Many motorists, especially beginners who have just purchased a VAZ-2114, have wondered how the 8-valve injection engine that is installed on this car works. This article will discuss the design of the motor, its main characteristics, as well as dismantling and repair features. This information will be very useful for beginners and those who do not know how the main power unit works.

Video about the VAZ-2114 engine

Video review of the VAZ-2114 engine operation, features and characteristics.

Main characteristics of the VAZ 2106 engine

The VAZ 2106 power plant is an improved version of the 2103 engine. Thanks to an increase in the cylinder diameter, the developers managed to increase the engine power from 71 to 74 horsepower. Otherwise, the design of the motor has not changed.

The VAZ 2106 engine is considered the best of all Zhiguli engines.

Table: characteristics of the VAZ 2106 power unit

| Positions | Characteristics |

| Fuel type | Petrol |

| Fuel grade | AI-92 |

| Injection mechanism | Carburetor/injector |

| Cylinder block material | Cast iron |

| BC head material | Aluminium alloy |

| Unit weight, kg | 121 |

| Cylinder position | Row |

| Number of cylinders, pcs | 4 |

| Piston diameter, mm | 79 |

| Piston stroke, mm | 80 |

| Working volume of all cylinders, cm3 | 1569 |

| Maximum power, l. With. | 74 |

| Torque, Nm | 87,3 |

| Compression ratio | 8,5 |

| Fuel consumption (highway/city, mixed), l/100 km | 7,8/12/9,2 |

| Engine life declared by the manufacturer, thousand km. | 120000 |

| Real resource, thousand km. | 200000 |

| Camshaft location | Upper |

| Valve timing width,0 | 232 |

| Exhaust valve advance angle, 0 | 42 |

| Intake valve lag,0 | 40 |

| Diameter of camshaft oil seals, mm | 40 and 56 |

| Camshaft seal width, mm | 7 |

| Crankshaft material | Cast iron (casting) |

| Neck diameter, mm | 50,795–50,775 |

| Number of main bearings, pcs. | 5 |

| Flywheel diameter, mm | 277,5 |

| Diameter of internal hole, mm | 25,67 |

| Number of ring teeth, pcs | 129 |

| Flywheel mass, g | 620 |

| Recommended Engine Oil | 5W-30, 15W-40 |

| Engine oil volume, l | 3,75 |

| Maximum engine oil consumption per 1000 km, l | 0,7 |

| Recommended Coolant | Antifreeze A-40 |

| Required amount of coolant, l | 9,85 |

| Timing drive | Chain |

| Cylinder operating order | 1–3-4–2 |

More about the VAZ-2106 device:

Engine tuning

- direct-flow exhaust system - spider circuit 4/2/1 and resonator with banks;

- sports camshaft – gas distribution modes change.

Tuning 2108

Tuning is usually used to add about 10 horsepower. With. by replacing the carburetor with an injector or a direct-flow muffler. There is a time-consuming option to replace the crankshaft with the following crank diameter. The piston stroke increases by 2 mm, but a KShG kit, precise calculation and adjustment of the mechanism are required.

Thus, the 2108 engine uses advanced technologies from the German automobile industry. The weight and dimensions of the engine have been reduced for transverse placement under the hood of a front-wheel drive car. In two versions, 1.1 l and 1.5 l, the modernization was carried out by employees of the manufacturer's plant.

If you have any questions, leave them in the comments below the article. We or our visitors will be happy to answer them

VAZ 2106 engine structure

The design of the VAZ 2106 power unit consists of four systems and two mechanisms.

Table: VAZ 2106 engine systems and mechanisms

| Systems | Mechanisms |

| Power | Crank |

| Ignition | Gas distribution |

| Lubricants | |

| Cooling |

VAZ 2106 power supply system

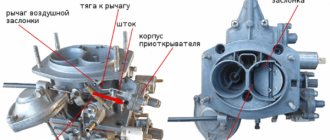

The power system is designed to purify fuel and air, prepare a fuel-air mixture from them, timely supply it to the cylinders, and also remove exhaust gases. In the VAZ 2106 it consists of the following elements:

- tank with fuel level sensor;

- fuel filter;

- gasoline pump;

- carburetor;

- air purification filter;

- fuel and air lines;

- intake manifold;

- an exhaust manifold.

Fuel from the tank is supplied to the carburetor using a mechanical pump

How does the VAZ 2106 power system work?

