In all cars, even the oldest ones, all electrical circuits are protected by fuses, and the 2nd generation Daewoo Nexia N150, produced in 2008, 2009, 2010, 2011, 2012, 2013, 2014, 2015 and 2016, is no exception. From the factory, each fuse has its own rating, and in no case should you install a fuse of a higher rating. If you put less, then it simply won’t withstand the load and will burn out, but if you put a higher rating, it may not withstand the wires, since, for example, their cross-section is rated for 10 Amps, and the fuse is rated for 10 Amps, but you set 30 Amps . In this case, the fuse will hold, but the wiring will not. The wires will begin to melt and the wires next to them will be affected.

The starter does not turn on the Nexia. Looking for reasons together

When we turn the ignition key to the starting position, we do not hear any reaction from the starter - a fairly common breakdown for Nexia. Moreover, in 80% of cases it is not the starter that is to blame , but first things first. First of all, we check the starter for performance. To do this, take a powerful short screwdriver and begin diagnostics.

- Turn on the ignition, set the gearbox to neutral and tighten the handbrake.

- Open the hood and look for the starter.

Checking the solenoid relay.

Checking the starter motor.

If both tests are passed and the starter basically works, we look for the cause in the circuit before it.

Contact group - the cause of starter failure

But perhaps the most common cause of starter failure is failure of the contact group.

If the starter works by itself, as the first test showed, then with a high degree of probability the fault can be caused by the contact group of the ignition switch. The fact is that when designing the electrical circuit, the engineers did not take into account the high load on the ignition switch contacts. When starting the engine, voltage from the battery is supplied directly to the contact group and when the starter is turned on, a large current passes through the contacts, they heat up and burn out over time.

How to prevent breakage of the contact group

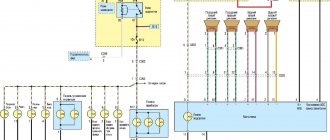

Of course, you can simply replace the contact group with Nexia, but there is no guarantee that the story of contact burnout will not repeat itself. To avoid problems in the future, it is necessary to unload contacts 15 and 30 of the contact group . To do this, it is necessary to install an unloading relay between these contacts. A regular starter relay from a VAZ 2108, connected according to the circuit between pins 15 and 30, is suitable.

What is this part?

Let's take a look at the starter. A visual inspection of this part from Daewoo shows that it looks like a four-pole, four-brush electric motor. It is also combined with a planetary gearbox and an electromagnetic two-winding traction relay.

If you disassemble the Daewoo starter into parts, you can identify the following components:

- Drive side cover;

- Screws securing the traction relay to the cover on the drive side;

- Drive clutch retaining ring;

- Drive coupling thrust ring;

- Drive coupling;

- Drive lever;

- Ring gear;

- Drive lever support;

- Drive shaft;

- Traction relay;

- Satellites;

- Planetary gear seal ring;

- Cover mounting bolts on the manifold side;

- Pinch bolts;

- Collector side cover;

- Brush unit;

- Stator;

- Rotor;

- Planetary gear cover.

Fuse and relay box Daewoo Nexia N100

Fuse links, fuses and relays for turning on the vehicle's electrical equipment are installed in a block located on the left behind the instrument panel.

On the cover of the block there is a diagram of the location of the fuses.

Part of the fuse and relay box covered by the instrument panel cover

Bottom of fuse and relay box

Replacing fuses and relays

Before replacing the fuse, it is necessary to determine and eliminate the cause of its blown. To avoid failure of electrical equipment, fuses with an increased rating or homemade fuses must not be installed.

Sequence of execution 1. Prepare the car for work.

2. Remove the instrument panel cover.

3. Using the diagram on the back of the cover and the tables (see above), we find the fuse for the faulty circuit and remove it.

A faulty fuse can be identified by a blown thread.

Sometimes the fuse thread remains intact, while its connection inside the fuse is broken. It is impossible to visually determine such a malfunction. In this case, you can assess the condition of the fuse using an ohmmeter.

4. Install a new fuse of the appropriate rating.

5. To replace the relay, remove it from the block, having previously identified the faulty one from the table (see above).

You can verify that a relay is faulty by checking it, or installing another one in its place that is known to be good.

6. Reinstall the block cover.

The information is relevant for Daewoo Nexia models 1994, 1993, 1994, 1995, 1996, 1997, 1998, 1999, 2000, 2001, 2002, 2003, 2004, 2005, 2006, 2007, 2008.

