Clutch pedal on grant creaking, clicking, adjustment

About the clutch pedal on the Lada Granta

Such a unit on any car is a transmission element, with the help of which, when the pedal is pressed, the transmission of torque from the engine to the gearbox, and then to the drive wheels, is interrupted. With its help, it is possible to smoothly start from a place after parking the car, or change gears while driving. On the Lada Granta, the clutch is installed from its predecessor, the Lada Kalina.

This transmission unit has a traditional, backlash-free classical design. This indicates that there is no play between the pressure spring and the bearing that releases the clutch. It is driven by pressing the pedal using a cable. This unit consists of a flywheel on which the basket is attached. It provides constant pressure on the pressure plate to transmit torque from the engine. This unit, like all mechanisms, sometimes requires adjustments and repairs. Let's talk about how the adjustment is performed in more detail.

Adjustment work

On this car, the drive is carried out using a cable that has an automatic tension system, or, as it is also called, a wear compensator. If everything is done and the adjustment is carried out correctly, then the owner of the car during operation does not need to adjust the gaps or make adjustments to the release pedal.

Be that as it may, problems still happen sometimes. A variety of reasons contribute to this. Various noises may appear during operation, the clutch clicks, the pedal creaks. There may be other unusual manifestations while driving the Lada Granta.

The correct gap is considered to be the case when its value between the power fork and the wing is 27 millimeters.

This is followed by mandatory lubrication of all elements in the pedal assembly. At the same time, we must not forget about the plastic of the compensator ratchet, clutch bushing, and the casing of its drive cable.

When this adjustment is made, there is usually no more clicking in the drive, and the pedal does not make unpleasant sounds.

Sometimes a squeaking sound can come from the engine compartment of a car. Its source may be the tip lead. To eliminate this squeak, it is enough to lubricate the contact point between the plastic nut and the clutch release fork.

In some cases, the cause of squeaks from the engine compartment may be a lack of lubrication on the gearbox input shaft. In such cases, graphite lubricant in a can comes to the rescue. To eliminate this malfunction, remove the engine protection and lubricate the rubbing parts.

When the source of extraneous noise is the clutch release cable, you should also try to lubricate it with graphite lubricant. Insert the canister tube between the cable and the casing and try to lubricate it. In cases where this does not help, change the drive cable.

If, after all the adjustment work, you still hear extraneous sounds from the clutch side, something clicks there and the pedal creaks. Then you need to contact a car service for a more complete check of this unit.

Clutch replacement work

Check the wear of the friction linings of the pressure plate. If wear exceeds the permissible limit, it is replaced with a new one.

Installation on the flywheel is carried out in the reverse order.

How to deal with a tight clutch pedal

Most drivers do not want to put up with this state of affairs and try in every possible way to improve the performance of the clutch.

Among the most common recipes for dealing with a tight pedal are the following:

- Replacement of the basket and all clutch assembly elements with a known quality product. The best option would not even be a new Valeo, but the assembly recommended by the manufacturer. Often, for many car enthusiasts, the situation became a revelation when, after replacing cool branded baskets with conventional Russian options, the clutch pedal turned from extremely tight to an option with a comfortable level of effort;

- It is considered cheaper and more accessible to pack all rubbing surfaces with lubricant. To gain access to blind lubrication points, there is a diagram indicating drilling locations, where transmission oil is subsequently pumped with a syringe or oiler;

- Replacing the cable with a stronger model, regularly filling brake fluid or engine oil with a syringe under the casing. If spindle or similar oil still gives a good effect, pouring brake fluid or WD-40 is pointless and useless. They only contribute to the destruction of the outer sheath of the cable.

Clutch adjustment on Lada Kalina

The first Lada Kalina car was produced by AvtoVAZ in 2004. The car has a number of shortcomings, one of which is the gearbox clutch. Without waiting for a breakdown, I advise you to adjust the clutch. We will tell you below how to adjust the clutch of the Lada Kalina with your own hands.

Clutch design Lada Kalina

Single-disk - refers to the dry type, has a central pressure spring. The pedal and clutch disc are connected by a cable. For this purpose, a special ratchet mechanism is used, which automatically adjusts the length of the rope.

Time leaves its mark on everything, including the linings of the driven disk - they wear off and become thinner. The ratchet mechanism compensates for this wear by tensioning the cable. This happens by turning the shutdown fork, which causes the spring located in the bushing of the adjustment mechanism to compress. Ta, in turn, presses the clamps of the toothed tip of the cable. The tip is released and the cable is tensioned.

The purpose of the ratchet mechanism is to make life easier for the owners. It relieves them of the need to spend time and effort on self-adjustment. But this is in theory. Practice has shown that it is not possible to operate a car without adjusting the clutch.