Fuel is supplied from the tank using a diaphragm type fuel pump. The device has a mechanical design and is driven by a pusher from the eccentric of the auxiliary drive shaft. In front of the fuel pump there is a fine filter that traps the smallest particles of debris and moisture. From the fuel pump, fuel is supplied to the carburetor, where it is mixed in a certain proportion with pre-purified air, and enters the intake manifold as a mixture. Exhaust gases are discharged from the combustion chambers through the exhaust manifold, exhaust pipe and muffler.

Video: operating principle of the carburetor engine power supply system

Ignition system VAZ 2106

Initially, the “sixes” were equipped with a contact ignition system. It consisted of the following nodes:

- ignition switch (lock);

- battery;

- generator;

- ignition coil;

- voltage distributor with breaker;

- high voltage wires;

- candles.

VAZ 2106 engines were equipped with contact and non-contact ignition systems

Subsequently, the ignition system was somewhat modernized. Instead of a breaker, which was used to create an electrical impulse and required constant adjustment of the contacts, an electronic commutator and a Hall sensor were used.

The principle of operation of contact and non-contact ignition systems of the VAZ 2106

In the contact system, when you turn the ignition key, voltage is supplied from the battery to the coil, which acts as a transformer. Passing through its windings, the voltage increases several thousand times. Then it goes to the contacts of the breaker, where it turns into electrical impulses and goes to the distributor slider, which “carries” the current across the contacts of the cover. Each contact has its own high-voltage wire, which connects it to the spark plugs. Through it, the pulse voltage is transmitted to the electrodes of the spark plug.

The contactless system works a little differently. Here, a Hall sensor installed in the distributor housing reads the position of the crankshaft and sends a signal to the electronic commutator. The switch, based on the received data, supplies a low voltage electrical pulse to the coil. From it, the current again flows to the distributor, where it is “spread” to the spark plugs through a slider, cover contacts and high-voltage wires.

Video: contact ignition system of VAZ 2106

Lubrication system VAZ 2106

The lubrication system of the VAZ 2106 power plant is of a combined type: oil is supplied to some parts under pressure, and to others by spraying it. Its design consists of:

- crankcase for lubricant storage;

- oil pump with oil receiver, pressure reducing valve and coarse filter;

- fine oil filter;

- oil channels located inside the cylinder block and cylinder head;

- emergency lubricant pressure sensor.

The VAZ 2106 lubrication system additionally performs a cooling function

How does the VAZ 2106 lubrication system work?

The circulation of lubricant in the system is provided by an oil pump. It has a simple mechanical design, the basis of which is two gears (driver and driven). Rotating, they create a vacuum at the pump inlet and a pressure at the outlet. The drive of the device is provided from the shaft of the auxiliary units through its gear, which is meshed with the oil pump gear.

Coming out of the pump, the lubricant is supplied through a special channel to the full-flow fine filter, and from there into the main oil line, from where it is carried to the moving and heating elements of the engine.

Video: operation of the VAZ 2106 lubrication system

Cooling system

The cooling system of the VAZ 2106 power unit has a sealed design where the coolant circulates under pressure. It serves both to cool the engine and to maintain its operating thermal conditions. The design of the system consists of:

- liquid pump (pump);

- thermostat;

- radiator with electric fan;

- cooling fan switch sensor;

- temperature sensor;

- heater radiator;

- expansion tank;

- connecting pipes;

- engine cooling jacket.

The VAZ 2106 engine is equipped with a closed-type liquid cooling system

How does the VAZ 2106 cooling system work?

The liquid cooling jacket is a network of channels located inside the cylinder head and cylinder block of the power unit. It is completely filled with coolant. While the engine is running, the crankshaft rotates the drive pulley of the liquid pump rotor using a V-belt. At the other end of the rotor is an impeller, which causes the refrigerant to circulate through the jacket. Thus, a pressure of 1.3–1.5 atmospheres is created in the system.

Read about the design and repair of the cylinder head system: https://bumper.guru/klassicheskie-modeli-vaz/grm/poryadok-zatyazhki-golovki-bloka-cilindrov-vaz-2106.html

Moving through the channels of the power unit, the coolant reduces its temperature, but heats up itself. When liquid enters the cooling radiator, it transfers heat to the tubes and plates of the device. Thanks to the design of the heat exchanger and constantly circulating air, its temperature decreases. Then the coolant again enters the engine, repeating the cycle. When the coolant reaches critical temperatures, a special sensor is triggered, which turns on the fan. It performs forced cooling of the radiator by blowing air flow from the rear side.

