There would be no question of any comfort while traveling in a VAZ-21099 car if the interior of this sedan were not equipped with a heating system. Moreover, ensuring a comfortable temperature in the cabin can be considered a secondary task, and the main one is heating the glass (windshield and side front doors) to ensure visibility in conditions of reduced temperatures.

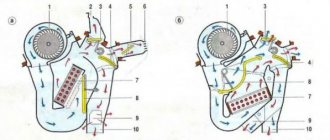

The VAZ-21099 uses a heating system that is classic for all cars, in which the air is heated using an additional radiator of the cooling system installed in the cabin under the dashboard. Thanks to this location, it is possible to provide heating for several zones - airflow onto the windshields and side windows, under the feet and directly into the cabin itself.

To ensure the efficiency of the stove, it is necessary that the flow movement is not spontaneous (due to temperature changes), but forced. And for this purpose, the heating system is additionally equipped with an electric fan.

Internal structure and principle of operation

The heating system installed on the VAZ-2109 has its own differences and features compared to other cars in the AvtoVAZ line.

The heater consists of a pair of plastic casings (on the right and on the left), which are connected to each other along the entire perimeter with clamping brackets. A special flagellum is placed in the grooves of the casings to seal it well. The fan supplies air flow to the interior of the machine. The VAZ-2109 stove is designed so that the fan can be easily removed independently from the engine compartment.

An electric motor of type 45.37230 is attached to the casing, and a fan is located on its shaft. To obtain its desired rotation speed, additional resistance was provided. It was attached to the left side of the hole in the heater casing using a screw.

Heating system radiator

A radiator is built into the stove body to heat the air flows, which then blow into the cabin. Using three screws, this element of the system is screwed to the right casing and sealed with a polyurethane foam gasket.

The radiator design is a combination of:

- 2 rows of tubes.

- 2 rows of cooling plates.

- 2 plastic tanks.

It has two pairs of pipes, it is connected to the cooling system by rubber pipes, where coolant circulation is ensured using a pump. In the valve casing, on the axis of the supply line, there is a plate valve, which has a hole; it allows the coolant to pass through. The valve lever is connected by a rod to the handle lever, which also controls the process of heating the air flow. If you turn this lever, the hole in the valve will open the line for coolant to enter the radiator.

To ensure uniform heating of the car interior, the stove has two central nozzles, as well as left and right, to which air ducts are connected.

Exhaust ventilation

The car is equipped with exhaust ventilation, which circulates air from the interior to the street. It is located behind the body openings for the side windows.

Air also passes out through the deflectors when the car moves. The ventilation process is carried out due to the vacuum that occurs at the deflectors during movement. Air is sucked out from the rear of the cabin under the deflector trim; for this purpose, the rubber valves are pressed out and the air flow goes out through the deflector hole to the street.

Rubber valves are needed to prevent outside air from entering the car interior.

Progress of work on replacing stove cables

Scheme of the VAZ-2109 stove

- The first thing you need to do is turn off the power to the car. To do this, simply remove the negative terminal from the battery.

- Remove the panel trim in the area of the ashtray, radio and the mounting of the heater control levers - to do this, unscrew the 4 fastening bolts.

- Disconnect the wires from all switches: lights, fog lights, radio, etc.

- Move the front seats all the way back or remove them altogether so they are out of the way.

- Remove the seat belt anchors on the floor. Also remove the plastic trim that holds the gear lever boot on. From under this casing you will need to remove the lower air duct.

- Very carefully disconnect the clamps from the faucet, and then the cables themselves. To make it convenient, first disconnect the leg heating flap rod (3), then the windshield heated flap rod (14), then the rod that controls the valve (19) and the rod that controls the flap (20).

- On the back of the heater, disconnect the wires that control the fan speed and the fastenings of the wires, backlights and levers.

- Not quickly, so as not to damage it, lower the heater control lever diagonally down.

- Now you can remove the cable and replace it with a new one.

Usually all the cables to the lever that controls the heater are included in the kit. You can’t buy them separately, but the set itself is not expensive, about 200 rubles.

After replacing the cables of the VAZ-2109 stove, the heating system should be assembled in the reverse order.

If you are not confident in your abilities and are afraid that you will not cope with the task, contact a car service. But keep in mind that the cost of replacement work will be decent, since replacing such a small part as a cable requires complete disassembly of the dashboard and quite a lot of time.

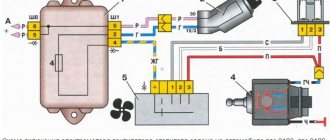

Electrical component of the stove

Below is an electrical diagram for turning on the fan. For it to work, you need a temperature sensor, which is located in the radiator. When the coolant reaches a certain temperature, the sensor gives a signal and the fan turns on automatically.

- Mounting block.

- Ignition.

- Additional resistance (resistor).

- Motor.

- Button that controls the motor.

A – to the terminal with a plus sign “30” of the generator.

Some cars still have an old mounting block installed, in which case the fan is turned on via a relay.

Basic faults

As a rule, a heater failure occurs due to the fact that its electric motor stops functioning. There are several reasons for this:

- combustion of the fuse link;

- breakage of the electrical circuit wires responsible for its operation;

- switch failure.

In the first case, the faulty protective device must be replaced. If the new fuse burns out, you need to find out why this is happening. Most often this happens if there is damage to the insulation of the wires or their separation from the connecting terminals. The electrical circuit is tested with a multimeter, and if a defect is detected, it is eliminated.

The regulator, in turn, usually does not work properly when its contacts burn out. A broken pusher also causes a similar result. The serviceability of this element is determined by measuring the voltage at its side contacts. Its presence when switching the toggle switch indicates operability. Otherwise, this unit will need to be replaced.

In addition, the motor itself may fail. The most common reasons are:

- breakage of armature winding wires;

- brushes sticking;

- collector oxidation.

If eliminating these causes does not correct the problem, then the engine is completely changed.

Sometimes a malfunction occurs due to a break in the wires supplying the mounting block or due to a burnout of the current-carrying track in it.

