VAZ 2107 is the first model of the Volzhsky Automobile Plant, which has undergone many modernizations, improvements and additions throughout the entire production period. This included replacing the engine from a carburetor to an injection engine. The only thing that remained unchanged was the exterior.

For forty years, starting in 1972, the “Seven” rolled off the plant’s assembly line. Initially produced with a 1.5 liter engine from the third model of the Zhiguli. In the process of evolution, the engine volume changed from 1.45 to 1.7 liters, but the power units were carburetor.

Only in 2006, the designers of the car plant managed to implement a distributed injection system on an engine with a volume of 1700 cc. From that time on, the era of production of cars of the Lada family with an injection engine began.

The game was worth the candle. The main thing is that the technical developers achieved what they set out to achieve:

- fuel economy;

- increase in power;

- equated to Euro-2 standards.

Subsequently, the VAZ 2107i (injector) ousted its counterparts with a carburetor power plant from production.

Characteristics of the car 2107

Dimensions Length: 4145 mm Width: 1620 mm Height: 1435 mm Wheelbase: 2424 Front track: 1365 Rear track: 1321 Ground clearance: 170 mm Maximum trunk volume: 325 l Curb vehicle weight: 1060 kg Permissible gross weight: 1460 kg Turning circle: 9.9 m

Carburetor-type engine versions are marked 2103 and 2106. The main malfunctions are associated with floating engine speeds, tripping and overheating. Thanks to its simple design, repairing the power unit is quite easy.

Injection versions of the VAZ 2107 engine are considered more modern. In the VAZ 2107, the air-fuel mixture in the cylinders is obtained thanks to a separate injection system. The injector has 4 nozzles, which are controlled by a microcontroller. Fuel supply is regulated depending on various parameters of the vehicle’s condition.

The efficiency of the VAZ 2107 injection engine is higher than that of the carburetor engine. The engine is resistant to idling and rarely stalls when starting from a standstill thanks to sophisticated electronics. The motor has low noise thanks to automatic chain tension adjustment.

VAZ 2107 technical specifications – Leading auto portal

VAZ 2107 is one of the best representatives of the Soviet automobile industry with more than thirty years of history, which today enjoys unprecedented popularity among our car enthusiasts. This sedan, thanks to its versatility, has become a favorite car of the middle class, allowing it to be used both in urban and rural environments.

The first “seven” rolled off the VAZ assembly line in 1982, and with its design it created a real sensation. In comparison with its predecessor, the “five”, it looked much more solid: a chrome radiator grille, an improved shape of the rear headlights, an updated instrument panel, complemented by a tachometer and a number of new sensors, and one-piece anatomical seats. For such “chic”, the VAZ 2107 was even called the Russian “Mercedes” in the southern regions of the USSR.

Modifications of VAZ 2107

The “Sevens” were equipped with carburetor power units of the VAZ 2103, VAZ 2105 and VAZ 2106 models with a four- and five-speed gearbox. Later versions were equipped with engines with distributed (injection) fuel injection, which made the cars more economical.

Let's take a closer look at the modifications of the VAZ 2107 in the order of their release.

| Brand and modification | Years of manufacture | Engine power, l/s | Engine capacity, cm cube |

| VAZ-21072 | 1982 – 2001 | 64 | 1290 |

| VAZ-21073 | 1982 – 2003 | 76 | 1689 |

| VAZ-21074 | 1982 – 2001 | 75 | 1569 |

| VAZ-21074 | 2001 – 2012 | 75 | 1568 |

| VAZ-21075 | 1982 – 2012 | 65 | 1524 |

| VAZ-21075 | 1982 – 2012 | 68 | 1451 |

| VAZ-21079 | 1995 – 2002 | 140 | 1308 |

The first modifications of the “sevens” (21072) were equipped with a 1.3 liter “five” engine. A little later, it was replaced by a 1.6-liter power unit from the VAZ 2106, which was installed on the VAZ 21074. The VAZ 21073 model, which was sent for export, was equipped exclusively with a 1.7-liter injection engine. Especially for Asian countries, the “Seven” was equipped with a 1.45-liter power unit adapted to A-76 gasoline. All other modifications were equipped with one and a half liter “three” engines.

After 2006, the VAZ 2107 began to be equipped exclusively with a 1.6-liter injection power unit that meets European environmental requirements EURO-3.

