January 23, 2017 Lada.Online 98 854 10

The adsorber is designed to capture fuel vapors and prevent them from entering the atmosphere. One of the elements of this system is the adsorber purge valve. Let's consider the main malfunctions of this part, as well as ways to eliminate them.

How to replace the adsorber valve on Lada Vesta

If it seems to you that the canister valve on the Lada Vesta is clicking loudly, try unhooking it from the body and moving it to another place. This could be due to resonance.

Considering the slow development of technology at Russian factories, the machines are not of the proper quality. So, a car enthusiast who bought a new Lada Vesta is faced with an unpleasant knocking, chattering and clattering sound from the Lada Vesta canister valve.

VAZ cars: repair, maintenance, tuning

Gasoline vapors are harmful not only when we inhale them in close proximity to a container or tank of gasoline. Thousands of cars in a big city could emit countless amounts of not only harmful exhaust, but also gasoline fumes. The adsorber is responsible for the amount of harmful fumes, and the adsorber purge valve on the Lada Vesta has some features that the owners would like to get rid of. We will figure out how to replace and repair the adsorber valve today.

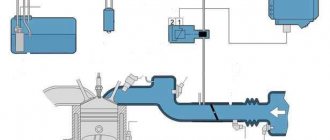

Purpose and principle of operation of the adsorber

The problem occurs on all trim levels (engines 1.6 and 1.8) and on all bodies (cross, sedan). The user encounters unwanted sounds and does not know how to get rid of it.

The canister is a component of a vapor recovery system called EVAP. It prevents fuel vapors from entering the tank into the atmosphere. Thus, the car is less harmful to the environment. The new product appeared on cars produced according to the Euro-2 standard.

On the plus side, gasoline vapors do not enter the cabin. If you remember old carburetor cars, there was often a smell of fuel in the cabin. Now the carburetor has been completely abandoned and only an injector with a filtration system is installed. Additionally, this provides savings, improves the operation of the internal combustion engine and compensates for the pressure difference in the tank. The absorber also has a number of minor auxiliary functions that depend directly on the design of the EVAP system on a particular vehicle.

Disadvantages - increased complexity of the design and the possibility of its breakdown.

Structurally, the device is very simple and consists of a large plastic cylinder with activated carbon that adsorbs gasoline vapors. Consists of the following components:

- gasoline vapor separator;

- connecting tubes;

- adsorbent part (container with filter substance);

- solenoid and air valves;

- pressure meter.

The principle of operation is very simple. At the top of the tank there is a separator with a gravity sensor. It prevents fuel leakage during accidents to prevent it from igniting.

Absorber valve tube

When the engine starts, the ECU sends a pulse to open the valve, after which purging occurs. This is how fuel vapors mix with air through the throttle. After this, the fuel enters the cylinder, where it is mixed with the bulk of gasoline and burned.

FakeHeader

Comments 31

The adsorber valve turns on when it warms up to 45 degrees, and then periodically. When they took the box apart, I also decided to change the oil, so as not to void the warranty, I told them to fill it with my own. Rosneft was filled with half-blue. After this, the box howls louder, before it was less, maybe it was oil, maybe they poured a little oil, maybe it was a lot, or they were just crooked, or they assembled it wrong, but I’m sure it howls louder. I don’t know what was there from the factory, but it was quieter, so you carefully drain the oil, if you don’t like the new one, you’ll put the old one back in. The bearings in the box are sealed, except for the needle ones, they don’t care about the oil. Ride the new one, if it gets quieter or worse write))

All one to one, mileage 500 km, I've owned it for 10 days. While I was choosing a car, I didn’t come across any reviews about the adsorber valve or the rattling of the clutch when warming up. It seems like the majority of the comrades were bought. If I had known and heard this before purchasing, I definitely would not have bought Vesta! I would take the Granta Liftback, it is at least 200 thousand cheaper, for this difference I could still close my ears to it. But for 700 thousand (I have a SW)… DON’T TAKE THE NEWS, THESE SOUNDS IN THE CABIN IF YOU’RE NOT A MUSIC LOVEN WILL BLIND YOUR ENTIRE BRAIN! IT WOULD BE A SHAME TO GIVE SOMEONE A DRIVE AND THIS IS ON A NEW ONE! CAR. If you are satisfied with the sedan body, then there is a sea of competitors, and the cabin will be quiet and pleasant. Do not take, do not repeat the mistakes of others.