When to adjust the clutch Warning :

Inspection and adjustment work must be carried out with the engine turned off.

1. Press the pedal several times in a row and listen for any extraneous noise (clicks, creaks, etc.). Pay attention to how the pedal moves: whether it sticks or not.

If you cannot determine by eye whether it returns to its place freely, but you have suspicions, then do the following: - press the clutch all the way by hand; - release, but Your hand should be on the pedal to feel its progress, but not interfere with it.

If it sticks or returns to place with characteristic jerking, then it is necessary to adjust the clutch on the Lada Kalina.

2. Take a ruler and measure the distance from the floor to the outer part of the pedal. Press the pedal until it hits the floor. Release and remove the size again: if the distance is more than 14.6 cm. then the pedal travel needs to be adjusted to the standards.

3. Parameters, deviation from which requires adjustment: - full pedal stroke - 14.6 cm. (possibly less, but not more than the specified value); - the lower guide of the cable can move relative to the release fork lever by a maximum of 2.7 cm; - beating of the linings home disk - no more than 0.5 mm; - the distance between the working surfaces of the linings and the rivets that hold – 0.2 mm. (less is unacceptable). Do-it-yourself clutch adjustment for Lada Kalina

1. Remove the air filter.

2. Pull the tip to give the cable maximum tension.

3. Take a caliper and measure the distance between the leader and the fork lever. If the distance does not correspond to the recommended above 2.7 cm. use a leash to straighten the dimensions. To do this, rotate it along the thread of the tip.

4. After setting the dimensions, press the clutch several times and take new measurements. If you are confused, please correct it again. And so on until you achieve the desired results.

The clutch of the Lada Kalina car has the ability to fail at critical moments. But, as you can see, the simplicity of its adjustment becomes a balm for the soul. I also advise you to familiarize yourself with another problem with the car - the steering rack. We talked in detail about how to carry out repairs yourself.

Source

Solution

In almost all cases, the problem of a squeaking clutch pedal can be eliminated with the help of lubricant. To do this, you need to lubricate all intensively rubbing parts.

Experts recommend using thick grease (CV joint or something like that) as a lubricant. If the car was designed in such a way that it is impossible to get to the pedal elements or spring, do not despair - there is a way out. Use a slotted screwdriver for this. Apply a little lubricant to its metal part, after which you can reach the necessary places with a screwdriver.

There is also a possibility that the squeak does not come from the pedal, but from the clutch fork. During operation, it serves as a place for dirt and used lubricant to accumulate. Because of this, this unpleasant sound appears.

In order to eliminate squeaking in the clutch fork, it must be washed from dirt. Naturally, it is very difficult to reach it, so this must be done through the engine compartment. To clean, you can use carburetor cleaner - it will do the job perfectly. Once you have removed all the accumulated dirt, apply a coat of thick lubricant to the fork.

Other possible squeaks

In addition to the clutch pedal, the reasons for the appearance of squeaks we have already figured out, the reason may lie elsewhere. For example, if the clutch mechanism uses a cable drive, then it is often the cause of unpleasant sounds. If this is the case, simply changing the lubricant will not help solve the problem. To do this, it is necessary to replace the clutch cable.

If you hear a squeak somewhere from the engine, this indicates a faulty release bearing. To fix this problem, you will most likely need to replace the release bearing.

The clutch pedal may make peculiar noises due to the clutch actuator. This is due to the fact that all the work of the clutch is mechanical friction of the working parts. Naturally, the appearance of noise cannot be avoided. In order to get rid of annoying sounds, you will need to periodically lubricate the rubbing parts. Because you will not be able to control a constant level of lubrication - everything is washed off during operation.

There is a more difficult way out of this situation. Using a skilled turner, turn the bushing between the rubbing parts from a softer metal or polycarbonate. In this case, the occurrence of unpleasant sounds will stop, because the friction of different materials will not create such noise as two materials of the same density and structure create.

Many owners of Lada Granta, Kalina and Priora notice the creaking of the clutch pedal. Moreover, this problem may arise after the first kilometers of driving. We will tell you about the possible causes of this disease, as well as ways to solve it.

First, make sure your car's clutch is adjusted correctly. While holding the clutch cable end in an extended position, measure the size between the fork and the driver, it should be 27 mm. How to adjust the clutch cable is shown in the video:

Principles of clutch adjustment on Kalina

Popular domestic model

Lada Kalina is very popular among Russian car enthusiasts, but most of its owners note that the model has a number of significant shortcomings. In particular, criticism is caused by the appearance, comfort and technical equipment of the machine.