Problems at work

Despite the complex device that the Daewoo starter is, in case of minor breakdowns it will not be difficult to return it to its normal working state. To do this, it is enough to know the reason.

For example, if the traction relay does not operate, there can be many primary sources of its occurrence. If, when you turn on the DAEWOO NEXIA starter, the armature does not rotate and the traction relay does not operate, then perhaps the whole issue is just a discharged battery. Alternatively, the cause could be a short circuit or network break in the relay. The same reasons (together with oxidation of the battery terminals) can also occur if, when turned on, the traction relay is activated, but the armature rotates too slowly.

The starter turns on, but the armature does not rotate and the flywheel does not work? The problem can be solved by replacing the clutch, drive or flywheel (depending on the breakdown).

If it seems that there is excessive noise when the starter is turned on, then perhaps the whole reason is excessive wear of the bearings (which will only need to be changed).

It is possible that only the teeth of the drive gear or flywheel are damaged (replacement will also be sufficient). Although sometimes the problem turns out to be quite insignificant - the starter is simply loosened (to eliminate this defect you will only need to tighten the fastening nuts).

In any of these cases, of course, you can repair the starter yourself. However, it should be remembered that in the Daewoo Nexia model, a similar spare part is located on the rear side of the engine. This means that such work can only be carried out on an inspection hole, overpass or lift. Unscrewing it from the top and removing it from under the intake manifold will be very problematic (besides, there is a high probability of getting hurt). So if you do not have the relevant experience, in the event of a breakdown, you can safely contact specialized auto repair shops, where they will quickly and inexpensively solve a similar problem.

Daewoo Nexia fuses

The Daewoo Nexia sedan is equipped with an electrical system with a negative contact (“ground”) to the car body. The standard voltage of the on-board network is 12 volts.

To protect the electrical equipment of the machine from short circuits or overloads, the main circuits are protected by fuses.

Nexia with an 8-valve engine and a 16-valve modification have identical electrical circuits.

The way fuses work is to open the electrical connection if a certain current is exceeded. In the event of an emergency electrical situation, the current-carrying fuse element is destroyed (blown), protecting electrical units from breakdown, and the car itself from possible fire.

Nexia uses flat blade (fork) type fuses, standard ATO size, 19 mm high. The rated current in amperes is marked on the top surface of each fuse. For ease of identification, fuses of different ratings have a specific body color, but not all manufacturers follow this rule.

VESKO-TRANS.RU

AutoNews / Reviews / Tests

Where is the Daewoo Nexia Starter Relay located?

What should a driver know about the operation of the Daewoo Nexia starter while driving

? The electrical equipment of the DAEWOO NEXIA has its own characteristics, which every driver behind the wheel of this car should know about. The fact is that electrical equipment is used here, the direct voltage of which has a nominal voltage of 12 V. All equipment as a whole is a single-wire circuit. Either the battery (when the engine is not running) or the generator (or, conversely, when it is in motion) is responsible for the power itself.

As for the starter, its functions are as follows: when you turn the ignition key, immediately after its command from the battery, an electronic current begins to flow to the starter. The latter will depend on the magnet that is connected to the motor. The engine starts to spin, the fuel ignites, and it starts.

Daewoo Nexia Starter

Thus, the starter of any car (including Daewoo Nexia) is a fundamental element on the way to starting your engine.

What is this part?

Look at the starter. Visual inspection of this part shows that the Daewoo appears to be a four-pole, four-brush electric motor. It is also combined with a planetary gearbox and an electric traction relay with two coils.

If you disassemble a Daewoo starter for parts, you can identify the following components:

Main fuses for Daewoo Nexia

The main set of fuses is located in the Daewoo Nexia mounting block. The block is located at the bottom of the instrument panel, on the left side of the steering column. On the outside, the fuse box is covered with a plastic decorative cover. For the convenience of the driver, the location diagram and purpose of fuses and electromagnetic relays are indicated on the inner surface of the cover, and the seats on the board are numbered.

Control and security:

Car starter design

Every car owner should know the design of the mechanisms and components of his vehicle. If you understand the operation of the mechanism, you can easily and quickly identify the breakdown and fix it.

Main components of the unit:

- electric motor,

- anchor,

- brushes,

- overrunning clutch.

Some car models may have differences in structure. This should not be taken as a deviation; this happens often. If you are purchasing a part, you must inform the seller about the model of the part that was previously used. If you select the element incorrectly, difficulties may arise with its operation, and it will quickly fail.

