Yes, the service life of the racks is impressive, but it is not eternal.

If a knock occurs from the stabilizer struts, it is strongly not recommended to continue driving.

However, not everyone understands why knocking is dangerous. Let's try to explain.

A stabilizer link that begins to fail and makes knocking noises reduces the quality of control, which can lead to an accident. At the same time, knocking sounds simply distract the driver.

A knocking sound indicates that the hinges inside the struts are gradually wearing out. Continuing to move, production will only progress. At first it’s just noise, then there are outright knocks, body roll and other signs.

Types of stabilizer struts

As already mentioned, different manufacturers have developed their own modifications of struts for lateral stabilization of vehicles. All modern cars have a front stabilizer by default, but there are also models with a similar element installed on the rear axle, even if the car is front-wheel drive. There are three types of racks:

- Hinged;

- Bushings;

- Bushing joints (used less frequently depending on the design features of the body and suspension).

Budget cars are equipped with modifications with bushings. This is a small steel rod with lugs at the ends. Bushings are inserted into them. On one side, the stabilizer rod is placed in the bushing, and the other part of the strut is fixed to the suspension arm.

If a car uses a hinged modification, it is often the same steel rod (its length is different in each car model), at the ends of which hinges are installed. They are necessary for the mobility of the node. Their fastening fingers are directed in opposite directions from each other (there are analogues with the same direction of the fingers or offset by several degrees relative to each other).

Some automatic stabilizers use hydraulic cylinders instead of struts, which change the stiffness of the bar depending on the type of road. The toughest mode is on a winding road, the middle position is most often suitable for dirt roads. When off-road, the active stabilizer is most often turned off.

Also, the stabilizer struts differ in the mounting principle. By default, the stabilizer itself is attached to one side. In some cars, the second part of the strut is fixed to the suspension arms. There is another type of fastening - to the shock absorber strut or the steering knuckle of the wheel. Depending on this, the rack will have its own mounting holes.

Stabilizer link location

There are front and rear struts depending on which axis the stabilizer is on. They movably attach it to the suspension. In order to see the struts, you need to gain access to the bottom of the car or remove the wheel.

Front pillar

Rear pillar

The influence of stabilizer struts on movement

From all of the above features, we can freely say what the stabilizer struts influence. The driver must first of all understand how to behave when cornering and generally drive correctly.

Car suspension

Stabilizer struts affect the following points:

- movement of the vehicle in general;

- without them it is impossible to operate the machine;

- there is a risk of getting into an accident;

- constant noise.

Signs of malfunctioning stabilizer struts

If the struts are worn out, the car will not be able to protect itself from skidding, since the hinges at the ends will not perform their functions. The driver gradually begins to feel a less smooth movement, there will be a feeling of riding on an ironing board. It will subsequently seem so unstable that the car enthusiast will be afraid to get behind the wheel. Quickly worn-out parts are a sign of careless driving, and when the struts are almost worn out, you need to hold the steering wheel with even more confidence than when the struts were still in good condition.

suspension arm

In addition to all this, do not forget that they also connect the anti-roll bar to the suspension arm, so it’s simply not possible to drive without struts. They have a fairly low price on the market and, as a rule, one of these is enough for six months of driving. In any case, there must be a component that allows you to do what the anti-roll bar does.

Drifting into a snowdrift

Do not forget about the risk borne by the driver. With worn elements both front and rear, you can drive, but not freely. At the same time, the driver is responsible for his own actions. The likelihood that a car will drive into a pole increases many times over, and in winter almost every driver will be able to visit at least one snowdrift.

When any element of the car dies, it lets you know by making a sound. When a driver is asked the question “what is the effect of the stabilizer struts,” everyone freely answers: “the struts make a rattling sound.”

Knock in the front suspension

Important: If a person experiences discomfort while driving and often skids and hears a rumble, this element definitely needs to be changed. Moreover, they rattle both front and rear, because the struts most often wear out both at once.

Mechanism design

This component is designed for a reliable and at the same time damping connection of the unsprung masses of the suspension (wheel, hub, steering knuckle) with the elastic part - the stabilizer beam. The common purpose of the stand is to provide a movable joint. In this case, the execution may be different:

- Ball joints. The most common scheme. Provides freedom to hinges in all directions.

Example of ball joints

With this design, wear occurs the fastest, since the ball joints take on a load comparable to ¼ of the vehicle’s weight. The stand is constantly in motion, experiencing forces aimed at compression, tension and bending. It is used in suspensions where the components are arranged compactly and the stabilizer beam has a complex shape. Can be installed at an angle. Practically beyond repair or restoration.

Earrings. A primitive but very reliable scheme.

“Earring” type design

Elastic elements (rubber, polyurethane, silicone) are threaded onto the pin and secured with washers. Between the rubber bands are the eyes of the suspension arm and the stabilizer beam. Some freedom of movement is provided by the rubber stops themselves, but significant deviation from the vertical is impossible. This drawback does not allow the use of such racks in complex suspensions. The advantages include the ability to withstand significant loads and high maintainability.

