Finally overcame laziness and decided to write about soldering the radiator! While there was silence in the blog, to my surprise, the number of subscribers exceeded a hundred! This makes me very happy, so it’s worth continuing to write!

I stopped writing while soldering the radiator. Unfortunately, during this time almost nothing has changed. Work, then a session, periodic repairs of the second car, etc. They didn’t let me deal with the Volga.

Now to the point: the experimental necromancy of radiators bore fruit - I learned how to solder radiators quite well, plus I realized that not everything that can be soldered is worth soldering. Let me remind you that after flushing the radiator with citric acid, it began to leak quite a lot, and therefore, I decided to try to solder it myself. I think it will be more interesting and useful if it is not just a story, but some kind of soldering manual. Fortunately, I have accumulated a lot of experience, and on the Internet, I haven’t seen much description of how this is done.

Tools and materials:

The first and necessary thing is a soldering iron, even two - one - “a la hatchet”, for good heating of large areas, the second - thin, for sealing in hard-to-reach places. A gas blowtorch is also an indispensable thing. Pliers for picking out the “mesh” of the radiator. Well, brushes for the drill for cleaning. At first I tried to use alcohol-rosin flux for soldering; I had it left over from when I soldered a guitar pedal in my adolescence. I really liked it then, but it’s completely unsuitable here. In addition to the fact that it solders poorly, it also leaves layers in the solder through which coolant can leak. So I decided to use soldering acid - it works great. And of course, solder. I used more than 300 grams of it. From the factory, the radiator was sealed with POS 40 brand solder. At first, I also tried soldering with it, but it was very tedious, and the radiator quickly cooled down to a temperature that was not enough for this brand, so I switched to POS 61.

Process: First you need to determine where the leak is. In the worst case, we'll just see a huge hole. The next level, easy leakage, when filling the radiator with water. And finally, when there are no large holes left, the radiator is pressure checked. I did it like this:

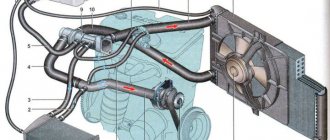

An automobile cooling radiator is designed to lower the temperature of the coolant (antifreeze or antifreeze) circulating inside the engine. Its design usually consists of two tanks and honeycombs located between them, which are a system of thin tubes equipped with thin lamellas. Reducing the refrigerant temperature is achieved through natural or forced air blowing of the cells.

Despite its simple design, the radiator sometimes fails. Its main malfunction is a violation of tightness. In other words, it begins to leak. A coolant leak while the power unit is running threatens the latter with critical breakdowns due to overheating.

Replacing a radiator is not so much a troublesome task as it is an expensive one. And the bill here runs into thousands and even tens of thousands of rubles. In this article we will talk about whether it is possible to solder a cooling radiator with your own hands and what tools you will need for this.

Why does a leak appear?

A leak in the device under consideration can occur only for two reasons: due to mechanical damage and due to corrosion processes occurring inside the tubes. In the first case, it may be the impact of a foreign object on the honeycombs or tanks. This usually happens as a result of traffic accidents, hitting a high curb, hitting a stone, etc. Everything is clear here. A visual inspection will allow you to accurately determine the location of the damage, as well as assess the possibility of repair. Corrosion is a little more complicated. In order not to make a mistake and solder the cooling radiator where needed, you will need to carry out a few simple steps to detect the problem area or even areas. The fact is that corrosion damage can occur in several places at the same time.

Finding a Radiator Leak

If a spot suddenly appears where the car is parked, it means the cooling system has leaked. In order to quickly and easily determine the cause, it is recommended to follow an easy inspection rule.

- Initially, you need to make sure that there is no external damage as such. Before removing the radiator, you need to carefully inspect all pipes and tanks for mechanical damage.

- Perhaps during movement the system touched some protrusion, which caused a crack to form. At this stage it is also worth checking the heat exchanger of the interior heating system.

- Next, if no external signs of failure were found, you need to prepare to dismantle the entire cooling system. To do this, you must first drain all the liquid from the system.

