Published: 01/28/2021

- Uneven wear of the vehicle on one axis

- Human factor

- Uneven wear of pairs of pads on one axis

- What determines brake pad wear?

- Drum pad wear

- Main signs of brake pad wear

- Problems with guides

- How to determine brake disc wear

- The principle of operation of the brake mechanism and types of uneven wear

- Brake fluid as the root cause of uneven pad wear

- What is the wear on brake discs?

- Severe wear on the caliper piston

- Signs of worn brake discs and pads

Hydraulics is everything

Nowadays, most cars have hydraulic brakes, that is, they work on a special brake fluid, which must be changed after a certain period of time . I would also like to note that these compounds are classified according to DOT (generally accepted standard); now there are already five classes from DOT1 to DOT5.1, some have already been discontinued, others are in use. By the way I wrote here which ones can be mixed and which ones cannot.

So that’s why I started with the “brake brake”, and because it is directly involved in this process, it is it that provokes uneven wear of the friction linings.

HOW? Yes, everything is simpler than it seems. Now I won’t go into detail about how the liquid absorbs moisture (everything is in the links above). You need to understand that after about 2 - 4 years (depending on what DOT you have), moisture accumulates in the car’s brake system (what it says inside), because the “brake fluid” is hygroscopic, it absorbs water and after a few years its percentage can be from 3.5 to 4%! What is really dangerous is that this mixture can boil when braking. But that is not all.

Signs of worn brake discs and pads

Brake discs and brake pads are the most wear-and-tear elements of the braking system, which is why it is vitally important to know the signs, so to speak, the warning signs that it’s time to change them. The phrase “vital” should be taken literally, because worn out discs and pads mean, first of all, an untimely stop of the car. And an untimely stop, in many cases, leads to fatal consequences for the driver, passengers, and pedestrians.

Since we live in the 21st century, most people drive, if not the newest, then modern cars exactly where the most likely sign of worn discs and/or pads is the indicator light on the dashboard. You should never ignore it, remember - it is the first of the bells foreshadowing imminent trouble.

And so, let's start with indirect signs of wear on brake discs and/or pads, which you can roughly navigate, so to speak, without leaving the car. Conditionally, because these signs can have many other reasons. Remember - it is possible to accurately determine whether the discs and pads are worn out only by inspecting them.

In recent years, many companies have begun to produce brake pads with a wear indicator - this is a metal strip installed under the friction material. When the mass of friction material is worn down to the initial degree of unsuitability (i.e. braking becomes less effective, but is still present), an indicator appears that produces a nasty grinding, squeaking, or whistling sound when it comes into contact with the metal of the disc. If the pads do not have an indicator, then squeaking and grinding noises will appear in the extreme stage of wear, which is very dangerous. In addition, the need for increased force when pressing the brake pedal and an increase in braking distance may indicate wear of the pads and discs.

Accelerated wear of the disc-pad pair can occur if solid particles of sand, dirt, etc. get between them. As a result, their partial destruction, unevenness and cracks are possible. This is indicated by the appearance of a barely noticeable vibration, the beating of the brake pedal when pressed, but its appearance is also possible when the brake cylinders malfunction, wear of the hub, caliper, CV joint, and also when the disc is deformed.

If one pad wears out faster, the car may skid in one direction or another when braking, and when stopping at high speed, it is quite likely to spin out even on a dry road.

At later stages of wear, the pad may burn (stick) to the disc, which is manifested by the absence of pedal return after pressing. Since the friction material is almost completely worn out, overheating causes the metal of the pad to melt and stick to the disc. Only a suicidal person can drive with such pads.

If any of the indirect signs appear, immediately inspect the brake system at a service station, or yourself! Remember that not only your life may depend on the serviceability of the brakes of your car!

Direct signs of wear on discs and pads can only be detected when inspecting them; this may be:

- a decrease in the thickness of the pad lining below the permissible level, which can also manifest itself in the form of gaps in the indicator metal;

- cracking and peeling of the friction material of the pad (formation of cracks, chips, pits, tubercles);

- reducing the thickness of the brake disc plane below the permissible level (like the thickness of the lining, it is checked with a micrometer);

- disk cracking;

- the formation of a protruding edge along the outer edge of the disk;

- deep scratches and chips on the disc and pad linings;

- deformation, distortion of the disc.

You can delay or even avoid the appearance of many of the above symptoms by using branded components specially manufactured for a particular brand of car. Don’t forget that your, and perhaps not only your, life may depend on the performance of your car’s braking system. It's one thing to die yourself, but to become a murderer due to your own negligence is a completely different matter.

Severe wear on the caliper piston

Perhaps the most common cause of uneven pad wear. It often occurs precisely because of untimely replacement of brake fluid. As you know, brake fluid needs to be changed because it becomes saturated with moisture. The presence of moisture in it negatively affects the piston, which begins to rust from the inside and, as a result, does not work well. When the driver presses the brake pedal, the piston compresses the brake pads. When you release the pedal, it should move away. But, if the piston is heavily rusted or worn, then when the pedal is released it may remain slightly (or significantly) pressed against the brake pad. Since there are two pistons on one axis, and one may be more worn than the other, the likelihood that they will both “jam” equally is extremely low. Hence it turns out that one pad wears out unnecessarily, but the second does not.

