Cars admin26.02.2020

We carry out work when replacing steering components and parts, as well as when dismantling the instrument panel.

EXECUTION ORDER

|

| « previous page 14.1. Description of design | to contents | next page » 14.3. Removing and disassembling the steering mechanism |

Copyright © 2007-2019 All rights reserved. All trademarks are property of their respective owners.

Reasons for replacement

There are more than enough reasons to want to replace your steering wheel. But everyone has their own:

- The old steering wheel was worn out;

- The current rim does not meet the driver's requirements;

- The driver feels uncomfortable with the factory steering wheel;

- The unit received mechanical damage;

- Tuning, modifications to the interior and the entire car, etc. are carried out.

Drivers can name many more reasons why they want to get a new one to replace their old steering wheel.

Signs of steering rack defects, dozens and pre-repair preparation

A sign indicating problems in the steering mechanism, and most likely in the rack, is a knocking sound in the steering mechanism. It manifests itself when driving on a bumpy road surface, where the road is replete with potholes, holes and bumps from uneven soil or expanding asphalt. This creates a feeling in the car user that this knock is heard directly into the steering column. If such sounds occur in the steering system, it is necessary to diagnose it.

At this stage of identifying a defect, it is too early to conclude that the VAZ steering rack, the price of which is quite high for the average car enthusiast, requires repair or replacement. To clarify the “diagnosis” of the car, it is necessary to conduct a personal visual inspection of the area where the steering shaft is connected to the rack. To do this, you need to try to move the steering gear shaft with vertical jerks using your hand at the mounting point of the steering system components.

If knocking noises appear when moving up and down, then the car needs to be serviced. As a rule, such a knock is produced by a needle bearing that did not receive its portion of lubricant in time. An alternative to the knocking noise can be a weak fastener of the steering wheel bushing with the gear. In this case, it is necessary to tighten the fastening of the parts.

When the cause of the malfunction is established, the car owner decides on the need to replace or repair this important element of the steering mechanism. On our website there is a video on servicing the steering rack of a VAZ 2110, which demonstrates the procedure for repairing and replacing a part by a car chassis specialist

Dismantling and replacement

We have already decided on the reasons and available steering wheel options for the “ten”. Therefore, it’s time to get rid of the old device and install a new steering wheel in its place.

- Disconnect the negative terminal from the battery. This way you can avoid a possible short circuit in the steering wheel wiring.

- Check if your wheels are level. Place it as level as possible in order to simplify the reassembly process for yourself.

- Unscrew the seven fasteners that hold the steering column housing in place, and then remove the steering column lower housing.

- Unlock the column position adjustment lever.

- Lower the column down.

- Moving it gradually upward, remove the upper casing.

- There is a decorative trim on the steering wheel. You need to pry it off with a flat screwdriver.

- You will see two fasteners that hold the signal button.

- Unscrew them and remove the button.

Steering column VAZ 2110 Lada

- Repair manuals

- Repair manual for VAZ 2110 (Lada) 1996+.

- Steering column

5.2.1 Steering column PERFORMANCE ORDER 1. Disconnect the wire from the “–” terminal of the battery.

2. Set the wheels so that the vehicle is moving in a straight line. 3. Unscrew the seven screws securing the steering column housings and remove the lower steering column housing. Then, lowering the steering column down... 5.2.2 Replacing the steering shaft bearings PERFORMANCE ORDER 1. Disconnect the wire from the “–” terminal of the battery. 2. Remove the steering wheel (see subsection 5.3.1). 3. Loosen the bolt securing the base of the steering column switches and slide the base towards you. 4. Disconnect the wire from the sensor...

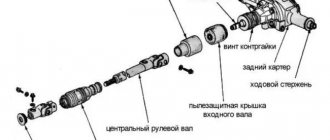

5.2.3 Replacing the intermediate shaft PERFORMANCE ORDER 1. Disconnect the wire from the “–” terminal of the battery. 2. Remove the steering wheel (see subsection 5.3.1) and disconnect the fastenings of the steering shaft bracket (see subsection 5.3.2). 3. Unscrew the bolt securing the intermediate shaft to the drive shaft...

5.2.4 Steering column adjustment mechanism For clarity, the operations are shown with the steering column removed. PERFORMANCE ORDER 1. Before starting work, remove the steering column covers. 2. If the steering column does not lock in the selected position, turn the lever until the column is securely locked. Then remove the retaining ring...

