The gas tank of any car always contains vapors formed due to a decrease in atmospheric pressure or heating of the fuel. In order to prevent the leakage of fuel vapors into the vehicle, a special gasoline vapor recovery system (VPSU) is installed. Thanks to it, the vapors retained by the adsorber (essentially activated carbon) enter the intake manifold and burn in the engine cylinders. To regulate the amount of gasoline vapor coming from the adsorber to the manifold, a special solenoid valve is used.

Principle of operation

The adsorber itself allows fuel vapors to accumulate in a special place - the separator. As a result, gasoline turns into condensate and goes back to the tank. Vapors that have not undergone treatment go through double valves of the system, one of which prevents fuel from spilling out during an emergency (for example, a coup), and the second “is engaged” in regulating the pressure in the tank. The adsorber purge valve is located under the hood, and the adsorber itself is located on the tank. The control unit ensures the normal operation of the entire system: it ventilates and removes condensation.

Error P0441

Owners of Lada Kalina often note that during the operation of the car, error P0441 appears, indicating that the gasoline vapor purge system is not operating correctly (the air flow differs from the norm). The cause of this malfunction may be:

- inoperative adsorber valve;

- clogging of the air line from the control unit to the air filter;

- air leakage through connecting pipes.

What should not be immediately considered is the line from the gas tank to the adsorber; here, a breakdown does not in any way affect the readings of the computer or diagnostic scanner. Still, most often Evap-Solenoid fails; this is a characteristic “disease” on Kalina.

If the EVAP valve stops functioning normally, it is not at all necessary that the engine will lose power, the fuel pump will fail, and so on. Mainly due to problems with the control gear, exhaust toxicity increases, and the Check Engine on the dashboard periodically lights up. There are car owners who do not pay attention to the diagnostic warning light, continuing to operate the car, but do not experience any great inconvenience. And most often in such a case, gasoline consumption does not exceed the norm, the engine starts normally, and no serious problems occur in the fuel system.

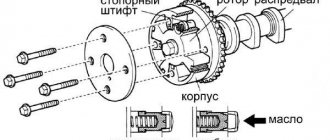

Design and operation of the adsorber purge valve

The KPA is an electromagnetic locking device that operates from the vehicle’s on-board network. The valve consists of:

- plastic case;

- valve with spring;

- windings;

- metal core;

- connector

When the vehicle's engine is turned off, no voltage is supplied to the valve and it remains in the closed position. That is, on the motor side, the system that captures vapors is blocked. At the same time, the adsorber begins to “collect” vapors. When the power unit starts, voltage is applied to the valve, causing it to open and fuel vapors to enter the intake manifold. As soon as the ignition is turned off, the control unit is de-energized and the pipeline is closed: no vapors enter the receiver.

Cars of a high price category have a more complex evaporation system. Such machines have special sensors that can “calculate” the amount of air and vapor as a percentage. This allows you to more accurately control the supply of gasoline to the injector.

Catalytic converter

To comply with Euro II standards for the content of harmful substances in exhaust gases, it is necessary to use a catalytic converter in the exhaust system.

The use of a catalytic converter provides a significant reduction in emissions of hydrocarbons, carbon monoxide and nitrogen oxides from the exhaust gases, provided that the combustion process in the engine is precisely controlled.

To speed up the process of converting hydrocarbons, carbon monoxide and nitrogen oxides into non-toxic compounds, the neutralizer has oxidation and reduction catalysts.

The oxidation catalyst is platinum. It promotes the oxidation of hydrocarbons and carbon monoxide contained in exhaust gases into water vapor and carbon dioxide.

The reduction catalyst is rhodium. It accelerates the chemical reaction of reducing nitrogen oxides into harmless nitrogen, which is one of the components of air.

Oxygen is required to neutralize hydrocarbons and carbon monoxide. At the same time, nitrogen oxides are reduced. Therefore, for the neutralizer to operate effectively, it is necessary to accurately maintain the balance of the air-fuel mixture supplied to the engine.