After dismantling the radiator, it must be carefully inspected. Particular attention should be paid to the lighting; it must be good in order to be able to examine the part in detail.

If the hole could not be found, you must first close all the tubes using plugs, thus sealing the radiator. Then place it in clean, clear water. Bubbles that appear in a chain will accurately indicate the location of the leak; this is the easiest way to diagnose.

Looking for a leak

A clear sign that the radiator is leaking is the presence of traces of coolant on the ground under the car, on the engine guard, or on the engine itself. Finding the location of the leak without dismantling the device is almost impossible. But before you remove it, you should make sure that the problem is in it, and not in the pipes or, for example, in the leaky plug of the upper tank. When this is done, you can safely drain the coolant and remove the radiator for diagnostics.

If a visual inspection of the device does not yield any results, check it by immersing it in water. To do this, take a container of a suitable size and fill it with water. Close all pipes with plugs and immerse the radiator in water. Now all that remains is to create air pressure in the device. This can be achieved by simply blowing into the filler neck of the upper tank or by coming up with another option with a compressor (pump). The escaping air bubbles will show you exactly where the damage is.

Copper or aluminum

In order to properly solder a cooling radiator, it is necessary to determine exactly what material it is made of. Most often, cooling devices are made from copper and aluminum. It is not difficult to determine the type of material. Copper honeycombs have a characteristic reddish-brown color, aluminum ones – gray.

If you have determined that you have a copper radiator, you can consider yourself lucky. This metal is easy to solder at home. If you get an aluminum device, then you will have to tinker with it, because this material is difficult to solder.

Radiator design by design type

Modern radiator devices are divided into several categories. Each model has characteristic differences in its structure. These include:

- Aluminum with a tubular-plate base. The design consists of many round tubes that are strung on cooling plates. The tanks in this case are made of thick plastic;

- Aluminum with a tubular-tape base. The main part of the structure consists of many tubes with a flat oval cross-section. Tanks are made of plastic or aluminum alloy;

- Models with copper-brass, tubular-tape base. They differ from other types in that the tanks are made of brass or dense plastic.

Repairing a copper radiator

To solder an engine cooling radiator made of copper, you will need the following tools and tools:

- powerful soldering iron or gas torch;

- solder;

- soldering flux;

- pliers;

- sandpaper.

First, you need to dry the radiator, especially if you checked it by immersing it in water. Next, the damaged area should be thoroughly cleaned with sandpaper. If there are slats on it, they need to be removed locally. After this, the soldering area is treated with flux and dried again.

You can solder the cooling radiator using either a gas torch or a soldering iron. In the first case, solder is applied in place and heated with a torch until it melts and fills the crack. When using a soldering iron as a heating tool, make sure that it has sufficient power.

If the solder does not adhere to the surface or lags behind, it is necessary to repeat the stripping and fluxing process. You can check the repaired radiator using the method described above.

How to seal plastic parts of a car radiator

Let's take a closer look at the adhesive method for repairing a damaged radiator using the example of using two-component industrial glue from Hosch.

To seal the radiator tank, you should prepare the following materials and tools:

- powder welding granulate and liquid component of welding adhesive;

- sandpaper;

- acetone for degreasing surfaces;

- gloves;

- cotton buds.

Stages of work:

- Preparation . Both surfaces to be bonded should be cleaned of grease and other contaminants. If traces of other glue remain on the parts, they must be completely removed. In most cases, regular acetone will do for cleaning;

- Applying glue. A minimal amount of welding adhesive is applied directly to the crack. To fill the void or in the absence of fragments of the body, the powder component of the glue is sprinkled onto the liquid base. If it is necessary to restore a large depression, gluing is recommended to be done in several stages (several layers are applied sequentially with an interval of 10 minutes). After the gap is filled with dry granulate, it must be evenly saturated with the liquid component.

- Seam processing. 10-15 minutes after completion of the work, you can begin mechanical processing of the seam using a grinding machine or fine-grained sandpaper to give the seam an aesthetic appearance.