General technical characteristics of VAZ 2107 cars

| 2107 | 210720 | 21074 | 2107420 |

| Body type | Sedan | ||

| Number of places | 5 | 5 | |

| Number of doors | 4 | 4 | |

| Body length, m | 4,145 | 4,145 | |

| Body width, m | 1,62 | 1,62 | |

| Body height, m | 1,446 | 1,446 | |

| Wheelbase, m | 2,424 | 2,424 | |

| Ground clearance, m | 0,164 | 0,164 | |

| Curb weight, kg | 1060 | 1060 | |

| Maximum speed, km/h | 150 | 150 | |

| Acceleration time to 100 km/h, s | 17 | 16 | |

| Fuel consumption in the urban cycle, l | 9,6 | 9,6 | |

| Fuel consumption on the highway, l | 6,9 | 6,9 | |

| Fuel tank volume, l | 42 | 42 |

Fuel consumption

- Fuel consumption in urban conditions is 9.4 liters per 100 km.

- On a flat road at cruising speed it will already be 6.9 liters per 100 km.

- In mixed mode, consumption will be from 8 to 9 liters per 100 km. Such figures do not allow us to call this engine economical, but in this case a lot depends on the driver himself.

- Another parameter that depends on the driver is oil consumption per 100 km. For the average driver of a car with this engine, it is 700 g per 100 km. This, of course, is not small, but with careful driving you can reduce this consumption down to 450-500 g/100 km.

- The weight of the 2103 engine when fully assembled is 121 kg.

When to replace

According to the manufacturer's instructions, replacement should be carried out after traveling 10 thousand km when driving long distances and every 6 thousand km if trips were carried out mainly over short distances.

Also, the moment of replacement can be determined by the oil pressure sensor. Long service life dilutes the oil, so a cold engine shows high pressure, but after warming up the indicator drops significantly. Such differences signal the need for maintenance.

Description of design

description of the VAZ 2107 engine design

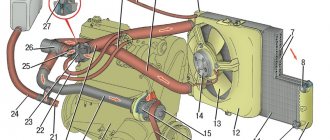

Depending on the modification, one of four engines can be installed on a VAZ 2107 car: 2103, 2104 (1.5 l volume) or 2106, 21067 (1.6 l volume).

VAZ 2107 car engine

- gasoline, four-stroke, four-cylinder, in-line, eight-valve, with an overhead camshaft. Engines 2103 and 2106 are carburetor, and engines 2104 and 21067 are with distributed fuel injection.

The 2104 engine is based on the 2103 engine, so the cylinder block, connecting rod and piston group, timing drive and crankshaft have the same design and dimensions.

Engine 21067 is based on engine 2106. Since engines 21067 and 2104 have different cylinder diameters, the pistons and rings are therefore not interchangeable. The timing drive parts and crankshafts of these engines are identical.

On the camshaft drive cover of injection engines there are brackets for installing the crankshaft position sensor.

Engines of VAZ 2107 cars equipped with an injection system comply with EURO II exhaust gas toxicity standards. Distributed fuel injection with a fuel vapor recovery system and a catalytic converter allows you to reduce fuel consumption and make it easier to start the engine on a VAZ 2107 in cold weather.

The ignition system of engines 2104 and 21067 is included in the control system. The functions of the ignition distributor on a VAZ 2107 car are performed by an electronic engine control unit.

Cylinder block

— cast from high-strength cast iron. The engine cylinders are bored into the block and honed. By diameter, the cylinders are divided into 5 classes every 0.01 mm and are marked on the lower plane of the block with the letters A, B, C, D and E. The cylinders are arranged vertically in one row.

Crankshaft

The engine of the VAZ 2107 car, cast from high-strength cast iron, is installed in the lower part of the cylinder block on five support journals. The crankshaft rotates in steel-aluminum liners; a layer of aluminum-tin alloy is applied to the steel base. The holes for the main bearings are machined together with the bearing caps, so the bearing caps are not interchangeable.

On the outer surfaces of the main bearing caps there are marks corresponding to their serial number (counted from the front end of the crankshaft). To prevent axial movement of the crankshaft, two thrust half-rings are installed in the grooves of its rear support - steel-aluminum and metal-ceramic. The camshaft drive cover contains a front crankshaft oil seal, which “works” along the outer surface of the pulley. The rear crankshaft oil seal is pressed into a holder attached to the cylinder block and “works” along the surface of the crankshaft flange. The front bearing of the gearbox input shaft is pressed into the rear end of the crankshaft.

Advantages and disadvantages of the model - an objective review

The presence of hydraulic compensators not only made the engine quieter, but also saved the owners of this model from adjusting the valves. And hydraulic chain tensioners make the engine run much smoother, which allows the engine mounts to wear out less.