And finally, destruction of the resistor circuit may also occur - it is checked and the element that has become unusable is replaced with a serviceable one.

Heating system elements

The stove diagram clearly shows the location of its main functional elements. It should be noted that the design of the stove on the VAZ-2108, 2109 and 21099 models is the same. Many car owners know that the heater in these models is not fully developed. As a result, the interior is not heated properly, so a decision is made to modify the stove with your own hands. Just in this case, it is important to know the design of the heater so as not to confuse anything.

The design of the stove of the VAZ-2109 car, whether it is a high panel or a low one, is absolutely identical. Therefore, the information presented will be useful to owners of this model with any instrument console.

Knowing the main points and what is located where, you can already try to independently deal with the problems that arise and fix the malfunctions that appear, while saving money and time on trips to the service station.

Expansion tank and its plug

Well, it is impossible to single out the most important element of the system. Here every little thing plays almost a major role. Even the cooling system of the VAZ 2109, the carburetor if installed in the injection system, has one important part - an expansion tank and a plug. At the very beginning it was mentioned that constant pressure is maintained in the system, due to which circulation improves many times. But this is not the last advantage of the sealed type of cooling.

On a VAZ 2109 car, the cooling system works in such a way that the liquid at high pressure boils not at 100 degrees, but at a higher value. This means that it becomes more difficult to destroy the engine. And the expansion tank plug helps maintain pressure. It has two mechanical valves - for inlet and outlet. The first one is triggered when the pressure in the system drops to 0.13 Atm. And the second one opens when the pressure rises above 1.3 Atm. There are, of course, small errors; these are average values.

Construction and operation of the VAZ-2109 stove. Repair instructions.

Heating of the interior of any car is provided by air, which is heated in the heater radiator. The VAZ 2109 heater radiator is connected in parallel to the main radiator, which is part of the cooling system of a car engine.

The heater itself is secured with four nuts in the passenger compartment under the instrument panel to bolts that are welded to the air supply box. The air heated in the heater is directed through an air duct system into the passenger compartment. The air ducts are attached to the instrument panel from below and sealed with gaskets.

Summarizing what has been written

As you can see, the design of the interior heating system of the domestic VAZ-21099 does not belong to the category of complex, but still, all its elements are interconnected. And this situation greatly complicates the troubleshooting of the heater in the event of a breakdown. For this reason, most car owners prefer to contact service station specialists rather than diagnose and repair the device themselves.

The measures for complete tuning of the VAZ-21099 include a procedure for modernizing the stove, which can significantly increase its efficiency. But it is meaningless, since with a properly functioning heater, the car interior warms up quite well.

Features of the VAZ 2109 stove design

1. Heater casing mounting bracket; 2. Heater control damper; 3. Left heater casing; 4. Leg heating damper rod; 5. Radiator gasket; 6. Radiator; 7. Heater gasket; 8. Electric motor; 9. Fan shrouds; 10. Fan impeller; 11. Heating damper; 12. Heated windshield air duct; 13. Side nozzle air duct; 14. Side nozzle; 15. Central nozzle flap; 16. Blade pusher; 17. Blade axis; 18. Shoulder blade; 19. Lever for shutting off the central nozzle; 20. Windshield heating damper rod; 21. Lever for changing the direction of air flow; 22. Air heating control handle; 23. Windshield air supply handle; 24. Leg air supply handle; 25. Control lever bracket; 26. Bracket for fastening the rod shell; 27. Crane control rod; 28. Heater control damper rod; 29. Foot heating flap; 30. Axes of air heating control levers; 31. Screw clamp; 32. Heater valve; 33. Crane body; 34. Valve lever; 35. Hoses connecting the tap to the heater radiator; 36. Internal ventilation duct; 37. Windows for heating the feet of rear passengers; 38. Heater valve; 39. Driver's foot heating window; 40. Facing the central pillar; 41. Internal cavity of the central pillar; 42. Exhaust ventilation duct; 43. Upholstery of the central pillar; 44. Exhaust ventilation deflector lining; 45. Rubber valve; 46. Deflector housing; 47. Exhaust ventilation deflector; 48. I. Heater; 49.II. Heater operation diagram; 50.III. Heater valve; 51.IV. Interior exhaust ventilation

The stove consists of 2 plastic casings (right and left), which are connected to each other along the perimeter with fastening brackets. A special harness is placed into the grooves of the casings for sealing. The electric fan, which forces air into the passenger compartment, is secured with two screws on top of the heater. The design of the stove is made in such a way that the electric fan can be easily removed from the engine compartment.

An electric motor of type 45.3730 is attached to the fan casings, on the shaft of which an electric fan impeller with three rotation speeds is installed thanks to two resistor spirals. To obtain the required rotation speed of the impeller, an additional resistor is provided, attached to the hole in the stove casing on the left side with a screw.

The radiator for heating the supplied air is installed in the heater casings. It is attached to the right casing with three screws and sealed with a polyurethane foam gasket. It consists of:

- two rows of tubes,

- cooling plates,

- two plastic tanks.

The heater tap, consisting of a housing with two pairs of pipes, is connected to the cooling system by rubber hoses. The cooling system pump circulates fluid through the radiator. On the supply line in the faucet body, a plate faucet valve is installed on the axis, which has a hole that allows coolant to pass through. The valve lever is connected by a rod to the handle lever, which can be used to control air heating. When you turn this lever, the hole in the valve will open the line so that fluid begins to flow into the radiator. Read more about replacing the heater valve here.

The stove is controlled using three handles, the levers of which are mounted on the axes of a plastic bracket attached to the instrument panel with four screws. The heating control handle acts on the valve lever through the rod and on the damper drive lever. When it moves completely to the right, both the valve and the damper are fully opened, and air is supplied by an electric fan through the radiator, where the heated coolant flows.

When the handle is in the middle position, the valve and damper are in intermediate positions; in this case, part of the air passes through the radiator, and part bypasses it. This reliably ensures the required degree of air heating at the moment. If the handle is placed in the extreme left position, the valve and control damper are completely closed, and the air supplied to the cabin is not heated.

Radiator pipes VAZ 2114

Next comes the upper radiator inlet pipe, connecting the radiator to the engine block head.