Anthers

They are on both the guides and the caliper piston. Usually made of rubber, less often of silicones. If they tear, then destructive agents - dirt, moisture, salt, dust and other delights of our roads - get to the surface. It must be said that if it breaks, then expect it to jam in a few days, maybe weeks.

This is an indirect reason and always nasty, however, there is a lot behind these rubber bands. So we keep an eye on them and change them if necessary.

Main signs of brake pad wear

Let's look at how to determine brake pad wear:

1. Strange behavior of the braking system.

If you begin to notice that the braking has become too harsh or weak, and the brake pedal drops lower than usual, then this is a signal coming from a worn-out pad.

2. Beating during hard braking.

The noise and sensation of beating indicate one of two possible causes. The first is pad wear. The noise occurs due to chips and cracks on the part that appear as a result of uneven abrasion of the surface of the product, the service life of which is already nearing the end, and the part itself requires urgent replacement. The second possible reason is brake disc wear. In this case, it is necessary to replace the spare part or sharpen it.

3. Metal shavings on rims.

This method of checking is only possible if you do not have ventilated brakes or alloy wheels. The check is as follows: under the wheel cap, you need to check for metal inclusions in the brake dust. If they are present, this indicates damage to the lining, causing the disc to be scratched by the pad. If they are absent (the color is charcoal and uniform), then everything is in order with the overlay.

4. Reduced brake fluid level in the reservoir.

Indicates possible problems with the brake pads or discs.

5. Sensor signal (if available).

The sensor is mounted in the friction lining. Wearing the pads to a minimum causes the circuit to close, which triggers the activation of a signal about the need to replace them on the car control panel. However, you should not completely rely on the sensor, because... the wire may corrode due to contact with water, which will disable the alarm system.

One of the most effective ways to detect faults is to diagnose the brake system in a car service due to the fact that not all problems are clearly visible. In addition, the level of pad wear and the time until it needs to be replaced is best determined by expert analysis. Here you can select and install a replacement for a worn-out part on favorable terms.

Braking of a car occurs as a result of friction between the brake pads of its wheels and the discs. This happens at the moment when the driver presses the corresponding pedal

Often we don’t even think about their condition, and only when problems begin do we pay attention to them. Over time, these elements wear out, this is quite normal, because the pad is specially made of a softer material than the disc so that wear is present on it

However, such “erasing” does not bring anything good; you need to clearly understand and “see” the signs of the main elements of braking, otherwise traffic safety decreases...

What factors influence wear?

Many car owners ask what is the acceptable level of wear on brake discs? The answer to this question is as follows: each manufacturer indicates its own specific wear limits. This applies not only to brake pads, but also to discs.

There are special tables for different car models. The indicators are related to the difference in vehicle weight and power. The combination of indicators affects the degree of load exerted on the elements of the braking system.

Let's consider a number of main factors that affect brake disc wear:

- the quality and properties of the material from which the parts were made;

- a number of mechanical factors;

- operating conditions of the vehicle;

- driving style.

Material of manufacture

The first thing that will affect the wear of the braking system elements is the material from which the parts were made. Initially, cast iron was used to make this part - a durable but at the same time heavy material. The development of modern technologies has made itself felt: now ceramics and carbon fiber are being used as materials for the manufacture of brake drums and discs. Therefore, the cheaper the material, the faster the part will wear out and will need to be replaced. This factor should be considered objective. Now let's look at the subjective part.

1 – ceramics; 2 – carbon; 3 – cast iron

Mechanical factors

The main mechanical factors include:

- car mileage;

- quality of brake pads.

The high mileage of a car plays an important role in the operation of the braking system, since all its elements are designed for a certain number of kilometers traveled. And no matter how hard you try to drive and brake smoothly, replacing discs or pads remains inevitable.

Poor quality brake pads also negatively affect the operation of the system. During operation, various “scores” can form on the disk plane, which appear as a result of uneven wear. In this case, it is necessary to bore the brake discs or drums, and then remove the worn pads and install new ones in their place.

How to determine whether a brake disc is worn

Vehicle operating conditions

This factor most likely depends on the driver. For example, at sub-zero temperatures there is a greater chance that the disc will become deformed. During movement, the temperature in the disc area rises, and if liquid gets there (for example, from a puddle), then at low temperatures the disc may become deformed. If repeated frequently, the part may fail, and only a recess or replacement will solve the problem.

Driving style

As statistics show, the service life of a brake disc is 100-200 thousand kilometers. But in some cases, even after 20 thousand kilometers, the disc can wear out completely. The result of such a premature “death” of a part is a peculiar driving style – “Schumacherian”, when braking and acceleration are very often repeated. Do not forget also that emergency braking often leads to wear and tear of the braking system elements.

The influence of driving style on the wear of brake system parts

Brake fluid as the root cause of uneven pad wear

Brake fluid is an important component of a vehicle's hydraulic brake system.

It must be changed in a timely manner so that problems do not arise with the brake system components. At the same time, it is important to use exactly the brake fluid that is suitable for your car, while many of its variations can be found on sale, classified according to the DOT system. As such, brake fluid does not affect uneven pad wear, but it does cause damage to parts that lead to the problem in question. Let's look at this issue in more detail below.

