Signs of a bad ball joint

The suspension transmits all the bumps and potholes of the road, taking the entire blow upon itself - it serves as protection against the constant rocking of passengers and drivers in the cabin, creating conditions for a comfortable trip. Therefore, in order to understand that something is faulty in the suspension, it is not necessary to go to a service center for diagnostics. Separately, the causes of ball malfunction include the following symptoms:

- The rubber on the tires eats up more (you can blame the wrong wheel alignment, but if the car doesn’t drive, it’s most likely the fault of the ball joint);

- When driving over uneven surfaces, unusual sounds are heard, and the car becomes less stable, it “throws” at the slightest bumps - this is how the support fingers slowly “die”;

- When turning, the car does not seem to react to the steering wheel and does not turn immediately; and at speeds above 30 km/h a knocking sound begins in the front suspension;

- It’s as if the car doesn’t “hold” the road, and the steering wheel turns harder and harder, with very unpleasant sounds. It seems that the wheels are starting to play, which indicates the urgency of the repair.

Replacing a ball on a Priora - faults, analogues, standard part

› Transmission

The connecting part of the front suspension that allows the wheels to turn is a ball joint. On a Priora car, this part becomes a consumable item if the driving style is harsh. Replacing a ball joint on a Priora can become almost a regular procedure.

You need to monitor the condition of your car, and even better, treat it with care, because the car struggles with the unevenness of Russian roads every day. The ball joint on the Priora consists of a boot (rubber gasket), a metal cylindrical body, a metal rod (pin), a pressure washer, rolling and a polymer liner.

The price of a ball joint for a Priora car is not high, but removing the part requires experience. Replacement will be easier if you have already done it.

With the introduction of front-wheel drive in Russian cars, ball bearings received a new, more important purpose, because instead of simple levers driving the front wheels into turning movements, complicated mechanisms appeared, and the part received a somewhat greater load. Replacing a ball joint on a Priora is not done so often if it is installed correctly and sudden maneuvers are avoided if possible. As you drive, change it often. Before changing a part, you can check it in 3 steps, read about them below. It is not necessary to install original ball joints - in the article you will find other manufacturers that will fit the Priora.

Standard support - article number and price

Finding/purchasing an original standard support for a Priora is, in a sense, a lottery. The plant does not always assemble them efficiently; this may be due to the poor condition of parts supplied by suppliers or a small amount of lubricant. Before purchasing, visually evaluate the item, and only then make a decision to purchase it.

The article number of the ball joint for Priora is 2108-2904185. A copy produced by VAZ is equally suitable for two generations of Samar, Ten and Prior. The price of a “VAZ” ball for a Priora can start from 250 rubles, but in most cases it is difficult to find it at a price below 450 rubles.

Signs of a bad ball joint

The suspension transmits all the bumps and potholes of the road, taking the entire blow upon itself - it serves as protection against the constant rocking of passengers and drivers in the cabin, creating conditions for a comfortable trip. Therefore, in order to understand that something is faulty in the suspension, it is not necessary to go to a service center for diagnostics. Separately, the causes of ball malfunction include the following symptoms:

- The rubber on the tires eats up more (you can blame the wrong wheel alignment, but if the car doesn’t drive, it’s most likely the fault of the ball joint);

- When driving over uneven surfaces, unusual sounds are heard, and the car becomes less stable, it “throws” at the slightest bumps - this is how the support fingers slowly “die”;

- When turning, the car does not seem to react to the steering wheel and does not turn immediately; and at speeds above 30 km/h a knocking sound begins in the front suspension;

- It’s as if the car doesn’t “hold” the road, and the steering wheel turns harder and harder, with very unpleasant sounds. It seems that the wheels are starting to play, which indicates the urgency of the repair.

Manufacturers and prices of supports

Any spare parts store can immediately offer a large selection of balls from Chinese masters, but don’t rush and don’t look - these parts may be trivial, inaccurately adjusted in size, or even come with a dry boot. Buying an additional part in order to remake it and pour lubricant into the boot is not entirely correct; it is better to turn to decent analogues:

- Teknorot (Türkiye, price - approximately 250 rubles);

- Delphi (USA, price - approximately 370 rubles);

- Lemforder (China; price - approximately 450 rubles);

- Denckermann (Poland, price - approximately 230 rubles);

- TRW (USA, price - approximately 470 rubles).

Diagnostics of the condition of the ball joint - how to check

You can check the ball joint of the Priora without tools; you only need a jack, which is mandatory for all car owners. The simplest way looks like this:

- Jack up the front of the Priora;

- Hands grasp the top and bottom of the wheel;

- Shake the wheel. If the play is noticeable, it means that the spare part has exhausted its service life. The cause of play may be the tip or stabilizer link. Moreover, the ball usually runs out of lubricant, and the boot or pin in the support wears out.

After this, you can get to work and start changing the spare part:

- We jack up the front of the car, put a support on it for safety - you can’t rely only on a jack for any job;

- We unscrew the bolts with a gas wrench and smoothly remove the wheel;

- Inside, lower the two fastening bolts on the ball joint and remove the ball pin nut;

- Use a special puller to press out the finger. Of course, it will work without a puller, but you will have to use force;

- We free the structure from the two mounting bolts of the support. Now you can remove the part with a pry bar;

- Install a new part in place of the old one. Reassemble the suspension.

It is highly advisable to go through the wheel alignment again: this is not necessary, but incorrect installation will force the driver to again encounter symptoms of malfunctions. Even if the part is lubricated and in perfect condition, any inaccuracy during installation will disrupt all wheel alignment settings.

In addition, you should not risk your safety: driving somewhere in a faulty car is not the best idea.

We are in contact: Ask a question - get an answer! Ball joint of a Priora car: tips for checking and replacing Link to main publication

Source: https://priorik.ru/sharovaya-opora-avtomobilya-priora-sovety-proverki-i-zameny/

Detailed manual for replacing ball joints

We will need 17 and 19 mm wrenches, preferably socket wrenches so as not to tear off the nuts, WD40, a ball joint remover, and a hammer. So, jack up the car, put stops under the rear wheels and remove the wheel.

Next, using WD40, we spray the bolts securing the ball joint to the lever and the ball joint nut itself so that there is no difficulty in unscrewing them. Let’s wait a few minutes until they “dissolve” and get to work.