In order for the engine to warm up faster in cold weather and not overheat in the summer, a thermostat is included in the design of the system. Its role is to regulate the direction of coolant. When the engine is cold, the device does not allow coolant into the radiator, forcing it to move only inside the engine. When the liquid is heated to a temperature of 80–850C, the thermostat is activated, and the refrigerant circulates in a large circle, entering the heat exchanger for cooling.

As the coolant heats up, it expands in volume and needs somewhere to go. For these purposes, an expansion tank is used - a plastic tank where excess refrigerant and its vapor are collected.

In addition to reducing the engine temperature and maintaining its thermal regime, the cooling system also serves to heat the cabin. This is achieved through an additional radiator installed in the heater module. When the refrigerant enters it, its body becomes hot, which heats the air that is in the module. Heat enters the cabin thanks to an electric fan installed at the inlet of the “stove”.

Video: operation diagram of the VAZ 2106 cooling system

Crank mechanism VAZ 2106

The crank mechanism (CCM) is the main mechanism of the power plant. It serves to convert the reciprocating motion of each of the pistons into the rotational motion of the crankshaft. The mechanism consists of:

- cylinder block;

- block heads;

- crankshaft;

- flywheel;

- elements of the piston group (connecting rods, pistons, piston rings and pins).

The crank mechanism is used to convert the reciprocating movement of the pistons into the rotational movement of the crankshaft

Operating principle of KShM

The piston with its bottom receives the force created by the pressure of the burning combustible mixture. He transfers it to the connecting rod, to which he is attached with a finger. The latter, under the influence of pressure, moves down and pushes the crankshaft, with which its lower journal has a hinged connection. Considering that there are four pistons in the VAZ 2106 engine, and each of them moves independently of each other, the crankshaft rotates in one direction, pushed by the pistons in turn. The end of the crankshaft is equipped with a flywheel, which is designed to dampen rotational vibrations and also increase the inertia of the shaft.

Each piston is equipped with three rings. Two of them are used to create pressure in the cylinder, the third is to clean the cylinder walls from oil.

Video: crank mechanism

Gas distribution mechanism VAZ 2106

The gas distribution mechanism (GDM) of the engine is needed to ensure timely admission of the fuel-air mixture into the combustion chambers, as well as the release of combustion products from them. In other words, he must close and open the valves in time. The timing belt design includes:

- camshaft;

- valves;

- pushers;

- push rods;

- rocker arms;

- drive elements (camshaft and crankshaft sprockets, drive chain with damper, tensioner, shoe).

The gas distribution mechanism of the VAZ 2106 is driven by a chain transmission from the crankshaft

How does the VAZ 2106 timing belt work?

The main element of the engine timing is the camshaft. It is he who, with the help of cams located along its entire length, through additional parts (pushers, rods and rocker arms), actuates the valves, opening and closing the corresponding windows in the combustion chambers.

The crankshaft rotates the camshaft through a tensioned chain. At the same time, the rotation speed of the latter, due to the difference in the sizes of the stars, is exactly half as much. During rotation, the camshaft cams act on the pushers, which transmit force to the rods. The latter press on the rocker arms, and they press on the valve stems.

In the operation of the mechanism, the synchronization of rotation of the crankshaft and camshaft is very important. The slightest displacement of one of them leads to disruption of the phases of gas distribution, which negatively affects the functionality of the power unit.

Video: operating principle of the gas distribution mechanism

Scheduled maintenance procedure

With a transverse arrangement, the internal combustion engine device requires a slightly modified maintenance schedule in comparison with engines of previous generations 2101 - 2106.

| Maintenance object | Time or mileage (whichever comes first) |

| Timing belt | replacement after 100,000 km |

| Battery | 1 year/20000 |

| Valve clearance | 2 years/20000 |

| Crankcase ventilation | 2 years/20000 |

| Belts that drive attachments | 2 years/20000 |

| Fuel line and tank cap | 2 years/40000 |

| Motor oil | 1 year/10000 |

| Oil filter | 1 year/10000 |

| Air filter | 1 – 2 years/40000 |

| Fuel filter | 4 years/40000 |

| Heating/Cooling Fittings and Hoses | 2 years/40000 |

| Coolant | 2 years/60000 |

| Oxygen sensor | 100000 |

| Spark plug | 1 – 2 years/20000 |

| Exhaust manifold | 1 year |

The official manual for the 2108 engine contains a description of the internal combustion engine parameters and recommends the type of oil and coolant.