Uneven wear of pairs of pads on one axis

If the front pads wear unevenly, there may be several reasons. Most often the problem occurs due to “fingers”

Since the caliper runs on guides, it is important that they are well lubricated. If the lubricant has dried out, the seal has been lost or failed, the operation of the system is disrupted, which leads to uneven wear of the pads

To avoid this, change the seals on time, check the guides for foreign impurities and contaminants, and lubricate them with special compounds. You cannot use pad lubricant for the “fingers” - they have different performance characteristics. The lubricant on the guides must be special.

The second common cause of malfunction is damage to the brake hose. It is located in such a way that it is regularly exposed to external influences, for example, impacts from stones flying from under the wheels. As a result, the tightness of the brake system decreases, its operation is disrupted, and the intensity of pressing the pad to the disc during braking changes. Plus, if the hose is damaged, brake fluid leaks. The hose needs to be changed.

Problems with hydraulics also affect natural wear and tear - braking occurs abnormally. Water lock is a common problem. The piston stops moving as expected, the pads are not pressed against the disc with the proper force, and the load is distributed unevenly.

An additional symptom of a hydraulic lock is that the car pulls to the side after pressing the brake pedal. To fix the problem, you need to take the car to a service station.

Unusual wear can occur when the brake disc is warped. This most often happens during heavy braking, when the system cools sharply (for example, a car drives through a puddle of cold water). A sharp temperature change - and the disk becomes deformed. This usually only happens on one side.

As a result of imbalance and uneven pressure, the pads also wear differently. An additional symptom of this problem is a wobbly steering wheel. The situation can be corrected by replacing the disk and related parts.

Souring and caliper wedge

The last reason to keep in mind is caliper souring. It can be caused by many factors - from drying out of the lubricant on the fingers when the vehicle is idle for a long time to moisture getting into the mechanism.

If the caliper jams due to souring, the brakes will not perform their functions correctly, which leads to uneven wear of the linings.

Wherever the reason for the poor performance of the car’s brakes lurks, it is important to identify and eliminate it as soon as possible, otherwise there is a risk of the brakes failing while driving, which is one of the most common causes of accidents.

What to do if you’ve already “got it”?

My verdict is clear - remove the damaged disks, throw them in the nearest trash can, buy and install new ones. But let me explain why I think so. Many at this point thought: “What a fool, you can save money and just sharpen the curved discs that have begun to “beat!” No matter how it is.

Grooving brake discs without removing them from the car. Quick and easy, as long as you leave the station quickly and leave the money. It is advisable to come again later. However, this is relevant

The grooving machine can really maintain the flatness of the plane with an accuracy of 0.0005 mm, and the discs will indeed be almost perfectly flat after grooving. But do not forget that they are most often driven by overheating, albeit due to various technical reasons. Brake discs are made of cast iron, which does not like overheating and quickly changes its properties as a result. The grooving will remove the surface layer of the metal, but literally 1-2 good braking times and the discs can again be removed and taken for grooving. Is it worth it?

A groove can also remove grooves and correct wear on one side. But there is another question - how much metal will have to be “cut off” and how much of it will remain after cutting? How many kilometers can you drive after such a repair? Maybe it’s better not to try to save money?

In addition, if you have obviously low-quality disks installed, this is an excellent reason to change them. Yes, the pleasure is not cheap, but it is better to buy the experience in this way than to later get into a serious accident.

The main reasons for uneven pad wear

There are 15 common and quite rare reasons that can lead to the mentioned problem. We list them in order with a detailed description and instructions on how to get rid of such troubles.

Brake fluid

Brake fluid itself does not cause uneven pad wear. However, it becomes a kind of catalyst for processes that can lead to this. They will be discussed further, but here it is worth mentioning that the brake fluid must be changed according to the regulations, without waiting until it is saturated with moisture. In this regard, you also need to monitor the tightness of the car’s brake system. Not only the condition of the brake system depends on this, but also the safety of the vehicle, its driver and passengers.

How often to change brake fluid Useful recommendations on how often to change brake fluid in a car. Regulations on the frequency of changing brake fluid. More details

Even when braking, the discs become very hot, and a squeaking noise is possible (although these symptoms may indicate other malfunctions). Therefore, along with inspecting the condition of the pads, it also makes sense to inspect the condition of the brake disc. If it overheats, this will be visible in the condition of its surface; instead of the usual shiny white color, there will be dark marks on its surface.

Caliper problems

Disc brake device

In particular, the caliper piston may be the culprit when the pads wear unevenly. That is, it does not retract completely into its seat. This happens, among other things (and most often) due to the fact that, as stated above, the brake fluid has become saturated with moisture, which causes rusting of the metal surface of the drive piston. And it rusts from the inside! And if one piston, after releasing the brake pedal, works normally and moves the brake pad to its normal seat, then a rusty piston may not do this, and its pad remains in place and rubs against the brake disc. And this not only harms the block, but also causes excessive consumption of engine power, and as a result, fuel.