VIDEO INSTRUCTION

Instructions - how to solder plastic parts of a car cooling radiator

To solder (weld) a plastic radiator, you should prepare the following materials and tools:

- A special construction hair dryer for heating the soldering area;

- Soldering iron with a sharp tip and precise temperature control;

- Solder for plastic - special welding rods. The markings on them must match the markings on the radiator housing. As a rule, this is “PA” - polyamide (nylon) or “PP” - polypropylene. Instead of purchased welding rods, you can use pre-prepared strips cut from a similar plastic tank;

- Acetone.

Work order:

- Degrease the repair area with acetone;

- While the soldering iron is heating up, heat the joint with a hair dryer;

- We connect the seam and gradually run a heated soldering iron along it, forming a groove equal in width to the thickness of the welding rod;

- We apply a welding rod and, heating it with a soldering iron, place it in the groove of the seam;

- We check the radiator for leaks, and then install it on the car.

The welding temperature (heating of the soldering iron) is selected in accordance with the brand of plastic. For PP this is about 250 degrees.

What is the difficulty of soldering aluminum?

Aluminum is a very specific metal. Its peculiarity lies in its high chemical activity, manifested in the formation of a so-called oxide film on the surface. It appears instantly when pure metal comes into contact with air, reacting with oxygen. And it is precisely because of this that it is impossible to solder an aluminum cooling radiator in the usual way. This will require additional substances that contribute to:

- removing oxide film from the surface;

- reducing surface tension;

- protection from adverse factors affecting the soldering process;

- improved solder flow.

What is the danger of a constant coolant leak?

If the cooling radiator is leaking, you need to know what to do or which specialists to contact to fix such a problem. Constant leakage can lead to negative and even dangerous situations:

- engine overheating and further failure;

- changing the configuration of the cooling system and violating the integrity of the material used as a gasket;

- engine jamming, which will entail costly and time-consuming repairs;

- thermal burns that can occur when a crack in the radiator ruptures and hot liquid flows out in a fountain.

Why is a radiator needed and why its leaks are dangerous? Now that we have figured out, it’s time to move on to the main issue - considering ways to eliminate leaks and return the cooling system to tightness.

Materials and tools for soldering aluminum radiators

In order to solder a cooling radiator, the honeycombs of which are made of aluminum, you will need:

- powerful soldering iron;

- solder (tin-lead or tin-bismuth alloy);

- iron filings;

- rosin;

- fireproof container (crucible).

It is desirable that the soldering iron has a power of more than 100 W. Otherwise, it simply will not be able to warm up the aluminum. As for solder, a tin-lead alloy is suitable for sealing small cracks (holes). If the damage is significant, then it is advisable to use solder consisting of 5 parts bismuth and 95 parts tin. Such an alloy can be easily purchased in stores that sell radio components. Usually, it has the form of wire and is marked as POSV-33 or POSV-50.

Preparing gumboil

Soldering a cooling radiator with your own hands is only possible if you have high-quality flux. You will have to prepare it yourself. And it’s better to do this just before you start soldering. So, pour 2 parts of ordinary rosin and 1 part of iron filings into a fireproof container. Sawdust can be made using a file with fine notches, processing any iron workpiece that comes to hand. Heat the resulting mixture over a fire, stir and let cool. That's basically it. Flux for aluminum is ready.

Basic methods for eliminating leaks

Before starting repair work, you should decide on the restoration method. Most often, damage is eliminated using:

- gluing. This method is chosen to eliminate minor cracks. To successfully solve the problem, pay attention to the composition of the glue: the substance must be selected according to the material of which the radiator body is made;

- cold welding. The adhesive mass contains epoxy resin and additives in the form of iron and other compounds. Repairs using cold welding occur efficiently and quickly. Despite the ease of use, a leak can be eliminated in a short time by forming a reliable seam at the crack site.

Flux for the most durable seam

To obtain the most durable protective seam at the site of damage to the radiator, a special flux called flux is used. It can also be obtained at home. To prepare flux, you will need the following substances in the following proportions:

- potassium chloride – 56%;

- lithium chloride – 23%;

- cryolite – 10%;

- coarse table salt – 7%;

- sodium sulfate – 4%.

