How to replace a grenade on a Lada Priora car?

According to the manufacturer's recommendation, replacing a grenade on a Priora means installing a new front wheel drive assembly - 2 CV joints and an axle shaft on each side. Since a new unit costs a lot of money, the cost of the work is too large. Therefore, in practice, only the worn part of a given unit is replaced - the outer or inner grenade, or even both at once. If you know how to change these parts yourself, you can save a lot on car service costs.

When is replacement required?

The hinge mechanisms of the Lada Priora, which transmit rotation from the engine to the front wheels, are considered quite reliable and in some cases last 100-150 thousand km. Grenades should be replaced in the following cases:

- The car's mileage is more than 100 thousand km;

- the parts of the unit have become unusable, as evidenced by crunching sounds when turning the front wheels.

The first type of replacement is preventative. Recommended for motorists for whom a car is a tool for making money, which must be constantly in combat readiness and serve without fail. Replacement due to wear is a more common option; it is practiced by most Priora owners.

In order to change expensive CV joint parts as rarely as possible, it is important to promptly detect torn boots, through which dirt and dust enter the mechanism. Grenades cannot be repaired; they only need to be replaced. It is much easier and cheaper to replace leaky anthers so that the assembly lasts as long as possible.

Preparing for work

To replace the grenades, you need a car lift or an inspection ditch, since some of the disassembly work is performed from below. The following tools and devices will be required:

- standard set of socket heads with a knob;

- mount;

- open-end wrenches;

- metalworking tools, which include screwdrivers, hammer and pliers;

- a device that helps press the steering rod ball pin out of its socket in the strut.

If you don’t have a steering rod puller, then it’s easy to find one from fellow car enthusiasts or just buy one; it’s inexpensive. This is a steel cylinder with a slot and a bottom into which an extrusion bolt is screwed. To carry out the replacement in the inspection hole, you will also need a jack with a wheel wrench to lift the car. To completely disassemble the unit, it is advisable to have a vice and purchase CV joint-4 thick lubricant.

Lada Priora Hatchback "Priorka" › Logbook › Replacing the boots of external CV joints

Even when replacing the right-hand drive oil seal in the gearbox, this picture appeared to my eyes. This is the right outer one.

I changed it today. 8 years and 128440 km. Quite a hemorrhoid task. I immediately bought original 154RU BRT kits in Avtopiter. Inside were truly original BRT 2110 anthers. They were glossy on both sides.

I didn’t use the lubricant from the kit - VMP-AUTO started putting its dubious slurry here too. And there’s not enough of it there.

I started with the right CV joint - the most problematic one.

Surprisingly, it was quite easy to remove with the remover.

When trying to gently pull off the original boot, it immediately tore at the site of the ring crack near the small clamp - which means it was just in time.

There was very little lubricant there from the factory.

I disassembled the CV joint and washed it in white spirit (I spent 1 liter in total) until the pig squealed. It also took a very long time to clean the CV joint from rye along the large diameter of the boot. The photo shows that moisture penetrated under the rubber. I used a file and a saw blade. It took me a long time to clean it to an acceptable condition.

We injected lubricant into the CV joint straight from the tube. I didn't regret it. And installed the home kit from the kit. I lightly lubricated the CV joint housing under the boot and the boot under the clamp with grease. At the same time, the clamp compressed the boot very well along its entire diameter.

I moved to the left side... Here the boot was a little better.

There was very little lubrication. The same rust on the CV joint body under the large boot diameter. And here the most interesting thing began - the CV joint did not want to be removed. I fooled around with him for an hour. At some point, one of the bolts on the puller simply broke off... That is. The CV joint has not yet come off the ring and the puller is hanging tightly on the drive...

How to independently replace the internal grenade on VAZ cars

CV joint (constant velocity joint) is a mechanism that allows you to transmit torque between misaligned shafts. The device is actively used on front-wheel drive vehicles. On each shaft coming out of the gearbox there are two of them - internal and external. Repair is impossible; if the unit breaks down, it is replaced as an assembly.

In what cases is it necessary to replace the inner CV joint?

Replacing the internal CV joint on front-wheel drive VAZ vehicles is required if the following symptoms are present:

- Crunching and knocking noises when driving and accelerating in a straight line;

- Vibration and shock when changing gears;

- Significant play when testing by hand;

- If the “grenade” fails completely, the vehicle cannot move further.

The main reason for the malfunction of the VAZ grenade is the entry of water and dirt through the hole in the torn boot. The second possible cause of failure is a sharp press on the gas with the wheels fully turned, although in this case you risk killing the external rather than the internal grenade.