The second reason is the presence of rust on the caliper bracket or, simply put, souring. Rust can form for various reasons, but most often it forms when a car sits motionless for a long time in a humid climate (for example, this is relevant for the Far Eastern region of the Russian Federation). However, such a situation can occur not only in a humid climate, but also in a normal climate, provided that the car has been standing motionless for a long time (for example, several months or even years).

Another reason why pad damage may occur is the use of inappropriate guide lubricants. In particular, to lubricate this unit, you need to use compounds that can withstand high temperatures. Unfortunately, some car owners neglect this requirement and use unsuitable compounds for lubrication, which, with a significant (and most importantly, sharp) increase in temperature, either evaporate or harden and crumble. As a result, a wedge of the caliper is possible with all the ensuing consequences - the guides become immobilized and uneven wear of the pads occurs. In this case, you need to inspect the place, check the movement of the moving part and, if necessary, replace the lubricant in the guides, as well as clean the elements of the brake assembly.

In addition to changing the brake fluid and using caliper lubricant, you should clean the guide bracket from rust before installation. Treat the caliper piston with cleaner and lubricate it too. If the piston is very worn due to rust, then it is necessary to replace it and also change the seal. But you need to do this yourself only if you are confident in your abilities and knowledge of how to carry out the appropriate procedure. Otherwise, it is better to contact the service.

Problems with guides

The most basic problem with this malfunction is damage to the boot. According to statistics, uneven wear of the front pads most often occurs for this reason. As you know, guides (or in common parlance “fingers”) should move easily and freely, without rubbing and not sticking. To provide them with such conditions, car owners or mechanics use special lubricants for guides. If dirt, debris, or moisture gets on the surface, then rust forms there, which prevents normal movement, and the moving part begins to jam. Accordingly, when braking, the pads are compressed, and one (in the worst case, both) of them cannot move back due to the fact that they are not given guides. For this reason, uneven wear occurs.

You can get out of the situation by carefully inspecting the mentioned unit, as well as, if necessary, cleaning and lubricating it. There should be no wedges, the pads should move in both directions easily and smoothly! After performing repair work, be sure to check the functionality of the specific brake unit, as well as the entire brake system as a whole .

Leaky boot

There are boots on both the caliper piston and the guides themselves. In the classic version, they are made from technical rubber, but more modern versions are also made from silicone. The latter are much stronger and more elastic, and also last much longer, do not crack, and withstand large mechanical loads (do not break when stretched). However, classic rubber boots are subject to all of the listed shortcomings, so over time (it’s only a matter of time) the boot body begins to let dirt and moisture into the mechanism. And the most unpleasant thing here is that in such a situation the brake can jam within a few days, or at best, after a few weeks. Typically, such a problem is more relevant for the external pad, although, of course, it can happen with the internal one.

Debris that gets inside can cause a lot of damage in a variety of areas. One of these troubles can be uneven wear of the pads, which can occur for the reasons described above (piston jamming, etc.). Therefore, when inspecting the brake system and a specific brake assembly, you should always pay attention to the condition of the boot, and if necessary, use a repair kit for calipers. It is better to buy new silicone boots, not old rubber ones, for the reasons described above.

Uneven rear pad wear

The rear pads themselves do not wear out as quickly as the front ones, but there are situations when they also wear unevenly. Among other things, in this case it makes sense to check the operation of the hand (parking) brake. If the drive cable is too tight, the “back” of the pad may wear unevenly. The solution is simple - adjust the normal force on the parking brake. You can do this yourself or by contacting a car service. You need to look up the force value in the machine manual.

The second similar reason is the jamming of the handbrake. That is, when it is constantly activated. In fact, this is a very unpleasant situation when excess engine energy is consumed (read excessive fuel consumption), the dynamics of the car are reduced, and excessive wear of the rear brake pads occurs. As a rule, a corresponding light on the dashboard indicates that the handbrake is on. Typically, the reason for the parking brake jamming is contamination of the cable entry point into its “jacket.” Accordingly, you need to clean the cable from dirt, or, if necessary, replace it with a new one (or, if possible, replace the “shirt” with a new one).

Uneven wear of the vehicle on one axis

The true cause of uneven wear of brake parts can be determined using diagnostics, which is carried out in a professional car service center.

The main problem is the uneven wear of the inner and outer brake pads of disc brakes, which occurs for several reasons:

- the piston moves with deviations from the design stroke - it does not retract completely due to damage to the rubber seal;

- the appearance of rust on the caliper bracket, leading to “sticking” of the brake caliper;

- The guide seal is damaged (dirt gets in), which prevents the vehicle from returning to its normal position after the end of braking.

Deterioration in the performance of one or another vehicle on one wheel is only one of the reasons for incorrect braking. Another fairly common situation is uneven wear of the brake pads on one axle: the right and left front (rear) wheels.

More intense wear on one of the wheels may be caused by:

- exit from standing one of the guides;

- problems with hydraulics that prevent the TC from being pressed with the required force;

- damage to the hose;

- ABS malfunctions;

- disc deformations.

Sometimes a situation arises when the rear brake pads, contrary to generally accepted practice, wear out faster than the front ones. In this case, with almost one hundred percent probability, the problem is that the parking brake cable is overtightened or jammed due to contamination or improper adjustment.