VAZ 2106 engine malfunctions and their symptoms

No matter how reliable the “six” engine is, it, unfortunately, sometimes fails. There can be any number of reasons for the breakdown of the power unit, ranging from a banal break in one of the wires and ending with wear of the piston group parts. To determine the cause of the problem, it is important to understand its symptoms.

Signs that the VAZ 2106 engine requires repair may be:

- impossibility of starting (no matter cold or hot);

- tripping, “floating” speed, unstable idle;

- reduction in power at start, under load;

- overheat;

- the appearance of extraneous noise (knocking, clattering);

- change in exhaust color (thick white or bluish smoke).

It should be borne in mind here that any of these symptoms cannot directly indicate a malfunction of a specific unit, mechanism or system, therefore, diagnostics should be approached comprehensively, double-checking your conclusions.

The engine does not start at all

If, with a charged battery and a normally working starter, the power unit does not start and does not “grab”, you need to check:

- ignition coil;

- breaker (Hall sensor, switch);

- distributor cap slider and contacts;

- high-voltage wires with lugs;

- spark plug;

- gasoline pump;

- filter on the carburetor fuel intake fitting;

- idle valve.

The absence of signs of engine life is a consequence of problems either in the ignition system or in the power system. It is better to start diagnostics with the ignition, “ringing” the circuit with a tester and checking whether there is voltage on each element. As a result of this test, you should be sure that there is a spark at the spark plugs while the starter is rotating. If there is no spark, you should check each component of the system.

More information about the spark on the VAZ 2106: https://bumper.guru/klassicheskie-modeli-vaz/elektrooborudovanie/zazhiganie/net-iskry-vaz-2106.html

The essence of checking the system is to understand whether fuel is reaching the carburetor and whether it is entering the cylinders. To do this, you need to disconnect the outlet pipe of the fuel pump from the carburetor, insert it into some container, and crank it with the starter. If gasoline flows into the container, everything is fine with the pump and filter.

To check the carburetor, simply remove the air filter and the top cover. Next, you need to sharply pull the accelerator cable and look into the secondary chamber. At this point, a thin stream of fuel should be visible directed into the intake manifold. This means that the carburetor accelerator pump is operating normally. There is no flow - the carburetor needs to be repaired or adjusted.

It's worth checking the idle air valve as well. If it malfunctions, the engine will not start. To check it, you need to unscrew it from the carburetor cover and disconnect the supply wire. Next, the valve must be connected directly to the battery terminals. During connection, the click characteristic of the operation of the electromagnet should be clearly audible, and the rod of the device should move back.

Video: why the car won't start

The engine is running rough and there is a problem with idle speed.

Troubleshooting of the power unit and idle speed problems can be caused by:

- failure of one or more spark plugs;

- breakdown of a high-voltage wire;

- burning of distributor cap contacts;

- clogging of the fine fuel filter;

- obstruction of the filter on the carburetor inlet fitting;

- incorrect carburetor adjustment.

As in the previous case, here it is better to start diagnostics with the ignition system. You should immediately check the spark at the electrodes of the spark plugs and measure the resistance of each of the high-voltage wires. Next, the distributor cap is removed and the condition of its contacts is assessed. If they burn, you need to clean them from carbon deposits or replace the lid.

Diagnostics of a fine filter is carried out by determining its throughput, as described above. But as for the carburetor filter, you need to unscrew it from the cap and, if necessary, blow it with compressed air.

If after these diagnostic steps the symptoms remain, it is necessary to adjust the carburetor, namely the quality of the mixture and the fuel level in the float chamber.

Video: why the VAZ 2106 engine troits

Reduced engine power

The deterioration of the power qualities of the power unit is caused by:

- clogged fine filters or carburetor;

- fuel pump malfunction;

- improper adjustment of the quality of the combustible mixture;

- violation of valve timing;

- incorrect adjustment of the ignition timing;

- wear of piston group parts.