In addition to the above, replacing the internal CV joint on VAZ-2110 and other models may be necessary if the quality of the previously installed joint is poor.

Replacing the inner CV joint with your own hands

The procedure for replacing a “grenade” is the same for the entire front-wheel drive VAZ line, starting with 2108 and ending with VAZ-2115, “Kalina”, “Priora”, “Grant”. Before removing the inner CV joint, the oil is drained from the gearbox. Then proceed according to the following algorithm:

- Unlock and unscrew the hub nut. To make the work easier, a piece of pipe about 1 meter long should be put on the key.

- The desired side of the car is hung on a jack or lift.

- Remove the wheel.

- Remove the washer located under the hub nut installation site.

- Disconnect the steering tip.

- The CV joint is removed from the hub.

- Using a pry bar, remove the drive and internal joint from the gearbox.

Note: when removing both drives at the same time, a suitable mandrel should be installed in their place.

How to change the “grenade” with the drive removed? To do this, clamp the shaft in a vice, loosen the clamps and remove the boot. After this, the hinge is knocked off the splines with hammer blows.

The new CV joint should be hammered by applying light blows to its end with a hammer. For this it is better to use a wooden mallet. The “grenade” is first filled with a special lubricant.

Before installing a new constant velocity joint, it is necessary to clean its seat from old grease and install a new boot. Assembly is carried out in reverse order.

The repair is considered complete after successful sea trials. In this case, there should be no extraneous sounds from the drive side in all modes of vehicle movement.

Boot replacement and repair

The boot can be changed without removing the grenade if you have special equipment. His work is demonstrated on video.

If you do not have such a device, to remove and replace it, you must perform the above procedure for removing the drive and dismantling the hinge. The procedure is necessary if there is even minor through damage on the boot.

Temporary repairs to the CV joint boot can be made without removing it from the vehicle. To do this, you need to thoroughly clean and degrease the damage, then seal it with a piece of rubber and cyanoacrylate-based glue (superglue).

An alternative repair method is to seal the holes with silicone caulk. It should be remembered that it takes a day to completely polymerize.

Note: express repair is a temporary measure. Replacing the inner joint boot may be delayed for a short time, but not completely cancelled. Typically, these types of repair methods are used to get to the point of repair.

CV joint repair

As mentioned above, the hinge cannot be repaired. Conventionally, one of the repair measures includes washing the “grenade” after driving with a damaged boot.

Washing is carried out at the same time when the damaged boot on the pomegranate is replaced. The hinge is carefully knocked off the shaft, inspected for damage and thoroughly washed to remove any dirt and grease in gasoline or kerosene.

After washing, the assembly is filled with lubricant and mounted in place, having previously installed the boot. The procedure makes sense only if there are no obvious signs of a joint malfunction.

A crunchy or knocking part definitely needs to be replaced, since wear forms on the working surfaces of the inner race, and it is no longer possible to stop the destruction. Continued operation of the vehicle may be dangerous for the driver and other road users.

Source: https://ZnanieAvto.ru/uzly/zamena-pylnika-i-vnutrennego-shrusa-na-vaz.html

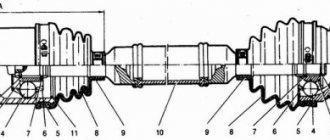

Disassembling the drive and replacing the boot

Sequence of work.

The car is driven into a pit, chocks are placed under the wheels, and the car itself is left in first gear.

Before completely removing the wheel, loosen all the wheel nuts.

The protective cap of the nut securing the drive to the hub is also removed.

To prevent the nut from unscrewing from the shaft, it is centered around the circumference, which is why it has bends that fit into a groove made in the shaft.

These bends need to be aligned, this is done with a thin screwdriver or a drift and a hammer.

After aligning the bends, using a socket and a powerful wrench, the nut is unscrewed, and the washer located under it is also removed.

Next, the car is jacked up and wooden stands are placed under its sills.

The wheel nuts are unscrewed and the wheel is removed.

Next, work is done under the car.

If there is a crankcase protection, it can be unscrewed. Then the oil from the gearbox is drained through the drain plug into the prepared container.

Next, you need to unscrew the two bolts securing the lower ball joint to the hub.

This will make it possible for the latter to move sideways. At the same time, you can check the condition of the support itself.

The steering wheel must be turned all the way to the left so that the drive is completely shifted in the inner CV joint, ensuring its minimum length.

After this, the hub is removed from the splines of the drive shaft.

The outside of the drive will be removed.

Then you can go in two ways.

The first way.

Knock down the outer “grenade” without removing the inner CV joint.