Silent blocks. Such a hinge has mobility in only one plane. Transverse deviations are allowed at a small angle.

Option for silent blocks (detail circled in red)

The advantages include a longer service life (compared to ball joints) and relative maintainability. Disadvantage: limited use on complex suspension structures.

Changing the properties of stabilizer links

The most noticeable effect of the front and rear stabilizer struts on the car is when the owner decides to do the suspension tuning with his own hands. The comfort, handling and safety of the car are changing. The various options that car owners often choose from are discussed in the table below.

Table - Effect of stabilizer struts on the car

Modernization Impact on the car

| Installation of a front stabilizer and standard struts on a car, the basic configuration of which does not have these elements, but is present on more expensive versions | Handling improves at high speeds. Rolls are slightly less. There is no too noticeable effect. |

| Installing the rear stabilizer and knuckles | Reducing rear end drift on high-speed turns. Reduced roll by 20-30%. Occasionally there is hanging of the rear wheels. Turn-in is smoother and can be performed at high speeds. |

| Installing only the rear stabilizer with struts without the front one or significantly strengthening it | Strong roll of the front of the car in fast turns. Throwing a car out of the road. |

| Installation of more powerful racks that differ significantly from standard ones | Increased cornering speed and noticeable improvement in handling. Installed reinforced struts without upgrading the remaining suspension elements are sources of excessive loads on other chassis parts, which is why they quickly fail. For example, a stabilizer bushing may require replacement after 10-15 thousand km. |

| Installation of cheap/weak stabilizer links | Mainly affects only the resource and reliability of the knuckles. Such a repair kit rarely lasts long. In most cases, a decrease in the mechanical strength of the struts does not in any way affect the comfort, handling and dynamics of the car. |

Most car owners believe that reinforced struts negatively affect the car. It is impossible to achieve the handling characteristics of sports cars by upgrading the knuckles, and the comfort of overcoming bumps decreases as the chassis becomes stiffer. Particularly dangerous are homemade knuckles, which, according to the assurances of the owners, have no wear. Such eternal racks cease to perform a “safety” function due to increased mechanical strength and do not meet safety requirements. Any excessive load causes significant damage to the suspension, which the standard knuckle could have prevented by breaking.

Machine controllability

Another symptom that indicates a malfunction of the stabilizer link is a significant deterioration in the controllability of the car. The movement is accompanied by “yaw”. Periodic drifts are possible. Steering becomes much more difficult even when driving in a straight line.

Due to a sharp deterioration in vehicle controllability, there is a high risk of getting into an emergency situation, for example, as a result of the vehicle deviating from the intended trajectory.

Vehicle deviation from the planned trajectory

How to check stabilizer links for malfunction?

When European automakers say that stabilizer struts have a lifespan of up to 100 thousand km, they count these kilometers according to their ideal European autobahns. On our roads, the declared figure can be safely divided by two, and only if you’re lucky. All suspension parts depend on the condition of the roads and driving style, and for us both of these factors are not encouraging yet. In fact, they, like some other suspension parts, turn into one of the most frequently changed elements. So it’s better to find out in advance how the first problems manifest themselves.

An indirect sign that all is not well with the struts is the behavior of the car:

- when cornering, the body rolls more;

- it becomes difficult to drive in a straight line (you have to steer all the time to stay in the lane);

- When driving over obstacles in the wheel area, a knocking sound is heard from one side.

However, given that other suspension faults can give similar “symptoms”, it is better to know in advance how to check whether the problem is really with the struts before going for new ones. You can joke that if a piece of the stabilizer link has fallen out and is lying on the asphalt, it is not advisable to put it back. However, even if they look intact, their hinges or bushings may be worn out and therefore unsuitable for use.

Purely visually, you can only determine the condition of the anthers: if they are torn or stained with grease, most likely the hinges themselves are no longer in order. Considering the enormous loads they experience, the ingress of water or dirt disables them almost immediately.

The main symptom of the problem is hinge play . Due to breakdown or wear, they become loose and begin to make that same unpleasant knock that gets on the driver’s nerves.

You can carry out diagnostics yourself:

- Turn the wheel as far as possible to the side to provide access to the hub and stand;

- Using your hand (or any tool such as a crowbar), strongly shake the stabilizer link. It is impossible to break it in this way; the metal and structure are designed to withstand much greater loads;

- If at the same time they knock or noticeably play, it’s time to change them.

- The second test option is to try to rock the car from side to side. A normal suspension stabilizes the body well, so if you managed to manually rock it, this is already a sign of a problem. In particularly advanced cases, the damaged rack will also tap.

Video on diagnostics and replacement

If it is possible to drive the car into a pit, you can involve an assistant in the diagnosis: one rocks the car, the second listens and looks from below. The play can be heard and even felt if you put your hand on a faulty hinge.