5.3.1. Steering linkage (Category). See the list of materials inside...

↓ Comments ↓

1. General information

1.0 General information 1.1. Vehicle Specifications

2. Engine

2.0 Engine 2.1 Possible engine malfunctions. 2.2 Replacing the coolant 2.3 Replacing the engine oil and oil filter 2.4. Installing the piston of the first cylinder to the TDC position of the compression stroke 2.5 Replacing the camshaft drive belt and tension roller 2.6 Adjusting the camshaft drive belt tension 2.7 Removing, troubleshooting and installing the flywheel 2.8. Replacing engine seal parts 2.9 Cylinder head 2.10 Grinding in valves 2.11 Adjusting clearances in valve drive 2.12 Removing and installing engine 2.13. Engine repair 2.14. Lubrication system 2.15. Cooling system 2.16. Exhaust gas system 2.18. Features of VAZ-2112 engine repair

3. Transmission

3.0 Transmission 3.1. Clutch 3.2. Gearbox 3.3. Front wheel drives

4. Chassis

4.0 Chassis 4.1. Checking the technical condition of suspension parts on the car 4.2. Rear suspension

5. Steering

5.0 Steering 5.1 Inspection and check of the steering on the vehicle 5.2. Steering column 5.4. Steering mechanism 5.5 Possible steering malfunctions.

6. Brake system

6.0 Brake system 6.1. Vacuum booster 6.2. Main brake cylinder 6.3. Pressure regulator 6.4. Brake hoses and tubes 6.5 Bleeding the brake system 6.6 Replacing brake fluid 6.7. Front wheel brakes 6.8. Braking mechanisms of the rear wheels 6.9. Parking brake 6.10 Possible malfunctions of the brake system.

7. Electrical equipment

7.0 Electrical equipment 7.1. Mounting block 7.2. Generator 7.3. Starter 7.4. Ignition switch (lock) 7.5. Checking and replacing spark plugs 7.6. Integrated engine management system (fuel injection system) 7.7. Contactless ignition system 7.8. Lighting, light and sound signaling 7.9. Windshield wiper 7.10 Replacing the electric motor of the radiator fan of the cooling system 7.11. Heater electric motor 7.12. Cigarette lighter 7.13. Instrument cluster 7.14 Checking the carburetor solenoid valve control unit 7.15 Possible malfunctions of the EPHH control unit. 7.16 Electrical diagram of a VAZ-21102 car 7.17 Electrical diagram of a car with a carburetor engine 2110 7.18 Engine control diagram 2111 (pin M1.5.4) 7.19 Engine control diagram 2111 (pin MP7.0) 7.20 Control diagram for engines 2111 and 2112 (pin M1) .5.4N, "January-5.1")

8. Body

8.0 Body 8.1 Possible body malfunctions. 8.2. Replacing the buffers 8.3 Removing and installing the radiator trim 8.4 Removing and installing the locker 8.5 Removing and installing the wing 8.6. Hood 8.7 Removing and installing upholstery, trim and windshield frame lining 8.8. Trunk lid 8.9. Side doors 8.10 Removing and installing the front seat 8.11 Removing and installing the upper and lower lining of the floor tunnel 8.12. Seat belts 8.13. Rear view mirrors 8.14. Instrument panel 8.15. Heater 8.16 Anti-corrosion compounds for body treatment 8.17. Features of body repair of models 2111 and 2112 8.18. Body care

9. Applications

9.0 Appendices 9.1 Fuels, lubricants and operating fluids 9.2 Basic data for adjustments and control 9.3 Filling volumes 9.4 Lamps used in the car

Preparatory activities

The first thing you need to do is buy a steering rack repair kit. Without it, starting work is completely useless. The set may have different configurations.

- Minimum (washers, fasteners, bushings, nuts, bearings).

- Medium (in addition to all of the above, shafts are added). The cost of such a kit is twice as much.

- Maximum (everything is included here, including the rack).

Please note that there are different slats - old and new. The former are intended mostly for the VAZ 2108, and the latter for the VAZ 2110. It is better, of course, to give preference to the second option, because in this case the bushing is much easier to change (there is no need to disassemble the entire rack).

Cotton steering wheel and how to deal with it

The design of front-wheel drive VAZ cars corresponds both to its price niche and partly to its purpose. An average car for economical travel over average distances at average speed. Know-how of the 80s of the Soviet automobile industry, the MacPherson suspension coupled with rack and pinion looked like something perfect in the early 80s. Although, in fact, the long-travel steering rack 2108 and the classic MacPherson of the 1948 model are not the most progressive solution even for a cheap car.

Compared to classic VAZ models, rear-wheel drive, with a classic steering mechanism and double-wishbone front suspension, the 2110 has more sluggish and imprecise handling. In a word, a wadded steering wheel. It won’t take long to figure out why this happened. Elementary geometry - MacPherson does not hold the car well in turns and during acceleration and braking, and the steering had a long stroke and an unsuccessful upper rack location. Hence the looseness of the steering wheel. It is technically inherent and cannot be cured by any settings or adjustments.

Video tutorial on repairing a VAZ steering rack

However, since the 2000s, a slightly improved design of the power steering rack has been used. There wasn’t enough for everyone at once, because first of all, cars with hydraulic booster were exported. Later, when Europe was full of Zhiguli cars, cars with power steering began to appear more often. But the hydraulic booster did not save the situation. And that's why.