Review of VAZ 2107 2008 injector. I purchased it in August 2011. Mileage at the time of purchase was 36 thousand km, one owner. Music, tinted semicircle, set of winter tires. Almost new car condition. There was no smoking in the cabin, everything was clean, the engine was injected, clean, it was clear that it had been recently washed, and the car was polished. There were uneven gaps on the hood, but this nonsense did not bother me. The doors closed well. In general, after driving the Niva in 1996, the car seemed to be in perfect condition, as some say - a Russian Mercedes. And when I drove it, turned the steering wheel, changed gears, was pleasantly surprised at how well everything worked and the engine pulled, I decided to take it. The owner offered for 135, they agreed on 130. In general, it’s worth saying a few lines about the cornfield. It was a design shifter, garage-assembled, with a mileage of about 120 thousand km. Of course, it constantly broke due to small things, either light bulbs or distributor (see age), on the highway it pulled to the left, ate tires, but it drove, carried everything like a truck and was quite happy with the engine and gearbox without any complaints. The body was strong, but rust appeared everywhere from under the rubber bands, sills, etc., and was tinted with gray household enamel PF-115. Everything in the cabin rattled and smelled of gasoline and burnt oil. After such a car, sitting in a seven-wheeler felt like being in a comfortable car. And the Niva was at the complete disposal of my father with a mileage of 200 km per month. After the purchase I was very happy, the car seemed dynamic and easy to control. That same day I went to the dacha and jammed the right rear door against a post in a narrow turn. The paint was a little worn down to the primer, but it still drove fine. With the beginning of autumn, a check began to appear - error p0036 (oxygen sensor 2), this seems to be a disease in all sevens with Euro3. The sensor is located after the catalyst, under the bottom, in the very middle, and of course water and dirt from under the wheels get on it. I bought the Prestige V-55 on-board computer and forgot about the problem. With the onset of cold weather, an incomprehensible glitch appeared - the instrument panel did not work until the car warmed up and sometimes I had to drive without instruments. When the cold got worse, the panel turned on only when I got to work. It was a little confusing. After searching for information, I realized that this is another disease. It turns out that the connectors are not soldered to the board but are connected with rivets - hence the poor contact. I spent the evening disassembling and soldering the panel, and at the same time replaced the backlights with LED ones. By the way, the battery charge lamp cannot be changed! It makes up the signal chain. In winter the car performed well. The stove was warm, the interior quickly heated up, it started without problems in any frost, but with a good battery. And the one that came with the car didn’t start at -25 and even the alarm didn’t open the door. I had to replace the battery, fortunately there was a spare one in the garage. On the roads the car handled itself quite confidently in ice and snowfall, of course you can’t go fast with rear wheel drive, it has its own specifics, but the car feels good. I went through the winter without any problems, but with the onset of warm weather, the seven again threw up a riddle. The car had an alarm and an actuator in all doors, and so the driver's door stopped closing. I took it apart, it turned out that the cheap Chinese signaling wires had cracked insulation, water got in and the wires fell apart... I replaced the wires. Around the same time, the limit switches on the right doors stopped working, and the wires rotted similarly... After the winter, spots of rust appeared on the thresholds from small chips. I had to clean and tint it myself, because I wanted to drive a car that looked beautiful. I also decided to make sound insulation. I bought the material, disassembled the interior - the inside of the car was clean, like new. At the same time, I also anticorroded the internal cavities. After the noise, the front floor and doors became much more comfortable and the music became richer. The suspension did not cause any complaints, it worked as it should and after the field it seemed that the car was floating along the road. The summer heat of '12 arrived, and with it the features of the classics - it was hot in the cabin. In traffic jams, the windows did not help, and the heater tap did not close completely and hot air always blew into our feet. What was a blessing in the winter turned into a disaster in the summer. I didn’t bother to fix anything, I just drove on. I noticed how the stove faucet was leaking a little - I stopped it and didn’t do it, I just wiped away traces of antifreeze from the shelf. In city traffic jams the car did not warm up, it was stable at 86-92 degrees, but then one day the temperature in the traffic jam began to rise and reached 105 degrees! The alarm on the on-board computer went off. I stopped and idled - the temperature was 98-100, the fan was humming, but the car was not cooling down... I turned off the car, opened the hood - everything was fine, but suddenly I noticed gurgling in the expansion tank. I waited, the heater was on full, the fan was on maximum and drove off, and after 500 m it was again over 100 degrees, there was a traffic jam all around... In general, I barely made it home with several stops. I thought about the thermostat then. I bought it and changed it. I added almost 3 liters of antifreeze. Moreover, the old one was kind of dirty or something. I cooked an old thermostat in a saucepan at home and it turned out to be working. The next day the car was heating up again. I started to think what was the matter. There weren’t many thoughts: the thermostat had fallen off, there was an air lock, a pump, a broken head gasket or a crack somewhere... I tried to get rid of the air lock - I drove uphill with my face, gave it gas, topped it up - it didn’t help. The pump was playing, and a lot, but it was not leaking, the liquid was moving properly, the blades were in place. One fig replaced it, but no such