If there is a noticeable decrease in engine power, the first thing you should do is evaluate the performance of the fuel system by checking the filters, fuel pump and adjusting the quality of the mixture. Next, you need to determine whether the timing drive marks on the crankshaft and camshaft sprockets match the marks on the engine and camshaft covers. If everything is in order with them, adjust the ignition timing by turning the distributor body in one direction or another.

As for the piston group, when its parts wear out, the loss of power does not appear so clearly and quickly. Measuring the compression in each cylinder can help determine which piston is to blame for the loss of power. For the VAZ 2106, indicators in the range of 10–12.5 kgf/cm2 are considered normal. It is permissible to operate the engine with a compression of 9–10 kgf/cm2, although such figures indicate obvious wear of the piston group elements.

Video: why engine power decreases

Engine overheating

Violation of the thermal regime of the power plant can be determined by the coolant temperature indicator. If the arrow of the device constantly or periodically goes into the red sector, this is a clear sign of overheating. It is not recommended to continue driving a car whose engine is prone to overheating, as this can lead to burnout of the cylinder head gasket, as well as jamming of the moving parts of the power unit.

Violation of the thermal regime of the motor can be a consequence of:

- insufficient refrigerant level in the system;

- thermostat jamming;

- obstruction (clogging) of the cooling radiator;

- cooling fan failure;

- liquid pump malfunction.

If signs of overheating are detected, the first thing you should do is pay attention to the coolant level in the expansion tank and, if necessary, add refrigerant. The functionality of the thermostat can be determined by the temperature of the radiator pipes. When the engine is warm, they should both be hot. If the lower pipe is hot and the upper pipe is cold, it means that the thermostat valve is stuck in the closed position and the coolant is moving in a small circle, bypassing the radiator. In this case, the device must be replaced, since it cannot be repaired. The permeability of the radiator is also checked by the temperature of the pipes. If it is clogged, the top pipe will be hot and the bottom pipe will be warm or cold.

The cooling fan on the VAZ 2106 usually turns on at a coolant temperature of 97–990C. Its work is accompanied by a characteristic buzzing sound produced by the impeller. It can fail for several reasons, including poor contact in the connector, sensor failure, and malfunction of the electric motor itself. To test the device, just connect its contacts directly to the battery.

It is quite difficult to diagnose a breakdown of a liquid pump without dismantling it, so it is checked last. Most often, its malfunction is associated with damage to the impeller and wear of the rotor bearing.

Video: why the engine overheats

Extraneous sounds

The operation of any power unit is accompanied by many sounds, so only a specialist, and not everyone, can distinguish by ear what is extraneous noise and what is not. To identify “extra” knocks, there are special car phonendoscopes that allow you to more or less accurately determine the place from where they are coming. As for the VAZ 2106 engine, extraneous sounds can be produced by:

- valves;

- main and connecting rod bearings;

- piston pins;

- timing chain.

The valves produce a high-frequency knock that comes from the valve cover. They knock due to incorrect adjustment of thermal clearances, wear of the camshaft cams, and weakening of the valve springs.

Main and connecting rod bearings make similar sounds. The reason for this is their wear, as a result of which the play between them and the connecting rod journals increases. In addition, knocking can also be caused by low oil pressure.

The piston pins usually ring. This phenomenon is often caused by detonation inside the cylinders. It occurs due to incorrect adjustment of the ignition timing. A similar problem is solved by setting a later ignition.

The noise of the timing chain is similar to a loud rustling or clanging, the cause of which is its weak tension or problems with the damper. Replacing the damper or its shoe will help get rid of such sounds.

Video: engine knocking

Exhaust color change

By the color, consistency and smell of exhaust gases, you can generally judge the condition of the engine. A working power unit has a white, light, translucent exhaust. It smells exclusively of burnt gasoline. A change in these criteria indicates that the motor has problems.

Thick white smoke from the exhaust pipe under load indicates the combustion of oil in the cylinders of the power plant. And this is already a sign of wear on the piston rings. You can make sure that the rings have become unusable or “stuck” by inspecting the air filter housing. If lubricant gets into the cylinders, it will be squeezed out through the breather into the “pan”, where it will settle in the form of an emulsion. A similar malfunction is treated by replacing the piston rings.

But thick white exhaust may also be a consequence of other problems. So, when the cylinder head gasket breaks down (burns out), the coolant enters the cylinders, where it turns into white vapor during combustion. In this case, the exhaust will smell like coolant.