An increased residual oxygen content in the exhaust gases (during the combustion of lean mixtures) makes it difficult to restore nitrogen oxides. The reduced oxygen content in the exhaust gases (during the combustion of rich mixtures) makes it difficult to oxidize carbon monoxide and hydrocarbons. Only an accurate balance of the air-fuel mixture ensures effective neutralization of all three toxic components.

The most complete combustion of the air-fuel mixture and the most effective neutralization of the above-mentioned toxic components of exhaust gases are ensured with an air-to-fuel ratio of 14.5. 14.6:1, i.e. 14.5. 14.6 kg of air per 1 kg of fuel.

When operating a faulty engine, the converter may fail due to thermal stress (above 970 °C) to which it is exposed during the oxidation of excess amounts of hydrocarbons. Under thermal stresses, the ceramic blocks of the neutralizer can collapse (clog), causing an increase in back pressure.

Signs of a malfunction of the control unit

First, start the engine: at idle or in cold weather, you will hear a characteristic, barely audible chirping sound. It indicates that the valve is working properly. In order not to confuse this sound with the noise from a working timing belt, sharply press the gas. The character of the chatter should not change. The following signs indicate a malfunction of the control unit:

- lighting of the CHECK signal on the instrument panel;

- determination of error PO441 during testing;

- increased gasoline consumption;

- unstable operation of the power unit when driving;

- unstable idle;

- increase in CO2 content;

- a hissing sound when unscrewing the tank lid (a vacuum has appeared);

- the appearance of a fuel smell in the cabin.

Valve check on site

You will need a tester (voltmeter, multimeter) and a screwdriver. The KPA itself is installed on the radiator frame. The device can be recognized by seeing two tubes approaching it, through which the evaporation moves. Further:

- disconnect the electrical connector from the control unit by releasing the block lock;

- using a multimeter, check for the presence of voltage by touching the negative (black) probe of the device to ground, and the red probe to “A” (the letter on the block connector);

- turn on the ignition: the multimeter should show the vehicle's on-board voltage. If not, check the wiring.

How to check the adsorber valve removed from the car

You need to take a medical syringe of suitable volume, simply pull out the piston 2-3 cm and connect it to the outlet fitting. If you press on the piston, it will move with difficulty, which indicates that there is pressure in the valve. Now connect the battery to the electrical part of the control unit and press the piston again: the resistance should disappear. If this does not happen, you will have to buy a new valve.

Injection system on Kalina

The system that serves in the Kalina car to capture fuel vapors prevents their unplanned leakage into the atmosphere. These vapors are formed due to heating of the fuel in the gas tank, as well as when atmospheric pressure decreases. The vapors do not escape, but accumulate in the system; when the engine starts, they enter the intake manifold and burn in the power unit. To regulate the flow of fuel evaporation from the adsorber into the intake manifold receiver, the Kalina adsorber purge valve is used. This valve is installed on all cars with an injection-type engine. Its location is usually under the hood.

The system includes a special adsorbing mechanism consisting of technical activated carbon, a special valve with an electric-magnetic pulse and functional pipelines suitable for it.

The entire system is based on a so-called adsorber, which is capable of collecting all the fumes from the gas tank. Small granules of technical activated carbon, which are part of the absorbent part, absorb gasoline vapors and retain them inside.

How does the Lada Kalina gasoline vapor recovery system work?

The EVAP system in question was created to prevent the release of harmful gasoline vapors into the surrounding atmosphere resulting from fuel evaporation; it includes:

- fuel shut-off valve;

- adsorber;

- solenoid valve for purging the absorbent element;

- connecting pipelines.

New Lada: Bolt tightening torque table VAZ 21126

The most important component in the system is the adsorber (also called a carbon filter), the basis of which is activated non-edible carbon, enclosed in a plastic housing. The resulting gasoline vapors are absorbed by the carbon of the absorbent element, gradually accumulating in it.

On the Lada Kalina, the adsorber is located in the gas tank area, and getting to it is very difficult. To dismantle this EVAP element, it is necessary to remove the fuel tank, but the control unit is located in an accessible place - the valve is located in the engine compartment, in close proximity to the battery, on the rear wall of the air filter housing.