Checklist: main malfunctions of the adsorber

First of all, if any part of this system is faulty, a “check” will almost always light up on the panel.

Checking through the diagnostic connector will produce errors P0443, P0444, P0458, P0459.

Deciphering these codes shows the specific cause of the problem in the system. A malfunction of a part of the fuel vapor collection system manifests itself in another way:

- The adsorber valve on the Lada Vesta is knocking - it’s true. Often this occurs due to deformation, and therefore failure, but in winter, increased knocking may be a consequence of the fact that the lid has simply frozen and hardened, causing the sound to become louder.

- If the adsorber on a Lada Vesta is loud, this is not always normal. When accelerating sharply, a “throttle failure” is heard and felt. This is the first sign that vapors are not collecting in the container - the ECU sends a signal, but there is simply nothing to enrich the mixture with.

- When you open the fuel tank, you hear a hissing that is not typical for Vesta. This is the second evidence that the vapors do not collect under the hood, but remain in the tank. The malfunction may be caused by a check valve, sensor, or purge valve.

- At idle, the speed literally “jumps”, “floats”. The engine may even stall.

What does the adsorber consist of - what's inside?

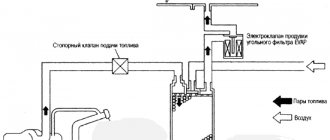

The adsorber on the Lada Vesta is a small-looking detail, but it “doesn’t work alone.” It is only part of the fuel vapor recovery system; it is a kind of container in which fuel vapors are located. They can be used as fuel in the fuel-air mixture; they enrich this mixture in the same way as the fuel itself. The fuel gas collection system component is located near the right wing.

- Fuel vapor pressure sensor (FVPS). It, like all sensors, transmits signals to the ECU.

- A check valve is placed on the tube coming from the fuel tank (directly next to the tank) and prevents fuel vapor from getting back. The same protection applies to fuel.

- Purge valve. Fuel vapor can be used to enrich the mixture in the cylinders. The moment of opening the resulting flap occurs when the engine is running at high speeds - in this case, the ECU sends a command to enrich the mixture.

Malfunctions of the adsorber and purge valve

If this system breaks down, there are no significant changes in the operation of the vehicle. However, several indirect signs can still be noticed:

- Floating engine speed at idle, the engine may even stall.

- Increased fuel consumption, especially when the engine is warm or increased temperature outside.

- Smell of fuel in the cabin.

- Unstable behavior of the engine while driving mainly consists of a drop in power.

- Error on the dashboard.

- Increased levels of carbon dioxide (CO2).

- Whistling of gases escaping from the fuel tank when it is opened.

- Knock on a cold engine.

System failure is not critical, and movement can continue. However, repairs are still worth making. If we talk about driver comfort, the smell of gasoline, noise, and unstable operation of the power plant negatively affect the driving experience.

Why is tank ventilation needed?

Any car with an internal combustion engine that runs on gasoline has a fuel tank. It stores fuel (gasoline). Any fuel tank must have ventilation, as it cannot be sealed.

There are 2 reasons for this:

- Gasoline evaporates strongly and its vapor creates high pressure. The higher the temperature of the fuel and the environment, the higher the pressure gasoline vapor can create. In the heat of summer, high pressure may occur when the tank is hermetically sealed. It can damage the fuel tank.

- The gasoline pump that pumps out fuel creates a strong vacuum in the tank. If the tank is also sealed, it will collapse inward and become deformed.

To prevent all this from happening, a ventilation system is provided in the tanks. My first car was a VAZ-21013 “kopek”, in which the tank ventilation system was implemented simply. A small fitting was welded into the upper part of the tank, onto which a hose was attached. It came out near the fuel filler neck. Through this hose the tank was connected to the atmosphere and the pressure was equalized.