luck. I measured the compression - it was approximately the same on all cylinders, the spark plugs were dry, but in the fourth cylinder it was a little lighter than the others, the exhaust steamed when cold and gurgled into the expansion tank. In the end I decided to remove the cylinder head. And as it turned out, the problem was in the gasket; it burned out on the 4th cylinder, and was barely noticeable to the eye. Who will disassemble, please note that there are new bolts on the injectors, firstly, they are tightened once without further tightening, and secondly, their head is in the form of an asterisk, it’s called TORX E16, sort of. When I opened the valve cover I was surprised and had to go to the store in the field to get this head, I paid 115 rubles. At the same time I adjusted the valves. There is also a subtlety here - the wide feeler gauge is so wide that it is wider than the groove from the rocker on the cam, so when setting it you will get the wrong clearance and a knock. It is necessary to remove 5 mm along the entire length of the probe using sandpaper! Replacing the gasket took almost a whole day, since the old gasket was stuck to the block and it took a long time to scrape it off. The condition of the engine was very good, it was clean inside. The valves are as they should be: light exhaust, dark intake. After this trouble with the engine, the car did not ask for anything else and worked properly. At that time, the mileage was about 48 thousand km. Consumption in summer is 6-8 l/100km. Depends on the number of traffic jams. For long distance driving on the highway 5.5-6 l/100. And in a traffic jam it can reach up to 11 l/100 km. Average consumption over the summer is 7.6l/100km. Autumn 2012 has arrived. Anyone who has driven knows - in the classic there is no cabin filter and dry leaves fall on the stove - there is an aroma of fried leaves in the cabin, almost like in a bathhouse))) Plus, through the air ducts, no, no, yes, leaves are flying... Before winter, it was only necessary to change the tires again - well, why is this so complicated, you ask, but for me it turned out that not everything was so simple. When tightening the bolts on the front wheel, I tore off the thread in the hub and pulled out the bolt with the remaining threads. And he twisted his hands and tore it off, like that!!!??? I'm not used to riding with three bolts. I decided to change the hub. Disassembled. I saw that the wheel bearings were all covered in shavings, although they were not humming, and even the brake hoses were in deep cracks. I sat down on the field and went to the store. At the same time I changed the brake fluid (it was opaque brown), hoses, bearings and the hub itself, of course. It took almost a day to do everything. After that, the car drove the same way as before - the result: there was nothing to break. Winter 2012-13 has arrived. The car drove, no problems, only the exhaust became somehow louder and smoke came from under the car. I drove onto an overpass - the resonator, the one in front of the muffler, was all rusty and in places had a small hole. And winter, frost. Screw him! So I drove for now... Until one day in the cold February I took the men from work to the store to buy tents. We drove through garages, the car was loaded, the rut was very deep and every now and then I scraped with something, but in one of the pits the car was carried away by an icy wave and something hit me against a tall ice hump on the road. After this, the sound of the exhaust suddenly increased in bass. I drove home, looked under the car - a pipe had been torn off from the muffler can, and everything there had completely rotted in three years and six seasons. I had to go buy a muffler. Replaced it, mileage is about 55 thousand km. The resonator was wrapped in asbestos and tied with wire - let it continue to rot. Another surprise awaited me in the dark early morning on the way to work. I was driving along the highway at 90 km/h, sleepy, in some thoughts, listening to music, leaning back in my chair, and then suddenly the back of the chair suddenly falls back. So I had to ride like a soldier. In the evening I looked - the teeth of the retainer had worn out. A thought arose: the car was either being driven by a taxi driver, or the previous owner was jumping in a chair. I bought this retainer - it’s a cheap part, but replacing it is something. I had to disassemble the seat, cut off the old retainer with a grinder and weld a new one. I didn’t have a welding machine, so I connected three car batteries in series with welding wires. I got 36 volts and a bunch of amps, “+” for the chair frame, “-” for the electrode and the retainer was welded. Been busy all evening. I couldn’t pull the upholstery properly - it was crumpled, so I drove like that, fine. Otherwise, there were no operational problems in winter. Consumption in winter is 9-11 l/100km. Average winter consumption is 9.2 l/100 km. Spring 2013 did not cause any problems, the mileage was 61 thousand km. the machine worked properly. True, by that time a second Lada Granta car was purchased in a luxury configuration. So, just after driving the Grant for several months, I got back into the seven - the question arose - how did I drive it before without all these bells and whistles? On the seven, it was unusually difficult to turn the steering wheel in place. And the pedals seemed heavier. The gearshift lever travel is short, otherwise the car is like a car. The pads were never changed, nothing was done to the suspension, the spark plugs were changed once with BOSCH ones. I changed the engine oil and filter according to the regulations, adjusting the valves each time. The wheels were balanced every year, the wheel alignment was normal, I did not adjust it. At my own discretion, I changed the oil in the box and the fuel filter, although there was no need. As a result, approximately 5 thousand rubles were spent per year on consumables and spare parts. By that time, the Niva had been in an accident; my father was driving it. He refused the seven offered in return in favor of a bicycle and purchasing another Niva in the future, so the seven, after almost two years of operation, was sold for 100 thousand rubles. Thank you iron friend for your faithful service!