Without electronic control

According to theory, about 20% of hydrocarbon (CH) emissions from cars come from fuel evaporation. The fuel vapor recovery system (EVAP - from “evaporative”) serves to accumulate and utilize them, preventing them from entering directly into the atmosphere.

Vapors are formed in the tank as the fuel temperature increases (especially in circuits with fuel return lines from the manifold), and with increasing pressure they begin to enter the adsorber with activated carbon.

In modes when the engine can normally accept additional enrichment of the mixture, these accumulated vapors are “blown” into the intake manifold and added to the charge of the air-fuel mixture for combustion in the cylinders.

The early type system included the following components: - fuel tank, - filler cap with vacuum check valve, - canister with a set of check valves, - thermal pneumatic valve (BVSV, TVV), - EVAP port in the throttle body.

In some cases, there should be a slight excess pressure in the tank to reduce the likelihood of fuel pump cavitation. This pressure is created by the fuel return line and is maintained by check valve 2 of the adsorber and a check valve in the cover.

When the fuel level in the tank drops, a vacuum can be created in it, in the worst case, leading to its collapse. To prevent this, atmospheric air enters the tank through check valve 3 of the adsorber or a valve in the neck cover. Thus, EVAP prevents the creation of excessive pressure or vacuum in the tank.

When the engine is running, the coolant temperature is above ~54°C and the throttle valve is opened beyond the purge port, accumulated fuel vapors from the high pressure zone in the adsorber pass through check valve 1 and the thermal pneumatic valve, entering the vacuum zone behind the throttle valve.

Electronically controlled, without control functions / 1 VSV

To provide more precise control of the influence of EVAP on the mixture composition and engine performance, the first electronically controlled circuit was introduced, with an electro-pneumatic valve instead of a thermo-pneumatic valve. Fuel vapor similarly flows under vacuum into the intake manifold (at coolant temperatures above ~54°C and operating in closed-loop mode), and the ECM can vary the width of the pulses supplied to the valve, adjusting the intensity of the vapor flow.

The simplest self-diagnosis here relates to the electrical part of the valve:

| P0443 - Evaporative Emission Control System Purge Control Valve Circuit |

| No appropriate response to ECM commands |

This scheme has been successfully operating on models for the Japanese and European markets for more than 20 years, creating virtually no operational problems.

Electronically controlled, with control function / 2VSV, vapor pressure sensor

But the founders of OBD did not stop there and added another electro-pneumatic valve and a fuel vapor pressure sensor to the next circuit.

When the sensor valve is closed, the ECM is able to measure the vapor pressure in the tank, and when open, the vapor pressure in the canister. When the purge valve opens, the vapor pressure in the canister should decrease, but if this does not happen, the ECM determines that the purge valve is “stuck in the closed position.”

| P0440 - Evaporative Emission Control System Malfunction |

| The pressure in the tank corresponds to atmospheric pressure after driving the car for 20 minutes |

| P0441 - Evaporative Emission Control System Incorrect Purge Flow |

| — The pressure in the adsorber does not drop in the purge mode. — When the purge is turned off, the pressure in the adsorber is poorly correlated with atmospheric pressure. |

| P0446 - Evaporative Emission Control System Vent Control Malfunction |

| — When the vapor pressure sensor valve is turned OFF, the ECM determines that there is no continuity between the vapor pressure sensor and the canister. — When the vapor pressure sensor valve is turned ON, the ECM determines that there is no continuity between the vapor pressure sensor and the tank. — When the purge is turned off, the pressure in the adsorber corresponds to atmospheric pressure. |

| P0450 - Evaporative Emission Control System Pressure Sensor Malfunction |

| 10 or more seconds after starting the engine for 7 or more seconds: - the vapor pressure sensor signal value is less than -4 kPa (-30 mm Hg) - the vapor pressure sensor signal value is at -2.1 kPa (-15 mm Hg .st.) |

| P0451 - Evaporative Emission Control System Pressure Sensor Range/Performance |

| The output signal of the vapor pressure sensor changes significantly under the following conditions: - speed 0 km/h - idling - solenoid valve of the sensor is ON |

Obviously, the complication of self-diagnosis of the EVAP system and the increase in the number of components does not affect its reliability in the most positive way, but increases the likelihood of false alarms.

