Starter operating principle

Before you start troubleshooting, it is advisable to know how the starter works and how it works. Only with this knowledge will you be able to most accurately determine possible problems with the device.

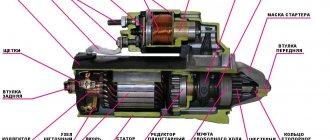

The starter on the VAZ-2109 consists of the following elements:

- A motor supplied with direct current through four brushes.

- A clutch that provides free play with a gear that is designed to run the engine flywheel.

- A traction relay responsible for extending the clutch and gear when the device is turned on.

As a motorist, you need to remember that the starter has bushings that ensure free rotation of the rotor, gear and clutch.

One of these bushings is located inside the device, and the second is located in the clutch housing.

The starter performs its functions by converting an electrical signal into the rotational movement of a drive gear. The brushes transmit electricity to the motor. At the same time, the clutch extends and the gear is connected to the flywheel.

To start the engine, a short rotation of the starter is necessary. As soon as the internal combustion engine has been started, the device’s clutch returns to its place.

VAZ 2109 starter - how to assess problems and fix them as well as a mechanic?

For owners of domestic cars, self-repair or assembly of vital mechanisms is familiar and accessible; in this article we will try to improve our skill level and replace the VAZ 2109 starter with our own hands.

Starter circuit and purpose

On all cars, without exception, and therefore on the VAZ 2109, the starter is responsible for starting the engine, or rather, spinning the crankshaft. Essentially, it is a small electric motor. The VAZ 2109 starter device includes a movable rotor, two windings, and a bendix with a set of brushes. How does it all work? Magnetic fields of opposite values are created around the starter and rotor windings, which drives the moving element into dynamics. It is quite easy to apply voltage to the starter, but for the rotor you need an intermediary - brushes consisting of graphite and copper.

What about the Bendix starter of the VAZ 2109, this element transmits movement to the flywheel. The part consists of the following parts: a fork connecting the mechanism to the retractor relay, an overrunning clutch that ensures movement in one direction, and a gear. Many motorists are familiar with the situation when this part is erased. The slipping of the Bendix is clearly audible and indicates that the installation of a new kit is inevitable. And although the cause is often contamination of the mechanism, cleaning it is not recommended. Due to dust and soot, Bendix is subject to wear, often unevenly, and even after washing it will no longer perform its function at the proper level.

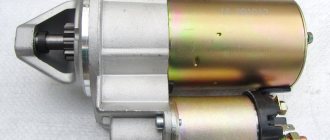

There is a gear starter and a simple one. The scheme for transmitting torque to the flywheel is excellent. The gear starter has an additional element between the armature and the bendix. Many consider this design to be more productive and less voracious. True, the gear unit is more difficult to repair.

Starter mechanism malfunctions

If any difficulties arise with starting the car, this unit is the first to be suspected, but now, knowing the design of the VAZ 2109 starter, you will quickly figure out where to look. Various sounds similar to metal grinding should also alert you; it is quite possible that your VAZ 2109 will need to disassemble the starter. The reason may lie in the flywheel, and its crown will need to be replaced. In this case, the car will most likely start, just not right away.

But if the car does not start and there are no alarming sounds, then you may have to replace the clutch. Disassemble the starter and dismantle it, try turning it in both directions. If it rotates freely, then calmly throw away the failed part. You can understand that it is necessary to remove and replace worn starter brushes installed on a VAZ 2109 by a characteristic click, after which the expected engine start will not take place.

Removing and connecting a new starter

In absolutely any of the cases described above, you will be faced with the need to take a closer look at the device. It should be noted that with the release of the VAZ 2109, the question of how to remove the starter became more easily resolved, because in this model the arrangement of components under the hood is much simpler. So, you will need socket and socket wrenches and an inspection hole. Now, regardless of whether it is necessary to replace only the bushings or the entire VAZ 2109 starter, it must be removed. First of all, all the wires of the traction relay are disconnected, after which the block is dismantled. Don't forget to remove the high voltage wire from the battery.

The next step is to dismantle the engine crankcase protection; to do this, simply unscrew the mounting bolts. Then the approach to the mechanism of interest to us is cleared. To remove it, you need to unscrew three nuts - two on the block and one in the engine compartment. The connection diagram for the new VAZ 2109 starter is the same, only it is in the reverse order, so it will not cause any difficulties.

The most common starter failures

It is recommended to carry out troubleshooting while it is running on the car, because after dismantling the starter, it will be quite difficult to identify some breakdowns. The main symptoms are expressed in the following situations:

- Uncharacteristic noise when starting the engine.

- slow rotation or no rotation at all.

- The device rotates, but the gear does not engage with the flywheel.

- The starter rotates with the flywheel, but subsequently there is a gap in the engagement.

- When you turn the key, there is no sign of the device being “working.”

In each of the above cases, it is necessary to look at the engine compartment. It is likely that the problem may be hidden in poor contact connections and electrical connectors. Additionally, check the condition of the battery; it may be discharged.

Starter diagnostics

You can check the functionality of the starter without dismantling the device using a multimeter. As practice shows, it is most convenient to use a digital device.

- The battery terminals are connected to the poles of the measuring instrument. Ask an assistant to follow the readings, and get into the car yourself. For safety, set the gearbox to neutral and tighten the handbrake.

- Once the tester has been connected, the voltmeter should show voltage. If everything is in order with the battery, the values will be in the range from 11 to 13 V.