To do this, you need to remove the boot clamps, and then cut the boot, and then wipe off the existing grease on the hinge.

Then you need to prevent the drive from moving on the internal hinge.

To do this, take a small vice or a butt wrench, clamp the shaft in them and hold it firmly in your hands.

An assistant, using a soft metal spacer and a hammer, knocks down the CV joint, striking the inner race of the hinge.

With this method, there is no need to drain the oil from the box. But there is a possibility that when striking, the inner race will jump out of the outer inner CV joint.

Also, shooting down a “grenade” in this way is not very convenient, since this work will be done in a limited space.

Second way.

Complete removal of the drive from the vehicle. To do this, a pry bar is driven between the gearbox housing and the internal joint and the shaft entering the gearbox is pulled back and forth.

After this, the drive is completely removed.

IMPORTANT: With this method, the oil must be drained.

The advantage of this method is also the ability to assess the condition and replace the gearbox seal, through which oil often leaks.

In the future we will consider work with the drive completely removed.

Replacing the CV joint on a Priora fret with your own hands: video instructions

Replacing the internal CV joint on front-wheel drive VAZ vehicles is required if the following symptoms are present:

- Crunching and knocking noises when driving and accelerating in a straight line;

- Vibration and shock when changing gears;

- Significant play when testing by hand;

- If the “grenade” fails completely, the vehicle cannot move further.

The main reason for the malfunction of the VAZ grenade is the entry of water and dirt through the hole in the torn boot. The second possible cause of failure is a sharp press on the gas with the wheels fully turned, although in this case you risk killing the external rather than the internal grenade.

CV joint repair

As mentioned above, the hinge cannot be repaired. Conventionally, one of the repair measures includes washing the “grenade” after driving with a damaged boot.

Washing is carried out at the same time when the damaged boot on the pomegranate is replaced. The hinge is carefully knocked off the shaft, inspected for damage and thoroughly washed to remove any dirt and grease in gasoline or kerosene.

After washing, the assembly is filled with lubricant and mounted in place, having previously installed the boot. The procedure makes sense only if there are no obvious signs of a joint malfunction.

A crunchy or knocking part definitely needs to be replaced, since wear forms on the working surfaces of the inner race, and it is no longer possible to stop the destruction. Continued operation of the vehicle may be dangerous for the driver and other road users.

How to remove the internal grenade of a Priora

Do you hear a characteristic crunch when turning? It's time to change the constant velocity joint(s) (CV joints, aka "grenades").

When performing any maintenance or during repair work on elements of the chassis, steering, as well as during a routine inspection, cracks were discovered on the boot of the outer CV joint (constant velocity joint, in everyday life - a “grenade”). After cracks, usually the boot breaks and dust and dirt gets into the CV joint housing, and this is a direct path to replacing the joint assembly, which is expensive and not justified. Therefore, to avoid this circumstance, it is necessary to replace the boot(s) in a timely manner.

To perform this operation you will need the following tools: a 17 mm wrench, a 30 mm wrench, a pry bar and a wheel wrench.

For clarity, as well as for simplicity, we replace the boot on the removed drive shaft. For this:

1. Install wheel chocks under the rear wheels and tighten the parking brake lever. We tear off the wheel mounting bolts, jack up the desired side and place a special support stand under the car. Finally unscrew the mounting bolts and remove the wheel.

How to replace a grenade on a Lada Priora car?

According to the manufacturer's recommendation, replacing a grenade on a Priora means installing a new front wheel drive assembly - 2 CV joints and an axle shaft on each side. Since a new unit costs a lot of money, the cost of the work is too large. Therefore, in practice, only the worn part of a given unit is replaced - the outer or inner grenade, or even both at once. If you know how to change these parts yourself, you can save a lot on car service costs.

Preparing to remove the outer CV joint

In order to remove the CV joint, you need to do a little preparatory work. This work consists of unscrewing the CV joint nut from the wheel side.

As you can see in the photo, the nut is covered by a cap; it must be removed, but this requires removing the wheel.

The car needs to be jacked up. And set additional stops so that the car rests on these stops and not on the jack.

Hanging the car is the most important procedure in all repairs. The car must be positioned in such a way that you can live under it. Drink coffee and watch TV. And you don’t worry about something falling on you from above. The jack is intended exclusively for raising and lowering the car. And if only the jack is under the raised car, it cannot be used.

If there are no factory stops installed with the jack. Wooden blocks or boards will do. You cannot lay bricks. They split and the car falls. In general, even if you spend the whole day securing a lifted car safely, it’s not a big deal. And much better than remaining crippled. Sorry for the digression. But we can't rush.