Using a 19mm wrench, unscrew the ball joint nut and a 17mm wrench to unscrew the nuts securing the ball joint to the lever.

Now we need a ball joint remover, it can be of several types, the principle is the same - remove the ball joint from the lever.

We take a new ball joint and, for our own peace of mind, check the grease under the boot. Carefully remove it and check - if there is no grease, fill the boot with Litol or similar grease. Be careful not to damage the boot.

Now install the new ball in the reverse order. You will have to tinker with the installation when screwing the ball to the lever.

We advise you not to install cheap balls of questionable quality, as they will affect the performance of the suspension and handling in general. A good option for ball conveyor BELMAG or TRACK.

Replacing a ball joint on a Renault Logan.

Owners of this brand of car are recommended to replace not only the ball joint, but also the lower suspension arm at the same time (here, I wrote on this topic). This procedure is performed as a result of wear or damage to the unit. To carry out the operation you need:

- Hammer.

- Flathead screwdriver.

- Socket wrench - size 30.

- Dimension key 13.

- Open-end wrenches for 16 and 18.

- Two pipes of different diameters.

- Bar.

Basic steps of the process.

- The car is hung up, or its front part is raised using a jack, and the car is placed on supports.

- The wheel is removed.

- The nuts of the upper and lower bolts, as well as the connecting rod, are removed.

- The nut at the stabilizer bar link is unscrewed, then the bolt is pulled out.

- The ball bolt is removed.

- The finger is pulled out from the rotating mechanism housing.

- The bolts of the silent blocks, both front and rear, are removed.

- The lower suspension arm is removed.

- The old ball joint is removed. To do this, remove the rubber cover and the metal fixing ring from the assembly. At the end, the support is knocked out with a hammer (more details in the video).

- The new ball is installed so that its teeth fit into the grooves of the spline.

Reassemble the mechanism in reverse order.

Replacing ball joints Lada Priora - step-by-step instructions

1. First of all, tighten the handbrake, put wheel chocks under the wheels, jack up the car and remove the wheel. I think everything is clear here, no need to describe it!?

2. Using a “19” wrench, loosen the ball pin nut.

3. Using a ball puller, press the support out of the lever.

4. When the finger comes out of the seat, unscrew the two mounting bolts, which are indicated by a yellow pointer.

Use a pry bar to remove the ball joint.

The support is now released and can be removed.

Take a new Priora ball joint, remove the boot from it, then fill it with lubricant, for example Litol.

Reinstall the boot, then reassemble everything in reverse order.

What is a ball joint?

The ball joint is a vehicle suspension element that provides a rigid and reliable fastening, while maintaining limited mobility of the arms relative to the wheel hub. When you are driving a car, the front wheels have two functions: to ensure that the car moves along the road, and also to provide the ability to maneuver - turning left and right. To maneuver and move correctly, the wheels must be positioned correctly relative to the road, that is, they must be level, freely roll back and forth, freely controlled by the steering wheel, and also firmly attached to the axle. To meet these requirements, a suspension was developed in which ball joints play a very important role. They connect the suspension arms and the steering wheel hub.

Initially, the ball joint was installed only in front-wheel drive cars, thanks to which the wheels could be turned around the vertical. Since the invention of the ball joint some 40 years ago, little has changed in its design.

The ball joint mainly ensures that the wheel remains in a fixed position horizontally while it rotates vertically. The ball joint pin can move in a circle in the body, while it will swing at a small angle. That is, the ball joint performs both rotational and limited movements of the finger in the plane where it is fixed.

Often, all elements of the ball joint are made of steel. In order to reduce friction between surfaces that are in contact, the surface of the spherical recess is coated with plastic or other polymer. But there are also ball joints that are devoid of this polymer coating. Often, such elements are installed in “older” domestic cars. Such models were equipped with collapsible supports; the gaps in them were removed by tightening the lid.

There are two known ways to install ball joints. The first method is to attach it to the lever using bolts. The second way is to press it into it. If a ball joint secured with bolts breaks, then only it can be replaced. If the pressed ball joint fails, then it will be necessary to change the suspension arm itself, in which the pressed ball joint will be in good working order. But the financial expenses in this case will be much greater, since you will have to buy not just a new support, but an entire lever.

Due to its functions, the ball joint experiences significant loads. Most machines rest on a very small surface area of the ball. Considering the total weight of cargo and passengers, poor quality of roads and decent speed, the load on the ball joint increases significantly. For these reasons, the unit wears out and fails. When you buy a new ball joint, it is better to choose a part from the original manufacturer. The market is filled with a large number of brands that produce something similar to the original ball joints, but your choice should fall on products only from trusted manufacturers.

The most common option is the front suspension, which has two ball joints, one per wheel. Most SUVs are equipped with four ball joints in the front suspension, with two of them per wheel. A very rare situation is when there are three balls. Modern cars with independent multi-link rear suspension also have ball joints on the rear wheels.

How to remove a ball joint without a puller?

Removing and replacing the ball joint is a fairly common task, which, although unpleasant, is doable.

It is impossible to change the support on a modern car and on a classic one using the same steps. The reason for this is the different design. Modern cars have more advanced ball joints. Still, if a problem arises, you must first of all understand the question: “Do I need to repair the ball joint or replace it?” In order to give the correct answer, you need to diagnose the chassis; you can do this yourself, but only if someone helps you. First you need to understand what diagnostics are. Method number one is to determine the condition of the support: lift the wheel, grab the bottom and top with both hands, and then try to shake it. This will make it possible to determine whether there is any play. The second method is more reliable. Use a crowbar or pry bar to try to get under the car. Fix it in the center between the lower lever and the edge of the support, then push it up. This way you can see the play. The third method is the most correct and accurate. You need to do the following:

1) Dismantle the ball joint and check it in your hands;

2) Clamp it in a vice, and then check the radial and axial play of the pin. Malfunctions will be indicated by the ability to move the finger without much effort. This is a signal that the ball joint needs to be replaced.

The ball joint wears out faster due to:

1) Lack of lubrication;

2) Gusts in the boot;

3) Excessively long operation;

4) The presence of a defect in one of the parts.