Uneven wear of the rear brake pads working with the drums is often associated with jamming of one of the cylinders, resulting in asynchronous braking of the wheels, accompanied by a skid of the car.

Among the most common reasons for the development of such a problem are the following malfunctions:

- Excessive wear of the caliper piston;

- Problems with guides;

- Violation of the integrity of the anthers;

- Souring of the caliper.

When particles of debris and dirt, moisture and other substances get on the guides, chips and scratches form in them. As a rule, this leads to jamming of the guides, which causes uneven wear of the pads in the future. To prevent this from happening, the guides must be lubricated with a special lubricant.

DETAILS: P0016 error code for violation of the relationship between CKP and CMP Causes of error p0016 and method of elimination for Toyota Volkswagen, etc.

Torn anthers usually lead to failure of the brake system very quickly. Sometimes a car doesn’t last even a month without breaking down. To prevent this unpleasant incident from happening, the anthers must be periodically inspected and replaced. Otherwise, it will not be possible to do without expensive repairs of brake system elements.

Wear of internal pads

The internal pads are structurally protected from the negative effects of external factors, so many car owners are puzzled by the discovery of their more intense wear. This state of affairs may be caused by the fact that after releasing the brakes, the piston does not return to its original position, partially pressing the pad against the disc element, or not pressing the brake mechanisms at all. This manifests itself in the abrasion of the part at a certain angle or the absence of wear due to a loose fit.

This often occurs due to damage to the piston seal (oil seal), which begins to let dirt into the cylinder, which causes rusting and jamming of the unit. Such a malfunction is solved by dismantling the caliper, washing and cleaning the cylinder, followed by replacing the damaged rubber product.

A decrease in the service life of internal pads can also be caused by heavy operating loads, which arise, for example, when driving over rough or mountainous terrain. In this mode, they begin to wear down many times faster than external pairs, regardless of the design of the brake mechanisms.

How to assess the wear of drum brakes?

Most machines have an inspection window on the side of the drum casing to assess the thickness of the linings. However, most often it can only be used if the car is hung on a lift or standing on a viewing hole. Otherwise, it is extremely difficult to see anything through this window.

The left photo shows the location of the inspection window relative to the drum shoe. Using it with only a jack at your disposal is not very convenient.

The left photo shows the location of the inspection window relative to the drum shoe. Using it with only a jack at your disposal is not very convenient.

Removing the drums is sometimes also very problematic. For example, for cars of French brands you will have to unscrew the hub nut. In the case of Kalina, everything is simple; the drums can be removed without any problems.

You can assess the wear of the elements of the drum brake mechanisms on Kalina by removing the drum casing.

You can assess the wear of the elements of the drum brake mechanisms on Kalina by removing the drum casing.

Typically, drum wear is assessed by the internal diameter: its increase by 1 mm means a death sentence.

Why do the rear pads wear out faster than the front ones?

Many car owners attribute greater wear on the rear pads to some kind of design defect due to the fact that the same hydraulic force must be transmitted to all wheels while driving. Therefore, in the absence of pronounced external influence, their friction linings should wear out evenly.

In fact, the brake pads of the rear wheels of some vehicles are equipped with protective linings with a more compact working area. In this way, the braking force is balanced between the axles without the participation of the brake pressure regulator (sorcerer). Due to the reduced contact area, the rear pads lose performance much faster than their front counterparts.

Another factor that causes uneven pad wear is the lack of protective shields on the rear brake mechanisms. The fact is that while driving, the front wheel of the car raises road dust and sand, which settle on the surfaces of the parts. Because of this, the lining becomes thinner and the rear brake pads jam.

Disc brakes

Disc brakes are most often found on mountain bikes, although recently, with the advent of budget models, they can be found even on road bikes, and they are finally being used on the road (braking on a carbon rim in the rain is even more fun).

Regardless of how many pistons you have, there are usually 2 pads in a disc brake, although there are all sorts of experiments, like the Magura MT7 with four pads.

To assess the degree of wear on disc brake pads, you will first have to remove them from the caliper; the title photo of this post once again confirms that it is better to inspect the pads when removed from the bicycle. Take a look at the photo below, it shows the difference between the worn and new pad.

You've probably noticed that the wear is also uneven; one part of the pad has worn out more. This happens with hydraulic brakes and may indicate that the piston is slightly distorted or the piston seal in the caliper is dirty. Before installing new pads, you will need to align the piston and lightly lubricate it. The best lubricant to use is not just any sprays or oils, but mineral fluid or DOT, depending on what is used in your brake. A couple of drops where the piston exits the caliper will be quite enough; the excess should be wiped off with a rag.

But let's get back to our pads. It's time to change them if the thickness of the working surface of the pad is less than 1 millimeter. Of course, such a block is “still good”, but don’t delay replacing it. If the abrasive wears off and the metal of the pads begins to rub against the brake disc, then most likely you will have to replace it too, or change the pads very often. Rotors with a damaged braking surface “eat up” the pads very quickly.