Many complaints have been made regarding how the Lada Kalina clutch works. Although, reading the instructions for this vehicle, it is difficult to believe that any malfunctions could occur when the clutch operates.

Clutch device

The clutch of this model from AvtoVAZ is single-disk and belongs to the dry subtype. It is equipped with a pressure spring located in the center. The pedal is connected to the clutch disc using a special cable, the length of which is adjusted by a ratchet mechanism. This can be seen if you watch a video demonstrating the design of Kalina.

The lining of the dependent disc wears off and becomes thinner during use. The malfunction is eliminated using a ratcheting mechanism, which compensates for wear by tensioning the cable. The tension causes the release fork to rotate and compress the spring, which is located in the bushing of the control mechanism. The spring, in turn, compresses the clamps located on the toothed tip of the cable. As a result of all these manipulations, the tip is released and the cable is tensioned.

The ratcheting mechanism eliminates the need for car owners to waste time and effort on adjustments. But this is only in the theory developed by Kalina's designers. In reality, when operating a car, you need to know how to adjust the clutch yourself.

When adjustment is required

Clutch adjustment

Clutch adjustment is only performed when the engine is switched off. It is required if there is a deviation from the following values:

- full pedal travel does not exceed 146 mm;

- movement of the cable lead relative to the release fork lever - within 270 mm;

- runout of the dependent disc linings does not exceed 0.5 mm;

- the distance between the pads and the rivets that hold them is 0.2 mm or less.

There are several ways to check if your car needs a clutch adjustment.

- You should press the pedal several times in a row and listen for any extraneous noise. If the clutch pedal sticks or squeaks, it is advisable to make an adjustment. In some cases, car owners are unable to visually assess whether the pedal returns to its place freely. In such situations, it is recommended to do the following:

- press the clutch with your hand until it stops;

stop applying force, but leave your hand on the pedal in order to feel if there is movement.

If the clutch pedal sticks and clicks, or it returns to its original position with characteristic jerking, you need to adjust the clutch.

It is necessary to measure the distance from the floor to the outer part of the pedal using a ruler or caliper. Then press the pedal until it hits the floor. After this, you need to release the pedal and take measurements again. If the distance exceeds 146mm, be sure to adjust the clutch.

The procedure for adjusting the clutch on Kalina

Owners of Lada cars who have discovered faults in their vehicles are interested in how to adjust the clutch. To do this you need to perform a number of steps.

- Pull the cable forward until it stops at the threaded end. In this case, it is necessary to overcome the resistance of the spring attached to the clutch pedal.

- While holding the cable, use a caliper to measure the distance from the plastic leash to the clutch release fork lever.

- By rotating the leash, bring the distance to the required values. Make sure that when releasing the cable, the leash fits tightly to the fork lever.

- Press the clutch pedal three times to activate the automatic cable length adjustment system.

- Check the full pedal travel.

Adjusting the clutch on a Kalina car is a procedure that every owner of this car must master. By performing timely adjustments, you can significantly extend the life of your vehicle.

expertVAZ.ru

Clutch design and functionality

The unit belongs to a cohort of mechanisms whose functioning is based on dry friction. The clutch mechanism in this model is single-disc and requires a pressure spring, which is structurally designed as an integral part of the basket. The cable is used to release the clutch. This action is activated when the advising pedal assembly is pressed. The cable transmission has a ratcheting device that allows it to autonomously change its length in accordance with the level of wear of the driven disk linings. This solution allows for a tight fit of the release bearing to the spring petals. Inside the basket there is a driven disk, through which rotation is directly transmitted from the flywheel to the input shaft of the transmission unit.

Pressing the designated pedal causes the cable to tighten, causing the special fork to rotate. Its lower bushing is integrated into the clutch housing. The upper element of the part, which is also presented in the form of a sleeve, is removable. During rotation, the fork, through the clutch and release bearing, acts directly on the petals of the pressure spring, which in turn opens the driven disk from the flywheel. In this way, the process of disengaging the clutch is implemented, which is necessary to ensure the ability to change gear in a mechanical transmission unit.

If the pedal is fully released, the disk tightly adjacent to the flywheel transmits torque to the input transmission shaft to its full extent.

In some cases, deviations from the correct functioning of the clutch assembly are observed. Among the signs characterizing this negative phenomenon are the following:

- Increasing pedal travel when its value exceeds the regulated 146 mm.

- Engaging the gearbox with the clutch pedal fully depressed is accompanied by characteristic grinding sounds of the shafts in the transmission, which indicates incomplete disengagement of the clutch.

- Starting and subsequent operation of the Lada Kalina engine is accompanied by a howling sound coming from the clutch housing (release bearing wear).