Before you start work, prepare all the necessary tools. You will need:

1) Socket wrenches for “17” and “19”;

2) Mounting;

3) Hammer;

4) Rust remover;

5) Metal brush;

6) Lift and stand for the car;

The process of removing a ball joint without a puller

The likelihood that you will cope with the procedure for removing the support yourself without a puller is extremely high, so get down to business quickly so as not to waste time.

You need to do the following: 1) Using a jack, lift the car and place it on some stationary object.

2) Put the car on the handbrake or place bricks under the wheels to prevent the car from rolling away.

3) Remove the wheel from the side where the broken ball joint is located.

4) In order to have the best access to the junction of the ball and the lever, you need to turn the steering wheel accordingly.

5) Clean the joints using a metal brush.

6) Coat the ball joint pin with anti-rust agent, after which you will have a few minutes to rest while it takes effect.

7) Using a wrench set to “19”, unscrew the pin nut and remove it. Next, you would need a puller, but if you don’t have one, proceed as follows.

Take a pry bar and secure it so that when you press on one end, it presses on the suspension arm. The mount can be installed in the steering knuckle.

Take a pry bar and secure it so that when you press on one end, it presses on the suspension arm. The mount can be installed in the steering knuckle.

9) If there is a lot of rust on the parts, remove it with a product.

10) After the lever is under the required pressure, try to knock it out with a sharp blow of a hammer at the junction of the lever with the ball.

11) After disconnecting the lever and the ball joint, press the lever with a pry bar and move the steering knuckle.

12) Using a key set to “17”, remove the pair of bolts that connect the ball and steering knuckle.

13) The ball joint is free.

How to replace ball joints on a VAZ 2170-VAZ 2172?

Note! We recommend replacing the supports with special equipment. a puller, but it is possible without it, but it is more difficult, in this article we described both methods of removing ball joints from a car and by the way, the supports are very easy to change and even a beginner can handle this, if, of course, he knows the principle, so do not be afraid to replace them and most importantly, tighten all the nuts that secure the support very, very tightly, if it comes loose while driving, the car will immediately crash to the ground, be careful!

1. First of all, hang one of the front wheels of the car, then put the car on wheels, or on boards; we categorically do not recommend leaving it on a jack; take a metal brush or sandpaper, clean all the nuts, all the threads, the ball joint, then Apply a penetrating lubricant (Type WD-40) to the threads or regular oil so that the nut is easier to twist and start turning it out (Indicated by a red arrow), if you have a puller, then unscrew it to the end, then adjust it and press the hinge pin out lever into which it fits, if there is no puller, then twist the nut to the same state as shown in the small photo below, then take a hammer and some kind of lever (the lever can be a crowbar, or a handle from a shovel, etc.), press it out the ball joint finger from the lever into which it enters, when pressing it out, insert the crowbar between the levers (Again, see the small photo) and hit the place indicated by the green arrow with a hammer, swing the crowbar at this moment when you strike and when the finger comes out of the lever and rests against the nut, stop, unscrew the nut completely and by hand remove the finger from the hole in the lever into which it fits, then unscrew the two bolts that secure the ball joint (They are indicated by blue arrows) and immediately then remove it from the car.

2. Installation of a new support begins with its assembly, many already know that the support comes in a disassembled state and that there is no lubricant in it, or there is some, but there is very, very little of it (Basically, new supports are sold that way), so the first thing is you will need to see if there is lubricant in the support, if it is missing then you will need to add it, it is placed in the boot (see photo 2), this is called grease lubrication (it got its name because it is not fluid), after which the boot is installed in its place (Before installation, place the spacer sleeve and lubricate the surface where the boot will rest with sealant so that the lubricant is not squeezed out, see photos 1 and 3 below) and the ball joint must also be installed in its place.

3. To install the support, first attach it to the surface at the top and secure it with two bolts, then insert the ball joint pin into the lever and secure it from below, if it is convenient for you to do the opposite, that is, first insert the finger into the lever and then tighten the ball joint bolts, then do it this way, it doesn’t play a special role and the most important thing is to tighten all the bolts very, very tightly (After 100 km, tighten them again in the same way), due to the ball joint the wheel stays level and if something comes loose, then as we have already said, the car will simply fall to the ground, here is a clear example of the fact that the ball joint could not withstand the loads (it was defective or was already very worn out) and the car simply fell to the ground.

Additional video: See an example of replacing a ball joint on a front-wheel drive vehicle in the video below:

Diagnostics, removal and replacement of the Lada Priora ball joint

The service life of ball joints on a Lada Priora depends on the operating conditions of the vehicle, and on the quality of the part itself, that is, the ball joint. They can cover several thousand km and 30-40 thousand. Factory installed parts last quite a long time. For example, the average service life of factory ball joints is 50-70 thousand kilometers. In this article we will take a detailed look at the issue of not only replacing ball joints, but also tell you which ones are better to buy and how to check them.

How to check a ball joint on a Priora

So, to make sure that the support needs to be replaced, it needs to be checked in several simple ways. Jack up the wheel and, placing your hands on the top and bottom points of the wheel, try to shake it. If you feel play, the ball joint may be faulty. Also, the cause of play may be the tips or stabilizer struts.

Another way to check is to drive into an inspection hole or overpass and use a mount or pry bar to check the ball play. Place the pry bar between the ball and the lever and try to shake it. A faulty ball will play easily, which indicates either high wear or lack of lubrication.

Carefully inspect the support, its boot should be intact, and it itself should be without chips or signs of deformation.

Signs of a bad ball joint

- When driving over small potholes and bumps, a distinct knocking sound is heard in the suspension.

- When turning, you may hear a grinding or squeaking sound, and the steering wheel may also be harder to turn.

- The car holds the road poorly, the wheels seem to blur on the asphalt.

- If you notice that there is “rubber”, one of the reasons may be the failure of the ball joints.

In order to accurately verify the malfunction of the ball joints, you must contact either specialists or independently, according to the instructions indicated above, carry out inspection and diagnostics. If during a visual inspection you find that the boot on the ball joint is torn, this basis is sufficient to replace it. Because dust and dirt get on the ball pin, mix with the lubricant and it fails.

Which ball joint to choose for Lada Priora

Today, a fairly large selection of balls is offered, from Chinese to conveyor and even reinforced ones. The choice is up to the buyer.