The ingredients are finely chopped and mixed. This melt must be stored in a hermetically sealed glass container in a dark place.

We repair an aluminum radiator with our own hands

The radiator, as in the previous case, is washed and dried. We thoroughly clean the soldering area with emery cloth and then degrease it. After this, we apply pre-prepared flux to it using a soldering iron. Rub it thoroughly over the surface. Next, we apply solder layer by layer, stretching it over the surface to be repaired. The role of the iron filings is to destroy the oxide film at the very last moment before soldering, thereby allowing the aluminum and solder to bond.

How to solder plastic on a cooling radiator

Most modern car radiators have tanks made of heat-resistant plastic. This material does not react with coolant and does not corrode, but it does not have the elasticity to withstand mechanical damage. That is why some car owners, faced with the problem of a broken tank, are wondering whether it is possible to solder a cooling radiator whose plastic has been damaged. Can! But it is better to entrust this matter to professionals. Heat-resistant plastic is very difficult to solder due to its rigidity. Yes, and choosing the right material for this is quite difficult.

Today you can find hundreds of offers from organizations and individuals who are ready to solder a cooling radiator with high quality. The price for such services ranges from 100 rubles per sq. cm. You will have to pay separately for removal, diagnostics and installation of the device.

If the issue of repairing the tank has become very acute, or you don’t really want to pay, you can try to do it yourself. To do this, the damaged area must be cleaned and formed in such a way that the material that will be applied as a restorer can easily penetrate into the gap. Next, the treated area is degreased.

As for the gluing material, it can be soft plastic or two-component epoxy adhesive. In the first case, the plastic is melted using a soldering iron and applied to the damaged area with a small spatula. The glue is applied in the same way. When performing work on soldering tanks, it is advisable to use a reinforcing mesh with small cells. It is placed between layers of adhesive material. Of course, such soldering cannot guarantee years of trouble-free operation of the radiator, but it is quite suitable as a temporary measure.

Mid-autumn is the last time to tidy up the cooling system before adding fresh antifreeze. Known, by the way, not only for its frost resistance, but also for its ability to seep even through microscopic cracks. And then, as luck would have it, the radiator leaked...

| Brass radiator soldering technology |

| Mid-autumn is the last time to tidy up the cooling system before adding fresh antifreeze. Known, by the way, not only for its frost resistance, but also for its ability to seep even through microscopic cracks. And then, as luck would have it, the radiator leaked... |

Solder - don't glue

At first glance, in the era of superglues, “cold welding” and other almighty chemistry, it seems awkward to take on such an archaic task as soldering. But when repairing radiators, the use of polymer preparations is not always justified. Do not forget about vibrations, temperature changes, differences in the coefficients of thermal expansion of metal and plastic; and if we add here the price factor and strength indicators... For example, in places where the pipes are attached to the tanks, “cold welding” does not always withstand vibration loads that are transmitted from the engine through rubber hoses. The same can be said about the filler neck. And additives that dissolve in antifreeze, under certain conditions, lead to a decrease in the throughput of the radiator. In a word, a soldered connection is no worse than a glued one. The main thing is that your radiator is not aluminum - this metal is soldered using a special technology.

Peculiarities

Traditionally, it was believed that only specialist coppersmiths could solder a radiator, even a brass one. In fact, there is nothing tricky about this, the main thing is to find a soldering iron of the right size and power and master a couple of simple techniques. In addition, the soldering procedure can be repeated over and over again an unlimited number of times until complete success is achieved.

Soldering such a large unit as a radiator has its own characteristics. First, the leak site is usually contaminated with coolant deposits or oxidation products. Secondly, it is necessary to heat a large mass of metal. And finally, body vibrations must be taken into account, so when repairing the most loaded elements (pipes, places where the radiator is attached to the body), for strength, a larger layer of solder should be applied than is usually recommended.