- The beginning of movement is characterized by jerks and insufficient clarity of gear switching.

- Moving at 3-4 speeds, the owner presses the accelerator and observes the following picture: the speed of the power plant increases vigorously, and acceleration is accompanied by sluggishness. This indicates clutch “slippage,” that is, a loose fit of the disc to the flywheel, caused by increased wear of the linings or excessive cable tension.

All these signs overwhelmingly hint to the owner that it is necessary to adjust the cable drive. How to adjust the clutch? You should also be inclined to such a procedure after replacing the clutch mechanism, the compensator loses its functionality (lack of the ability to autonomously adjust the length) or the Lada Kalina car has been idle for a long time.

Setting up the clutch mechanism on Lada Kalina at home

Like all “basins”, Kalina is not at all flawless. Over its more than ten-year history, the model has been refined more than once, but it has not been possible to get rid of some problems. Among the “Kalinovodov” it is recognized that the torque transmission mechanism, due to its design features, is the weak link of the car. Despite all the modernization in this area, car enthusiasts have to periodically adjust the clutch.

Features of the VAZ 2112 clutch

The machine is equipped with a dry-type single-plate friction clutch with a central pressure spring. Before adjusting the clutch on Kalina, any motorist must take into account that the control pedal is connected to the disc via a cable with a special ratcheting mechanism.

How does automatic cable tightening work?

As a result of intensive use, the friction linings of the disc gradually wear out. The ratcheting mechanism built into the drive design allows you to compensate for wear for a certain period of time - it gradually tightens the cable. During operation of the device, the fork rotates and the bushing spring is gradually compressed. As a result, the cable end clamps are compressed, after which the latter is released and tensions the cable.

The purpose of this design is to facilitate the maintenance process. According to the plans of VAZ engineers, the mechanism should save the owner from the need to make adjustments himself. But this is all only in theory, but in practice it turns out that you cannot do without adjusting the clutch.

When should adjustments be made?

Before adjusting the clutch on a Kalina car, you need to determine the moment when the automatic cable locking no longer functions. This is not difficult, especially since the machine itself signals problems:

- Loss of traction, friction clutch does not provide a reliable connection between the flywheel and the disk. The consequence of such a defect will be the loss of a significant part of the torque force.

- The clutch control pedal does not return to its initial position, which, in fact, is a consequence of the first point.

- Poor clutch disengagement - the pedal is not pressed all the way, which makes changing gears difficult.

The symptoms, however, are similar to those when clutch adjustment is needed on a VAZ 2107, so experienced motorists can skip this unit and proceed directly to the test.

How to check the clutch?

To make sure that the mechanism needs to be adjusted, you should perform a number of basic checks:

- Press the pedal several times and release - any extraneous sounds are unacceptable. For better control, you can press with your hand, this way you can feel the pedal stroke more fully.

- Check the pedal for sticking; if it returns with noticeable twitching, then adjustment is necessary.

- Check the full travel of the pedal using a ruler or tape measure. Press and release the pedal several times, then measure the distance of its outer edge to the floor; if it is more than 146 mm, then the mechanism needs to be adjusted.

- Check the movement of the cable guide relative to the clutch release fork; the maximum distance between these elements is 27 mm.

- If the runout of the driven disk linings is more than 0.5 mm, adjustment is also required.

When performing checks, it is important that the car engine is turned off. You need to start working no earlier than the engine has completely cooled down.

The setup method is simple and does not require a visit to a car service center, because you can do everything yourself. The step-by-step scheme for completing the work is as follows:

You should start working no earlier than the engine has completely cooled down. The setup method is simple and does not require a visit to a car service center, because you can do everything yourself. The step-by-step scheme for completing the work is as follows:

- Before adjusting the clutch drive on Kalina, you should open the engine compartment hood and remove the air filter.

- Visually assess the condition of the cable casing and replace it if damaged.

- Pull the tip toward you until the cable is fully tensioned. After this, check the distance between the fork and the leash with a caliper.

- If the measurements show more than 27 mm, then the distance is corrected by rotating the leader along the thread of the tip.

- Press and release the clutch pedal several times and repeat the measurements.

- If necessary, repeat the adjustment until the required standards are achieved.

The technology for setting up the clutch on Kalina is not as complicated as installing the VAZ 2110 clutch, therefore it is quite feasible in a garage environment without the involvement of specialists. And this fact pleases domestic motorists, because the clutch plays an important role in driving a car.