This hose goes to injection engines. Its internal diameter is 32mm, see catalog number 21082-1303025.

The next one is the lower radiator outlet pipe, which connects the radiator to the engine cooling system thermostat.

Its catalog number is 21082 – 1303010, internal diameter is 32 mm.

“Angle” pipe for connecting the thermostat to the water pump (pump).

Catalog number – 2109-1303093-01. This pipe fits almost all front-wheel drive VAZ models.

The expansion tank pipe is popularly called the “filler pipe.”

It serves to connect the expansion tank to the thermostat. Through it, antifreeze enters the cooling system when the system is filled or topped up through the expansion barrel. See catalog number 21082-1303080 for its number.

Stove pipes VAZ 2114

The pipe that connects the heater to the block head is often called “big goose” in everyday life because of its resemblance to this bird.

The hose supplies coolant from the block head to the heater radiator. We look at the catalog number 2114 – 8101206.

These considered rubber hoses are reinforced, except for the throttle heating hoses and antifreeze steam exhaust hoses.

The goose curve hose is located under the hood of the car and serves to drain coolant from the heater radiator to the water pump.

Catalog number of the crooked goose 2114- 8101208, factory BRT.

The “short” pipe connects the thermostat to the engine block head.

Shorty catalog number 2108-1303082, BRT plant.

The “small” cabin pipe of the stove supplies coolant to the radiator of the stove, through the tap, from the “crooked goose”.

Its VAZ catalog number is 2114-8101200 from the BRT plant.

The cabin “large” outlet pipe is designed to drain coolant from the heater radiator through the “big goose” hose to the water pump.

Catalog number 2114-8101204 from the BRT plant.

Under the hood, the “big goose” supplies coolant to the heater radiator through a tap. And it takes the liquid to the pump from the radiator of the “goose curve” stove through the “large” cabin hose. For example, thanks to a set of rubber pipes, coolant circulates through the heater radiator.

The rubber pipe, the so-called injection “breather”, serves to connect the valve cover of the block head with the “snail” (2111) for supplying air to the engine.

The upper catalog number of the factory breather is 2111-1014058-10.

All connections presented in the video are located under the hood and in the interior of the VAZ 2114 car, related to the cooling system. In addition to the large breather pipes, small breather pipes and volutes, which serve for the passage of air.

The car also contains well-known gas supply hoses, brake hoses, a vacuum hose, as well as windshield washer fluid supply and others. They will also need to be viewed on video and described in the article.

All rubber hoses in a car need constant replacement, as they are exposed to aggressive liquids and gradually lose their properties. They lose their elasticity, become tanned, crack and sometimes break when used for a long time without replacement.

Therefore, it is recommended to periodically review their condition and replace them if any malfunction is detected.

This video ends the review; I hope that the video will be useful to someone both for information and when servicing their car.

Watch the video

Thank you for watching the video, subscribe to the channel, write comments and ask questions.

Features of operation and repair of the VAZ 2109 stove

Many owners of a domestic car of this brand know that the VAZ 2109’s heater does not heat well. As a result, the interior warms up poorly, and driving in such a car is not comfortable. In such cases, the stove is modified. Most often this is done within the framework of VAZ 2109 tuning with your own hands. Video and photo instructions for do-it-yourself tuning work can be found on the Internet. But sometimes it is enough to remove the VAZ 2109 stove and take it for repairs.

The operating procedure is described below.

- Loosen the clamps and disconnect the two hoses from the tap pipes under the instrument panel from inside the cabin.

- Loosen the clamps and disconnect the hoses in the engine compartment from the tap pipes.

- Unscrew the nuts securing the stove faucet.

- Remove the valve from the front panel.

- Remove the crane rod holder.

- Disconnect the rod from the crane lever.

- Remove the cover protecting the gear shift lever from the floor tunnel lining.

- Remove the floor covering.

- Unscrew the fastening screw at the rear of the floor covering tunnel.

- We remove the floor tunnel lining with a shift back.

- We remove the internal ventilation duct and disconnect it from the stove body.

- Disconnect the wires from the heater motor.

- Disconnect the wires from the resistor.

- Unscrew the mounting nuts on the right side of the heater.

- Unscrew the fastening nuts and remove the heater along with the control panel.

After these manipulations, it is enough to choose a good workshop and take the stove there.

When the stove blows weakly, you can adjust the dampers. How to do this is shown in the video.

The radiator may be the culprit for leaving a cold heater in your car.

Instructions for replacing it are presented below:

- Open the heater valve completely and drain the coolant from the system.

- We remove the instrument panel: first disconnect the wire from the battery terminal with a minus sign, set the wheels in a straight position, disconnect the drive cable and the choke rod.

- Remove the heater control knobs, the fan switch and disconnect the trim.

- We disconnect all connectors with wires: fog lamps, exterior lighting, hazard warning lights, cigarette lighter illumination, rear window heating.

- We unscrew the screws that secure the control panel and the canopy over the instruments.

- Disconnect the fitting hose, speedometer cable and block with wires.

- We remove the devices from the panel.

- Remove the hydraulic light corrector handle and unscrew the nut that secures the headlight corrector socket.

- We remove the steering wheel and all switches.

- We take out the ignition switch with the steering column pipe.

- We remove the handle from the rod, disconnect the screws that attach the rod guide to the dashboard.

- Unscrew the screws securing the instrument panel on the left and right sides.

- We take out the panel.

- We unscrew the screw from the right edge of the stove, which secures the damper rod clamp, which is responsible for heating the glass.

- We take out the heater radiator by unscrewing the 3 mounting bolts.

- Loosen the clamps securing the hoses and remove them from the pipes.

The radiator must be thoroughly cleaned, and in case of serious problems, it is better to replace it with a new one.

DIY repair

To carry out repairs yourself, you need to use the following tools:

- a Phillips head screwdriver;

- 10mm wrench.

