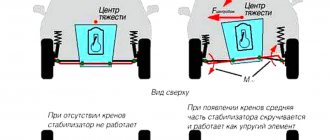

When turning at high speed, centrifugal forces act on the car body, as a result the body rolls in the direction opposite to the turn. While the roll is insignificant, it does not affect the car’s handling, but there comes a moment when the body has deviated so much that the wheels on the “inner” side begin to lose traction. To avoid this, anti-roll bars are installed.

There are two types of stabilizers used on modern passenger cars:

- lever;

- torsion bars

Lever stabilizers (aka reaction rods) are made in the form of a hollow pipe, at the ends of which fasteners with silent blocks (rubber-metal hinges) are installed. They are installed between the fist mount on one side and the seat on the body on the other. Thanks to the rigid fixation of springs and shock absorbers, the installation of a stabilizer creates a triangle, the sides of which are the spring (shock absorber), beam (bridge) and stabilizer. When the body is subjected to centrifugal force, the rigidly connected sides of the triangle do not allow the body to deviate to a dangerous value. For greater effect, install X-shaped stabilizers that form two identical triangles, one for each side. The disadvantage of such stabilizers is excessive rigidity, so they are most often used on the rear suspension.

Torsion stabilizers are made in the form of a steel rod of complex shape, 10–25 mm thick. The middle parts of the stabilizer are attached to the body, and the edges are attached to the suspension arms. When the distance between the bottom of the body and the lower part of the suspension changes on one side of the car, the location of the stabilizer mounts shifts, resulting in the torsion bar bending. The greater the height difference, the stronger the torsion bar resists. Thanks to this, the stabilizing effect is smoother than that of a lever. Therefore, on most cars it is installed on the front suspension.

Purpose, design and principles of operation of the VAZ 2107 stabilizer

It has already been written above that the SPU is one of the important parts of the car. But why? The answer is simple - thanks to it, driving improves significantly, becoming more comfortable. This device makes it possible to keep the chassis tilt under control without increasing the pressure on the camber of the rear wheels.

The increased control over the vehicle on sharp turns is especially noticeable.

Thanks to the stabilizer, it will be possible to enter such turns at higher speeds without the risk of capsizing.

The roll bar SPU looks like a C-shaped hose that is installed next to the axle. The stabilizer is mounted on brackets with rubber bushings inside.

It is worth noting that the VAZ 2107 stabilizer bushing is the weakest point in the design and breaks most often.

The stabilizer works on the principle of distributing the load between two suspensions.

It works relatively simply - when making a sharp turn, the car can roll. Stabilizer, since one wheel lowers and the other, accordingly, rises. The stabilizer prevents this from happening by twisting the rod and raising the lowered wheel and lowering the raised one. Thanks to this, the car is leveled.

Why did I decide to replace the stabilizer?

When diagnosing the suspension of my car, it was discovered that the stabilizer struts had a lot of play on the stabilizer. Perhaps there is wear on the metal, we'll see after it's removed from the car.

In addition, cracks appeared on the rubber bushings, although they did not start to loosen, and there were no suspicious knocking noises. But since it got under the car, we’ll change them for prevention.

Diagnostics

A breakdown can occur for a variety of reasons, so it is impossible to determine the exact time of full operation without breakdowns. Basically it all depends on the operating conditions. For example, if you often drive off-road, the stabilizer will break down often.

Basically, the SPU is checked during annual maintenance, but no one bothers you to do it yourself at any time.

First you need to remove the wheel. After this, use the steering wheel to make a maximum turn in any direction and shake the “bare” stand from side to side with your hand, grasping the middle third. If there are faults, looseness will be noticeable.

Signs of a broken rear stabilizer

The most common signs of failure are:

- Vehicle roll during sharp maneuvers, instability;

- The car begins to sway, as soon as you turn the steering wheel a little to the side;

- If you drive on an uneven road, you will hear a sound from the suspension;

- The car begins to “yaw” when braking;

- If you lower the steering wheel, the car will start to swerve.

How should the stabilizer be positioned?

A correctly installed SPU should twist when the wheels turn.

Therefore, on passenger cars it is strictly forbidden to weld to the frame, since there must always be an intermediate link between it and the wheel. For example, in the VAZ 2107 bushings act as such a link. It is not recommended to use a stabilizer without them.

Causes of creaking stabilizer bushings

Drivers most often complain about bushings creaking either in cold or dry weather. But these are not the main factors and each driver may have his own reasons for this problem. They are individual for everyone. Main reasons:

- The material from which the bushings were made is of poor quality;

- When it freezes, the rubber from which the bushings are made becomes harder and loses its elasticity, which is why squeaks are heard;

- The bushing has simply worn out and can no longer fulfill its direct duties;

- Due to the design features of the car.