If the starter does not respond to the rotation of the key and is in silent mode, then the check is divided into the following stages:

- The battery charge level is detected.

- The ignition switch contacts are being checked.

- The traction relay is being diagnosed.

- The operation of the part of the starter responsible for torsion of the clutch and the mechanism itself are checked.

Additional fuses for Daewoo Nexia

Nexia owners often equip their car with additional electrical equipment that is not installed as standard. When properly installed and connected, such devices are protected by additional fuses and relays directly in their electrical wiring.

So, for additional lighting devices and DRLs, the fuses are typically located in the engine compartment or under the dashboard. The electrical components of the seat heating system are most often located in the passenger compartment and to access them you need to disassemble the lower part of the center console or remove the tunnel lining in the area of the gearshift lever.

It should be remembered that connecting a large number of additional energy consumers can negatively affect battery charging and the operation of the machine's electrical system.

Sample control procedure

The procedure for conducting inspections of the technical condition of vehicles is enshrined in the road safety instructions; recommendations can also be obtained from the Ministry of Transport.

The control plan includes a list of manipulations, the main ones look like this:

- study of the appearance of equipment;

- checking the body, driver's cabin, signals, lights, brakes, battery;

- control of the main systems: air suspension, steering, clutch, engine;

- checking axle parameters, integrity of hoses, turn signals;

- analysis of wheels, tires, bumpers.

Let us remind you that the driver is present when drawing up the inspection report.

Types and scope of checking the technical condition of a vehicle

Technical control is divided into visual and manual. The technician uses the second option if a specific part or system is suspicious. A diagnostic map using some diagrams - that is, bypassing the official expert opinion. Such “tricks” threaten the company with fines from the traffic police, and also increase the risk of accidents. Let's return to the “white” schemes.

Verification methods

Technical control (pre-shift and post-trip) is divided into a full inspection and monitoring of a specific system. A full inspection, required by orders of the Ministry of Transport, is designed to ensure road safety and control all components of the vehicle. Partial inspection is used when one of the systems breaks down or malfunctions. Let's look at the nuances in each machine system.

Brake systems

Checking the brake system.

Brakes are one of the main parts of the vehicle, responsible for the safety of the driver and others.

When inspecting them, the following problems may be revealed:

- reduced system efficiency;

- jamming, interruptions;

- fluid leak;

- failure of brake lights.

If the above is detected, the car is sent for a detailed examination.

Steering systems

Failures here can be like this:

- control jamming;

- violation of adjustment of parts.

The car is also sent to a repair station.

External lighting devices

When inspecting the headlights, a technician may find:

- contact closure;

- Malfunctions of the rear/front lights.

The vehicle is not allowed on the road until the situation is corrected.

Wheels and pneumatic tires

The fastening and external condition of the “shoes” of the vehicle are checked. If necessary, place the car on a jack and tighten the nuts. Rubber damage, bumps, different tread patterns, and worn tires are unacceptable.

Engine and its systems

The engine is the “heart” of the car. Its operation is checked at full and low speed, as well as at idle. An increased concentration of smoke, its entry into the driver’s cabin, and clutch failure are reasons to send the equipment to the station.

Other structural elements

The mounting of the tractor with the semi-trailer, stable mounting of mirrors, canopies and license plates are subject to detailed inspection.

The mechanic also rules out deep dents, damage to the platform, and cracked headlights. If the inspection reveals the above, the parts that have become unusable are replaced and the fastenings are adjusted.

Verification Tools

For full maintenance in the garage, organizations must have:

- several types of jacks (for each type of equipment);

- pressure gauge for checking wheels and tire pressure;

- hammer with a long handle;

- sets of tools (wrenches, nuts).

In large companies, it is advisable to supply equipment for computer diagnostics.

Documenting results

Documenting the results.

The monitoring results are recorded in the logbook. A sample document can be found in the public domain.

An example of the required graphs is:

- make and model (truck, passenger) of the vehicle;

- state number of the car;

- brief information about the driver;

- inspector data;

- time/date of recording the technical condition;

- odometer data, mileage;

- a note about passing a technical inspection;

- signatures of the inspector and the driver.

Also, the results of the inspection are included in the “travel book”.

Rules for replacing fuses

To replace a blown fuse or a failed relay, you need to de-energize the corresponding circuit of the vehicle's electrical system (turn off the ignition or remove the terminal from the battery), open the mounting block and remove the faulty part from the terminals. For ease of use, some sets of fuses are equipped with special plastic pliers that facilitate dismantling.