The principle of operation of the VAZ 2107 injection engine

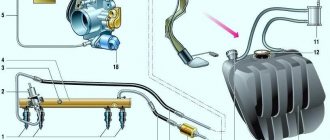

Unlike carburetor systems, where the preparation of the air-fuel mixture occurs in the carburetor chambers, the injection system involves injecting fuel directly into the cylinders. Therefore, such a system is called a “distributed injection system”.

Injection systems are qualified depending on the principle of operation and the number of injectors. “Seven” is equipped with a separate injection system with 4 nozzles (one per cylinder). VAZ 2107 injectors are controlled by a microcontroller of the electronic engine control unit. It regulates the flow of fuel into the cylinders depending on the operating mode, the position of the gas pedal and other parameters read by special sensors.

The ECU (electronic control unit) controls the amount of fuel and air entering the engine combustion chambers. In addition, it controls the formation of a spark on the spark plugs, changing the timing depending on the speed. The ECU also turns the fuel pump on and off, regulates idle speed, controls the amount of CO in the exhaust gases, and the temperature of the coolant in the cylinder block. It all works as follows.

Gasoline from the tank, passing through the fuel filter, is supplied by a pump to the fuel rail. The latter has a pressure regulator that regulates the flow of fuel to the injectors. A pressure of 300 MPa is maintained in the fuel rail, and excess fuel is sent to the gas tank through the return pipe.

The electronic control unit opens and closes the injectors, ensuring that gasoline is supplied to the intake manifolds with each engine revolution. The amount of fuel entering the cylinder depends on the time during which the injector is open. The ECU calculates this time based on the readings of many sensors. The main indicators that affect the injector opening time are information from the mass air flow sensor and the throttle position sensor. The opening moment of the injector is determined based on the position of the pistons in the cylinder, which is transmitted to the ECU by the crankshaft sensor.

Other parameters are also taken into account:

- coolant temperature, which affects the combustion process of the fuel mixture;

- on-board network voltage, on which the injector response time depends;

- engine speed;

- exhaust gas composition.

Video - Why a fuel-injected car won’t start

Reduced engine power

If you find that your car suddenly begins to pull weaker or accelerates more slowly, do not start checking with the injector. First of all, check the condition of the air and fuel filters, then determine the tire pressure, then measure the engine compression and use a strobe light to check the OZ. Carefully inspect the hose that goes from the intake manifold to the brake booster. Perhaps one of the clamps is not tightened well or there is an air leak at the point of contact with the amplifier. Remove the hose from the intake manifold and plug the inlet with a rubber or cellophane plug. Start the engine, if the idle speed increases by at least 2 - 3 percent, the problem is air leakage through a hose, a faulty fitting or a damaged vacuum booster membrane.

Lastly, compare the marks on the crankshaft pulley and the camshaft gear(s). If you find any problem, fix it; in most cases, this will solve the problem. If all parameters are normal, diagnostics of the injector is necessary. For this, it is advisable to use an appropriate scanner, which will show which of the devices or systems is faulty. If you don't have a scanner, you can do without it.

Put the car in neutral gear and ask an assistant to press the gas pedal sharply and all the way down several times. Gray, gray or black smoke from the exhaust pipe when the gas pedal is pressed all the way indicates a possible malfunction of the TPS, DPKV, mass air flow sensor, DD or DC. Constant black, gray or bluish smoke, the density of which increases when the gas pedal is pressed all the way, indicates serious clogging or damage to the injectors.

Sharp increase in fuel consumption

If fuel consumption has increased by more than 40 percent, but engine power has not decreased or decreased slightly, check the serviceability of the mass air flow sensor. If the sensor breaks or the sensor is damaged, the controller considers that the cylinders are filled with air as much as possible and supplies the largest amount of fuel. This mode allows you to protect the pistons, rings and cylinder head from damage caused by running on an excessively lean mixture. After all, the combustion rate of the air-fuel mixture, in which there is a large lack of fuel, is several times higher than that of a normal one. Therefore, instead of smooth combustion, which gradually transfers energy to the pistons, an explosion occurs. As a result, destruction and deformation of the head, pistons and connecting rods occur. If the mass air flow sensor is working properly, check the wiring that connects it to the controller, as well as the condition of the pads. If the mass air flow sensor, block and wiring are in good condition, diagnostics of the controller is necessary, for which a scanner is needed.