Before replacing the anti-roll bar, you need to figure out what the problem is. Most often you just need to replace the rubber bands.

Why does the stabilizer bushing squeeze out?

In fact, the bushing is quite gentle to use. It can wear out pretty quickly. This mainly happens in winter. In cold weather, the bushing freezes, which can cause cracks to appear on it. Various reagents that are used to sprinkle roads during icy conditions can also play a role in this.

If the driver did not notice the problem in time, the cracks continue to grow. Because of this, the bushing begins to lose its elasticity. And so, at the next turn, it can simply be squeezed out of the eyelet. It is no longer possible to return it back - it is too worn out and will not be able to perform its direct functions.

After this, when entering a turn, the motorist may hear a creaking and grinding sound. The vehicle's handling will also decrease.

About double stabilizers

As the name suggests, there are two rods in this stabilizer. But such a device is installed only on the front wheels. Basically there are no fundamental differences.

Thanks to this SPU device, the stiffness of the suspension will increase significantly, which on the one hand is good, but on the other hand, some problems may arise. The fact is that on the classic VAZ 2107 the two front wheels operate independently of each other - that is, if the left front wheel lifts, the right one does not. But due to the installation of a double stabilizer, everything will change - the suspension will become semi-independent and the steering will become much stiffer, and the traction will become worse.

Therefore, before purchasing and installing a double SPU, you need to think carefully - either comfortable driving and good cross-country ability, or no roll.

Reasons why you need to change the shock absorber struts of a VAZ 2110

- Knock in the suspension.

- A slight vibration feedback to the steering wheel, which impairs vehicle controllability.

- The appearance of rocking of the front of the car.

- A slight deviation of the wheels from straight-line movement.

If the driver detects such deviations, an urgent replacement of the VAZ 2110 stabilizer strut is needed. The durability of the struts depends on the quality of the road surface and the manufacturer.

The price of quality products is slightly higher than that offered by less popular manufacturers of structures. Tip: There is no need to check the wheel alignment after replacing the shock absorber struts; they do not have any effect on the wheel alignment angles.

Replacing stabilizer parts for a VAZ 2110 car

To work you need to purchase:

The instructions suggest the following procedure:

- The car is installed on a viewing hole or its front part is raised and fixed on supports.

- For safe operation, the car is placed on the handbrake.

Tip: To prevent unexpected movement, the car must be firmly secured in place by placing “shoes” or wheel chocks under the rear wheels.

Unscrew one nut at a time, securing the car body to the arms of the anti-roll bar struts, on both sides.

Unscrewing the stabilizer fixing nuts

- The spring washers are removed.

- The bolts are removed from both sides.

- Unscrew two nuts holding the stabilizer bars to the body.

- The spring washers are removed from the studs.

- Along with the struts, the brackets and stabilizer bar are pulled out.

- If you only need to replace the stabilizer bar on a VAZ 2110 or its bushings, unscrew the nuts securing the struts to the levers, then knock the struts off the assembly rod with a polymer or wooden hammer.

- The VAZ 2110 stabilizer strut and bushing are visually inspected. In case of deformation of the racks, rupture, wear, loss of elasticity, cracks or loose fit of the bushings to the surface of the rod, all elements are replaced with new parts.

Tip: To remove bushings that have become unusable, a press is required, so it is easier to replace the rack together with the bushings.

The assembly rod is inspected. It should be without deformation, the ends should be located in the same plane.

https://youtube.com/watch?v=WHWGaJjP3xM

Tip: Minor changes in geometric dimensions on the stabilizer bar can be corrected, in other cases the part needs to be changed.

- Stabilizer pads that are worn, torn, have lost elasticity, or do not fit tightly to the bar must be replaced with new ones. To do this, new cushions are put on the stabilizer bar, at a distance of 350 millimeters from its center. Their cuts are located towards the front of the car.

- The struts, lubricated with soapy water, are placed on the stabilizer bar, as shown in the photo.

The shock absorber strut is placed on the rod

- The structural rod is installed in place, the nuts securing the cushion brackets are tightened until the play in the cushion sections is eliminated.

- Tighten the front nuts first, from the side of the cut, then the rear ones.

- The nuts are tightened to hold the front struts until the gap between the arms and the struts disappears.

- With the suspension loaded, all stabilizer fixing nuts are finally tightened. The car is standing on a hard surface. The tightening torque of the rack elements is 4.3 – 5.3 kgf-m; bracket 1.3 – 1.6 kgf-m.

How to correctly replace a strut on a stabilizer bar on a VAZ 2110 can be clearly seen in the video.