When dismantling, you need to remove the plastic trim, which is located on the outside of the windshield. To remove it, you need to open the hood and remove the 5 bolts that secure the trim to the body. Remove the rubber seal from the engine compartment and pry the casing with a screwdriver to get to the motor and oven fan. Now you can remove the motor. It is attached to the body of the VAZ 2108 with two bolts.

When the clamps are disconnected, you can turn off the power and disconnect the positive wire of the furnace under the dashboard. The negative one is attached over a special thread and pressed down with a special nut. You need to unscrew the nut by touch and fold back the negative wire. By disconnecting the wires, you can remove the motor and install a new fan. The entire structure is assembled in reverse order.

It is important to note that breakdowns associated with the stove also depend on which panel is installed on the VAZ - low or high. Both have their downsides

For example, on a high one the central flap does not open completely. It is she who is responsible for supplying cold and hot air to the car interior. To solve this, you need to adjust the damper. And to get to it you need to disassemble the dashboard.

If we talk about the low panel, this is where the thermostat often breaks. Of course, if it wears out, the oven will not work. It is recommended to change it every two or three years. And if replacement does not solve the problems, it is worth replacing the hoses that connect the stove and radiator.

Photo gallery “Stove removal and repairs”

In the photos provided below you can see in more detail how the furnace repair scheme occurs.

1. Unscrew the motor fixing bolts.

VAZ 2109: interior heating and a detailed description of all components of the system

Ventilation and heating system VAZ 2109

As you know, on the VAZ 2109, interior heating is provided by air heated by a radiator. On the VAZ 2109, heating and ventilation of the interior are interconnected and represent a special system. In this article we will look at the general principles of operation of the heating and ventilation system of the VAZ 2109.

Cooling system pipes VAZ 2114, 2115

Greetings, Lada VAZ car enthusiast on the RtiIVAZ website!

A YouTube channel subscriber came up with the idea to make a video about the rubber radiator pipes of the VAZ 2114 and the heater pipes of the VAZ 2114, just like his car. This video was filmed at the request of Boris Zverev, and the article was edited on the initiative of Albert Aukhadullin.

Let's start with the steam exhaust hose of the cooling system. This hose serves to remove steam from the radiator to the expansion tank. The length of this product is slightly more than one meter, the diameter of the internal hole is 8 mm.

This hose is installed on VAZ 2108, 2109, 21083, 2113, 2114 and VAZ 2115 models with injection and carburetor engines.

On models of the “ten” family, the same hose is installed as in the photo above, catalog number 2110-1303095.

Next we will consider the hoses installed to heat the throttle assembly.

These are inlet and outlet hoses for coolant. The diameter of the hose when measured with a school ruler is about 10 mm, and the length is 48 cm.

Heating system

As a rule, the heating system of a VAZ 2109 car consists of several main elements and components, shown below.

Heater

VAZ 2109 interior heating system

The heater or stove itself is the main link in the heating system. It is secured with 4 nuts in the car interior under the dashboard to the bolts. There are air ducts installed on the stove, which are fixed to the instrument panel from below. Their design requires sealing gaskets.

What does the stove consist of?

The VAZ 2109 system heater consists of:

- 2 plastic casings connected to each other with brackets (fastening brackets are connected along the perimeter);

- A special harness placed in the grooves for sealing;

- An electric fan that forces air into the cabin and is attached with screws on top of the stove;

Note. The motor is installed on the stove so that its removal is convenient and does not cause any difficulties.

- Heating radiator, which is installed in the heater casings;

- faucet;

- Cooling system pump, which circulates fluid through the radiator;

- Stove handles that allow you to control the heater.

Controlling the stove handles

You can achieve the most comfortable conditions in the cabin by moving the heater control knobs and adjusting the position of the nozzles in the following way:

- The upper right handle regulates the air supply to the feet of the driver and front passenger (if the position is to the extreme left, the supply is maximum, if the handle is in the extreme position to the right, the supply is blocked).

- The upper left knob controls the air flow to the windshield.

- The lower handle regulates the temperature of the air that enters the cabin (the extreme left position is cold air, the extreme right position is hot air).

- The left rotary button, visible in the photo above, connects the stove fan. It will increase the air supply. The button has 4 positions: 0 – off state, 1 – initial speed, 2 – average speed, 3 – maximum speed.

If the outside air temperature is minus 20 degrees Celsius, the stove begins to provide maximum heating mode automatically. The indicators in this case are as follows:

- +20 degrees Celsius is provided in the vehicle interior;

- +25 degrees Celsius is provided in the passenger and driver foot area.

Radiator

Heater radiator "nine"

This is one of the most important parts of a car's heating system. Unfortunately, the radiator in the VAZ 2109 begins to leak after a certain amount of time. Traces of antifreeze on the passenger carpet or under the carpet are a symptom of a leaking heater core. In this case, the interior heating of the VAZ 21093 will be completely compromised and the radiator will have to be replaced.

Types of radiators

For the VAZ 2109 there are several main types of radiator. The most popular are:

- Aluminum original;

- Aluminum non-original;

- Copper.

Of all this trinity, the most expensive is the copper radiator, which can be soldered if necessary and which is significantly more reliable than the others. Aluminum radiators are less reliable, but cheaper. The original one costs about 700 Russian rubles, while a non-original one can be bought for 400 rubles. The design of both types of aluminum radiators is different:

- The plates in the original radiator are located much denser than in the non-original version.

- The heat exchange area in a non-original radiator is smaller than in the original one.

- The design of the original aluminum radiator is much stronger.

- On an original radiator, the air begins to warm up already at a coolant temperature of 60 degrees, and on a non-original radiator only at 90 degrees and above.

- Inside the original radiators there are special coolant swirlers made in the form of spiral ribbons. They significantly increase operating efficiency, because the coolant does not “fly” through the radiator, but circulates slowly, releasing heat more efficiently.

Why does the stove blow cold air?