Video: why white smoke comes out of the exhaust pipe

Reliability, weaknesses, maintainability

Reliability

During factory tests, the VAZ-2108, and later in wide operation, proved to be reliable and economical, stable in operation. High-quality assembly, the use of reliable components and parts is confirmed by the fact that the units of early releases operate reliably to this day.

At various specialized forums, car owners share their impressions of the engine. The vast majority of reviews are positive.

For example, Vladimir from Krasnodar writes the following: “... over 23 years of operation, it has traveled more than 500,000 km and is now on the move. On the negative side: oil was leaking from under the timing cover and I had to change the heater radiators and cooling system - I filled it with low-quality antifreeze...”

Den from the Zaporozhye region speaks of his long-liver as follows: “... the engine has never had major overhauls (but the rings and pistons have been changed), the condition of the cylinder walls is ideal, the fuel consumption is frankly pleasing, although the car is 22 years old...”.

All car owners, without exception, emphasize the importance of timely and quality service. And they emphasize that only in this case the engine will serve flawlessly.

Dmitry from Moscow says on this topic: “... mileage 175,000 km, starts with half a turn. The car never failed. I would like to give advice to respected car enthusiasts: if you want your iron comrade to serve you faithfully for many years, treat it with respect...”

Reliability is convincingly demonstrated by the fact that the resource declared by the manufacturer is exceeded by more than three times.

The safety margin indicator is of no small importance.

Tuning VAZ-2108

The engine can be boosted to 200 hp. With. True, to the detriment of the resource. Here it’s not for everybody – either the original engine will last for a long time, or a particularly powerful one, but for a short time.

Thus, the reliability of the VAZ-2108 is beyond doubt.

Weak spots

Immediately after leaving the assembly line, car owners discovered several weak new engines.

- The valve cover required modification because its gasket often failed.

- A low resource of the cooling system components was noted. Particularly annoying were the water pump and connecting hoses, which required frequent replacement.

- Engine detonation. The reason for its occurrence was low-quality fuel. The slightest deviation in this matter, in addition to detonation, caused clogging of the carburetor.

- The Solex carburetor turned out to be quite capricious in operation. Particularly annoying was the need to frequently adjust the idle speed and clean it. Subsequently, the Solex was replaced by a more efficient Ozone carburetor.

The occurrence of other problems was a periodic occurrence. Almost all of them are directly or indirectly related to violations by the car owner.

For example, leakage of oil or coolant from under the seals. It is enough to detect the malfunction in time and fix it immediately. Or loud engine operation. The phenomenon is unpleasant, but it is enough to adjust the valves or set the ignition and the problem disappears. Often, saving on fuel (low-octane refueling) contributed to the appearance of detonation, and therefore unnecessary noise.

Overheating of the engine could be caused by a faulty thermostat or electric fan of the cooling system. In the case of constant monitoring of the operating temperature of the internal combustion engine by the driver, engine overheating is excluded.

Despite the existing shortcomings, we can conclude that they do not exceed the critical threshold in comparison with the motors previously produced by the plant.

Cylinder head

Cylinder head 19 is common to four cylinders and is cast from aluminum alloy. Cast iron seats and valve guides are pressed into the head. Spiral grooves for lubrication are cut into the holes of the guide bushings. To reduce the penetration of oil into the combustion chamber through the gaps between the bushing and the valve stem, metal-rubber oil deflector caps are used.

The cylinder head is attached to the cylinder block with eleven bolts. Between the head and the cylinder block there is a gasket made of asbestos material on a metal frame and impregnated with graphite.

Design

Any DXH provides air flow inside the engine when the throttle valve is closed. Moreover, if previously the idle speed sensor of the carburetor VAZ 2109 functioned as a shut-off valve, the calibrated hole of which could only be either open or closed, then the new idle speed sensor VAZ 2109 injector is capable of independently, depending on the position of the throttle valve, reducing or increasing the amount air, which is needed at different periods of time. That is why experts consider the new version of the IAC not to be a sensor, but a measuring device, and recently it has received the name idle air controller (hereinafter referred to as IAC).

The idle speed control of the VAZ 2109 injector is structurally reminiscent of a miniature module; in addition to the stepper motor, its body contains a rod with a needle with a cone-shaped tip.