- Turn the ignition key, turn on the starter. At this moment, measure the voltage. If the system loses 1-2 V, then the starter provides no resistance. If the readings decrease by half, then we can conclude that “the starter is taking over.” In this situation, the brushes or bushings may have worn out.

- After dismantling the device, you can check the condition of the traction relay. Apply 12 volts from the battery to the terminals on the case. If the overrunning clutch moves towards the front cover, then everything is fine with this unit. Otherwise, you will need to buy a new element and replace it.

Tuning VAZ cars

In VAZ models that do not have oil nozzles and the engine is hot, it is advisable to install such elements from the VAZ 2112 engine. In this case, the most heavily loaded parts of the engine will receive additional cooling. The VAZ 2112 oil nozzle is installed using a drill in the cylinder block. Initially, a hole of small diameter is drilled, then with a large diameter to a depth of 5 millimeters. There is not much space to install the injectors, so the top of the injector is cut off, as shown in the figure below.

It is better to install the injectors as shown in the figure with red dots.

In this case, the devices will “sit” more in the block, and if the oil spray hole is directed correctly, the crankshaft will not touch the crankshaft. Using a hammer and file, if necessary, you can adjust the installation of the nozzle. You need to act carefully so as not to damage the body of the part; it cracks and breaks very easily.

Glory to the buckets! Cars 2Atmotaz - Born to run, you won’t get 3.14 years! Turbotaz - Born 3.14 to die, one horseradish will catch up, and from 3.14 will die =) by sharky

STK Yaroslavka - sports training and repair of domestic and foreign cars

https://sc.yaroslavka.ru/

blog.yaroslavka.ru/

www.yaroslavka.ru

https://youtube.com/watch?v=2lX9fJXOk_s

Sources

- https://vaz-russia.ru/remont-vaz-2108/proverka-forsunok-na-rabotosposobnost-na-vaz-2108-vaz-2109-vaz-21099.html

- https://masteravaza.ru/dvigatel/obsluzhivanie-dvigatelya/vaz-2112-maslyanye-forsunki-ohlazhdeniya-424

- https://www.lada.cc/board/index.php?showtopic=63384

Removing the starter

There are situations when the starter can be repaired only after it is dismantled. Everything here is quite simple, and no difficulties should arise. You can remove it in a matter of minutes. To do this, you will need an inspection hole, an overpass or a lift, as well as a set of keys.

- Put the car on the handbrake and the gearbox in first gear.

- Remove the negative terminal from the battery.

- The connector with the wire is disconnected from the starter traction relay output.

- Unscrew the nut that secures the relay contact bolt and remove the wire.

- If there is engine crankcase protection, then remove it by unscrewing the fixing bolts one by one.

- Remove the two nuts that hold the starter in place. It is better to do this from below the engine compartment. It is better to unscrew the third nut from the top.

- The starter can now be removed.

Clean the device from any dirt before disassembling it.

Sequential disassembly of the starter

The whole process occurs in several stages, and at each stage a potential malfunction can be identified.

The first stage involves inspecting the brushes after removing them. This is generally the most common problem that prevents the starter from working properly. To do this, do the following:

- Unscrew the two screws that secure the protection cover. It comes off very easily.

- Using a screwdriver, remove the retaining ring and adjusting washers from the shaft.

- The next step is to remove the two tie rod nuts and the cover can be removed from the manifold side.

- Now, using a screwdriver, you can press the springs and pull the brushes out of their seats.

To measure the height of the brushes, use a ruler or caliper. If the element height is less than 12 mm, then they should be replaced. If there are chips and cracks on the surface, this is also a reason to update them with new parts.

Individual situations

If the VAZ 21099 injector stops starting, you can try to close the contacts of the mechanism in a straight line.

But sometimes there are emergency situations when the device stops functioning, let’s consider a few of them:

- The injection engine does not start in cold weather, but all devices work normally, the battery is charged. If there is no click, you should first diagnose the safety components, electrical circuit, and also the solenoid relay. If the device clicks, the relay must be replaced.

- The starter turns all day, there is a spark, but in the evening the engine stops starting. Before checking the starter, it is necessary to fully charge the battery, and then clean the contacts on both the battery and the mechanism itself. If these steps did not help solve the problem, you need to check the battery itself more carefully - try closing the contacts with a wire, which may cause a spark to melt. If this does not help, try applying a positive charge from the battery directly to the relay. If there are no changes, the unit will have to be replaced.

- If the car was operated normally all day, but after parking for five minutes it stopped starting, you can try to close the mechanism. You need to directly close two bolts on the relay; if this helps, but later the problem reappears, then disassemble the unit completely. Most likely, the problem lies directly in the erasing of the brushes. In this case, they will need to be changed.

- The unit does not turn at all, but the car can be started from the pushrod. If the problem is not with the starter, then check the fuse box and ignition switch. But before this, you should check the wiring - the reason may lie in the oxidation of the contacts.

Checking the overrunning clutch with gear

In order to get to the overrunning clutch with the gear, you will need to pull the armature out of the front cover. Sequencing:

- Remove the retaining ring next to the overrunning clutch, and then remove the restrictor ring.

- The next step is to remove the plastic lever stop and remove the anchor.

- Now remove the intermediate support from the shaft.

- Visually assess the condition of the gear teeth. If obvious defects are noticed, then this element must be replaced.