After hanging the car, you need to remove the wheel. to remove the protective cap. Then the wheel must be installed back. And lower the car until it makes full contact with the floor. This must be done in order to unscrew the CV joint nut. It tightens with great effort. And stalled. In the groove of the CV joint.

To unscrew it, you will need a powerful wrench. On which you can put the pipe as an extension. This is why you have to put the car on the floor so that there is support. And the gearbox did not turn over due to the applied effort. After the nut is unscrewed, the car must be returned to its jacked state and the safety stop must be securely positioned. And remove the wheel.

Replacing the boot of the outer CV joint - how to replace it yourself, instructions with photos

To transmit torque to the drive wheels, special shafts are used. hinges protected by rubber parts. When they collapse, the lubricant is washed out and dust gets onto the rubbing surfaces. Timely replacement of these parts reduces repair costs, extending the service life of the hinge. Its design is quite complex, and the abrasive particles inside will inevitably lead to failure. External elements break more often.

Diagnostics can be carried out without removing the wheels. Turn the part all the way and illuminate the area of interest with a flashlight.

Also, breaks are easy to detect by touch. It is optimal to check with the wheel removed - this can be combined with a seasonal tire change or when repairing tires. It is also convenient to carry out diagnostics when the car is located on an overpass (while adjusting the handbrake, replacing the working fluid, etc.)

Find out the cost of replacing the outer CV joint boot online in 3 minutes

Don't waste your time - use the Uremont search and get offers from nearby services with specific prices!Get prices

How to replace a CV joint boot with your own hands

The rupture occurs for the following reasons:

- overload during twisting (sharp turns);

- driving on a washed out road;

- errors when repairing suspension elements.

Experienced car owners are advised to check mechanical defects once every two weeks.

The price list for replacing the outer CV joint boot includes labor and the price tag of the part. The amount ranges from 150-1000 rubles. The final price tag is determined by the car make and brand status. Replicas, as usual, are cheaper. In some situations, the cost is high due to the “loud” name and can reach 8,000 rubles. If you wish, you can find a suitable option of decent quality from other cars (make sure that it is suitable for your “iron horse”).

To replace the CV boot with your own hands, you will need stops, a jack, a pry bar, a hammer, a metal brush, lubricant, wrenches (with a swivel head or standard), fuel (for flushing). Make sure there is an inspection hole. It would be a good idea to find a video with a detailed description of the process.

Replacing the outer CV joint

After changing the boot according to the above instructions, changing the external hinge should not cause any serious difficulties:

- Work begins with removing the wheel.

- After removing the wheel, the hub nut is unscrewed, the caliper and the external parts of the brake system are dismantled;

- Lastly, remove the ball joint and steering tip.

Photo instructions for analysis are published above.

The CV joint is removed with a hammer, which is used to tap it through the prepared stand. Spline fasteners give in immediately, but sometimes you have to use a little more force (do not overdo it!). Having freed the boot from the clamps, you need to unscrew it towards the gearbox - now all that remains is to pull the CV joint to the surface, and if any difficulties arise, knock it out through the gasket with a hammer.

Removing the old outer CV joint

Changing components looks like this:

- The boot is installed on the shaft, the retaining ring is replaced;

The boot is secured, the clamps are tightened;

- The entire device is mounted in the hub;

- The rest of the suspension assembly takes place.

For more information about replacing the outer CV joint with your own hands, see the following video:

How to change the boot on a Priora grenade?

CV joint (constant velocity joint) is a mechanism that allows you to transmit torque between misaligned shafts. The device is actively used on front-wheel drive vehicles. On each shaft coming out of the gearbox there are two of them - internal and external. Repair is impossible; if the unit breaks down, it is replaced as an assembly.

Replacing the outer CV joint boot of VAZ 2109, 2110, 2114, photo, video

For front-wheel drive cars of the VAZ family, from model 2108 to model 2115, as well as more modern Kalina and Priora cars, maintenance of the drive wheels comes down to periodically checking the condition of the CV joint boots, both external and internal.

Otherwise, the ball-type constant velocity joints with guide grooves used on these machines do not require maintenance.

Reasons for replacing the boot

The service life of CV joints can be reduced very quickly due to damaged boots. Dirt and dust that gets inside the “grenade” act as an abrasive.

And since the hinge elements are heavily loaded and are constantly in contact with each other, the trapped dirt very quickly damages them and the “grenade” fails.

Even if you do not check the condition of the boot, the hinge itself will signal that it is damaged.

For example, as shown in the photo below, the CV joint turned.