The greatest practical benefit is only the possibility of promptly detecting a jammed purge valve in a constantly open position (such leakage of the intake system, naturally, has an extremely negative effect on engine operation). But although such a malfunction is, in principle, well known, it is difficult to call it widespread for Toyotas.

Among other things, a number of models also implemented the function of vapor recovery during refueling (ORVR - Onboard Refueling Vapor Recovery). This version of the system was replenished with a filling valve and an air release valve.

Operation

Purge Under certain engine operating conditions (feedback mode, coolant temperature above ~74°C, etc.), the ECM opens the purge valve and the vapors accumulated in the adsorber enter the intake under vacuum. The flow intensity is controlled by the duration of the pulses supplied to the valve. Atmospheric air enters the adsorber through an air line, providing through blowing.

The principle of operation of the fuel system

An adsorber is a small part in a car designed to collect all gasoline vapors. The system allows fuel vapors to accumulate in a specially designed place called a separator, converting them into condensate and releasing them into the gas tank.

Valve on car

Untreated gasoline vapors pass through double system valves. The first valve is gravity and serves to protect fuel from leaking out of the gas tank during an emergency vehicle rollover. The second valve regulates the pressure created in the fuel tank.

Passing through the entire fuel system, gasoline vapors reach the adsorbing chamber and are absorbed by the activated carbon contained in it. When the engine starts, the purge valve starts to operate. If it is faulty, this may result in a loss of power from the power unit and increased fuel consumption.

The adsorber purge valve is installed inside the device filled with activated carbon. The device itself is located on the gas tank. The purge system is designed to ensure that everything functions correctly and without interruption. Ventilation and condensate removal are the main purpose of this electromechanical unit.

A slight chirping sound when the Kalina engine is turned on in cold weather or at idle speed means the canister purge valve is operating. To distinguish this noise from the sound of a faulty timing belt or rollers, you just need to sharply press the gas pedal - the chattering noise should not disappear or change. If this happens, then the cause of the noise needs to be looked for elsewhere.

Automotive absorber design

In simple words, the absorber design is a plastic jar with a filled filter catching element. The best substance for trapping and neutralizing fuel vapors is activated carbon.

The absorber consists of:

- Separator. The separator captures gasoline vapors and sends them back to the fuel tank.

- Gravity valve. The gravity valve protects against fuel overflow if the car overturns. The valve blocks the movement of fuel.

- Pressure meter. The pressure sensor performs an important function - it monitors the vapor pressure in the fuel tank. When the maximum permissible pressure in the tank is reached, the sensor opens and releases the pressure.

- Filter element (activated carbon). The filter element in a car absorber is carbon in large granules. Large granules allow vapor to pass through the layer of carbon powder and condense.

- Connecting tubes. Connecting tubes serve to connect all structural elements.

- Solenoid valve. The solenoid valve changes the fuel vapor recovery modes.

Diagnostics of the canister purge valve

A failed adsorber valve is dangerous because the gas tank begins to be poorly and poorly ventilated. This leads to deformation and damage to the fuel pump. A desiccant layer that is not well ventilated can cause fuel to accumulate in the intake manifold, causing poor engine performance.

A faulty canister purge valve is to blame for dips at idle. The Kalina engine has weak thrust. When the motor is running, the characteristic chirping sound will not be heard if the valve is faulty.

When unscrewing the gas tank cap, you need to listen carefully. If a characteristic hissing sound appears, this means there is a vacuum in the tank, that is, the ventilation system is faulty. If any signs of failure appear, the adsorber valve should be replaced with a new one. A faulty Kalina valve will affect the filtration and purge system. It will poorly collect and accumulate fuel vapors, and they will leak out. This situation will be indicated by the unpleasant smell of gasoline in the cabin and near the car.