- BZAK BA08-2904192-01 from 250 rub. piece

- TRACK BJ70-107, 2108-2904192 from 300 RUR

- LADA IMAGE 2110-2904192-82 from 400 RUR

- AMT-Miass AM08-2904192 from 220 rub.

- BELMAG BM10-2904192-01 reinforced with fastening (conveyor) from 500 rub.

- VAZINTERSERVICE /OAT/ VIS08-2904185-10 sunset - from 350 rub.

- ASOMI, Tolyatti A110.2904.193 Comfort PRO from 500 rub.

The most expensive conveyor ball joints are from the BELMAG company; also in terms of price, the ball joints from ASOMI, which also produces front and rear struts, as well as support bearings, stand out.

Detailed manual for replacing ball joints

We will need 17 and 19 mm wrenches, preferably socket wrenches so as not to tear off the nuts, WD40, a ball joint remover, and a hammer.

So, jack up the car, put stops under the rear wheels and remove the wheel.

Next, using WD40, we spray the bolts securing the ball joint to the lever and the ball joint nut itself so that there is no difficulty in unscrewing them. Let’s wait a few minutes until they “dissolve” and get to work.

Using a 19mm wrench, unscrew the ball joint nut and a 17mm wrench to unscrew the nuts securing the ball joint to the lever.

Now we need a ball joint remover, it can be of several types, the principle is the same - remove the ball joint from the lever.

We take a new ball joint and, for our own peace of mind, check the grease under the boot. Carefully remove it and check - if there is no grease, fill the boot with Litol or similar grease. Be careful not to damage the boot.

Now install the new ball in the reverse order. You will have to tinker with the installation when screwing the ball to the lever.

We advise you not to install cheap balls of questionable quality, as they will affect the performance of the suspension and handling in general. A good option for ball conveyor BELMAG or TRACK.

Video on replacing a ball joint

Welcome! Ball joint - used exclusively in the front suspension, it consists of: A ball pin, a boot, and there is still grease packed inside it, but when buying cheap bearings, the price is not even the point, even if you take the expensive ones (the sellers themselves determine the price for them install, and whether to buy or not is your choice), then they may not really have any lubricant in them, so we recommend that before installation you always check how much lubricant is in the new ball joint and, if necessary, add lubricant (What kind of lubricant you will add, decide for yourself , use the Internet for this, where a lot of articles have already been written on this subject), so that there is not too much and not too little, and in this case, the ball joint will live a long life in the car suspension.

Note! To replace the ball joint on a Front Drive vehicle, stock up on: Special. puller and ring wrenches, as well as wrenches, we advise you to take long wrenches, because the ball joint nuts turn sour over time and you can only unscrew them with the help of large wrenches, since the hand force applied in this case will be less!

- Replacing the ball joint

- Additional video clip

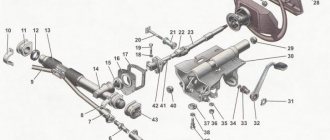

Where are the ball joints located? At the beginning of the article, we already mentioned that ball joints are used in the front suspension, but we kept silent about the number, in general there are only two ball joints, only on the classics there are 4 of them installed, two on one side and two on the other, with PP at all everything is different, because the suspension is made in a different way, for clarity, see the location of the ball joints in the photo below (Pay attention to the blue arrows, the photo shows a VAZ 2109):

When do you need to change ball joints? If there is increased play (the fingers of the supports in this case, you can even wobble with your hand, a clear example is shown in the video below), the supports must be replaced, and also if the boot of the support is torn, but if dirt has not yet managed to get inside, then everything can be fixed, hang up the wheel , unscrew the nut securing the support pin, press out the support using a special tool. puller and then remove the torn boot, find a new boot in the auto shop, buy it and install it on the support, don’t forget to fill it with lubricant and by the way, remove the old lubricant because it will be all covered in dirt, after the operation, put everything back and see the result, with the ball joints in good working order, the steering wheel should begin to rotate more easily (this will be noticeable), and there should absolutely be no knocking when hitting a bump (by the way, the shock absorbers can also knock if they leak), and the most important thing is probably this stability of the car when driving at high speed, if your ball joints are all already dead, then at high speed the car will throw, especially when you drive over bumps or over waves (the road is not level), but in the case of serviceable bearings, this is much It will be felt less.

Replacing a ball joint on a Lada Priora

Checking and replacing the ball joint of the Lada Priora

Before changing the ball joint on a Priora, you should worry about safety: apply the handbrake, securing the rear of the car and preventing a rollback. Additionally, you can put anti-roll bars or bricks. Before installing a new spare part, check it - if the boot is at least half empty, it needs to be filled with lubricant, otherwise the life of the part will be significantly reduced. For these purposes, lubricants for CV joints, graphite lubricants or lithol are suitable.

After this, you can get to work and start changing the spare part:

- We jack up the front of the car, put a support on it for safety - you can’t rely only on a jack for any job;

- We unscrew the bolts with a gas wrench and smoothly remove the wheel;

- Inside, lower the two fastening bolts on the ball joint and remove the ball pin nut;

- Use a special puller to press out the finger. Of course, it will work without a puller, but you will have to use force;

- We free the structure from the two mounting bolts of the support. Now you can remove the part with a pry bar;

- Install a new part in place of the old one. Reassemble the suspension.

It is highly advisable to go through the wheel alignment again: this is not necessary, but incorrect installation will force the driver to again encounter symptoms of malfunctions. Even if the part is lubricated and in perfect condition, any inaccuracy during installation will disrupt all wheel alignment settings. In addition, you should not risk your safety: driving somewhere in a faulty car is not the best idea.

Do-it-yourself replacement of ball joints on a Priora

The first step is to lift the front of the car with a jack, having first removed the wheel bolts. Then we finally unscrew the bolts and remove the wheel.

Apply penetrating lubricant to all threaded connections. After a few minutes you can start working.

Using a 19mm wrench, unscrew the lower nut securing the pin, as is clearly shown in the photo below.

Then, using a special puller, press the pin out of the front suspension arm. We position the puller as shown below.

Now, using the puller bolt, we perform this procedure. When the pin is freed, you can unscrew the two bolts securing the ball to the steering knuckle.