You also need to remember a few rules that will help avoid damage to the electrical system of the Daewoo Nexia:

- Do not use fuses with a higher current rating than specified in the instruction manual. This can cause burnout of contact tracks on the printed circuit board of the unit, breakdown of final energy consumers, and even fire of the car.

- It is strictly forbidden to replace fuses with metal jumpers or short-circuit the legs of burnt fuses with wire.

- You should not save on buying fuses, since products of dubious quality from the lower price range often do not correspond to the rating indicated on the case and, therefore, do not perform a protective function.

Preventing fuel pump malfunctions

What should you pay attention to so that the fuel pump runs as long as possible? First of all, this is the quality of the fuel and, of course, timely replacement of the fuel filter. If the gasoline you fill contains various foreign inclusions, this will most likely negatively affect the condition and service life of the fuel pump, and not only it

Therefore, it is not worth saving on the quality of fuel, since such savings then result in very significant expenses for car repairs.

Monitor the fuel level in the tank. The fact is that the fuel pump is cooled by the same gasoline that it pumps. Accordingly, if there is little fuel, or the pump runs idle, it may overheat and therefore fail. Knowledgeable people also advise cleaning the gas tank at the appropriate time and not neglecting this procedure. This is, perhaps, all the prevention of problems with the fuel pump.

Daewoo Nexia › Logbook › Nexia does not turn the starter - SOLVED (ALARM)!

Hi all! I need help identifying the problem, I’ll write what I’ve already done:

I started the car from autostart (alligator s825), drove it, turned it off. I start it with the key, the starter does not turn. I try autostart, the ignition turns on, the starter does not turn. In the cabin, the relay clicks when you try to turn the starter (possibly in the alarm system). No clicks are heard from under the hood. I googled it, checked the battery terminals, everything is fine, reset them, no result. I checked the KG, when you turn the key to the starter, +12 appears on the purple wire. I checked the 30A voltages at the signaling, they are normal. I haven’t checked the lilac wire that controls the starter yet; there should be a + on it when trying to autostart, or just from the key. I couldn't find a fuse on this lilac wire. It may be a coincidence that the problem appeared as soon as it got colder. I tried to close the contacts on the starter, but it didn’t work, or I closed it the wrong way. It’s inconvenient to get there... Tell me what could be wrong, and how to close the starter directly?

PROBLEM SOLVED! I DECIDED TO CLOSED THE CONTACTS ON THE RETRACTER WITH A SCREWDRIVER, AN EXPERIENCED GUY DRIVED UP IN A NEXIA N100, SHOWED WHERE TO LOCK IT, IT STARTED. HE RECOMMENDED LOOKING FOR AN BREAKDOWN TO THE CONTROL WIRE WITH A PULL-IN RELAY. IT IS CONTROLLED BY A SIGNAL. IT TURNS OUT THAT THERE WAS A + OR NOT ON IT (THICK LILAC WIRE FROM THE POWER CONNECTOR OF THE AUTO START CONTROL). WHEN I CLOSED TO THE LILAC WIRE ON KG 30 CONTACT KG, BYPASSING THE SIGNAL, THE STARTER TWISTED. I CHECKED THE 30A SIGNAL CONNECTORS, INTEGRATED. I INSERTED THE PLUG TIGHTER, REPLACED THE WIRES, EVERYTHING BECAME NORMAL. I'M BLAMING EITHER A LOOSE CONTACT IN THE SIGNAL PLUG, OR THE BUILT-IN RELAY IN THE SIGNAL.

MEN! HAPPY FEBRUARY 23!

The best AUTO GIFs - join us) | Topic author: Sergey

Hello everyone, this is the situation, I’m driving a Daewoo Nexia, I came to the store, left for 15 minutes, I came back and started the starter, but it didn’t engage, tell me what’s wrong? how to fight!

Sergey (Gabir) there may be a problem in the contact group of the ignition switch. It’s easy to check: with the ignition on (the switch is in the neutral position), from the positive terminal of the battery, throw a wire to the “positive nut” of the starter (this is where the positive thick wire comes to the starter) and also from the positive terminal of the battery to the male connector of the starter solenoid relay , if the problem is in the contact group, the buzzer will start. This method is called “direct”. If the reason is something else, then the engine should catch at least a little, but I understand that there are no flashes at all.

Sergey (Gabir) it can be even simpler: when on. ignition, throw the wires from the positive nut of the starter onto the male plug of the solenoid relay. This is how it turns on for me too.