Video - Eliminating crackling and squeaking noises from the clutch pedal

Another source of squeaking may be an insufficiently lubricated input shaft of the box, in the place where the pressure bearing “runs”. This is where it transfers the force received from the clutch fork to the clutch disc. To eliminate squeaking, use a can of graphite lubricant. Lubrication can be done in two ways:

— placing the vehicle on a pit and dismantling the protection of the power unit;

— dismantling the air filter and the clutch fork lever boot.

Replacing the clutch cable

In the cabin under the instrument panel..

. Using an “8” wrench, unscrew the nut securing the cable sheath bracket to the pedal assembly bracket.

Use a slotted screwdriver to pry up the spring clip. . and remove it from the groove of the clutch pedal finger.

Remove the eye of the housing of the automatic cable length adjustment mechanism from the clutch pedal pin.

We remove the upper part of the cable from the pedal assembly bracket. In the engine compartment.

. Pull the cable forward and remove the cable guide from the groove of the clutch release fork lever.

Rotating counterclockwise, unscrew the leash from the threaded end of the cable.

Remove the rubber protective cover from the cable end.

We remove the end of the cable sheath from the hole in the bracket on the gearbox. In the cabin, remove the cable sealing cover from the hole in the front panel.

. and pull the cable into the cabin. Before installing the cable...

. check the condition of the plastic bushing on the pedal pin. We replace the worn bushing with a new one and apply grease to the pin. We install the cable in the following sequence: – thread the cable through the hole in the front panel from the passenger compartment into the engine compartment; – install the sealing cover into the hole in the front panel; – put the automatic cable length adjustment mechanism on the pedal pin and secure it; – screw a plastic leash onto the threaded end of the cable so that the end of the cable tip is flush with the end of the leash; – insert the leash into the groove of the clutch release fork lever; – adjust the clutch drive. To do this, pull the cable forward by the threaded end until it stops, overcoming the force of the clutch pedal spring, and hold the cable in this position.

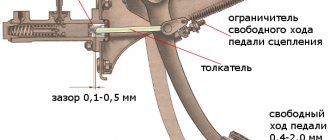

Using a caliper, we measure the distance from the end of the plastic leash to the clutch release fork lever, which should be 27 mm. If necessary, rotate the leash to achieve the required distance. When removing the load (releasing the cable), the leash should adhere to the fork lever without play. After this, press the clutch pedal three times to activate the automatic cable length adjustment mechanism. The full pedal travel should not exceed 146 mm.

One of the disadvantages of the Lada Kalina is problems with the clutch. To avoid visiting a car service center and save time and money, you can diagnose the malfunction and adjust the clutch on the Lada Kalina yourself in the garage. The article describes step by step how to adjust the clutch, and also includes a video that demonstrates the entire procedure.

Squeaks when using the clutch pedal

As mentioned above, the Lada Granta clutch cable drive has a circuit that provides for the presence of a wear compensator (automatic tensioner). Its participation in the work process significantly simplifies the operation of the vehicle, since it eliminates the need to independently adjust the clutch fork gap or adjust the pedal. However, shortcomings in the production assembly (some of which we mentioned above) reduce the functioning of the wear compensator to nothing.

The solution to the problem involves a complex that includes several, not technically complex, measures:

The initial step is to adjust the clutch fork clearance. This process involves two options:

a) With removal of the air filter housing. We dismantle the (cold) air intake pipe, the air supply pipe to the receiver, and the wiring of the (mass) air flow sensor one by one. We disconnect the electrical harnesses attached to the filter housing, release the housing from the grip of the rubber stops, and then remove it.b) Without removing the air filter. This method is less common because it requires quite a lot of effort to perform manipulations in the limited space of the engine compartment.

To set the clutch fork gap to 27 millimeters, we perform the following manipulations. Pull the clutch cable all the way (in the direction of vehicle movement) and by twisting (unscrewing) the plastic “lamb”, set the required gap (L) between it and the fork.

The next stage (after setting the working gap on the fork) of a set of measures to eliminate the causes of extraneous noise during operation of the clutch pedal will be lubrication of the elements of the pedal assembly. As a lubricant, experts recommend using a substance that is extremely popular among car enthusiasts - WD-40. Lubricant is supplied not only to the clutch bushing, but also to the plastic ratchet that compensates for wear. Applying lubricant to the cable sheath won't hurt either.

In addition to the information presented above, let's look at a few more reasons that cause squeaking clutch pedals.

One of these reasons may be the friction of the plastic bushing, which is one of the parts of the pedal mechanism, on the bracket. This happens when the pedal is pressed on the microswitch of the mechanism that automatically tensions the clutch cable.