If the ball is clamped, which happens quite often, then you will have to compress the rack a little, thereby relieving the lever with the support. This can be done using a jack and a brick or other support. It will look like this: we place a brick under the brake disc and lower the car slightly. The front suspension spring compresses slightly, and the pressure on the lever decreases.

Remove the ball from the lever:

Before installing a new support, you need to lift its boot and generously lubricate everything inside with lithol or other special lubricant.

We put it in place and replace the ball. We install everything in reverse order.

If you have difficulty connecting the finger to the lever, you will have to work a little with a pry bar, and also “play” with the suspension using the same jack and brick. After everything is done, we finally tighten all the bolts and fastening nut to the required torque, using a torque wrench for this.

Symptoms: knocking noises in the front suspension.

Possible cause: damaged ball joint.

Tools: jack, wheel chocks, body supports, socket set, wrench set, ball joint remover.

1. Brake the vehicle with the parking brake, then install wheel chocks under the rear wheels.

2. Raise the front of the vehicle and place it on supports.

How to replace a Lada Priora?

In this case, the role of a puller can be performed by a hammer and a reinforcement rod. To remove a worn or broken ball joint, you will need:

- The car is raised using a jack.

- The front wheel is removed.

- The two ball mounting bolts are unscrewed and the fastening nut is unscrewed (wrench 17 and 19).

- The reinforcing rod is inserted between the lever and the support body, and then pulled down.

- The pin must be hit from bottom to top in different directions so that the cone of the ball pin pops out of the lever.

- Once the cone is out, the support turns away from the steering knuckle.

- To prevent the ball from being pressed against the fist by means of a lever, the hub is supported, or the wheel is placed and the jack is lowered.

- Next, the ball joint, which is attached to the lever and knuckle, is replaced.

Video instruction.

Replacing a ball joint on a VAZ 2109 car.

This process is carried out not only when the ball joint is worn out, but also when there is a breakthrough in the boot. This cannot be ignored, as it poses a danger to passengers and the driver.

It is most advisable to use a lift or inspection hole for work. If you don't have one, you can use a jack. What you need to do:

Remove the wheel on which the diagnostics revealed problems with the wheel brake. All structural parts are cleaned of dirt. Plus, the fastening elements are treated with a special rust removing compound. This will make installation and dismantling easier. Using a 19mm wrench, unscrew the nut that secures the ball joint to the suspension arm. Using a hammer and a pry bar, the SHO pin is pressed out of the suspension arm. To do this, the nut is not completely unscrewed, but several strong targeted blows are applied to the lever. Using a pry bar, the suspension arm is moved down to free the SHO pin from the lever. The bolts connecting the ball joint and the steering knuckle are removed using a 17mm wrench. The damaged ball joint is removed. The condition of not only the support, but also the boot is checked. Sometimes replacing the latter may be enough to fix problems

If obvious damage is detected, the ball joint is removed, a new one is installed, and the unit is put back together. It is necessary to pay attention to the condition of the finger. It should contain a spacer sleeve

If it is missing, it should be returned to its place, otherwise the updated SHO will not work correctly. The rubber boot is lubricated with grease before the reassembly process. Plus, grease will need to be applied to the installation site of the boot in the ball joint.

https://youtube.com/watch?v=QSB88vJE3zs

Article number and price for the original ball joint

The original ball joint of the Lada Priora car has article number 21082904185. The price for the product varies from 150 to 420 rubles. The quality of auto parts varies from batch to batch.

Ball joint for Priora

When purchasing an original product, special attention should be paid to the presence of lubricant under the boot. In some cases it is completely absent. Such a ball can last no more than a couple of thousand kilometers.

Article number and cost of ball joint analogues

There is a constant debate among car owners about which ball joints are best to install. Some drivers believe that original parts are optimal in terms of price to reliability ratio. Other owners claim that the instability of the quality of their original balls completely eliminates the possibility of purchasing them. They advise buying analogues from third-party manufacturers, especially since the cost of non-original components is quite attractive. According to driver reviews, below is a list of pole brands that they recommend as an alternative to the original.

Table - Good analogues of the Lada Priora ball joint.

| Manufacturer | vendor code | Approximate cost, ruble |

| Delphi | TC583 | 340-400 |

| Denckermann | D110112 | 210-250 |

| Teknorot | L303 | 230-280 |

| Lemforder | 1545602 | 420-500 |

| TRW | JBJ156 | 445-490 |

Diagnostics of the ball joint condition

Signs that you need to diagnose a ball joint malfunction are:

- the intersection of small holes and bumps is accompanied by distinct extraneous sounds from the front suspension;

- decrease in vehicle controllability when entering a turn;

- turning the steering wheel becomes more difficult and is accompanied by a creaking or grinding sound;

- it feels like the wheels are blurring on the asphalt, which is why the car doesn’t hold the road well;

- driving over uneven road surfaces is accompanied by poor vehicle stability;

- on the tires it is clearly noticeable that the rubber is being “eaten up”;

- cornering at speeds over 30 km/h is accompanied by a knocking sound coming from the wheel arches.

One way to monitor the condition of the ball joint is as follows:

- Jack up the front of the Priora.

- Hold the wheel firmly with your hands at the top and bottom points.

- Shake the wheel rim. If play is noticeable, the ball joint most likely needs to be replaced. It should be borne in mind that the cause of play can also be stabilizer struts or steering ends.

Checking the condition of the ball joint by shaking the wheel

Another method of control can be used if there is an inspection hole, overpass or lift. It is necessary to gain access to the bottom of the Priora. Using a pry bar or other metal rod, you need to check the play in the ball. To do this, insert the assembly between the support and the lever, and then shake it. If the ball is faulty, an easily noticeable play will be observed, which indicates the need to replace it.

During diagnosis, it is important to visually inspect the condition of the anther. The performance of the ball directly depends on the lubrication. If there are cracks, tears or other mechanical damage to the cuff, moisture and abrasive debris get under it. If an unsatisfactory condition of the boot is detected, replacement of the support is mandatory.

If it is impossible to determine the malfunction of the ball or if you have doubts about its failure, it is recommended to contact a service station, where technicians using special equipment will check the condition of the support. For example, diagnostics on a vibration stand allows you to find a defective unit with 99% confidence.

Replacing the ball joint race for a VAZ 2110 gearbox

To work, you need to have a new clip, a set of keys, several screwdrivers, thick lubricant and about half an hour of time.