Self-diagnostics

Periodic monitoring of the condition of the stabilizer struts can be carried out during annual maintenance. It is best if this is done by car service specialists, but it depends on your desire. In addition, you can independently carry out express diagnostics of the condition of the stabilizer struts at any time. Follow a simple sequence of actions:

- Free up the wheel arch as much as possible and turn the steering wheel all the way to one side - there should be enough space to access the stabilizer link;

- Grab the middle part of the stabilizer link and try to swing it from side to side;

- If noticeable play appears when swinging, then the stabilizer link needs to be replaced.

It is better to entrust the replacement of stabilizer struts to car service specialists - it is inexpensive and will not take much time. In addition, it is possible to obtain a car service guarantee for the work performed. The guarantee, although short, will certainly not be unnecessary!

It is better to start selecting stabilizer struts from the original spare parts catalogs - this way there is less chance of error. And then, in the process of searching by article, it will be possible to consider possible analogues.

Detailed rack inspection

The most complete check of the stabilizer link can be performed by removing it from the car. Car owners are not advised to frequently resort to removing the knuckles, since their fastenings are exposed to an aggressive external environment and often become tightly stuck.

After removal, you should carefully inspect the rubber elements. They very often lose their elasticity, become discolored or have mechanical damage.

When diagnosing stabilizer struts, the design of which includes hinges, it is necessary to remove the boots and check the condition of the lubricant under them. The presence of moisture and various debris is unacceptable. At the same time, you should also inspect the hinge. There should be no traces of corrosion or mechanical damage.

Backlash control

You can check the front stabilizer link for play by turning the wheel out. To diagnose the absence of problems with the back knuckle, you will need to install the machine above the inspection hole. You can check the malfunction of the stabilizer link by following the instructions below.

- Grasp the center of the rod with your hand.

- Shake the knuckle with a little force.

- The presence of any play is unacceptable and indicates that the stabilizer link must be replaced.

- Ask an assistant to rock the car. In this case, you should try to move the stand with your hand. The appearance of knocking and free movements indicates that the knuckle has lost its functionality.

Rack repair

Many car owners do not recommend repairing the strut, since after restoration it can rarely last for a long time. Despite this, there are many ways to restore the functionality of your knuckles. One method is given below.

- Remove the boot.

- Clean out the old grease and add new one.

- Squeeze the joint in a vice in the direction shown in the photo.

An alternative repair option is given below.

- Remove the boot.

- Rinse with kerosene.

- Tap the body with a core.

A more complex method for repairing a rack is shown below.

- Drill the side of the hinge.

- Insert the grease fitting.

- Fill with lubricant.

If the rod breaks, there are also methods to solve the problem. If you have welding, you can use it to fasten the two ends together. An alternative is to cut threads and use special connectors.

Replacing stabilizer struts

To replace the bones with your own hands, you should purchase the necessary tools:

- Jack.

- Spray WD 40.

- A set of keys, a head, ratchets (for the lower bone), a spanner (the size of which can be found in the instructions for the car).

- Wheel chocks.

- Actually, the racks themselves.

Usually the rods are changed in pairs

The procedure for replacing the front stabilizer struts:

- Apply the hand brake and install wheel chocks under each wheel.

- The front part of the car is raised with a jack.

- The connecting elements are treated with WD-40 spray.

- A hexagon or ratchet head holds the axle shaft (from the end).

- The rod securing nut is unscrewed and the old part is removed.

- The installation site is cleaned and a new rack is installed.

- The nut securing the bone is tightened.

- The car is lowered.

- The nuts are tightened completely.

Replacement of the rear pillars (if they are provided for in the design) is carried out in a similar way.

After a run of two to three hundred kilometers, it is necessary to check and tighten the fastening nut.

The best stabilizer links

It is difficult to say how to choose the best racks: the technical characteristics of the car decide everything. However, there are patterns that can be taken into account when choosing new spare parts:

- The best choice is always an original (OEM) rack. Yes, Mazda or BMW do not produce parts themselves, but everything that is supplied to the market on behalf of automobile brands is thoroughly tested. The high price pays off with both high quality and long service life, so in the rating of racks the original always comes first;

- More affordable than OEM, but usually no worse in quality, products from premium brands will be. Often in a box with a Mercedes logo you can see the same Lemforder, Moog or TRW;

- The middle price segment may be the best option for finding a quality stand for reasonable money. For French cars, Sasic offers an excellent range, for Japanese and European cars - GMB;

- But the budget segment does not justify itself in the future. As a rule, spare parts from inexpensive brands are not reliable. Yes, you can install Sidem, Nipparts, and even Profit if you urgently need to save money, but you shouldn’t count on their long service life. However, budget suspension parts are often installed before selling a car, so they also have a right to life.

If the cause of the suspension malfunction was the stabilizer struts, this can be called luck. And they themselves are relatively inexpensive, and they are easy to replace, so there is a chance to get away with little damage. But only if you carry out diagnostics and repairs immediately when the first signs of a problem appear. Otherwise, you will also have to change the stabilizer bushing, the silent block of the lever, and other adjacent elements. So it’s better not to take things to extremes, but to do repairs right away, efficiently and for a long time.