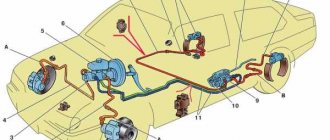

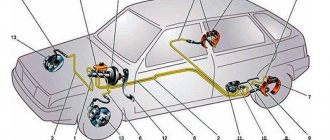

The principle of operation of the brake mechanism and types of uneven wear

It is not easy to understand why brake pads wear unevenly if you do not have an idea of the operation of the mechanism as a whole. The operating principle does not have complex elements. The entire mechanism is shown in the figure below.

It includes: a brake disc, above which a U-shaped caliper is installed, containing a working cylinder piston. The caliper holds two pads, between which the disc rotates. By pressing the brake pedal, the driver activates the hydraulic mechanism. The fluid in the system pushes out the piston, which presses the first pad against the disc. The counterforce moves the caliper along the guides, after which the second pad is pressed.

Drum brakes, which are installed on the rear wheels, work on a different principle. There are two pistons in the brake wheel cylinder. When you press the pedal, the pistons press the pads against the walls of the drum. The car slows down. By releasing the pedal, the driver starts the reverse process, in which the springs attract the elements to the center of the drum.

See also:

Which alloy wheels to choose for your car

Features of operation

To begin with, let’s briefly look at the principle of operation of the mechanisms, so that in the future it will be clearer why uneven wear occurs.

Disc brakes are becoming more common, and many cars come with this type on all wheels.

The operating principle of these mechanisms is quite simple. Above the brake disc mounted on the hub is a U-shaped caliper.

Its design includes a working cylinder-piston. There are two pads between the caliper lugs and the disc.

When you press the brake pedal, the fluid compresses the piston and begins to press on the pad.

In this case, a counterforce appears, which forces the caliper to move along the guides. Due to this movement, the second block is pressed.

Drum mechanisms are now used less and less and are located only on the rear axle.

Here the principle of operation is even simpler: two pistons are installed in the working cylinder, which, when exiting the cylinder, each presses its block against the drum.

It should be noted that uneven wear on brake pads is always present and is considered normal.

The fact is that elements on the front axle wear out more than on the rear axle.

And if you take a car with drum brakes at the rear, the difference in wear rate is very significant.

The faster disengagement of the pads installed on the front axle is due to the fact that the load on them is greater, since the vehicle's weight moves forward when braking.

As a result, they are the ones who do the main work, but this makes their cancellation stronger.

Proof of this is the fact that the rear pads are changed two or even three times less than the front ones.

Types of uneven wear of brake discs

The second point of our excursion today is the types of wear and their manifestations. I’ll say right away that the handles will have to get dirty, because the best way to determine the condition of the brake discs and the reasons for the improper operation of the brakes is by simply looking at them! And to do this you will have to jack up the car and remove the wheel from the side you are interested in. And everything will be visible there.

There are not so many types of uneven wear and you will notice them immediately:

- Grooves left on the outer or inner side of the disc.

- The presence of obvious signs of wear on one side of the disc, but no signs on the other.

- "Wave", i.e. curvature of the axial plane of the disk.

The furrows are, of course, the most obvious mark. It looks as if someone scratched the disks with a stone, leaving deep marks:

There may also be chips, even inclusions of material from the pads, cracks, etc. One-sided wear is also easy to notice, because the disk will be heavily worn on one side, but not on the other. Here, as they say, it will be noticeable “with the naked eye.” The “wave” is somewhat more difficult to notice, because the curvature of the disk can amount to tenths of a millimeter. Vibration when driving will indicate this.

An example of brake disc wear due to a soured piston in the caliper on a Mitsubishi Pajero. I wonder what it was like to drive with such brakes, my teeth were probably chattering, literally

How to find out the abrasion thickness?

In order to find out the permissible maximum thickness of the brake disc, you should look at the end of the product. There are two meanings to this part. This is the original thickness, as well as the minimum allowable. The numbers may vary depending on the car and wheel manufacturer. How to determine the degree of wear of brake discs? It is enough to simply measure with a caliper and compare the numbers with acceptable standards. This is how you determine whether the product can still be used or not. The disc should also be changed if it has different thicknesses at different points.

Human factor

The most common reason for brake pads to wear out too quickly is human error. The pads wear out quickly on cars driven by drivers who use both feet (the left one is on the brake pedal, the right one is on the accelerator) when operating the car. The left foot of such drivers is constantly in contact with the brake pedal.

Any pressure on the pedal activates the brake mechanisms. Even a small force applied to the edge of the pedal causes the pads to contact the brake disc on a moving vehicle. This contributes to rapid wear of the brake pads.

This process is also accompanied by overheating of the brake discs, which can be easily identified by bluish marks of tarnish on the surface of the disc.

Features of work

Of course, the first advice you will hear from specialists is to take your car to a workshop for a full diagnosis on special stands. But such an undertaking costs a lot of money, and not every person will be able to find enough free time for this.

When braking, the contact surfaces of the discs and brake pads generate a large amount of heat. Strong heating of the brake system components leads to their damage. To prevent premature wear, developers equip the system with different cooling methods. In most cases, this is air ventilation of discs or drums.

But this does not mean that you do not need to know how brake disc wear is determined.

Caliper wedge due to souring

Perhaps the last reason that is important to pay attention to in this article is caliper souring. It can occur due to various problems - from drying out of the lubricant on the guides when the car is idle for a long time to water ingress or simply poor-quality workmanship of the part.