- First of all, we climb under the car and unscrew the torque rod from the ball joint. To do this, unscrew the four fastening points (two bolts and two nuts with a “13” wrench). Here you have to get a little used to it because the exhaust gets in the way. If the bolts are rusty or won't budge, use WD-40 penetrating fluid.

- Next, we remove the lever itself in the cabin. To do this, take a flat screwdriver and pry off the decorative cover.

- Once you have access to the fasteners, you can begin dismantling the lever itself. We unscrew the screw with a Phillips screwdriver, preferably an “L-shaped” one, which can easily fit into the limited space of the tunnel. Then take the key and unscrew the nut securing the lever.

- Now, using a flat-head screwdriver, remove the retaining ring of the gearbox ball joint cage, after which you can try to pull out the shift lever, as well as the “butterfly” itself.

- Next, we take a new “butterfly”, remove the retaining ring from it and take out the plastic bushing. We take lubricant such as “Litol”, “Solidol”, etc. and generously lubricate the friction points. We put the bushing on the lever, then install it all in the holder and secure everything with a locking ring.

Required tools and materials for replacement

To replace ball joints on a Priora with your own hands, you will need the tools from the list below.

Table - Tools and materials required to replace the ball joint.

| Name | Note |

| Jack | To lift the car |

| Mount | Can be replaced with a durable rod |

| Hammer | Medium size |

| Spanners | “at 17”, “at 19” |

| Socket head | TORX E12 |

| Vorotok | Preferably with a ratchet |

| Balloon wrench | For mounting and removing the wheel |

| Grease | Special for CV joints or graphite |

| Penetrating lubricant | For example, WD-40 |

| Rags and wire brush | To clean dirt |

| prop | It is prohibited to carry out repair work on a vehicle that is only supported by a jack. |

A set of tools needed to replace the ball joint

Replacing the ball joint of Lada Priora (VAZ Priora)

One of the reasons for the appearance of extraneous sounds (knocks) from the front suspension of the Priora is wear of the ball joints. This usually happens closer to 100,000 km on normal roads and quiet driving. But cases cannot be ruled out when the ball joints have to be changed every 15-20 thousand km, in the conditions of Russian roads.

To replace the supports yourself, you will need the following tool:

- Ball or end cap remover

- Hammer

- Mount

- Keys for 17 and 19 or heads

- Driver and ratchet

- TORX E12 head (on later versions)

- Penetrating lubricant

Do-it-yourself replacement of ball joints on a Priora

The first step is to lift the front of the car with a jack, having first removed the wheel bolts. Then we finally unscrew the bolts and remove the wheel.

Apply penetrating lubricant to all threaded connections. After a few minutes you can start working.

Using a 19mm wrench, unscrew the lower nut securing the pin, as is clearly shown in the photo below.

Then, using a special puller, press the pin out of the front suspension arm. We position the puller as shown below.

Now, using the puller bolt, we perform this procedure. When the pin is freed, you can unscrew the two bolts securing the ball to the steering knuckle.

If the ball is clamped, which happens quite often, then you will have to compress the rack a little, thereby relieving the lever with the support. This can be done using a jack and a brick or other support. It will look like this: we place a brick under the brake disc and lower the car slightly. The front suspension spring compresses slightly, and the pressure on the lever decreases.

Remove the ball from the lever:

Before installing a new support, you need to lift its boot and generously lubricate everything inside with lithol or other special lubricant.

We put it in place and replace the ball. We install everything in reverse order.

If you have difficulty connecting the finger to the lever, you will have to work a little with a pry bar, and also “play” with the suspension using the same jack and brick. After everything is done, we finally tighten all the bolts and fastening nut to the required torque, using a torque wrench for this.

Symptoms: knocking noises in the front suspension.

Possible cause: damaged ball joint.

Tools: jack, wheel chocks, body supports, socket set, wrench set, ball joint remover.

1. Brake the vehicle with the parking brake, then install wheel chocks under the rear wheels.

2. Raise the front of the vehicle and place it on supports.

3. Remove the front wheel.

Note. Wheel nuts should only be unscrewed with the vehicle on the ground. The tightening torque of the bolts is 65–95 Nm.

4. Unscrew the ball joint mounting nut.

5. Remove the ball joint pin from the lever by pressing it out using a special puller. If you do not have a puller, you can press out the finger as follows:

- do not completely unscrew the nut;

- press the lever using the mounting spatula;

— press the hinge pin out of the lever by striking with a hammer along the axis of the lever.

6. Unscrew and remove the two ball joint mounting bolts to the steering knuckle.

7. Press the lever down using a pry bar and then remove the ball joint.

8. Clamp the hinge in a vice.

9. Rock the finger in the support and check for play.

10. Replace the ball joint if the pin moves even with slight force.

11. If the mudguard is torn, clean the joint and pin of grease, and then lubricate them with fresh grease. If contamination is found in the hinge itself, it should be replaced.

12. Install the spacer sleeve (it is installed until it stops).

13. Fill the new dirt boot halfway with grease.

14. Install a new front suspension ball joint in the reverse order of removal.

15. Before installing the mud boot, apply a sealant to the surface of the front suspension ball joint.

Note. Install the mudguard with extreme care to avoid damaging it.

16. Lower the car to the ground, then rock it vigorously several times.

17. Tighten the fastening nut of the ball joint to the lever with a torque of 80–96 Nm.

18. Tighten the nut securing the ball joint and steering knuckle to a torque of 50–63 Nm.

19. After a hundred-kilometer run, re-tighten these threaded connections to the above torques.

Replacing a ball joint on a Lada Priora

Replacing the ball joint on a Lada Priora car with your own hands is carried out according to the step-by-step algorithm presented below.

- Secure the vehicle with the parking brake.

- Place wheel chocks under the rear wheels.

- Jack up the vehicle on the side from which repair work is planned.

- Remove the wheel.

Jacked Priora with a removed wheel

- Loosen the two ball joint mounting bolts.

Location of fasteners

- Unscrew the ball stud nut.

Unscrewing the ball pin nut

- Press the support out of the lever. This operation can be performed without a puller, but having one will greatly simplify the procedure.

Pressing the ball out of the lever using a puller

- Unscrew the two support mounting bolts.

- Using a pry bar, remove the ball.