Of course, it is worth checking other components of the fuel system. For example, a vapor leak may occur due to a loose tank lid or a hole in it. But if after checking the entire system the cause is not identified, then the purge valve is faulty.

Replacing the adsorber on a VAZ 2104, VAZ 2105, VAZ 2107

Welcome! Adsorber - someone removes it immediately after buying a car, and someone leaves it and drives until it becomes unusable, and after it arrives, they either throw it away and buy a new one, or they throw it away and continue to drive without it, turning it off in the same way at the same time, through the diagnostic connector there is an error that will then constantly light up on the dashboard (check engine) after you remove the adsorber and thereby turn off the purge valve that relates to it and do some other little things related to the hose that goes from the separator to the adsorber and with a hose that comes from the valve itself.

Note! In order to change the adsorber to a new one, you will need to take a set of tools, which will include: A screwdriver, as well as a set of wrenches, if possible (If available), also stock up on socket heads and wrenches or extensions on which you will put these heads on!

- Replacing the adsorber on a VAZ

- Checking the purge valve

- Additional video clip

Novaya Lada: YurMarket™: Trademark registration and “Ukraine”.

Nuances. Where is the adsorber located? It is located in the engine compartment of the car and if you pull the lever from the passenger compartment which opens the hood and then open the hood of the car, then after opening it will be possible to see with the naked eye where the adsorber itself is located (Indicated by a red arrow), as you see in the photo It is located inside the car engine and takes up very little space.

When do you need to change the adsorber? It itself fails quite rarely, usually the canister purge valve sometimes becomes unusable (we talked about how to check the valve for serviceability in the same article below), but still, when something happens to the canister itself, then after that the machine at idle, it may start to work unevenly, in addition, the pressure in the fuel tank increases because of this, when you open the tank cap, you can hear a hissing sound, like when opening any soda, there should not be such a hissing and it indicates that there is increased pressure in the fuel system may be due to the adsorber or other parts that relate to the car’s engine power supply system.

How does the adsorber work and why is it installed on all new cars? People ask us this question from time to time, as you have already noticed, this unit is installed only on those cars that are of a very recent year of manufacture, for example 2009, etc., but this unit was not installed on cars before, now we will explain why and what it is connected with.

Valve repair

Checking and purging the valve

The first signs that the Kalina adsorber needs to be repaired are the appearance of a persistent smell of gasoline in the car interior and difficulties that arise during draining the fuel. For repairs, it is necessary to remove the adsorber and disassemble it. Since the device is usually solid, for disassembly you will need to cut off the cover. This can be easily done with a regular file. After repair work has been carried out and replacement of the main parts, the cover is usually simply sealed. For complete sealing, the seams are treated with resin. The resin dries within 12 hours. After this, it can be lightly sanded to bring the filter into proper shape.

Spent and unusable coal is poured out of the adsorber. Foam rubber is suitable as intermediate filters. Remove the old filters and replace them with new ones, prepared in advance. Some craftsmen believe that foam rubber is not particularly effective and will allow all the dirt and coal to pass through, so filters can be made from felt. You can place a piece of cotton fabric between the device and the felt, which will prevent small threads from getting into the system. The resulting gaskets are glued to the base and treated with sealant.

New coal can be obtained from gas mask boxes. It is important that it is completely dry, so dry it thoroughly before adding it to the system.

When the dry coal is filled in, felt filters are installed again. All the plates and springs are put in place, and then the filter itself. As can be seen from the above, it is not difficult to diagnose and repair the Kalina absorber valve; you can do it yourself. Good luck!

Purpose of the adsorber purge valve

In the Lada Kalina model, as in principle in any other car equipped with distributed fuel injection, an adsorbing system is necessary to localize the resulting gasoline vapors. They accumulate inside the tank after the engine stops, and after a certain time necessary for the transformation of these vapors into a condensation state, they turn back into liquid fuel. The remaining volume of vapor that failed to return to the tank moves to the adsorber, where it is retained by two valves. The first (gravity type) is necessary to prevent fuel spillage when the LADA Kalina body turns over (in an accident, etc.), and with the help of the 2nd, the pressure indicator inside the tank is monitored.