Operating principle of the electronic engine control system (ECM)

In a modern car, all process control, except for the rotation of the steering wheel, and even then, is entrusted to the computer, or Electronic Control Unit (ECU). It contains a program with many different tables. In general, the ECU receives data about the state of the car, speed, revolutions, and activated mechanisms from a large number of sensors. Based on the results of these observations, the ECU, using these tables, includes certain ignition modes, fuel supply and other executive functions.

The role of the clutch sensor

It would seem, what does the clutch have to do with it? And here's what it has to do with it. When the clutch engages, the most sensible thing to do is to reduce the engine speed. But not to idle, but according to the speed of the car. This is not always available to the driver, especially a beginner. And here the computer will come to the rescue. Reacting to the signal from the clutch sensor, it can independently adjust the engine speed.

Important! In addition, in accordance with the Priora speed sensor, the ECU can obtain information about the serviceability of the clutch. Summarizing the above, we can say that the presence of a sensor on the clutch allows:

Summarizing the above, we can say that the presence of a sensor on the clutch allows:

- saves fuel;

- make driving easier;

- monitor the serviceability of the coupling;

- increase its service life.

Therefore, its serviceability is an important factor in the Priora control system.

Design and location of the Priora clutch sensor

In principle, this is the simplest switch. In the position when the clutch is disengaged and the pedal is not pressed, the sensor circuit is open. If you press the clutch drive, the limit switch of the sensor closes and the signal “clutch is on” is sent to the ECU.

It is located on the clutch pedal mounting assembly, where the very tip of this pedal is located opposite the sensor end switch.

Clutch pedal squeaks - causes and solutions to the problem

Hi all. I recently talked about the reasons for clutch pedal failure, as well as ways to solve this phenomenon. Today I decided to supplement the series of articles about the clutch with another, no less relevant topic - the creaking of the clutch pedal.

You will learn about the reasons why the clutch pedal squeaks and how to get rid of it.

I’ll say right away that the creaking of a pedal, whether it’s a clutch or a brake, in most cases does not affect its functionality and, by and large, is a common irritant that infuriates many motorists. Creaking or grinding of pedals rarely indicates serious damage, but before you give up on it with the words “I still have nerves of iron,” I recommend making sure that the problem is really not worth attention.

Clutch adjustment on Kalina, design and adjustment

Clutch adjustment on viburnum, design and signs of the need for adjustment, procedure for adjusting the clutch cable.

Undoubtedly, the Lada Kalina is a fairly popular car among domestic car enthusiasts. Moreover, the fact that it has quite a large number of flaws and shortcomings does not at all affect the high popularity of this particular model from the Lada family. The clutch on the viburnum has always been problematic. If you look at the design of the clutch itself, it’s hard to believe that the Lada has problems there and requires fairly frequent adjustment of the clutch on the viburnum.

Clutch design for Lada Kalina

Clutch Lada Kalina

The Lada Kalina is equipped with a dry clutch type, which has a single disc and a central pressure spring. The fret design has a ratcheting mechanism for adjusting the length of the cable. The work process is accompanied by constant wear of the friction linings of the disk, and as a result the cable changes its tension, and here the ratcheting mechanism comes into play, which compensates for this wear. The working process of the ratchet mechanism is as follows:

- The tension of the cable turns the release fork, thereby forcing the spring to compress;

- Compression of the spring causes compression of the clamps, which are located on the toothed tip of the cable;

- The tip is released and the cable is tensioned.

Naturally, this is the theory that was used when designing the Lada Kalina. The reality is somewhat different from the theory; the Viburnum clutch simply forces its owners to sometimes roll up their sleeves and adjust it. Don’t be afraid to do this yourself, because this is a fairly simple procedure, because the Kalina clutch itself is so simple in design that even replacing the unit is not a particularly difficult job.

Signs that your clutch cable needs to be adjusted

It is necessary to adjust the clutch cable after the following symptoms appear:

- Extraneous sounds when disengaging the clutch;

- Problems when shifting gears;

- Poor traction;

- Incomplete release of the clutch.

Adjusting the clutch cable Lada Kalina

You can check the clutch by performing a few simple steps: with the engine turned off, you need to depress the clutch pedal several times, and you should listen carefully to see if there are any extraneous noises during the pressing process.

If during this procedure you hear noises or feel increased play or jamming of the pedal, then most likely it is worth adjusting the cable, but first pay attention to its appearance; if the cable itself is rusty or has tears at the attachment points, then it may be necessary its replacement. However, not all car enthusiasts can easily determine play and jamming by eye.

In such cases, it is best to press not with your foot, but with your hand, because it is a more sensitive human organ

However, not all car enthusiasts can easily determine play and jamming by eye. In such cases, it is best to press not with your foot, but with your hand, because it is a more sensitive human organ.