Dismantling process

Removed old ball

- Install the new support into the seat. It is recommended to fill the boot with grease first.

Installation of a new ball joint

- Reassemble everything in the reverse order of removal.

- Checking the toe and camber angles on a stand is not a mandatory procedure when replacing ball joints, but experienced car owners still recommend checking them.

How to replace ball joints on a Lada Priora

It is quite possible to replace ball joints on a Lada Priora with your own hands. Our guide allows you to replace ball joints yourself, in a garage.

We will need:

spanners “17”, “19”, ball joint remover.

Replacing ball joints on a Lada Priora with your own hands

1. Raise and place the front part of the car on supports. Remove the wheel.

Attention.

Brake the car with the parking brake and install wheel chocks (“chocks”) under the rear wheels.

Note that on our website there is already a publication about replacing the ball joint on a Lada Kalina with your own hands.

Recommendation.

Loosen and tighten wheel bolts only with the vehicle on the ground. The tightening torque of the bolts is 65–95 N m (6.5–9.5 kgf m).

2. Unscrew the nut securing the ball joint.

3. Press the ball joint pin out of the lever using a special puller.

Note.

This is what a universal puller for the ball joint of the suspension arm and tie rod ends looks like.

4. If there is no puller, do not unscrew the nut completely. Press the lever with a mounting spatula and press the hinge pin out of the lever with hammer blows along the axis of the lever. After this, finally unscrew the nut.

5. Remove the two bolts securing the ball joint to the steering knuckle.

6. Press down the lever with a mounting blade and remove the ball joint.

7. Rock the ball pin in the support, holding the joint in a vice. The finger should not move due to hand effort (a play of no more than 0.7 mm is allowed).

8. If the pin moves in the support with a slight force, replace the ball joint.

9. If the protective cover is torn, remove the top dirty layer of lubricant (if it is noticeable that dirt has gotten inside the hinge, it will have to be replaced) and apply new grease.

10. Install the spacer until it stops.

11. Place half the volume of grease in the new protective boot.

12. Install the ball joint in the reverse order of removal. Before installing the dirt cover, apply sealant to the surface of the support.

Attention.

When installing, be careful not to damage the ball joint protective boot. Be sure to replace the damaged cover.

13. Lower the vehicle to the ground and rock it vigorously several times. Tighten the nut securing the ball joint to the lever with a torque of 80–96 Nm (8.0–9.6 kgf m), the nut securing the ball joint to the steering knuckle with a torque of 50–63 Nm (5.0–6.3 kgf m). After driving 100 km, tighten these threaded connections again to the required torque.

Now you know how to replace ball joints on a Lada Priora with your own hands. Let us remind you that the previous article on our website was about replacing gearbox seals on a Lada Priora.

Additional recommendations for replacing the ball joint

When purchasing original ball joints, it is extremely important to control the amount of lubricant in them. Many car owners complain that the boot is completely empty. The quantity and quality of lubricant directly affects the service life of the unit and its performance characteristics.

Completely dry original ball joint

Filling the boot with lubricant

If an insufficient amount of lubricant or its absence is detected, it is necessary to fill the boot completely. Special means for CV joints are optimally suited for these purposes. In extreme cases, you can use Litol 24 or graphite lubricants. If there is a small amount of substance under the cuff, it is recommended to dispose of it first to prevent mixing.

Replacing a ball joint on a Priora - VAZ

The service life of the Lada Priora ball joint directly depends on the operating conditions of the machine, correct installation, the presence of a sufficient amount of lubricant and the quality of the part itself.

The unit is one of the weak points of the suspension, so most car owners have to replace it.

It is not difficult to install a new product yourself, but this event has its own subtleties.

Checking and replacing the ball joint Lada Priora

The service life of ball joints on a Lada Priora depends on the operating conditions of the vehicle, and on the quality of the part itself, that is, the ball joint. They can cover several thousand km and 30-40 thousand.

Factory installed parts last a long time. For example, the average service life of factory ball joints is 50-70 thousand kilometers.

In this article we will take a detailed look at the issue of not only replacing ball joints, but also tell you which ones are better to buy and how to check them.

How to check a ball joint on a Priora

So, to make sure that the support needs to be replaced, it needs to be checked in several simple ways. Jack up the wheel and, placing your hands on the top and bottom points of the wheel, try to shake it. If you feel play, the ball joint may be faulty. Also, the cause of play may be the tips or stabilizer struts.

How to check a ball joint on a Priora

So, to make sure that the support needs to be replaced, it needs to be checked in several simple ways. Jack up the wheel and, placing your hands on the top and bottom points of the wheel, try to shake it. If you feel play, the ball joint may be faulty. Also, the cause of play may be the tips or stabilizer struts.

Another way to check is to drive into an inspection hole or overpass and use a mount or pry bar to check the ball play. Place the pry bar between the ball and the lever and try to shake it. A faulty ball will play easily, which indicates either high wear or lack of lubrication.

Carefully inspect the support, its boot should be intact, and it itself should be without chips or signs of deformation.

Removing and disassembling the gearbox control drive

We disassemble the drive to replace the bushings of the gear lever shaft and the lever ball joint. We change the plastic bushings of the lever axis if there is a large play in the connection of the lever with the drive rod. We replace the parts of the ball joint if they are worn out or broken. We change the control rod when it deforms. Remove the floor tunnel lining (see “Removing the floor tunnel lining”). If it is necessary to replace the plastic lining of the reverse gear lock bracket, which can be worn by the mating part during long-term use...

Signs of a bad ball joint

- When driving over small potholes and bumps, a distinct knocking sound is heard in the suspension.

- When turning, you may hear a grinding or squeaking sound, and the steering wheel may also be harder to turn.

- The car holds the road poorly, the wheels seem to blur on the asphalt.

- If you notice that there is “rubber”, one of the reasons may be the failure of the ball joints.

In order to accurately verify the malfunction of the ball joints, you must contact either specialists or independently, according to the instructions indicated above, carry out inspection and diagnostics. If during a visual inspection you find that the boot on the ball joint is torn, this basis is sufficient to replace it. Because dust and dirt get on the ball pin, mix with the lubricant and it fails.

Is it possible to restore the support?