If the heater radiator on a VAZ-21099 has stopped heating, most likely the coolant circulation in it has been disrupted. This problem is also caused by a number of reasons, let’s look at them:

- It is quite possible that the coolant is outdated and, as a result, has lost its properties. Note that its service life is approximately five years. If during this time the antifreeze or antifreeze has never been changed, their structure begins to deteriorate with the formation of sediment, which, settling on the cooling lines, interferes with the normal operation of the system. This sediment also clogs the radiator, pipes and pipes of the heater, causing it to stop functioning normally and giving off heat. Therefore, it is necessary to free the system from the old cooling fluid by completely draining it, and then flush it using a special flushing compound. This liquid is poured into the cooling system, after which the power unit starts. The manufacturer indicates on the packaging how long it takes to use the flushing compound in the system with the engine running before draining it. After the flushing has been drained (it usually comes out of the system quite dirty), new coolant should be added in accordance with the manufacturer's instructions and the heater's performance checked. If after this the stove still does not heat, then its radiator is clogged. If, after cleaning and washing it, performance is still not restored, you will have to buy a new radiator.

One of the most vulnerable elements of the cooling system is the heater valve, which is controlled from inside the car using a special lever on the heater panel. The lever and faucet have a traction connection. It is necessary to check the functionality of the faucet. This is done like this: we move the lever, while controlling the opening and closing of the tap. If the faucet remains motionless or does not open/close completely, then the draft needs to be adjusted. The VAZ-21099 stove heats poorly or does not work at all due to a drop in the antifreeze level in the cooling system. Because of this, air accumulates inside the heater radiator, and it practically does not function (it gives off little heat). To eliminate this, you only need to replenish the level of “cooling” in the system and constantly monitor it. Airiness in the cooling system of the power unit is also a common cause. The carburetor has a heating pipe, which must be disconnected, since it is the highest point of the system, and accordingly, an air lock forms there. The next step is to free the system from air; to do this, remove the cap of the expansion tank and blow it out. Air will begin to escape from the hose that was previously removed from the carburetor, but as soon as coolant flows in instead, the hose must be put back in place. Air in the system has been eliminated. The cause of the malfunction of the VAZ-21099 heater may be a failed thermostat, because of which the power unit does not reach the required temperature (90 degrees). Failure of the pump deprives the cooling system of fluid circulation. At the same time, the engine boils and cold air blows from the air ducts. In this case, it is recommended to replace the pump.

As you can see, there are several reasons for poor operation of the stove in the VAZ-21099, and each of them is a consequence of other malfunctions.

Car owners of “nines” know the operating features of their car’s heating system. When everything is fine in summer, in winter the opposite situation occurs, and cold air enters the cabin. And this is already unpleasant, and also harmful to health. In addition, the side and windshields fog up. Problems with the VAZ-2109 stove must be resolved in advance in order to be fully equipped for winter.

The stable operation of the heating system in a car can be influenced by a huge number of factors. Therefore, before you begin troubleshooting, you need to generally understand how the system works.

Features of the stove operation and its modification

VAZ 2109 interior heating

Owners of a VAZ 2109 car are often concerned that over time the stove begins to heat poorly. Needless to say, driving in such a car will no longer be comfortable. In such cases, only upgrading the stove can solve the problem.

Refinement methods

There are many ways to modernize a stove. Below are a few of them.

Damper control lever

- You can simply tighten the heater damper control cable to solve the problem. Make 1-2 turns of the cable located on the damper control lever (the lever itself is located on the stove body, near the gas pedal).

Note. The joints of the air ducts and the edges of the heater damper are covered with foam rubber, which does not compress completely. In this regard, a gap of several millimeters is formed, and the damper does not close completely. The above method will help you adjust the lever properly.

- There is another way to get to the control lever. There is a place on the driver's side and you need to try to reach with your hand and pull the lever, always with the heater fan on. During the adjustment process, the left ear will be in the area of the air duct nozzle and thus it will be possible to hear how the sound of the escaping air changes.

Heater valve

The reason for the ineffective operation of the heating system can also be incomplete opening of the stove faucet. This problem, by the way, occurs in almost all front-wheel drive cars of the VAZ family.

- The solution to the problem can be to tighten the valve control cable and then adjust the control lever to the maximum open position.

Note. In this case, it is possible that the valve will no longer close completely. But this is not the problem, but the fact that after adjusting the lever, the damper may lose its tightness and begin to leak (seen in the photo). In this case, we can recommend wrapping the leak area with a cloth that has been soaked in sealant and fixing it all with cold welding.

Heater valve leak location

Air ducts

Poor functioning of the heating system may be caused by leaky air ducts. The air that is pumped by the heater fan partially goes into the cracks, and the air flow thereby weakens and cools.

- The solution could be complete sealing and gluing of the connections that are located in the places where air flows from the stove to the outlet.

Air jams

VAZ 2109 interior heating system

In addition, the cause of poor operation of the stove can be air pockets formed in the heater radiator.

- The solution would be to stop the front of the car on some hill. Then you should open the heater tap completely and press the accelerator pedal several times.

Above were some ways to eliminate problems with the heating and ventilation system of the VAZ 2109. Instructions and advice given by experts are a chance to “cure” your car with your own hands, thereby saving a lot on repairs. As you know, the price of technical procedures at a service station is not low, and if they are carried out regularly, the family budget will become noticeably poorer. It is recommended to use photo and video materials in the process of independent work.

Why does the stove blow cold air?

If the heater radiator on a VAZ-21099 has stopped heating, most likely the coolant circulation in it has been disrupted. This problem is also caused by a number of reasons, let’s look at them:

- It is quite possible that the coolant is outdated and, as a result, has lost its properties. Note that its service life is approximately five years. If during this time the antifreeze or antifreeze has never been changed, their structure begins to deteriorate with the formation of sediment, which, settling on the cooling lines, interferes with the normal operation of the system. This sediment also clogs the radiator, pipes and pipes of the heater, causing it to stop functioning normally and giving off heat. Therefore, it is necessary to free the system from the old cooling fluid by completely draining it, and then flush it using a special flushing compound. This liquid is poured into the cooling system, after which the power unit starts. The manufacturer indicates on the packaging how long it takes to use the flushing compound in the system with the engine running before draining it. After the flushing has been drained (it usually comes out of the system quite dirty), new coolant should be added in accordance with the manufacturer's instructions and the heater's performance checked. If after this the stove still does not heat, then its radiator is clogged. If, after cleaning and washing it, performance is still not restored, you will have to buy a new radiator.

