Symptoms of a clogged breather include oiling of the outer surface of the cylinder block in the area of the pipe leading from the crankcase and the oil dipstick, the air filter housing or the throttle valve. Typically, this problem occurs due to untimely maintenance of the crankcase ventilation system or when the engine intensively ejects oil through the breather. The latter may be a sign of serious problems , including critical wear of parts of the cylinder-piston and valve groups.

Leakage due to simple clogging of the pipe and oil separator is also dangerous, as it leads to disruption of the engine lubrication system. We will talk about all the main consequences and causes of oil release from the breather and ways to prevent this phenomenon in this article.

Why does oil come out through the breather?

A small amount of oil getting into the breather is not a sign of a problem . One of the functions of this unit is precisely the separation of suspended oil particles contained in crankcase gases and their return to the engine. The main purpose of the breather is to relieve excess pressure in the sub-piston space of the cylinder block by diverting a mixture of water and fuel vapors into the intake manifold.

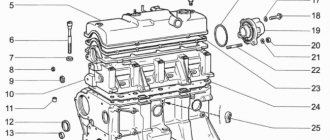

Breather in the crankcase ventilation system

To make it easier to understand why oil is driven through the breather or dipstick, let’s briefly analyze the design and operating principle of the crankcase ventilation system.

The design may vary slightly depending on the model , but it always includes three main elements - a housing, an oil separator (oil slinger) and one or two pipes. In some cars, the breather is additionally equipped with a valve that opens when a certain pressure in the crankcase or vacuum in the intake is reached.

The flexible hose can connect the crankcase outlet to the intake manifold, engine air filter housing and carburetor (directly through the filter housing or valve cover) or the air hose in front of the throttle body. The oil deflector can be placed in the breather body, in a separate housing, or under the valve cover if the air outlet into the intake is organized from under it.

Additionally, the function of an oil trap is performed by a flame arrester built into the pipe in the form of a spiral wire or mesh.

The general operating principle of all systems is the same: crankcase gases enter the combustion chamber directly through the intake or carburetor, and the oil they contain enters under the valve cover or into the crankcase.

Oil in the intake manifold entered through the breather

Oil trap clogged with sludge

If the ventilation system does not function correctly, the volume of crankcase gases or the content of oil particles in them is too high, the engine throws out oil through the breather in excess, it is not completely separated by the oil deflector and enters the intake manifold and carburetor along with the gases.

Diagnosing the cause of oil rush

Since there are a large number of reasons for oil leaking through the breather, a comprehensive check of the engine is necessary to determine exactly why the problem arose.

At the same time, to carry it out, you don’t even need to disassemble the power plant, it’s just enough to take measurements of some parameters, as well as visually assess the condition of the ventilation.

For example, let's take the already mentioned VAZ-2110. Let's assume that in the engine of this car, plaque and oil deposits were noticed in the intake manifold, which indicates oil leakage through the breather.

To determine what caused this problem, you will need little - a set of open-end wrenches, a screwdriver, a compression gauge.

We'll start the test by assessing the exhaust gases. To do this, just start the engine and look at their color shade.

If it is gray or black in color, this indicates oil getting into the cylinders due to wear or sticking of the CPG rings or problems with the timing belt. Only this can help determine the cause; read more here - the causes of smoke from the exhaust pipe.

It is also necessary to check the compression in all cylinders. In the normal state of the cylinder-piston group, it should be in the range of 11-13 MPa. The difference between the readings in the cylinders is allowed to be no more than 1 MPa.

If the compression in one cylinder is significantly lower, it can cause oil leakage.

But why exactly this is happening - rings or valves - can be determined by the spark plug that was installed on this cylinder.

Heavy carbon deposits on it will indicate a problem with the CPG.

But if the compression is low, and the spark plug has a normal working appearance without carbon deposits, you should check the valves.

If the compression in all cylinders is normal, we proceed to inspect the elements of the ventilation system.

Symptoms of a malfunctioning crankcase ventilation system

- the smell of burnt oil in the car interior when the engine is running;

- increased fuel and oil consumption;

- traces of oil on the body and breather pipe outside or near them;

- smoke from the oil filler neck when unscrewing the cap;

- clogging of carburetor jets, oiling of the air filter housing, throttle body and the insides of the intake manifold;

- squeezing out oil through gaskets, seals, and dipstick hole.