Alexey (Nalini) Most likely the fuel pump is dead

Sergey (Gabir) the high pressure fuel pump does not die right away, at first there will be a sluggish reaction to pressing the gas pedal, but it should be enough to start

Alexander (Leta) Somehow my fuel pump died right on the road... the car just stalled and that’s all. Didn't make noise, didn't buzz. In the case described above, it is not clear: does it not start at all, or does it not, and then starts after standing? In the first case - from problems with the fuel line - fuel pump, filters. in the second - maybe the temperature sensor is giving the wrong temperature - the mixture is wrong - - it won’t start

The starter does not turn on the Nexia. Looking for reasons together

When we turn the ignition key to the starting position, we do not hear any reaction from the starter - a fairly common breakdown for Nexia. Moreover, in 80% of cases it is not the starter that is to blame, but first things first. First of all, we check the starter for performance. To do this, take a powerful short screwdriver and begin diagnostics.

- Turn on the ignition, set the gearbox to neutral and tighten the handbrake.

- Open the hood and look for the starter.

We find the starter.

We clean the terminals from dirt. - We see three terminals - one on top and two large ones on the bottom. The upper terminal is responsible for the operation of the solenoid relay, which starts the starter motor.

- To check the retractor relay, we close the upper and positive (large, farthest from the starter housing) terminal, red arrows in the photo. The relay should operate, the gear should engage with the flywheel, and the power contact should start the electric motor. That is, if these two terminals are closed when the ignition is on, the starter should start the engine. If the solenoid relay does not operate, the starter needs repair.

Checking the solenoid relay.

If this does not happen, we close the two lower terminals, green arrows in the photo. The starter motor should start without engaging the flywheel crown. If the electric motor is silent, then we are dealing with a short circuit in the windings or other malfunctions of the rotor or stator of the motor.

Checking the starter motor.

If both tests are passed and the starter basically works, we look for the cause in the circuit before it.

Contact group - the cause of starter failure

But perhaps the most common cause of starter failure is failure of the contact group.

If the starter works by itself, as the first test showed, then with a high degree of probability the fault can be caused by the contact group of the ignition switch. The fact is that when designing the electrical circuit, the engineers did not take into account the high load on the ignition switch contacts. When starting the engine, voltage from the battery is supplied directly to the contact group and when the starter is turned on, a large current passes through the contacts, they heat up and burn out over time.

How to prevent breakage of the contact group

Of course, you can simply replace the contact group with Nexia, but there is no guarantee that the story of contact burnout will not repeat itself. To avoid problems occurring in the future, it is necessary to unload contacts 15 and 30 of the contact group. To do this, it is necessary to install an unloading relay between these contacts. A regular starter relay from a VAZ 2108, connected according to the circuit between pins 15 and 30, is suitable.

New contact group.

Starter relay - 30 A (VAZ-2108) or 50 A (VAZ-2110).

Contact terminals.

Let's understand the connection diagram: you can relieve not only the ignition circuit (pins 30 and 15), but also the starter circuit (pins 30 and 50).

We connect the wires to the terminal block.

We get to the ignition switch by removing the steering column covers.

We assemble an electrical circuit.

Checking the battery

Another reason for a non-working starter is a discharged battery or oxidized contacts at its terminals.

We check the condition of the battery, contact terminals and wires.

If a situation arises when the starter does not turn, check the voltage at the battery terminals and, if necessary, charge it. In addition, it is useful to check the contact density on the positive terminal of the starter itself. The battery terminals are cleaned and lubricated with conductive lubricant, the contact of the positive wire is cleaned and tightened tightly. This way you can avoid problems with starting the engine in the future. Instant launches and sunny roads to everyone!

How do the parts interact with each other?

Turning the key in the ignition switch of a Daewoo car (its transition to position III) will supply voltage from the battery to the traction relay. The armature of the latter will move the drive lever and the clutch gear will engage with the ring gear of the engine flywheel. At the same moment, the traction relay armature will close the power contacts and voltage from the battery will be supplied to the starter motor. After this, the starter rotor will begin to turn the crankshaft of the engine through the placental gearbox.

But how can high starter rotation speed (and, accordingly, its damage) be avoided? Immediately after starting, when the speed of the gear still exceeds that of the starter, the freewheel is unlocked and begins to slip.

In fact, all of the above happens within 10 seconds. And if the temperature is below zero, then it is allowed that the starter will operate for up to 15 seconds.