- One of the most vulnerable elements of the cooling system is the heater valve, which is controlled from inside the car using a special lever on the heater panel. The lever and faucet have a traction connection. It is necessary to check the functionality of the faucet. This is done like this: we move the lever, while controlling the opening and closing of the tap. If the faucet remains motionless or does not open/close completely, then the draft needs to be adjusted.

- The VAZ-21099 stove heats poorly or does not work at all due to a drop in the antifreeze level in the cooling system. Because of this, air accumulates inside the heater radiator, and it practically does not function (it gives off little heat). To eliminate this, you only need to replenish the level of “cooling” in the system and constantly monitor it.

- Airiness in the cooling system of the power unit is also a common cause. The carburetor has a heating pipe, which must be disconnected, since it is the highest point of the system, and accordingly, an air lock forms there. The next step is to free the system from air; to do this, remove the cap of the expansion tank and blow it out. Air will begin to escape from the hose that was previously removed from the carburetor, but as soon as coolant flows in instead, the hose must be put back in place. Air in the system has been eliminated.

- The cause of the malfunction of the VAZ-21099 heater may be a failed thermostat, because of which the power unit does not reach the required temperature (90 degrees).

- Failure of the pump deprives the cooling system of fluid circulation. At the same time, the engine boils and cold air blows from the air ducts. In this case, it is recommended to replace the pump.

As you can see, there are several reasons for poor operation of the stove in the VAZ-21099, and each of them is a consequence of other malfunctions.

The device of the VAZ-21099 stove

There would be no question of any comfort while traveling in a VAZ-21099 car if the interior of this sedan were not equipped with a heating system. Moreover, ensuring a comfortable temperature in the cabin can be considered a secondary task, and the main one is heating the glass (windshield and side front doors) to ensure visibility in conditions of reduced temperatures.

The VAZ-21099 uses a heating system that is classic for all cars, in which the air is heated using an additional radiator of the cooling system installed in the cabin under the dashboard. Thanks to this location, it is possible to provide heating for several zones - airflow onto the windshields and side windows, under the feet and directly into the cabin itself. To ensure the efficiency of the stove, it is necessary that the flow movement is not spontaneous (due to temperature changes), but forced. And for this purpose, the heating system is additionally equipped with an electric fan.

How to make a car heater burn fiery in winter

Useful lifehacks

And, finally, a few useful life hacks to improve the operation of the stove in the Russian winter.

Closing the radiator

On some car models sold on the Russian market, electric cooling radiator shutters are installed as standard or plastic screens are applied, by installing which you can partially block the flow of incoming air to the cooling radiator. This is a simple and effective way to speed up the heating of the interior and improve the operation of the stove in extreme cold. If such devices are not available, you can make them yourself

However, it is important to take all precautions to prevent self-ignition of the screens - they should not come into contact with hot elements of the engine compartment

Reducing the air flow through the stove

In extreme cold, some car enthusiasts increase the air flow through the heater radiator to the maximum, and are surprised that the heater still does not warm up the interior well. The secret is simple: passing through the stove at high speed, impressive volumes of cold air simply do not have time to warm up. By reducing the speed of the motor, you will increase the heating of the interior.

Open the window slightly

In some cases, good heating of the interior is hindered by the design of the car itself, or more precisely, by an ill-conceived ventilation system. If the body ventilation valves are not working and the doors are well sealed, increased pressure is created in the cabin, and almost no air escapes outside. Every minute it becomes more and more difficult for the heater motor to pump oxygen into the car. By lowering one of the windows slightly, you will increase the flow of air through the heater and, possibly, improve the climate in your car.

Experiment and you will undoubtedly find the best way to improve the efficiency of the heater specifically for your car!

Design of the VAZ-21099 heater

And then everything is simple: the created flow passes through the radiator honeycombs, where heat exchange occurs, as a result, heat is transferred to the air, which then blows into the required zones through the air ducts.

The design of the VAZ-21099 stove includes several main components:

- stove body made of plastic;

- heating system radiator (connected to the cooling system);

- electric fan;

- air ducts;

- heater control mechanism.

This car used heaters of two modifications (old and new), which were slightly different in design, but their components were completely identical.

Housing, radiator, dampers

Thanks to the housing, the required redirection of heating is ensured, since the movement created by the fan motor is immediately fed into it, rather than being dissipated. The body of the VAZ 2109 stove itself consists of two halves, connected to each other with special brackets. To reduce flow losses, a seal is placed between its halves. Partitions are made inside both halves, which provide the correct direction.

There is also a niche inside this case into which the radiator is installed. Initially, the radiator was made of brass, but now it is almost always made of aluminum. The design of the stove radiator 2109 is identical to the main one (consists of two tanks, tubes through which coolant circulates, and plates that form honeycombs), but is significantly smaller in size.

Video: The stove in the VAZ 2108, 2109, 21099, 2110, 2111, 2112, 2113, 2114, 2115 HEATS poorly

Air is blown through the stove dampers, also installed inside the housing. These elements are movable, and thanks to them it is possible to close some and open other air ducts. There are three of them in total - the main one (heater control), an air duct that redirects between the foot area and the supply to the cabin, and a damper for supplying flow to the windshield.

Additional flaps are installed on the side and central deflectors. It turns out that by default, air from the housing constantly blows onto the deflectors and this is done so that the flow always has an exit. Thanks to the existing dampers, it is possible to provide simultaneous supply of hot air to several zones at once (the interior and the windshield or the windshield and the footwell area).

Description

HEATER RADIATOR 2108 (SOLDERED COMFORT)

CODE LUZAR LRh 0108b

OEM NUMBER: 2108-8101060 2108-8101060-51P

CONSTRUCTION: COMFORT, aluminum non-assembled (brazed) tubular-tape

Heater radiators

Brand name – LRh – Luzar Radiator heater

Heating radiators (also known as heater radiators, also known as heater radiators) are heat exchangers that use the heat generated by the engine to heat the vehicle interior. They allow you to maintain a comfortable temperature and prevent the car windows from fogging up.