Some car owners, faced with the problem of oil escaping through the breather, disconnect its pipe from the inlet or filter housing and turn it down. This doesn't fix

the root cause of the problem, but only prevents oil from entering the intake, carburetor and throttle valve.

In addition, toxic crankcase gases

will partially end up in the car interior.

Crankcase ventilation hose lower silicone blue VAZ 2108 (8V)

- We guarantee fast processing of your order during business hours (we work from 11-00 to 20-00, Saturday and Sunday are days off).

- We guarantee reliable packaging of your order (when sending it by Russian Post or transport company).

- We guarantee the fastest possible dispatch of your paid order (within 2-4 business days after receipt of payment).

- We guarantee a refund or exchange for another product (with recalculation) within 14 days from the date of receipt of the order (the product must be in good condition, without traces of installation, delivery costs are not reimbursed).

- We guarantee a free exchange of goods (transportation costs at our expense) if the purchased goods turn out to be defective.

Payment Methods

Delivery in Russia and abroad

Pickup in Moscow

- Description

- Reviews

APPLICABILITY: VAZ 2108, 2109, 21099, VAZ 2110, 2111, 2112, VAZ 2113, 2114, 2115, VAZ 1117, 1118, 1119 (Lada-Kalina), VAZ 2170, 2171, 2172 (Lada-Priora ), VAZ 2190, 2191 (Lada-Granta), VAZ 2192, 2194 (Lada-Kalina 2) with an 8-valve engine.

Reinforced silicone lower crankcase ventilation hose, blue.

The hose is 3-layer, wall thickness 4.5 mm.

Advantages:

— the silicone used in production makes the product resistant to wear and prevents the appearance of microcracks;

Reasons why oil leaks through the breather, gaskets and seals

When the breather is heavily clogged, such high pressure is created in the sub-piston space that oil can be squeezed out of the crankcase even through the inspection hole for the dipstick, oil seals and engine gaskets. Therefore, at the first sign of a malfunction, it is necessary to establish the reasons for the release of oil through the breather. The main problems and their consequences are listed in the table below.

| Cause of oil release | Why is this happening | Consequences |

| Critical wear of the piston rings, less often burnout of the valve or piston | Gases from the combustion chamber break into the sub-piston space. The ventilation system cannot cope with the increased volume. | A drop in compression, a noticeable decrease in engine power, difficulty starting, tripping, oil squeezing out through the seals. |

| Wear of valve stem seals | Excess oil enters the combustion chamber and the piston ring grooves become clogged. Due to the loose fit of the valves to the seats, gases penetrate into the space above the valve, creating excess pressure and disrupting the operation of the crankcase ventilation system. | Increased oil consumption, carbon formation on valve plates and seats, oiling of spark plugs, burnout of valves, accelerated wear of piston rings. |

| Oil deflector clogged | Due to the blockage, the oil particles contained in the crankcase gases are not separated, as a result of which they, along with vapors, enter the intake. | Oiling of the air filter, carburetor jets, throttle valve, deterioration of engine performance due to a violation of the air-fuel mixture. |

| Clogged breather pipe | Oil is released along with crankcase gases as a result of an increase in pressure in the crankcase due to the inability to discharge it through the breather. | Squeezing oil through the dipstick hole, pan gasket, crankshaft oil seal and other seals. It is possible for the pipe to break off from the breather outlet or for gases to penetrate through cracks formed in it. |

| Failed breather valve | Due to the jamming of the valve, pressure does not release when it increases above permissible limits. | Oil squeezing out through seals due to a non-working ventilation system, tripping, deterioration of engine performance due to excess pressure in the sub-piston space. |

| Clogged air filter | Due to the reduced filter capacity, suction occurs along with oil particles from the crankcase ventilation system. | Oiling of carburetor jets, throttle valve (in injection models), violation of the composition of the air-fuel mixture. |

| Oil level exceeded | Excess oil along with gases enters the breather, and the oil separator cannot cope with their removal. | Rapid clogging of the oil separator, formation of oil clots in the hose, and its entry into the intake manifold. |

Features of ventilation design, operating principle

The simplest diagram of the crankcase ventilation system used on internal combustion engines previously consisted of only one fitting - a breather installed in the crankcase.