Having overcome these valves, the vapors move into the cavity of the adsorber, which is made in the form of a can filled with activated carbon. Immediately after starting the engine, the vapors accumulated inside the tank are sent to chambers where they are burned.

To ensure that the circuit of this unit is ventilated and has the ability to regulate the volume of vapors, the adsorber contains an electromechanical adsorber purge valve for purge (KPA). The adsorber sensor is controlled by a special controller.

If a malfunction occurs in this unit, the LADA Kalina engine immediately reacts to this by increasing fuel consumption and reducing power. Also, if the adsorber sensor does not work correctly, this can cause unsatisfactory ventilation of the tank or even damage the fuel pump.

How to check the operation of the sensor? To diagnose the system, you need to take into account a few simple signs. A malfunction of the adsorber can reveal itself as engine failure at idle speed, in addition to which there is a presence of fuel smell inside the Lada Kalina’s cabin. It is in this case that it will be necessary to immediately replace the control unit, otherwise there is a risk of significant damage to the engine components and elements of the fuel supply circuit. Now you know how to check the system.

Reviews

| № | Positive |

| 1. | Vladilen: I have no problems with the gas exhaust system, the mechanism works properly. I regularly carry out technical inspections and fill up with high-octane fuel. |

| 2. | Vitaly: at 30,000 km the purge valve began to knock. I took the car to the service center, they replaced it with a new one, since then there have been no comments on the work, the mechanisms are working properly. |

| 3. | Kirill: I’ve been actively driving Grant for the second year, it works like a watch, there are no complaints. I believe that compliance with maintenance schedules, high-quality oil, high-octane fuel is the key to long-term operation |

| 4. | Ivan: I’ve been actively using the car for a year and a half, there are no complaints about the quality of workmanship or assembly. Breakdowns happen, but they are minor. I fix it myself, I don’t go to a workshop. |

| 5. | Vladlen: two years have passed since I bought the car, I haven’t made any investments. My recommendations to motorists: buy domestic. |

| 6. | Dmitry: in a year and a half of using the car, I went to the service station twice unscheduled, no breakdown was found, but there was a whistle in the exhaust system. |

| 7. | Georgy: I’m happy with the purchase of the car, the car works like a watch, there are no complaints. I strictly comply with the manufacturer’s requirements, visit official services, and fill up with high-quality fuel. |

| Negative | |

| 1. | Ignat: the first valve flew 30,000 km, the second after 20,000 km. The workmanship is low, the model is crude, there are many shortcomings and shortcomings. I expected better from the Lada Grant. |

| 2. | Dmitry: I drove it for a year and a half without problems, after which the car began to fall apart, I visit service stations more often, carry out repairs and preventive maintenance. |

| 3. | Victor: I do not recommend the domestic brand due to the poor quality of the machine and many defects. |

Changing the purge valve on Kalina

The replacement procedure itself is not a complex undertaking. To perform this, the owner will need to acquire a regular Phillips screwdriver and know where the valve is located.

Below we provide an algorithm of actions that allows you to quickly and efficiently complete this procedure.

- Disconnect the corresponding terminal from the negative terminal of the battery.

- You will need to disconnect the power connector from the valve itself.

- For ease of access to the unit, we move the suction pipe of the intake system slightly to the side together with the “Max Air Mass Airflow” sensor. For this purpose, use the indicated screwdriver to loosen the clamp of the pipe and perform the action.

- Now we proceed to dismantling the unit. To do this, disconnect a pair of fittings located on the sides of the product. One of the fastening elements is fixed with a latch and to dismantle it, you will need to recess the latch, then lift the antennae and finally tighten the fitting to the side.

- Before installing a new component, we check that the markings on both valves match and make sure that they are identical.

- Installation and fixation of the product is carried out in the reverse order.

The canister purge valve has been replaced.