Process

While the soldering iron is cold, its tip must be freed from scale with a file, as it heats up, lubricate the working edge with flux and carefully cover it with a layer of solder, as if rubbing it in. If this is not done, problems will arise with heating the parts and collecting solder on the tip.

The soldering area must be cleaned until shiny with a scalpel or sandpaper. If you are going to solder a hole in a tank or radiator tube, you should clean a 3-4 mm wide strip along its edges, and free the hole itself from dirt. It happens that only by cutting out the adjacent pipe can you get to the leaking one. Subsequently, it must be completely drowned out - the design of the radiator allows it to be deprived of a certain part of the “honeycomb” (up to 20%). When eliminating a crack at the attachment point of the pipe, you need to clear the gap and its edges. In any case, do not forget to drain the coolant from the radiator and leave the neck open.

The main reasons for the loss of radiator tightness, signs, repair features

Loss of tightness of the radiator of the cooling system may be due to the following reasons:

- Natural wear and tear. The approximate lifespan of a radiator is about 10-12 years. As the device wears out, its internal working surface becomes covered with a layer of scale and deposits formed as a result of chemical and thermodynamic processes. The walls of the radiator plates and tubes become thinner. Since the liquid in the device is under pressure, microcracks are possible, as a result of which the liquid begins to leave the system.

Considering that the sizes of microcracks are small, a strong leak is not observed in this case. Wet traces of leakage may disappear after cooling the engine and antifreeze. It is advisable to immediately detect the consequences and place of fluid leakage. The sooner repairs are made in this situation, the less damage will have to be repaired. Can be successfully repaired by cold welding .

- Filling the cooling system with water. Freezing in the cold season. If there is a slight leak of antifreeze, many drivers add limited amounts of water to the system. During the warm season of vehicle operation, the number of such top-ups can be large. As a result, the concentration and characteristics of antifreeze change. In winter, even at slightly below zero temperatures, it can freeze. In this case, volume expansion occurs. The radiator may “break”.

This is what they teach in school

According to plumbing textbooks, soldering is the process of creating a permanent connection of parts using a special alloy (solder). Unlike another popular method - welding, when soldering the metals being joined do not melt, only the solder melts, which wets both parts and fills the gap between them. After cooling and crystallization, the solder, adhering to both surfaces, like glue, securely binds them. Strength depends on the cleanliness of the surfaces and heating (it is important to melt the solder, heat the parts and maintain the required temperature for a certain time). The characteristics of the selected solder and flux, as well as the properties of the materials of the parts being repaired, are important.

Soldering iron is half the success

In most cases, to solder a radiator you need a massive soldering iron with a power of at least 100 W. But a damaged tube can be soldered with a regular 60-watt one. Much depends on how efficiently the soldering iron transfers its temperature to the part. This, in turn, is due to the correct tinning of the tip, the presence of a sufficient amount of solder at the point of contact of the tip with the part, and the angle at which you hold the soldering iron relative to the surface being repaired.

In addition to electric ones, soldering irons heated over an open fire are also used. There is no fundamental difference in their use, except that during the soldering process it is necessary to additionally control the heating and cooling of the working part of the tool.

Classification of cooling systems

There are several types of engine cooling systems:

- air;

- liquid;

- combined.

The air system uses the flow of outside air to operate. Used in motorized vehicles with low power engines.

In a liquid system, a heated engine is cooled with a special coolant. Most modern car engines are equipped with such a cooling system.

The combined system combines the operation of liquid and air systems. Used to operate high-power power plants. Widely used at energy sector enterprises.

Safety precautions

| The electric soldering iron must have intact cord insulation and a working plug. During operation, make sure that the cord does not touch the tool or heated parts. |

| Hold the soldering iron by the handle only. You cannot determine its heating by touch - just hold your hand at some distance from the sting. |

| Vapors from heated solder and fluxes are harmful to health. Work should be carried out in a ventilated area or in the fresh air. |

| Please note that the solder takes a long time to cool down on a heated part, so after removing the soldering iron, do not rush to immediately touch the seam with your hands. |