Difficult starting of a hot or cold engine

When the engine suddenly becomes difficult to start, but works normally in other modes, try starting it by slightly pressing the gas pedal. If this helps, you must first check the condition of the DX. For information on how to do this, read the article (Injector diagnostics). If the sensor is damaged, replace it; if it is working, then disconnect the battery, remove the air filter and its pipe, then carefully inspect the throttle valve. The idle passage may be clogged with a mixture of oil and dust. Inspect the air filter pipe - the presence of oil inside it indicates improper operation of the lubrication system and the need to clean the throttle valve.

Power loss at high speeds

If at high (over 4 thousand per minute) speed the power drops even with the accelerator (gas) pedal fully depressed, it is necessary to carry out the same engine diagnostics as described above. If the engine is working properly, the problem is in the fuel pump or ramp pressure reducing valve. Measure the pressure in the fuel line before and after the pressure reducing valve, as described in the article Injector Diagnostics.

Unstable engine operation

Floating idle speed, periodically appearing drop in power or tripping of the engine, in most cases are associated with poor contact of one or more sensors or a pinched gasoline hose. Therefore, start checking by placing the car on a lift or inspection hole. Check the fuel supply and return hoses and tubes. If you find bruised tubes or a kinked hose, they must be repaired. After this, check the condition of the contact blocks of all sensors and the fuel pump; perhaps one of them is dirty or oxidized. If all the pads are clean, a check with a scanner is necessary, which will help identify the malfunction of a specific unit. For such a check, contact a large, preferably dealer, car service center.

Once you have fixed the problem and the injector is working properly, visit a major auto dealership to have the system scanned. This is necessary to check the operation of the system and detect problems at an early stage. If you are not a professional diagnostician of injection engines, then do not carry out this procedure yourself, even if you have a scanner. Because only an integrated approach to diagnostics - the use of a scanner and the experience of a diagnostician - will allow a high-quality check of the system.

Advantages of VAZ 2107 injection models

- Due to the optimal formation of the fuel mixture, the efficiency of an injection engine is higher than that of a carburetor. Accordingly, the VAZ 2107 injector engine consumes less fuel and is at the same time more powerful than a carburetor engine with the same volume.

- Electronics regulate engine speed, thanks to which it idles more steadily, stalls less often when starting from a standstill, and starts better in cold weather.

- Unlike a carburetor engine, an injection engine does not require frequent adjustment of the fuel supply and ignition systems.

- The optimal composition and quantity of the fuel-air mixture entering the cylinders, as well as the presence of a catalyst, ensure a minimum content of harmful substances in the exhaust. This is an important point from an environmental and health perspective.

- Hydraulic chain tensioner and hydraulic valve clearance compensators eliminate the need for manual adjustment of the mechanism and ensure quieter engine operation.

- The torque curve is smoother - high torque is achieved over a wider rpm range.

The main pros and cons of the carburetor and injector

A huge number of engine manufacturers are abandoning carburetor systems and using injectors. So what are the main reasons?

- Less environmental pollution. Injection engines produce approximately two times less harmful substances than their predecessors. We can say that this is the main reason that carburetors were abandoned. Since this system does not comply with established EURO - 3 standards;

- Economical. An engine with such a system uses approximately 40-50 percent less fuel;

- Increased power ratings. Thanks to the improved design, manufacturers were able to increase engine power by 15 percent. Also thanks to this, the dynamics of the car improves several times;

- Quality and reliability. The fuel injected engine is very reliable. The presented system rarely breaks down;

- Easy to start. Unlike a carburetor, there is no need to warm up the injector in cold weather;

Read all about car repair and maintenance here. Reviews and test drives are presented here.

Disadvantages of the injection model of the VAZ engine

In addition to its advantages, the injection VAZ 2107 has some disadvantages:

- The location of the engine and other units in the engine compartment remains the same as in the old-style “classic”. This makes it difficult to access some parts. However, the injection system is quite reliable, so it does not require frequent maintenance during operation.

- The injection “seven” is equipped with a catalyst, which is easily damaged when driving through obstacles. Therefore, you need to be careful when driving on uneven roads.

- An engine with an injector is more demanding on fuel quality than a carburetor variation. When using low-quality gasoline, the system may become contaminated, requiring unscheduled maintenance of the unit.

- If the injection system breaks down, it will not be possible to repair it and adjust it “on the knee” in a garage. You'll have to go to a service station.

Characteristics of oils for VAZ

The service life of the engine depends on the correct selection of oil for injection VAZ 2107. The recommended quality standard for the lubricating fluid is given by the manufacturer. Any type of oil that meets API SJ/CF, SG/CD quality standards can be filled into the car.