This breather connected the internal cavity of the cylinder block with the external environment, and crankcase gases simply escaped through it into the atmosphere.

But this scheme had one significant drawback - the exhaust gases contained oil particles, which also entered the external environment. And this is not only loss of lubricant and the need for periodic refilling, but also air pollution.

On modern cars the ventilation system is closed. It also has a breather, but a pipe is connected to it, allowing gases to be vented into the intake manifold or air filter housing, from where they enter the cylinders and burn. That is, the atmosphere is not polluted by them.

Additionally, the system includes elements that ensure oil separation and return back to the crankcase so that it does not enter the cylinders along with the gases.

There are several options for oil separators, and on cars from different manufacturers they may differ in design and operating principle.

It is worth noting that part of the exhaust gases enters the supra-valve space, and they must also be removed.

Therefore, the entire circuit of the engine ventilation system on a modern car consists of a breather, an oil separator and two pipes.

Additionally, a special valve can be included in the system to regulate the pressure of gases entering the intake manifold.

The configuration of the system can be very different, but this does not change its purpose and operating principle. For example, consider the ventilation design of the VAZ-2110.

At the bottom of the cylinder block of this car there is a breather, onto which a pipe is attached; the second end of this hose is connected through a fitting to the cylinder head cover. At the same time, an oil separator is located inside this cover at the inlet of the pipe.

On its other side there is another fitting, to which a tube is connected that goes to the air inlet pipe.

The principle of operation of such ventilation is simple - gases enter the cylinder head cover space through the breather and pass through the oil separator, while the separated oil flows to the valve assembly.

After this, the gases are mixed with those that have broken into the supra-valve space and are supplied to the air pipe, and then to the manifold. There is no pressure regulating valve in this car.

On other machines, the oil separator may be located immediately next to the breather, and a valve is installed behind it.

Diagnosis and elimination of causes

If a problem occurs when the engine throws oil through the breather, inspect the intake system, crankcase ventilation and perform engine diagnostics. To eliminate the consequences and the cause, start with the air filter and its housing. We replace the clogged filter element and remove oil on the components with a cleaner.

Diagnosis of why oil was squeezed out through the breather: video

- Check the engine oil level by first turning off the engine and waiting at least 15 minutes. The level should not exceed the maximum mark on the dipstick by more than 5 mm. Excess oil must be pumped out through the dipstick hole.

- Inspect the crankcase ventilation system for cracks and blockages in the pipe, oil clots in the oil separator, check the functionality of the PVC valve (if equipped). Contaminants are removed by washing with solvent, gasoline, diesel fuel or kerosene. Failed elements must be replaced.

- We diagnose the condition of the engine. First of all, we unscrew and inspect the spark plugs. The presence of a black glossy coating clearly indicates excess oil in the combustion chamber. We consistently measure the compression in the cylinders.

Normal value

for a diesel engine

24–30 atm

, for an injection car

12–14 atm

, for a carburetor car at least

10 atm

.

The exact value for your model can be calculated by multiplying the engine compression ratio by 1.4

.

The spread between cylinders should not exceed 1 bar. A decrease in compression indicates a leak in the combustion chamber due to burnout of the valve, piston, wear or stuck piston rings. If compression is normal, but there are traces of oil in the chamber, you need to check the valve stem seals.

How to clean the breather?

To clean the breather, you need to disconnect the pipe, remove it from the engine and disassemble the housing, remove the oil separator and valve (if equipped). Wash all parts with gasoline, kerosene or diesel fuel, removing oil deposits. Dry and reassemble in reverse order.

How to disassemble and clean the breather: video

How to clean oil from an air filter: video

How often should cleaning be performed?

If the ventilation system is clogged and its filter is unable to clean the mixture passing through it, then not only unburned gases, but also oil particles and other pollutants will enter the engine. All this will ultimately have a negative impact on both the operation of the engine and its remaining service life.