The IAC is secured to the throttle body housing with two screws.

The device is also equipped with a 4-pin connector designed to connect the device to the car's ECU.

Principle of operation

The basic principle of operation of the IAC is reduced to changing the cross-sectional area of the calibrated hole in the bypass channel based on the current position of the throttle valve. This change begins with the translational movement of a needle connected to the armature of a stepper motor through a worm gear. Completely closing the bypass channel with the throttle valve fully open does not affect the operation of the power unit. When the needle moves back, the amount of air increases in proportion to the closing angle of the throttle valve. Due to this, it is possible to smoothly regulate the crankshaft speed during the transition from the operating state of the car engine to the idle mode.

Piston pins

Piston pins 14, 16 and 17 are made of cast iron. The outer surface of the upper compression ring 17 is chrome-plated to increase wear resistance and to improve run-in, it has a barrel-shaped generatrix. The lower compression ring 16 is of the scraper type (with a groove along the outer surface), phosphated.

The ring must be installed with the groove down. Oil scraper ring 14 has slots for oil removed from the cylinder and an internal coiled spring (expander).

Lubricating parts

Combined engine lubrication device for the VAZ-2109 (2110). Oil is supplied to the main and connecting rod bearings, as well as to the camshaft supports under pressure; the cylinders, pistons, pins and rings, camshaft cams and pushers are lubricated by splashing; all other associated parts are lubricated by gravity.

A gear-type oil pump with a bypass valve is installed at the front of the block. The oil receiver is mounted using bolts on the cover of the second main bearing and the pump housing. The oil filter is non-separable and has bypass and anti-drainage valves. The design of the lubrication system and other engine systems is discussed in detail in separate articles. » alt=»»> Crankcase ventilation is forced, gases are removed through the oil separator.

Source

Crankshaft

Crankshaft 1 is five-bearing, cast from cast iron. The shaft journals are hardened by high frequency currents to a depth of 2-3 mm. At the rear end of the crankshaft there is a seat for the front bearing of the gearbox input shaft, along the outer diameter of which the flywheel 31 is centered. The flywheel is installed on the crankshaft so that the mark (a cone-shaped hole near the gear rim of the flywheel) and the axis of the crank pin of the first cylinder are in the same plane and one from the crankshaft axis.

Checking the serviceability and restoring the functionality of the IAC

Check the functionality of the regulator as follows:

- Connect the battery to the vehicle's on-board network and, holding the IAC in your hands, put the power supply block in place.

- Turn on the ignition. In this case, the regulator rod should retract inward and then extend back to a certain distance. If the IAC acts this way, then it is operational. Otherwise, it must be replaced.

Sometimes the functionality of the regulator is restored after cleaning the spring, valve hole and needle.

Clean the IAC with a cleaner like WD-40. In this case, there is no need to disassemble the device - just treat the rod, needle and spring with a solvent. It also doesn’t hurt to spray the cleaner inside the XX channel, which will clear the valve hole of any contaminants. As soon as the cleaner dries, the functionality of the regulator is checked again and only after that a decision is made on the advisability of replacing it.

IMPORTANT! Before installing a newly purchased or repaired IAC, it is recommended:

Make sure the product matches the vehicle ECU firmware; check functionality; Lubricate the spring and rod with grease.

When choosing an IAC VAZ2109 injector, avoid purchasing counterfeit products. A fake is distinguished by the following characteristics:

- information on the packaging does not allow identifying the manufacturer;

- yellow color of the sticker on the product body;

- dark tip of the locking needle;

- thin sealing ring.

The figure below will help you distinguish the old-style sensor (on the right) from the new-style sensor (on the left):

Service

Maintenance of the Lada “Classic” engine is often carried out at home. This is due to the simplicity of the design. Maintenance is quite simple for the Lada Classic engine. An oil change is carried out every 10,000 km.

It includes changing the lubricant and oil filter element. The amount of oil required for replacement is 4-4.5 liters. When choosing an oil, everything is simple; the manufacturer recommends using a mineral lubricant.

But, as practice has shown, semi-synthetic motor oil is best suited.

Instead of a heart: the history of the Zhiguli engine from the VAZ-2101 to the present day

When talking about engines from the 70s, the first thing that comes to mind is the “classics” themselves - VAZ-2104, 05 and 07. But the last batches of these models have long been sold. What remains?