If the caliper becomes wedged due to souring (or any other reason), the brake system will not work properly, and uneven wear of the brake pads may occur.

( 395 votes, average: 4.53 out of 5)

Souring

It seems that the boots are intact and not torn, and the caliper seems to be in order. But “damn” sticks, that’s it! What can be wrong?

Over time, especially if you do not use the car for a long time (it was parked during the winter), the lubricant on the guides can simply dry out or become sour. Then we get the same effect, a wedge of the caliper; again, uneven wear is possible.

These are the main reasons; of course, it can also be caused by poor-quality pads, leaking seals, or air in the system. But these are very rare reasons; the main ones still lie in the calipers and its moving parts.

I think you were interested, read our AUTOBLOG, subscribe to updates.

Similar news

- Is it possible to mix brake fluids? Let's say you produce different...

- Brake fluid composition. Basic properties, necessary information

- Rust converter composition. Can I do it myself?

Add a comment Cancel reply

One of the pads is rubbing faster

So, it has been noticed that the inner pad of a disc brake is much thinner than the outer one, although their wear should be uniform.

The reason for such wear usually lies in the fact that the piston, after releasing the brake, does not completely return to its original position, which is why the inner pad remains slightly pressed against the disc and is constantly in contact with it, which leads to its faster erasure.

This often happens due to damage to the piston seal, which causes dirt to get inside the cylinder, which causes jamming.

This problem is solved by disassembling the caliper, washing and cleaning the cylinder, as well as replacing the damaged rubber element.

Increased wear of the outer pad also occurs due to the fault of the rubber components - guide seals.

As a result, dirt and moisture that gets on the guides lead to corrosion, which causes the caliper itself to jam, which is why the outer pad is constantly in contact with the disc.

In this case, the problem is solved by removing the caliper, cleaning and lubricating the guides, and replacing the seals.

Rust and dirt can also cause wear, both external and internal.

Their formation on the component elements can lead to jamming of both the pads themselves and the caliper.

Therefore, it is necessary to periodically disassemble and clean the component elements of the mechanism.

The pads of one mechanism rub faster than the second

If on one side, for example, the pads on the right rub faster than on the left, the drive most often becomes visible, although not always.

If we consider only the working elements themselves, then increased wear can occur due to rust and dirt, especially on the guides.

Due to corrosion, the mobility of the caliper is greatly reduced, and if you add dirt in the cylinder itself, then it turns out that both pads will be constantly pressed against the disc, which will ensure their accelerated wear.

Another option concerns the mechanisms themselves. If the brake disc is warped and its geometry is damaged, then this will certainly affect the pads in the form of their accelerated wear, so if necessary, you need to re-groove the brake discs.

But if we take the drive, then the reason should be sought not in the mechanism that wears out more, but in another one.

If an air lock appears in one of the drive lines, or it is clogged with dirt, then the liquid will not be able to properly influence the piston, and because of this, the pads simply will not be pressed against the disc.

Typically, this problem additionally manifests itself in the form of the car pulling to the side when braking.

The causes of this problem can be partially attributed to a breakdown of the drive line. But usually such a breakdown is detected very quickly, so it does not particularly affect the wear of the pads (unless, of course, you continue to operate the car with one inoperative circuit).

Uneven wear on one side of the axle (right or left) may cause a malfunction of the ABS module (if equipped).

If this module breaks down, it stops regulating the fluid pressure, which can cause one of the mechanisms to be supplied with increased pressure, which will lead to accelerated wear.

To fix this problem, you should carry out comprehensive maintenance:

By carrying out these measures, it is possible to identify the reason why the elements of one of the mechanisms are worn out more and eliminate it. And the prevention of the brake system itself will not be superfluous.

Problems with guides

As you know, when working, the caliper “walks” along guides, which are often called “fingers”. If dirt, moisture gets on them, they rust, chips, scratches or other mechanical damage appear on them, then a problem arises with their jamming. The problem is similar to the situation with caliper wear - the friction part on one side may be excessively compressed, which is why uneven wear of the pads will occur.

To prevent such a situation from arising, you should not only monitor the brake fluid and change it in a timely manner, but also be sure to lubricate them with a special lubricant when installing the pins. Please note that a common mistake is to use pad lubricant on the guides. This is wrong; there is a special lubricant for them with the necessary properties.

Guides

You and I know that the main part of the caliper runs along special guides or, in common parlance, “fingers”. They should always be clean, smooth, and it is advisable to have a special lubricant for the guides (there should simply be no “sticking”). By the way, you CANNOT use lubricant on the pads themselves , they are not the same!

If something is disturbed, for example, moisture, dirt, dust gets in, or rust forms, then the moving part can also jam. Again, when you press the brake pedal, the friction parts are compressed, but the rear part does not move away (the guides do not provide), and the piston has moved away, so uneven wear occurs.

WHAT TO DO? When changing brake pads , lubricate these “fingers” with grease and check their performance, there should be no WEDGES!

A short video on the topic.

What determines brake pad wear?

1. Operation process.

Under normal operating conditions, brake system pads wear out after 15-30 thousand kilometers or more. However, these are not reference values. Wear can occur later or earlier, especially if the emergency braking is abused. Here a lot depends on the driving style and the quality of the pads themselves.