For reference: different names of this node have equal rights of use. For example, “heating radiator” and “stove” come from the function of this heat exchanger, “heater radiator” and “stove radiator” - from the installation location.

LUZAR manufactures hundreds of heater radiators for a wide range of cars presented on the Russian market. They can be purchased in partner stores throughout Russia or online.

Many models of heater radiators are supplied to car factories in Russia and Ukraine - both for passenger cars and for trucks and buses.

The production range of manufactured stoves is constantly increasing; New types are being developed for the most popular cars in Russia.

Powerful R&D allows us to conduct research in the field of improving heat exchangers and create new designs that provide increased performance properties of heater radiators. Main areas of research:

- use of different types of tubes

- changing the location of the tubes

- change in the “fillability” of the core

- use of turbulators-swirlers

- use of various aluminum alloys

- testing of solders with different characteristics

- improving the corrosion properties of metal

- ... and many other R&D areas.

Design of heating radiators from LUZAR

LUZAR heating radiators are available in three types:

- Tubular-plate, prefabricated, aluminum. It consists of aluminum plates through which aluminum tubes pass, inside which coolant runs. The tanks on such radiators are made of plastic. Heater radiators of this type are used for heating small-sized salons due to limited heat transfer; have the best rigidity and light weight, as well as the lowest price.

- Tubular-tape, non-assembled (brazed), aluminum. The corrugated aluminum tape in such a radiator is located between aluminum flat-oval tubes. Radiator tanks of this type can be made of either plastic or metal. The design of non-assembled (brazed) aluminum devices is the most universal, allowing the creation of heat exchangers with any specified characteristics. Aluminum stove radiators are lightweight and relatively high rigidity, as well as optimal prices.

- Tubular-tape, non-assembled (soldered), copper-brass. The design is very close to type 2 - between the copper flat-oval tubes there are copper strips folded in the form of an “accordion”. At the same time, the tanks on such heating radiators are made of brass - in order to increase the overall rigidity of the structure. Copper heating radiators - due to the high specific heat capacity of copper - have excellent heat transfer rates. However, due to the high softness of copper, heating radiators made of this metal are forced to have a narrow tube and a large interval (step) between the tubes, which imposes serious limitations on maximum efficiency. Also, copper heater radiators have the highest cost and the lowest rigidity to torsion, fracture and internal pressure. In this regard, copper heater radiators are “outdated” and are gradually falling out of use.

LUZAR: TESTED BY TIME AND ROADS

LUZAR radiators have been awarded the “Radiator of the Year” award several times

Heaters old and new

Finally, we note that the VAZ-21099 of different years of production used heaters with certain design features that related to the angle of the radiator and the location of the main damper.

In so-called old-style stoves (on cars before 1998), the radiator was installed almost vertically, and the main damper was located under the heat exchanger. There was a partition between the rear wall of the case and the radiator, which formed a channel that provided air supply down the case.

When the damper was open, the air flow moved through the radiator, where it was heated and supplied to the air ducts. In ventilation mode, the main damper closed the heat exchanger, forming, together with the front wall of the housing, another channel through which the flow went directly to the air ducts.

In the new model stoves (on cars produced since 1998), the radiator position angle was significantly smaller than on old heaters, which is believed to provide a larger contact area of the air flow for heat exchange.

The position of the main damper and its shape also changed (it became arched). It began to be located above the radiator. In the closed position (ventilation mode), the damper ensures air movement along the shortest path to the air ducts. In heating mode, it blocked the cold air supply channel to the air ducts and directed the flow down the housing, from where it went to the heat exchanger.

. WINTER COLD - INSTRUCTIONS FOR REPAIRING OVEN 2109

. WINTER COLD - INSTRUCTIONS FOR REPAIRING OVEN 2109

The cold weather has arrived, and most owners of the VAZ 2109 are once again faced with a problem: from the nozzles of the heater pipes at the operating temperature of the coolant (about 90 degrees), barely warm, and often completely cold air is blowing into the cabin; in short, the heater does not heat well. In this state of affairs, in severe frost, even frosty side windows in the cabin “do not come off.”

The simplest solution to this problem is as follows. It is necessary to tighten the heater damper control cable. To do this, you can make one or two turns of this cable on the damper control lever. This lever is located on the body of the VAZ 2109 stove, next to the gas pedal (see photo).

All the joints of the air ducts and the edges of the stove damper are covered with foam rubber, which is difficult to fully compress using the damper control lever. This leaves a gap of several millimeters. In this case, the damper directing the flow of air either from the street directly or through the heater radiator does not close completely. It closes “up”, while air flows into the front nozzles through the heater radiator, and into the top and side nozzles from the street, through those same millimeters. When the heater fan is running, and the car is moving, these millimeters are quite enough.

You can even get to this damper lever on the driver's side and try to tighten this lever with your hand while the heater fan is on. In this case, the left ear will be in the area of the air duct nozzle, and you can hear how the sound and temperature of the air leaving the nozzle changes. Also, the reasons discussed below may be the reason for the ineffective operation of the Samara interior heating system:

Incomplete opening of the heater tap

This problem occurs in most front-wheel drive VAZ cars. You can check this by comparing the temperature of the inlet and outlet pipes of the heater radiator; if it is different, most likely the valve is not fully open. The solution is to tighten the control cable for this valve and adjust the valve control lever to the maximum open position. In this case, it is possible that now the valve will not close completely, but as they say, the heat does not break the bones. But here lies another problem. It is known that this valve in Samar is a weak point, and after a certain number of “open-close” operations, the valve at the location of the axis connecting the control lever and the valve itself inside the valve loses its tightness and begins to leak. Some owners simply set the “heat-cold” lever to a certain position and leave it out of harm’s way. In this case, attempting to move the heater tap valve will most likely cause it to leak. If this happens, you can wrap a strip of fabric soaked in sealant around the leak site and fix it all with “cold welding”; this can also be done in the field if the necessary materials are available.