If the fuel evaporates, it comes out through this hose. If a vacuum occurs in the tank, air is sucked in through the hose. The hole in the gas tank cap also works and performs the same function. The system proved itself well and worked perfectly.

Over time, environmentalists began to sound the alarm that fuel vapors were harmful to the environment. It is clear that on the scale of one car nothing terrible happens. But there are more cars every year; there are more than 1 billion of them in the world. Therefore, harm is caused on a planetary scale.

Gradually, environmental standards for road transport began to be introduced. Automakers must adhere to them, otherwise they will not be able to sell cars. If the country allows the sale of vehicles only with class 5 eco-standards, then factories will not be able to sell cars with class 4 standards.

Removing and installing the adsorber on Lada Vesta

After analyzing the entire fuel vapor collection system to find a fault, determine the part that needs to be replaced. The purge valve most often fails and becomes the “culprit” for a knock that can be heard even inside the car. Replacing the adsorber on a car should be done according to the following algorithm:

- Stop the car in place and open the hood. The part you need is near the right wing.

- Disconnect the wires. First move the retainer stopper upwards and tighten it so that the wires are released smoothly.

- Clamp the spring clips securing the tube to the intake module and disconnect it.

- Do the same with the valve pipe and the wire connected to the adsorber.

- Remove the valve. Put a new part in its place.

Ways to get rid of noise

Initially, I didn’t plan to get rid of it, but then I decided to. I watched a lot of videos, read on forums what they do with the adsorber valve. I'll tell you about some of them.

- One common control method is regular silicone . Remove the hose that goes to the intake manifold and spray silicone there. It seems that after this the valve begins to work more quietly. Then it turns out that you need to spray more. If you do this once, nothing bad will happen. But if you spray constantly, nothing good will come of it. There is a lot of silicone. This is due to the fuel system, the adsorber, which is designed for gasoline, not silicone. The car obviously won't get any better. The valve will still be heard, the problem will remain.

- Adjusting the adsorber . I think this is the most harmful method that can cause a lot of harm. Initially, the adjustment is made at the factory for a certain air throughput. What happens during self-regulation? Remove the valve, which has an adjusting screw for Torx T15. It can be tightened up a little. It is advised to tighten it until the sound is satisfactory and the check light comes on. If you tighten too much, the sound will disappear, but the check light will light up.

When you tighten too much, the valve closes completely, that is, the opening amplitude decreases. The car’s brains see that a signal is sent to open the canister valve. The amount of air passing into the collector does not change. The electronics understands that the valve does not work or is clogged. The instruments display an engine error.

If you open it a little, the ECU sees that some air is coming in and there is no error. But from the factory the throughput is set to the level that is necessary for normal purging of the adsorber. If you close it with your own hands and reduce the throughput, then desorption does not occur. The adsorber will not be cleaned properly and will last much less.

The canister valve is knocking, clicking or clicking

We make sure that the noise comes specifically from the adsorber valve, and not from the timing belt, rollers and other elements. To do this, simply press the gas pedal sharply. If the chattering noise does not change, then the source of the noise is the adsorber valve. It is not uncommon for the clatter of the adsorber valve to appear only in cold weather at sub-zero temperatures.

What can you do about it?:

1. Contact an authorized dealer with the problem. If the adsorber valve is truly faulty, it will be replaced under warranty. If they consider that such valve operation is the norm, then there is no point in writing in support of AvtoVAZ.

2. Advice from car enthusiasts (you lose your warranty!). There is an adjusting screw on the side of the valve, which is filled with glue. Remove the glue and turn the screw clockwise 90 degrees. After this, the adsorber valve no longer clicks in the cold.

3. Owners of LADA cars advise spraying silicone grease into the adsorber hole:

If you decide to buy a canister purge valve, then look for it by article number:

- 82 00 248 821 (for Lada Vesta or XRAY).