When making turns, the CV joint with dirt trapped in it will begin to crack loudly. If the damage is not quickly repaired, the “grenade” will soon simply disintegrate and will have to be completely replaced.

But replacing a CV joint will cost much more than a boot. Therefore, upon discovering damage to the boot, or hearing a cracking sound from the CV joint, it is better to immediately begin troubleshooting the problem.

And such a malfunction is eliminated by replacing the boot, washing the CV joint and adding new lubricant to it.

Next, we will consider the sequence of actions for replacing the external CV joint boot of front-wheel drive VAZs using model 2199 as an example.

We choose the outer boot because it is damaged much more often than the inner one, since it is located near the wheel hub and the impact on it is more intense, therefore the chance of a crack appearing on it is greater.

Preparation

So, damage to the boot on the VAZ 2199 has been identified. You can replace it and wash the CV joint itself in the garage, the main thing is that there is an inspection hole.

Tools you will need:

- Set of wrenches (socket wrenches, open-end wrenches);

- Set of heads and collars;

- Metal brush;

- WD-40;

- Mount;

- Hammer;

- Jack;

- Wheel chocks;

- Wooden coasters.

You will also need a new boot, CV joint grease-4, a container for collecting oil, a container with gasoline for washing the CV joint, and rags.

It is better to do all work together with an assistant.

For convenience, we will describe the process of replacing the external boot on the left side. The replacement work on the right side is identical.

Replacing the outer CV joint of the Prior

The CV joint sits on the shaft using a splined connection. The splines have two slots into which retaining rings are installed. On the inside, the ring limits the movement of the CV joint inside the shaft. And it is a rigid thrust ring. On the other side of the shaft, the CV joint retaining ring is springy and when the CV joint is installed, it is compressed. There is a slot in the inside of the splined part of the CV joint.

The ring gets into it and, straightening, stops the CV joint from coming out of the shaft. This connection ensures that the CV joint is in a fixed position and eliminates its beating. In order for the CV joint to come out, it is necessary to apply several sharp blows to the CV joint. As a result, the retaining ring will compress and the CV joint will freely come off the shaft. All that remains is to remove the remaining old grease from the torn boot from the shaft. And wash the spline connection.

Packing the CV joint with lubricant

Before installation, the CV joint must be filled with lubricant. Special CV joint oil 4 is used as a lubricant. Lubricant must be filled into the splined part until it begins to show from the balls.

This will fill the entire internal volume of the CV joint.

Replacing the CV joint boot on a Priora

Before installing the CV joint on the shaft, it is necessary to put the CV joint boot on. It is not necessary to remove the internal retaining ring. The boot is put on the shaft like a stocking. At the same time, he turns inside out. After the boot passes the locking ring, you need to turn it back out.

To install the narrow part of the boot on the shaft there is a ring-shaped extension. The boot should slip through it... and rest against it with its back side. this will look like a stopper for the boot. If it is installed before this expansion, the boot will quickly tear. And the replacement of the Priora CV joint boot will need to be repeated.

Installing the CV joint on the shaft

The CV joint must be inserted into the splined part of the shaft up to the outer retaining ring. After the CV joint rests against it, apply a slight sharp blow to the CV joint from the outside. Be sure to place a wooden block at the impact site. To avoid damaging the CV joint threads.

The outer retaining ring is compressed by the impact and the CV joint is pushed onto the shaft until it touches the inner retaining ring. As soon as the CV joint rests. The outer retaining ring will snap into place in the groove of the CV joint. It is necessary to put the boot on the CV joint. After the boot is in place. Clamps are installed.

How to tighten a clamp on a CV joint

Tightening clamps requires a lot of patience, especially if you don’t do it often. The clamp that comes with the kit. Most precisely suited for installation on the CV joint boot. Because after installation it has minor protrusions. Which do not allow catching grass, wire and all possible fibers.

The installation principle is quite simple. At the end of the clamp there is a slot with a protruding peak. it is necessary to hook the peak onto the protrusion on the clamp located exactly in the place that gives the normal tension of the clamp. There are two additional tabs on the clamp. Designed for gripping with pliers or pliers. With the help of these protrusions the clamp is tightened. A clamp with a smaller diameter can be pulled together almost without problems. Using pliers.

Their span is enough to reach the protrusions on the clamp. But I had to tinker with a larger diameter clamp. A larger span of something is required that can tighten the clamp. I couldn't find anything of that size at hand in the garage. I had to use old metal scissors, having previously sharpened the hooks on the tips of the scissors. And only after that it was possible to tighten and connect the clamp.

That is, it is very difficult to tighten the clamp on the CV joint without special tools.