The abbreviation API means that a lubricant meets the following basic criteria:

- cleaning properties;

- temperature regime;

- indicator of deposits on engine components before the first oil change;

- release of harmful substances;

- corrosive properties;

- effectiveness of protecting components from friction.

The letters indicate performance characteristics. The further away the letter is from A, the better the quality of the product.

It is recommended to use the following types of oils.

| Oil brand for VAZ | SAE viscosity groups | API standard |

| RAVENOL LLO | 10W-40 | SJ/CF |

| SHELL HELIX SUPER | 10W-40 | SG/CD |

| TNK SUPER OIL | 5W-40, 10W-40, 15W-40, 20W-40 | SG/CD |

| TOTAL QUARTZ | 5W-40, 10W-40 | SL/SF |

| MOBIL SUPER M | 15W-40 | SJ/CF |

| LUKOIL LUX | 5W-40, 10W-40, 15W-40 | SJ/CF-4 |

| NOVOIL-SINT | 5W30 | SG/CD |

| CONSOL | 5W-40, 10W-40, 15W-40 | SG/CD |

| BIZOL GREEN OIL | 10W-40 | SL/SF |

| ESSO ULTRA | 10W-40 | SJ/CD |

| LUKOIL SUPER | 5W-40, 10W-40, 15W-40, 10W-30 | CF-4/SG |

| RAVENOL SUPER HD | 15W-40 | SJ/CF |

| LUKOIL SUPER | 5W-30, 5W-40, 10W-40, 15W-40 | SG/CD |

| ANGROL-SUPER | 5W30, 5W-40, 10W-40 | SG/CD |

| LUX | 5W30, 5W-40,10W-30, 10W-40, 15W-40, 20W-40 | SG/CD |

| ESSO UNIFLO | 10W-40, 15W-40 | SJ/CD |

Malfunctions of the VAZ 2107 injection engine

Problems with the 7 injection engine usually manifest themselves as follows:

- The engine is running erratically.

- Fuel consumption of the VAZ 2107 has been increased.

- There is an increased CO content in the exhaust gases.

- Dips when pressing the accelerator pedal.

- The engine “does not pull” (reduced power).

- To diagnose injection system faults, special equipment is required. In particular, in order to read error codes and check sensor readings and the operation of the engine ECU, a special computer (tester) is required. Therefore, repairs and diagnostics of the VAZ 2107 injector are carried out at specialized service stations. The most common cause of injector failure is clogged injectors.

VAZ injector malfunctions

An injection engine is a complex balanced system in which a malfunction of one of the units always affects the overall operation of the system. Modern injection systems are equipped with self-diagnostic tools, so the rule is that if the injector is operating normally, power and fuel consumption are within the standard range, and the “Check Engine” indicator is not on, there is no need to diagnose or adjust it. Any interference with the injector will only worsen the functioning of the system.

Causes of injector clogging

Typically, problems with the injection system occur when using low-quality gasoline. Heavy paraffins contained in such fuel settle on the walls of the system, cutting off the fuel supply. Manufacturers of high-quality gasoline add detergent to it - a special additive that dissolves deposits. Low-quality gasoline contains too much paraffin, which forms deposits faster than detergents can remove them.

Deposits form more intensively at low temperatures, so when the car is frequently driven with a cold engine, the injector becomes clogged more often.

Deposits can accumulate not only in the injectors. Often vapors settle on the throttle valve, which leads to a change in the proportions of the air-fuel mixture entering the cylinders.

Deposits of substances contained in low-quality gasoline may also appear on the back of the intake valve plates. This can lead to valve burnout or fuel detonation.

To clean the injection system of deposits, it is necessary to use special flushing fluid and equipment. You can wash the injector in a garage. To do this, you need a syringe and washing liquid. The latter is mixed with gasoline and poured into the injection system through the hose of the vacuum brake booster. First, the operation is performed with the engine turned off, then with the engine running. The mixture is fed into the running engine gradually, in small portions. As a result, the deposits dissolve, enter the engine cylinders and burn there. In this case, clouds of smoke may briefly appear coming out of the muffler.

The power unit of the injection VAZ 2107 was the first at AvtoVAZ in a number of injection models. Therefore, the new product raised many questions and comments: Soviet drivers did not know how to maintain and repair such an engine. However, practice has shown that the injection equipment of the “Seven” is very practical and convenient, and also allows for a number of alterations and modifications for the driver himself.

Engine optimization options

Many drivers tune the VAZ 2107 engine in order to improve performance and increase power. An important factor that affects power performance is clean injectors. Their contamination reduces engine performance, impairs efficiency, reduces the injected volume of fuel, which will lead to failures when pressing the gas pedal.

Usually the problem occurs due to the use of low-quality gasoline. Such fuel will contain heavy paraffins that build up on valve plates, injectors and the throttle valve. There are several options for cleaning them.