There is a more effective way to check the clutch of a viburnum. It consists of measuring the pedal stroke, for this you need to:

- Measure the distance using a ruler from the floor to the pedal itself;

- Press the clutch pedal to the floor and measure the distance again;

- Perform the procedure several times for the most accurate result.

Now let’s compare the obtained value with the regulated one, which is 146 mm. If you have more value, then adjustment is simply inevitable.

Troubleshooting Sensor Problems

This mechanism is installed only on the Lada Kalina clutch with an electronic gas pedal. Its function is to control engine modes when changing gears, starting to drive, etc. Sensor malfunctions are reflected on the engine controller as “error 0830”, and the Check Engine lamp lights up.

Physically, malfunctions are felt as jerking of the car when changing gears, when the engine is running at low speeds, or a sudden increase or decrease in engine speed when you press the pedal. It is impossible to adjust the clutch sensor on Kalina; it will have to be completely replaced.

This part is located above the pedal, under the steering column. When buying a new one, you should choose sensor 1118-3720015 (for Kalina, Priora, Grants). Replacing it is a little complicated by the inaccessibility of the 2 screws on which it is attached to the pedal bracket.

To remove the sensor, you need to pull the wire block holder out of the hole on the pedal bracket. Then disconnect it from the dashboard wiring harness. Use a screwdriver to remove the spring hook from the holder and unscrew the sensor mount on the pedal bracket (screws).

The clutch sensor is removed together with the holder, released and replaced. Reassemble in the reverse order, starting with attaching the sensor to the holder rods.

Adjusting the Lada Kalina clutch or replacing the sensor is not very difficult. When carrying out work, the engine must be turned off. If after adjustment measures extraneous noises and other malfunctions do not disappear, you should contact a car service for diagnostics and possible repairs with the replacement of clutch discs.

To be more precise, we will talk about adjusting the clutch cable

on Lada Kalina. The Kalinovsky cable is much easier to adjust than the same cable on the 9, 10, 15. All because of the installed auto-compensator, which does this work for you. So if the autocompensator does everything itself, then why bother with it at all? Let's figure it out.

The fact is that for the correct operation of this machine, the clutch cable must be installed correctly. Correct installation is determined by measuring and adjusting several distances. The first is between the clutch fork and the plastic cable end. We pull the cable to the maximum possible distance, holding on to this plastic tip and using a caliper we measure the gap - it should be 27 mm (as in the book). To get to the fork you need to remove the air filter. If the distance is not the same, we adjust it to the norm using the same plastic tip.

The second thing you need to pay attention to is the cable rod on the interior side. The distance of its end to the plate should not exceed 3 mm, but at the same time some gap should remain. It is located on the clutch pedal itself.

You can set the gaps either from the hood or from the interior, where it is more convenient for you. Having set one gap, the second should happen automatically.

How to replace and adjust the clutch cable on a VAZ 1117-VAZ 1119?

Removal: 1) First, while inside the car, get to the clutch pedal and remove the stop of the cable sheath from the pedal bracket, this is done very simply, namely, take a wrench and use it to unscrew the nut securing the stop (see photo 1), as soon as the nut will be unscrewed, the stop is removed from the bracket stud (see photo 2), after which you will have access to the clutch pin from which you will need to remove the stopper with pliers or a screwdriver (see photo 3), after the stopper is removed, remove it from of the same pin is the housing of the wear compensation mechanism for the driven disk linings (see photo 4).

2) Now remove the plastic bushing from the clutch pedal finger by hand (see photo 1), check its condition, it should not be deformed or heavily worn, otherwise replace it with a new bushing (Before installing the new bushing, lubricate it with Litol lubricant -24 or LSC-15), then remove the rubber seal of the cable sheath from the hole that it covers (see photo 2), then get out of the car and move into the engine compartment of the car to the box, having reached it, pull the tip of the clutch cable forward and then disengage it from the fork (see photo 3) and then unscrew the leash and remove it from the cable tip as shown in the fourth photo.

3) And finally, remove the cable from the bracket on the box, let’s immediately note the fact that the bracket on Lada Kalinas is solid and not split as shown in the photo below (The photo below just shows another car and it’s not the bracket, but the clutch fork that is shown there), so from this hole the cable will need to be taken out (the cable is indicated by a blue arrow) towards the car interior (in the direction indicated by a green arrow) and therefore you will bring the entire cable out into the car interior from the engine compartment and thereby completely remove it from car (When removing the cable, remove the guide sleeve of the clutch cable sheath).