Benefits of timely replacement

Replacing bushings is a simple process that any driver can handle. As they say - “if there is a desire.” If it is not there, it is better to contact a car service center, where you will be provided with professional assistance.

Thanks to the timely replacement of worn bushings, the anti-roll bar of the VAZ 2107 can last longer.

Thanks to the new bushings, driving on roads, regardless of whether they are of high quality or not, will become much more comfortable and safer.

McPherson suspension

A similar design is named after the engineer Earl McPherson, who developed it in 1960. In the language of car enthusiasts, it is also called a “pumping spark plug.” The device is represented by one lower arm, a block of a spring element, and a stabilizer bar.

A special feature of this type of suspension is the use of a shock-absorbing strut, which is what is popularly called a candle. It consists of a shock absorber and a spring. At the bottom, this component part is attached to the wheel hub, and at the top it is fixed to the support (glass) of the car body.

This type of car front suspension performs several important tasks at once. The stand not only absorbs and dampens vibrations, but also serves as a fastener for the wheel to the vehicle body. The functionality of the wishbones is to provide a movable connection between the wheel and the car body, as well as to prevent its longitudinal movement. As for the stabilizer, it is, in fact, a torsion bar, which has an equally important role - to counteract the torsional force.

McPherson suspension is used not only for the front axle, but also for the rear axle, which determines its enormous popularity. Its advantages include compact size, simplicity of design, and reliability. As for the minuses, this is a change in the camber angle with a significant wheel travel relative to the car body.

Solution

Many beginners may experience problems or difficulties when replacing bushings. This section of the article will help you solve them.

When to replace transverse stabilizer bushings

SPU bushings are replaced immediately after wear is detected. If this is not done and you continue to drive with worn bushings, then irreparable problems may soon appear and then you will have to replace the stabilizer completely.

Installation materials and tools

In order to successfully change rubber bands you will need:

- A set of new bushings for the rear stabilizer;

- Set of open-end wrenches;

- Flathead screwdriver and hammer;

- Composition WD40;

- Mounting blade.

Sequence of operations for replacing rear stabilizer bushings on a VAZ 2107

Having prepared everything you need, you can begin the repair:

- After the car is placed in the pit, you need to inspect the fastenings. Usually, due to long-term use, a layer of dirt and rust could appear on them. To eliminate these unpleasant consequences, you need to treat the compounds with WD 40. After that, all you have to do is wait about fifteen minutes. During this time, dirt and rust should dissolve and work can continue.

- The nuts must be unscrewed with a 17mm open-end wrench.

- In order to loosen the stabilizer bar with the clamp, you will have to use a mounting blade. Having inserted it into a narrow hole, you need to use the lever principle and bend the clamp.

- After this you need to get rid of the old gum. This can be done with a knife.

- The place where the new bushing will be installed must be cleaned of dirt and rust. After this, you can install a new rubber band, having first lubricated its inside with grease (it should be sold with the kit). Now you need to put it on the rod and move it along it to the installation site.

- After the fifth step is completed, you need to tighten the nut on the clamp.

- Then all that remains is to replace all the other bushings according to the instructions above. Afterwards, you need to evaluate the quality of the work performed - if the stabilizer is not warped and no play is detected, then the replacement was carried out correctly. You can drive.

Video of replacing stabilizer bushings on a VAZ 2107. Useful video:

Let's summarize - the stabilizer for the classic VAZ 2107 is an extremely controversial tuning element. On the one hand, it increases the stability of the car, but on the other hand, it reduces cross-country ability and driving comfort. However, it has one undoubted advantage - ease of maintenance. Even a novice car enthusiast can cope with this. After all, the only part of the SPU that is subject to rapid wear is the bushings, replacing which will not be a problem for a person who has at least once held a wrench with a mounting blade in his hands.

Front shock absorber malfunctions

The fact that the shock absorbers have become unusable can be judged by the sharply increased braking distance and the gradual deterioration of adhesion to the road surface.

In addition, there is a risk of aquaplaning, a state of complete loss of vehicle control while driving on wet asphalt.

Typically, hydroplaning lasts a few seconds, but this is enough to cause an accident, and only a very experienced driver can cope with such a nuisance.

In order to prevent this problem, you should watch for the following signs, which determine the condition of the front suspension.

- Uneven tire wear.

- Oil leak. If even a small oil trace remains after parking, this first of all indicates a malfunction of the shock absorbers.

Nodes become defective for several reasons:

- damage to the seal;

- piston rod defect or corrosion;

- break in the spring;

- deformation of bushings and other fasteners. This malfunction causes loud noise while driving.

- mechanical defects of the case;

- poor condition of the spring or its incorrect installation. A breakdown in the spring is indicated by deterioration in vehicle stability and the appearance of noise at speed;

- wear of silent blocks.