The frequency with which the crankcase ventilation of the VAZ 2114 should be cleaned directly depends on the condition of the engine. So, if the car just recently came off the assembly line, and its engine has not clocked up 50,000 km, you shouldn’t even think about cleaning it, since the piston rings are still new, and there is practically no leakage of gases through them.

Valve cover of VAZ 2114 engine

The first cleaning (as recommended by AvtoVAZ itself) should be performed after the car has covered 60,000 km. And all subsequent cleanings should also be performed after every 60,000 km.

Many owners of domestic cars with extensive experience say that 60,000 km is too much, and cleaning should be done at least every 30,000 km - this will help avoid many problems with the engine and extend its life. In this case, the first cleaning should be carried out after the first 60,000 km.

Frequently asked questions (FAQ)

Why does oil come out through the breather?

The breather provides crankcase ventilation by removing water, fuel and oil vapors formed in it and penetrating from the combustion chamber. A small amount of oil in crankcase gases is acceptable. Oil droplets are collected by the oil separator and returned to the engine. However, the release of excess oil through the breather is a sign of a malfunction in the engine, a clogged crankcase ventilation or air filter.

Why does the engine throw oil into the breather too actively?

Intense squeezing of oil through the breather indicates excess gas pressure in the sub-piston space or improper functioning of the crankcase ventilation. The main causes are worn piston rings or pistons, a clogged pipe or oil separator, and an excessively high oil level.

What happens if you close the breather?

The pressure of the crankcase gases will increase many times, the oil will be squeezed out through the control hole of the dipstick, from under the pan gasket, crankshaft seals and other seals. Therefore, under no circumstances should the breather be turned off.

Improved crankcase ventilation. beneficial improvements

Not long ago I came across an interesting article on a website. The essence of which is to change the path of crankcase gases through low crankcase ventilation.

AvtoVAZ has always allowed a small ventilation of crankcase gases into the throttle assembly, both on 8 and 16-valve engines. But, with the release of the Lada Grant and the advent of the 126th engine, the circle of low ventilation has changed, now it does not enter the throttle, but directly into the receiver. And this is more correct.

After all, by increasing the amount of air behind the throttle valve, you can reduce jerks in transient modes. Roughly speaking, make the engine more elastic.

The advantages of this modernization should be the following: • Increases traction at low speeds; • The engine jerk disappears when the throttle is closed abruptly; • Cleaner throttle assembly; • Decrease in crankcase pressure;

So, without hesitation, I decided to do this on my 8-valve engine. The materials that I read said that there would be no special effect on an 8-valve engine; it would only be noticeable on 16-valve engines.

But even on the 8-valve engine in Grant the ventilation is made directly into the receiver, which means it’s better. It’s not for nothing that AvtoVAZ came to this decision years later.

This is what the ventilation picture looks like initially

We remove the low ventilation hose; it will no longer be needed. I wanted to take clamps from it, but they don’t tighten very well

To ventilate the receiver, you will need a hose of the same diameter, only twice as long. I still have a hose for HBO in my bins (from the ramp to the injectors). It fit perfectly

I plugged the hole in the throttle assembly using a small piece of hose and a bolt. For greater reliability, I tied the ends together with plastic ties.

The receiver has two rubber plugs that are pulled together with a little effort. I had a vacuum connected to one hole from the HBO reducer, and the second was free. It was in the second hole that I connected the small crankcase ventilation circle. The hose fit freely, so I tightened it with a clamp

Now the small ventilation circle looks like this:

The new hose does not interfere with anything. When the decorative engine cover is installed, the changes are not noticeable at all.

Now about impressions. On my first test ride, I didn’t feel much of a change in traction at low revs, but there was some effect. I would say that traction improved by 5%, no more. Or maybe this is just my own self-hypnosis. But I don’t have a 16-valve one, where it should be really noticeable.

But the nods when releasing the gas almost disappeared. Everyone is familiar with the situation when you are driving in 1st or 2nd gear at a speed of over 3 thousand and sharply release the gas pedal without squeezing the clutch, the car “nods” and a noticeable nod appears.

So, now these “nods” are barely noticeable. They remain, there is no longer the feeling that someone suddenly pressed the brake.

In general, I consider the revision extremely useful and can recommend it. Simple manipulations that will take no more than 10 minutes and will increase driving comfort.