- 11180-1164200-00, 11180-1164200-01 (for Lada Granta/Kalina)

- 21103-1164200-01, 21103-1164200-02 or 21103-1164200-03 (for Lada Priora and Niva 4x4)

- 8200692605 (for Lada Largus)

Have you encountered problems with the adsorber valve?

Keywords: sound insulation lada xray | sound insulation of Lada Vesta | sound insulation of Lada Largus | soundproofing of Lada Granta | sound insulation of Lada Kalina | sound insulation of Lada Priora | soundproofing 4x4 | lada xray sensors | Lada Vesta sensors | Lada Largus sensors | Lada Granta sensors | Lada Kalina sensors | Lada Priora sensors | 4x4 sensors | ECM Lada Vesta | ECM Lada XRAY | ECM Lada Largus | ECM Lada Granta | ECM Lada Kalina | ECM Lada Priora | ECM 4x4 | soundproofing Niva | Niva sensors | esud niva | universal article

Found an error? Select it and press Ctrl+Enter..

- Online store Lada.Online - we tell you in detail

- How to replace the timing belt on a 1.8 liter engine (VAZ 21179)

- Is it worth buying a used Lada Vesta? Study

- Test drive Lada XRAY (1.8l, 122 hp, AMT) from Stillavin and Vakhidov

How to remove extraneous noise

For many people, after a long time, the adsorber begins to make unpleasant sounds. The official dealer is in no hurry to fix the error, and car enthusiasts are looking for ways to fix it. The solution is quite simple. If the adsorber valve is knocking on a Vesta, you need to:

- Buy vibration isolation and take a hair dryer.

- Remove the valve and try it on.

- Cut the vibration isolation to size, heat and smooth it to completely wrap the knot, even in two layers.

- After this simple procedure, install it back.

You can get rid of the sound of the absorber on the Vesta easily and inexpensively. There will be no noise even with the hood open. The asking price is 500 rubles.

If it seems to you that the canister valve on the Lada Vesta is clicking loudly, try unhooking it from the body and moving it to another place. This could be due to resonance.

Checking the canister purge valve

1. Disconnect the block with wires and visually check the condition of the contacts. If oxides are detected on them, we treat the terminals with a means for cleaning and protecting electrical contacts.

2. Remove the adsorber valve. We measure the resistance of the valve winding with a multimeter, which should be within 20-30 Ohms. The canister valve should be replaced if a short circuit or break is detected in the valve winding.

3. To avoid short circuit, one terminal of the valve should be insulated with PVC pipe. We supply 12 V from the battery to the valve terminals. At this moment, the valve terminals should open with a characteristic click. We repeat the test, creating a vacuum in the valve with a rubber bulb.

The M86 Euro-5 controller 21803-0000013-51, by controlling the solenoid valve, purges the canister after the engine has operated for a specified period of time from the moment it switches to the closed-loop fuel supply control mode. Air is supplied to the adsorber through the “AIR” pipe, where it is mixed with gasoline vapor. The mixture thus formed is sucked into the engine intake pipe for combustion during the operating process.

The M86 Euro-5 controller 21803-0000013-51 regulates the degree of canister purge depending on the engine operating mode. By supplying the valve with a signal with a variable pulse frequency (16 Hz, 32 Hz). The controller constantly monitors the effect of purge (the state of the canister being filled with fuel vapor) on engine operation using signal information from the control oxygen sensor.

How to check

If the clatter of the canister valve is too loud, you will have to start checking. The most accurate method is manual using a multimeter. It works like this:

- Under the hood of the car, find the wiring block adjacent to the part and inspect it for damage.

- Treat oxidation with contact cleaning mixture.

- Using a multimeter, measure the resistance level of the valve winding. The norm is up to 20-30 Ohms. Any violation of the integrity of the winding or exceeding the resistance limit can lead to a short circuit, and this is very bad.

- In order to subsequently avoid a short circuit in the winding, insulate one of the terminals. To do this, cover it with PVC pipe.

- To check reliability, pass 12 V from the battery. If the pins do not open, the protection does not work.