A radical solution to the problem with a leaking heater tap on the VAZ 2109 would be to completely remove it from the system, or install a water supply ball valve. True, in the first case, the ability to adjust the volume of coolant entering the heater radiator is lost, and in the second case, this adjustment can only be made by looking under the hood. But, having got rid of a obviously unreliable unit, we get rid of possible problems in the future, and the remaining adjustment of the temperature of the air entering the cabin by the damper is enough for the eyes. By the way, in the “tens” the manufacturer removed this ill-fated valve.

Air duct leaks

The air forced by the stove fan partially goes into the cracks in the air paths, while the air flow weakens and cools. The solution would be to seal and seal all connections along the air path from the stove to the outlet nozzles. True, this operation is very labor-intensive, since you will have to disassemble the entire front panel, but the result will be a noticeable increase in air flow from the heating system deflectors.

Air locks in the heater core

Interior heater 2108

Greetings to all subscribers and those who just visited the page of my car. This post will talk about the interior heater of VAZ 2108,2109. About what factors influence the efficiency of the stove. And how to improve its efficiency.

In the distant times of the Soviet Union, when our cars were produced, many Samara car owners were pleased with its interior heating system. Every owner will say that a car with a low panel is very warm and heats up so much that your ears are burning. But gradually, as the car aged and after human intervention in the factory design, this efficiency decreased.

Let's look at the main factors that worsened its performance:

- Aging and wear of the foam rubber seals of the heater dampers and incorrect operation of the dampers (can be observed after replacing the radiator, when the foam rubber is damaged, the dampers and their drives may be damaged after some kind of repair requiring the removal of the torpedo.

- When the torpedo is installed slightly offset and its air ducts do not fall into place. (After removal/installation.

- Incorrect operation of the thermostat (sticks when opening). This is already affected by the quality of spare parts. And this is observed in almost every car. The engine must be able to quickly warm up to an operating temperature of 90 degrees. And its stable maintenance throughout the entire range of operation. If the temperature is, for example, not 90 but 84 degrees. This will affect the warmth in the cabin, especially in severe frost.

- Aging of the heater radiator, as well as if a Chinese analogue of the PRAMO KRONER LUZAR PEKAR type is installed, etc. (Full heating is provided by an aluminum DAAZ or a copper radiator) I do not consider an air lock and a water pump with a modified impeller to have a lesser effect on performance. Air is easily expelled from the system. And the pumps... This also doesn't work.

If the pump is more efficient, then it gives us more heat, thereby taking 2-3 degrees from the engine due to better circulation, lowering the main temperature. If the pump is less efficient, the coolant circulation is lower and the engine temperature is higher. And in the end it turns out + - the same thing. You need to choose the middle option.

So. We figured out the reasons. Now practice. We remove the heater from the car and carefully tear off the old foam rubber. We will use it to cut a new, thicker one.

heater removed from car

After that, we wash our stove. I washed the bathroom at home, with fairies. Because it was already dark and cold outside. Then we dry it and remember or photograph how the cables are attached to the damper control unit and how the cables are located on the body itself.

We disassemble the case, carefully unsnapping all the clips.

workplace

Now we see the following picture.

What kind of compaction and warmth in the cabin can we talk about?

Now our task is to replace the old foam rubber with new one.

To do this we need BITOPLAST 5MM, GLUE MOMENT, SCISSORS, DEGREASER. We clean the damper and degrease it, apply glue and stick BITOPLAST

Spread it well with glue, wait 3 minutes and stick it on.

Then we insert it into the body and check the tightness and clarity of operation. We trim off the excess bitoplast.

The recirculation control flap is ready. Now we do the same with the “face/legs” flap.

flap face/legs

And we check the accuracy of the work by installing it in the case. We trim off excess bitoplast if necessary.

face-closed/legs open

face-open/legs-closed

Great. Now let's move on to the glass shutter. I broke mine. I had to buy a new one.

Many will say that it is not necessary to smear it immediately because bitoplast already has an adhesive layer. Nothing will stick to this glue, after assembly it will all fall off due to the temperature difference inside the case, so we apply it and check the accuracy of the work.

The dampers are ready. Then I ran into a problem. A piece of the pin on which the cable is attached broke off. And for a long time I could not find such a curtain anywhere. I went to Voronezh to the car market and found it there. All spare parts are available and they are not expensive.

left new right old

We're done with the flaps, now let's assemble them. We lubricate all the scenes with grease. We assemble the body carefully. I personally suffered. It took me a long time to connect it. My valves were constantly shifting and getting knocked out. But soon I adjusted and won. I checked the operation of all the dampers by pulling the cables with my hands. We also coat the cables with oil.

damper

damper

Now we need to cut out a new one using the old foam rubber. to those places where the torpedo air ducts are adjacent. I found foam rubber in my attic, traced it over the old ones with a marker and cut it out. The foam is wider. It will fit tightly and there will be less loss.

I cut out two pairs. I left it in reserve.

The joint of the stove body does not need to be sealed with anything, but I sealed it with double-sided Chinese tape, for peace of mind, so to speak.

Now we connect the lever damper control unit. The cables are pressed against it specially. clamps. I bought a new unit because everything in the old one was broken. To do this, we take pictures or remember at the beginning how everything is attached. We set it so that the opening and closing of the dampers is clear and complete. so that there is no lack of income anywhere. So everything easily falls into place there. I got it right the first time.

Ready updated stove

The lower lever that simultaneously controls both the tap and the recirculation damper. After installing the stove, connect the cable to the tap. move the shell forward or backward and clamp it with a clamp. We achieve full opening of the tap and complete closing of the damper. Painstaking work. there's nothing to be done. The ends of the radiator must be wrapped in bitoplast.

That seems to be all. What else to say. With this operation, we achieved the condition of the stove as in the old days. The main problem when working with all these plastics is that this plastic dries out due to temperatures and becomes sooooo fragile and breaks when pressed with your hands. My block was all broken. Therefore, I bought a new one, and the upper damper, as well as some small things. the car market has it all. Well, the main thing is patience in work and calmness. I won’t say anything about the effect now. This is in subsequent entries. After all, important things also depend on the torpedo, the air ducts and the correct fit.