The last carriers of the first generation engines are the “relatives” of the Lada 4×4 and Chevrolet Niva. But the first, according to preliminary data, will receive a boost to 90 hp during the update. the engine is from Priora, and the second, when the generation changes, will acquire a 135-horsepower engine under the Peugeot-Citroen brand.

Spear tip

It is generally accepted that the VAZ-2101 is a Fiat 124 localized in the Soviet Union, but this is not entirely true. The cars look very similar, but more than 800 key changes were made to the design before the Fiatic became a penny. And, perhaps, the most important thing that happened along the way was an engine change. At the insistence of the VAZ team, the Fiat-124 engine, which had a rather archaic design even at that time with a lower camshaft, was turned into an overhead camshaft.

In addition, while maintaining a working volume of 1.2 liters, the cylinder diameter increased from 73 to 76 mm, and the piston stroke decreased from 71.5 to 66 mm, as a result of which the engine turned from a long-stroke to a short-stroke, and therefore became more revving and “responsive” " It was the move of the camshaft up that made it possible to increase the speed - the engine became a little noisier, but also more compact, simple, and economical.

According to one version, Fiat carried out this metamorphosis with the help of a subsidiary Italian tuning center, according to another - in collaboration with specialists from VAZ itself. Be that as it may, the engine turned out fine. If we compare it in terms of power, then it has not become fundamentally higher, but if you believe one of the VAZ legends, the Italians liked the characteristics of this engine so much (acceleration response, efficiency, simplicity of design, maintainability, service life) that they very quickly began to replicate the resulting solution on of its products.

A legend is a legend, and the very next after the “one hundred and twenty-fourth” Fiat 131 had an engine with an overhead camshaft, that is, a design first used by Fiat on the Soviet “kopek” and which has now become generally accepted. Well, the VAZ-2101 engine, coupled with an improved transmission (increased clutch, modified synchronizers, modified cardan, new rear axle), reinforced front suspension and a completely replaced rear, more rigid body, as well as a number of other “adaptation” measures, served as the basis for the first VAZ model and laid down the architecture of the Zhiguli model range for many years to come.

Evolution

Whatever they say now about the VAZ “classic” (however, about the dead or well. Well, you know), but in the 70-80s of the last century, the Zhiguli was a dream car, completely superior to everything that the domestic auto industry produced at that time. And in many ways this happened precisely thanks to that first engine.

Its most important “trick” was the wide possibilities for modernization, and using inexpensive methods - for many years, engineers could obtain new modifications without changing the main constant, the distance between the centers of the cylinders (for all “classic” engines it is equal to 95 mm) and, in fact, playing only with the cylinder diameter and piston stroke. Let's take a look at the main stages of development of the gasoline (based on the VAZ-2101, diesel variants were also created, but they are the topic of a separate story) “penny” engine.

Source

Injection modification

The first in the line of internal combustion engines of the AvtoVAZ manufacturer, the 2106 engine received tuning in the form of distributed injection. At the same time, the owners received a headache:

- intense heating, since the mixture is lean, the manufacturer’s cooling system cannot cope with temperature loads;

- increased fuel consumption up to 13 l/100 km in winter.

Injection 2106

A positive feature is the low budget for major repairs within 10,000 rubles.

IAC connection diagram and its operation

The IAC is connected to the ECU control controller with a 4-wire harness through a standard connector.

The existing electrical circuit does not allow the driver to influence the operation of the IAC, since the control algorithm of the controller is reflashed exclusively on special equipment.

The IAC mechanism works according to the algorithm indicated below:

- When you turn the ignition key, the regulator rod moves to its extreme position and the calibration hole of the air pumping channel in the throttle pipe is completely closed.

- The IAC returns the valve to the primary position after starting to read steps. At this location of the rod, the motor starts and its operation begins in the XX mode.

Important! The basic position of the rod is determined by the ECU firmware - for example, it is equal to 50 steps for Bosch firmware, and for January 5.1 firmware it is 120 steps.

The disadvantage of the VAZ 2109 injector idle speed sensor and its connection to the ECU is the lack of a self-diagnosis system. In case of malfunctions and errors in operation, the driver will not receive any useful information about this. The Check Engine light on the dashboard will not illuminate. Therefore, the driver must independently guess about the malfunction of the regulator based on his own analysis of randomly appearing indirect signs that affect the operation of the engine.