The first is cleaning and bench testing.

| Names | Indications |

| Number of injectors tested | 6 |

| Supply voltage, V | 220 |

| Injector control voltage, V | 6;12 |

| Diameter of injector sockets, mm | 11;14 |

| Resistance, Ohm | 2…6; 11…20 |

| Maximum power consumption, W | 60 |

| Extreme limit pressure in the ramp, atm | 6 |

| Extreme limit pressure during cleaning, atm | 6 |

The permissible imbalance should be within 1.5%. If the deviation is more than:

- 2.5% - fuel consumption increases;

- 3.5% - unstable operation at idle, difficult cold start;

- 4% - dips occur during sudden acceleration;

- 5% - the engine does not start well, a persistent tripping appears.

The second option is to use special flushing fluid and equipment. Cleaning can be done at home. To do this, you need to dilute the flushing fluid with gasoline and add it to the power system. As a result, the deposits are corroded and enter the cylinder, where they are completely burned.

The quality of the oil used has a great influence on keeping the car in working condition.

What engines was equipped with the VAZ 2107

"Seven" was produced for a very long time - from 1972 to 2012. Of course, during this period, the vehicle’s configurations and equipment changed and were modernized. But initially (in the 1970s) the VAZ 2107 was equipped with only two types of engines:

- From its predecessor 2103 - a 1.5 liter engine.

- From 2106 - 1.6 liter engine.

On some models, more compact 1.2 and 1.3 liters were also installed, but such cars were not widely sold, so we will not talk about them. The most traditional for the VAZ 2107 is a 1.5 liter carburetor engine. Only later models began to be equipped with 1.5 and 1.7 liter injection engines.

Moreover, a number of rear-wheel drive VAZ 2107 exhibits were equipped with front-wheel drive engines, but the designers immediately abandoned such an idea - it was too labor-intensive and unjustified.

Where is the engine number

The engine number is unique to each vehicle. This is a kind of model identification code. On injection-powered "sevens" this code is stamped out and can be located only in two places under the hood (depending on the year of manufacture of the car):

- on the bottom shelf of the air supply box on the right;

- on the cylinder block.

All designations within the engine number must be clearly readable and not cause double interpretation.

What kind of engine can be installed on the “seven” instead of the standard one?

The driver begins to think about changing the engine when, for some reason, he is no longer satisfied with the operation of the standard equipment. In general, the 2107 model is excellent for various kinds of technical experiments and tuning, but the rational approach to choosing new equipment has not yet been canceled.

Therefore, before you even think about a new motor for your swallow, you need to weigh the pros and cons, namely:

- what goals need to be achieved when replacing a standard engine;

- are there technical capabilities to safely connect the motor;

- Is it possible to do the replacement yourself, etc.

Engines from other VAZ models

Naturally, engines from cars of the same family can be installed on the VAZ 2107i without significant modifications and loss of time. Experienced car enthusiasts advise taking a closer look at engines from:

These are more modern power units with an increased number of “horses”. In addition, the engine dimensions and connection connectors are almost identical to the standard equipment of the “Seven”.

Engines from foreign cars

Imported engines are rightfully considered more reliable and durable, so the idea of installing a foreign-made engine in a VAZ 2107i often excites the minds of drivers. It must be said that this idea is quite feasible if we take Nissan and Fiat models from 1975–1990 as donors.

The thing is that Fiat became the prototype of the domestic Zhiguli, so structurally they have a lot in common. And Nissan is also technically similar to Fiat. Therefore, without significant modifications, you can install engines from these foreign cars on the VAZ 2107.

Rotary power units

On "sevens" rotary engines are not that uncommon. In fact, due to the specifics of their work, rotor mechanisms can significantly optimize the operation of the VAZ 2107i and give the car acceleration and power.

An economical rotary engine ideal for the 2107 is a modification of the RPD 413i. The 1.3-liter unit develops power up to 245 horsepower. The only thing the driver should know about in advance is the drawback of the RPD 413i - a service life of 75 thousand kilometers.

Today, the VAZ 2107i is no longer produced. At one time it was a good car at an affordable cost for living and working. The injection modification of the “Seven” is considered to be maximally adapted to Russian operating conditions; moreover, the car is easily amenable to various kinds of under-hood upgrades and alterations.

Expert advice

- You need to fill in the oil of the brand that was used before. If you want to change the brand, you need to flush the system.

- There is no need to pour synthetics into old engines. It has cleaning properties that will wash away the deposits that cover microcracks in the crankcase.

- On new engines it is recommended to use exclusively synthetics. This will increase its resource and protect it from overheating.

- Perform maintenance regardless of mileage. Under different operating conditions, the maintenance period may vary.