We correct the operation of the mechanism

All of these factors that cause deviations in the effective operation of the clutch mechanism require immediate adjustment of the position of the cable drive in the Lada Kalina 2. Adjusting the clutch involves performing such a series of manipulations.

- We dismantle the air filter housing to provide access to the adjustment mechanism.

- Holding the tip, pull the cable to the maximum possible length.

- We use a caliper to measure the distance between the tip and the previously designated fork. The norm assumes a value of 27 mm.

- If a discrepancy is detected with the indicated gap value, then proceed as follows: turn the driver along the thread until the previously specified distance value is reached.

- Let go of the cable end and make sure that it is pressed tightly against the fork.

- Press the clutch pedal several times to activate the automatic length adjustment unit.

- Now we resort to measuring the indicated gap. If a deviation is detected again, then we perform these manipulations again. This completes the clutch cable adjustment.

When the clutch adjustment is completed, the clutch assembly in the Lada Kalina is sometimes able to remind itself of squeaks or noises. This can be caused by the leader rubbing against the surface of the fork. A lubricant that should be applied to the contact between the cable lug nut and the fork will help eliminate the annoying sound effect. Among other reasons, there may be a creaking of the pedal assembly bushing, as well as the deterioration of the sensor located there.

Timing belt

The timing belts that are now used on VAZ can survive more than one water pump, but it is better to replace the parts as a set.

The timing belts that are now used on VAZ can survive more than one water pump, but it is better to replace the parts as a set.

How would you act on your own without clear instructions in the service book? On both an 8-valve and a 16-valve engine, I would change at least the pump, and better yet, the belt and tensioner between the 60th and 70th thousand kilometers. According to the period, if the mileage is small, for the sixth year of operation.

Delayed action pump: what VAZ is keeping silent about

What if the sensor is faulty?

This component can only be installed with an electronic version of the accelerator pedal. The main function of the sensor is to control the operating modes of the Lada Kalina engine when switching gears in the transmission or starting movement.

- jerking of the Lada Kalina 2 car at the moment of switching gearbox stages;

- a sudden increase in speed (the engine is idling) when you press the clutch pedal assembly.

The replacement procedure is characterized by inconvenience due to inaccessibility to the two screws by which the component is fixed to the pedal bracket.

- Dismantling involves removing the cable holder holder and the corresponding hole present on the pedal bracket.

- We also disconnect the block from the wiring harness under the instrument panel.

- You will need a screwdriver to remove the spring hook from the holder.

- Now unscrew the previously mentioned hard-to-reach screws.

- We remove the sensor with its holder and then install a new element.

We carry out the assembly process using the reverse algorithm.

Clutch

On Lada Kalina II vehicles equipped with a manual gearbox, single-disk, dry, permanently closed clutches with a pressure spring 11 in the center (see figure below) and torsional vibration dampers on the driven disks 7 are installed. Clutch housings 3 are attached to the flywheels 6 using six There are 4 bolts, and they are connected to 5 pressure plates by 3 pairs of plates.

Clutch housings are structurally combined with car gearbox housings.

The clutch release drive is a backlash-free cable drive.

The clutch release drive is equipped with a special ratchet-type mechanism, which is designed to compensate for changes in the length of the drive during use when the driven disk linings are worn (due to which there is no need to adjust the drive during use).

The clutch pedal is installed in a bracket, which is fixed to the shield on the front end, on a special axis with two plastic bushings.

Clutch: 1 – cable tip guide, 2 – fork lever to release the clutch, 3 – clutch housing, 4 – bolt for attaching the clutch to the flywheel, 5 – pressure disk, 6 – flywheel, 7 – driven disk, 8 – input shaft for the box gears, 9 – front cover from the clutch housing, 10 – clutch housing, 11 – pressure spring, 12 – bearing for engaging the clutch.

Clutch discs: 1 – pressure disc, 2 – clutch housing, 3 – pressure spring, 4 – driven disc.

The upper part of the pedal is connected directly to the housing of the lining wear compensation mechanism on the clutch driven disc. The upper end of the cable sheath is secured to the clutch pedal bracket with a special plate stop, and the lower end is secured inside the bracket, which is installed on the gearbox housing.

Plastic leash 1 of the lower cable end is connected to lever 2 of the fork to disengage the clutch. Bearing 12 for clutch release (closed subtype) does not require lubrication during use. The main parameter that determines the operation of the drive to disengage the clutch is the travel of the clutch pedal itself to the maximum - the stop against the floor mat in the body. The travel of this pedal is not adjustable during use, since it is structurally provided with a working mechanism for compensating for wear of the linings from the driven clutch disk, as well as with the correct initial installation of the drive cable (see the article on how to replace and adjust the drive cable to disengage the clutch).