2. Manufacturer, model of the brake system and quality of friction linings.

Each specific case has its own estimated wear time. They are usually indicated by the manufacturer on the part itself.

3. Technical faults.

The reason for uneven wear of brake pads, as well as shortened service life, is a malfunction of the brake cylinders, which also leads to damage to the brake disc.

Determining wear

Often, checking the condition of the braking system does not require the help of specialists, since the driver can do all the necessary work on his own. In addition, no special tools are required for testing.

Which will allow you to determine the wear of elements:

- metallic grinding noise when braking;

- presence of vibration;

- outside noise;

- jerking when braking;

- the presence of cracks and/or gouges on the working surface of the disk.

The presence of the symptoms described above indicates a problem in the braking system, to eliminate which the necessary measures should be taken.

Important! The presence of smooth and quiet braking without external sounds indicates the good condition of the braking system. If you hear noises while braking, and your car begins to jerk and turn in every possible way, then the system is not functioning correctly and you need to diagnose it for malfunctions.

If, during a visual inspection, you find some defects and malfunctions, then repairs must be carried out as soon as possible. Don't put it off until later, as a faulty brake system is a threat to your health.

When you are not 100 percent sure, special measurements will help you figure it all out.

Carrying out measurements of brake disc wear

Measure the thickness of the outer part of the disc using a caliper. Then compare the data obtained with the recommended thickness, which you can find on the official website of the manufacturer or in the repair manual for your vehicle. There you can also find information about the service life of the brake disc on your specific model. Based on the information found, you can determine the effectiveness of your braking system.

If the recommended parameters are violated, you can be sure that your brake discs are badly worn. This means that the braking system will not be able to fully function and cannot be considered reliable.

How to avoid problems?

I would like to say something fundamentally new and unique here, but no. I won't say anything new here. Just watch your brakes, service them promptly, do not ignore the slightest signs of malfunction and forget about Chinese parts if you value your life! Do not forget to regularly lubricate the caliper guides, change the brake fluid and choose the right brake pads.

An example of pads that wore unevenly along with a disc, one half of which did not work. This usually happens due to jammed caliper guides.

Driving style also plays a significant role here. If you are a “city racer”, starting from a traffic light with the gas pedal on the floor and also braking, then uneven wear of the brake discs is generally not a problem for you, but a consequence of your driving style. You will either have to reconsider your behavior on the road or come to terms with the need to frequently replace discs.

If the car is driven in mountainous areas, then you should try to use engine and transmission braking so as not to overheat the brake discs on long descents. Many people ignore these methods of slowing down a car, although older drivers still remember how this was taught in driving schools. Engine and transmission braking are quite effective, do not ignore them, this will help extend the life of the brake discs.

What affects wear?

Each manufacturer prescribes brake disc wear standards. These parameters are obtained based on engine power, vehicle weight and other factors. But it is very difficult to calculate the mileage after which you will need to change the discs. Wear is influenced by various factors that cannot be taken into account.

First of all, it's your driving style. If the car owner prefers to drive more extreme, where sharp accelerations are replaced by equally sharp braking, then the service life of the disc is significantly reduced.

Mechanical factors also affect the service life. The material from which the brake disc is made is important here, as well as the quality of the pads. Often, discs are made from cast iron and its alloys - the material wears out more often than ceramics. The use of low-quality pads (for example, with asbestos) also leads to uneven wear.

Drum pad wear

Finally, a little about the drum mechanisms that are used on the rear axle. There are cases when the pads of these mechanisms wear out faster than disc ones.

In addition to their main function, drum mechanisms are also an integral part of the parking brake. And it is the handbrake that usually causes accelerated wear.

Moreover, because of it, they can be intensively erased both on both mechanisms at once, and on just one.

If accelerated wear is observed on two mechanisms, you should check the condition of the handbrake drive.

An overtightened cable causes the lever installed inside the mechanism to constantly keep the pads in a relaxed state, and they come into contact with the drum, rubbing against it.

If there is wear on the elements on only one side, you need to check the adjustment of the release mechanism. If this mechanism is not adjusted correctly, it will press them against the drum.

Well, don’t forget that the cause of wear on one side can be problems with the drive - airing of the line, its blockage, damage to the cuffs of the working cylinder.

Wedge erase

Wedge wear (part of the friction lining surface wears out faster) usually occurs due to careless maintenance.

So, in some cases, when assembled without following the technology, the guides bend. And this leads to the fact that the caliper fails, which is why at some point a greater pressure force is created on the block. This problem is solved by replacing the guides.

It is worth noting here that wedge wear is considered normal in some cases.

This result can be caused by using calipers with multiple pistons - two or more.

The fact is that the pistons do not always come out at the same time and at the same distance.

For example, when you press the pedal, the first piston may start moving a little earlier than the others, so the pressure will be somewhat uneven.

But it should be noted that wedge wear is considered normal if it is insignificant.

Damage to anthers

The integrity of the anthers determines how much moisture, stones and other debris gets onto the components of the car’s brake system.

When the boot has become unusable, the brake mechanism will not withstand even a month of use. It is worth changing them immediately to prevent damage to more important components.