We carry out repairs

Remember that this unit is a rather “delicate” and fragile mechanism.

under the octagonal nut of the stop there is a spring that needs to be removed;

then remove the retaining ring, which is located under the specified spring;

lightly tap the wooden spacer to tap the rack stop out of the crankcase (note that there is a rubber sealing ring in the groove of the stop);

Next you need to remove the front shield seal;

- under the seal there is a boot, which is also removed (you can use a screwdriver that has a wide and thin blade);

- behind the boot there is a locking ring, which is also removed;

Using a 24mm octagonal head, unscrew the gear bearing mounting nut and remove the nut from the shaft;

we press out the shaft from the gear together with the bearing using a 14mm wrench, which we rest on the mounting blade; the shaft can be clamped in cleats;

- we remove the protrusions of the support sleeve from the holes in the crankcase using a screwdriver;

- •Next we remove the bushing.

Before installing the new support bushing, install new damping rings on it. This must be done in such a way that their thin part is opposite the cut of the bushing. Next, make sure that the purchased repair kit fits your steering rack (VAZ 2108 or 2110), if it does not fit, then you will have to go and change it, we also recommend getting special keys for repair the steering rack, if it has not been done before.

install a new bushing, before doing this, do not forget to lubricate the area under the bushing;

now you need to cut the rubber rings along the contour of the bushing and remove the cut parts with a special knife;

- the next step is to remove the retaining ring from the gear shaft;

- then you need to press out the ball bearing with a special puller to replace it with a new one;

to press out the needle bearing, we use another puller; if there is none, you will have to cut the bearing with a chisel;

- wash the crankcase cavity;

- install the rail;

but before that we check it for the integrity of the teeth;

we install a new needle bearing (we use cold welding for this; we perform reassembly; it is recommended to install a new protective cover and secure it with clamps (the price of the cover is low); we adjust the rack clearance (it is important to tighten the nut all the way, bending the thread, and then loosen it , turning the key in the opposite direction 30 degrees; do not forget about the lubricant that needs to be filled with the steering rack

That's the whole process, which involves repairing the steering rack of a VAZ 2110 car.

This instruction will help you save significant money and allow beginners to become familiar with the main parts and fastening options for this mechanism.

And it will help experienced car enthusiasts avoid many common mistakes.

Selection of repair kit

Before starting repair and restoration work, you should decide on the choice of repair kit.

Minimum set. This set includes the necessary list of fastening and sealing elements: washers, bearings, nuts and fluoroplastic bushings.

The basic set has bearings and shafts in addition to the minimum set, but its cost can be twice as high as the first option.

Please note that the steering rack can be either old or new. The old racks are designed for the VAZ 2108, while the new ones are designed for the “tenth” model. The new version is also more convenient to repair. If there is a need to repair the steering rack, which involves replacing the bushing, then there is no need to disassemble the entire mechanism. Remove the corrugation, unscrew the central nut and disassemble the rack into two component parts. One part will contain the mechanism, and the other part will be the one where the bushing is located.

Diagnosis of steering problems dozens

Every car has weaknesses. For VAZ 2110, this is the tie rod end. This part is an integral part of the car's steering system. The tie rods on the tenth generation VAZ end with tie rod ends. Rods are rarely changed, but tie rod ends must be replaced every 40 thousand kilometers of the car.

But this is an average and approximate figure. The service life of the steering tip depends on the driving style of the car owner and the conditions in which the car is operated.

Any driver of a vehicle can notice a problem with the steering. The main signs of the need to replace steering tips on a VAZ 2010 are as follows:

- difficulty driving, especially when turning;

- strong noise and knocking from one or both sides in the front, more pronounced when turning;

- The tread on the tires wears unevenly.

In the latter case, most likely the problem is not only with the tips. It is necessary to diagnose the front suspension as a whole. Perhaps replacing the tie rod end won't do the trick.

The steering tips in the VAZ 2110 car are a hinged joint. Wear in the tip joint leads to a malfunction in the steering. You can check the steering tips on the VAZ 2110 yourself.

First of all visually. To inspect the tip on the left side of the car, you need to turn the steering wheel all the way to the right; to inspect the right steering tip, turn the steering wheel to the left.

You should pay attention to the rubber boot that protects the tie rod end. If it is torn or cracked, then it is time to replace the tips.

Through the hole in the boot, dust and dirt enter the hinge, which leads to faster wear of the steering tip.

To carry out the second stage of diagnosis, it is necessary to jack up one of the sides of the car so that the wheel is freely suspended in the air. Tug the tip with your hand, if there is any play, then you need to replace the steering tip. The tips should be changed on both sides. It is not worth saving and changing one tip; it is better to save on the services of a service station technician and carry out the replacement procedure yourself.