This element has 2 types of faults. Most often you may encounter the depletion of lubricant in the housing. With this development of events, restoring the ball joint to working condition is easy. Using a special syringe, the amount of lubricant in the housing is updated. Experienced craftsmen prefer graphite lubricant, but you can use another type of it, preferably with similar values. I advise you to read the article - how to lubricate a ball lubricant.

If the performance of the ball was restored using the above method, it is worth considering that it will not be possible to extend it for a long time. In cases where there is a high degree of wear, adding lubricant will not change the situation. A replacement part will be required.

The condition of most domestic roads means that car suspensions cannot last for a long time, as a result of which regular and frequent replacement of its elements is required. As for the ball joint, removing it without a puller is not a big problem. This process requires a minimal set of auxiliary tools. At the same time, the absence of a professional tool will not have a negative impact on the parts of the mechanism.

Which ball joint to choose for Lada Priora

Today, a fairly large selection of balls is offered, from Chinese to conveyor and even reinforced ones. The choice is up to the buyer.

- BZAK BA08-2904192-01 from 250 rub. piece

- TRACK BJ70-107, 2108-2904192 from 300 RUR

- LADA IMAGE 2110-2904192-82 from 400 RUR

- AMT-Miass AM08-2904192 from 220 rub.

- BELMAG BM10-2904192-01 reinforced with fastening (conveyor) from 500 rub.

- VAZINTERSERVICE /OAT/ VIS08-2904185-10 sunset – from 350 rub.

- ASOMI, Tolyatti A110.2904.193 Comfort PRO from 500 rub.

The most expensive conveyor ball joints are from the BELMAG company; also in terms of price, the ball joints from ASOMI, which also produces front and rear struts, as well as support bearings, stand out.

Detailed manual for replacing ball joints

We will need 17 and 19 mm wrenches, preferably socket wrenches so as not to tear off the nuts, WD40, a ball joint remover, and a hammer.

So, jack up the car, put stops under the rear wheels and remove the wheel.

Next, using WD40, we spray the bolts securing the ball joint to the lever and the ball joint nut itself so that there is no difficulty in unscrewing them. Let’s wait a few minutes until they “dissolve” and get to work.

Using a 19mm wrench, unscrew the ball joint nut and a 17mm wrench to unscrew the nuts securing the ball joint to the lever.

Now we need a ball joint remover, it can be of several types, the principle is the same - remove the ball joint from the lever.

We take a new ball joint and, for our own peace of mind, check the grease under the boot. Carefully remove it and check - if there is no grease, fill the boot with Litol or similar grease. Be careful not to damage the boot.

Now install the new ball in the reverse order. You will have to tinker with the installation when screwing the ball to the lever.

We advise you not to install cheap balls of questionable quality, as they will affect the performance of the suspension and handling in general. A good option for ball conveyor BELMAG or TRACK.

Algorithm for replacing ball joints on Lada Priora cars

- Tighten the handbrake, support the wheels with wheel chocks, jack up the car, and remove the wheel.

- Using a "19" wrench, unscrew the ball stud nut.

- Use a ball joint remover to remove the support from the lever.

Question answer

Is it possible to restore the support?

If the performance of the ball was restored using the above method, it is worth considering that it will not be possible to extend it for a long time. In cases where there is a high degree of wear, adding lubricant will not change the situation. A replacement part will be required.

The condition of most domestic roads means that car suspensions cannot last for a long time, as a result of which regular and frequent replacement of its elements is required. As for the ball joint, removing it without a puller is not a big problem. This process requires a minimal set of auxiliary tools. At the same time, the absence of a professional tool will not have a negative impact on the parts of the mechanism.

How to check a ball joint?

The ball is very easy to check. It is enough to get to the part and check it for play. At the slightest play it should be replaced. You can even try to shake the ball with your hand, and then everything will become clear. It is best to replace in pairs, since taking everything apart and then reassembling it twice in a short period of time is a dubious pleasure.

Signs of a faulty mechanism are as follows:

Generally speaking, the car will immediately signal if the ball joint needs to be replaced urgently. In some cases, work has to be done every 30 thousand kilometers; much depends on the quality of the road surface.

How to choose spare parts?

You can use parts designed for installation on all front-wheel drive models of the ninth and tenth VAZ families. Here are the requirements for parts and their features:

- On new supports the pin should be made of hardened steel. The color of the metal is gray, scale may be present. Be sure to make sure there is no paint on it. The thread of these products is rolled.

- The body is made of two halves. Please note that the welding seam is visible only on one side.

- When scrolling, you need to apply a lot of effort. Make sure there is no snacking. This is the first sign that the part is of low quality. It is impossible to manually scroll on new products, so you need to use a crank. This indicates that the product is of good quality.

- It is best if the ball joint comes with a boot and a nut. If it turns out that these components are missing, it is better to choose another option.

- There are a lot of manufacturers of these elements, but, as a rule, there are three on sale - “Trek”, “BelMag” and “Trial-Lux”.

Which ball joints are better for the VAZ-2110 is up to you to decide. But if you have to choose from the above trinity, then they are approximately the same in quality.

Sources

- https://RetroTruck.ru/obsluzhivanie-avto/zamena-sharovoj-na-priore-svoimi-rukami.html

- https://gil-service.ru/ts/sharovyj-na-prioru.html

- https://o-ladagranta.ru/kak-snjat-sharovuju-na-priore-bez-semnika/

- https://zapchasti.expert/proizvoditeli/sharovaya-opora-na-lada-priora.html

- https://remontautomobilya.ru/proverka-i-zamena-sharovoj-opory-lada-priora.html

- https://prometey96.ru/tyuning/sharovaya-opora-priora.html

How to check a ball joint?

The ball is very easy to check. It is enough to get to the part and check it for play. At the slightest play it should be replaced. You can even try to shake the ball with your hand, and then everything will become clear. It is best to replace in pairs, since taking everything apart and then reassembling it twice in a short period of time is a dubious pleasure.

Signs of a faulty mechanism are as follows:

- The feeling of wheels spreading along the road while driving

- If the ball joint starts to “eat” rubber

- A squeaking sound is heard when turning the steering wheel

- Knocks are heard from the suspension while driving on asphalt

Generally speaking, the car will immediately signal if the ball joint needs to be replaced urgently. In some cases, work has to be done every 30 thousand kilometers; much depends on the quality of the road surface.