A CV joint is a constant velocity joint. It is a loaded, very significant element of the chassis for front-wheel drive VAZ 2109. Under ideal operating conditions, the resource of the element is designed for a long service life, almost equal to the service life of the car itself.

Causes and breakdowns

In reality, the resource of the CV joint turns out to be significantly less, which is caused by operating conditions, poor quality of roads, driving habits and other factors.

People usually call a CV joint a “grenade,” which is due to the external similarity of the element to this explosive device.

Here's what you should know about grenade malfunctions:

- Practice shows that the most common cause of CV joint failure is dirt, dust, and sand that enter the mechanism through a damaged boot;

- Sometimes the problem of a non-functioning grenade can be solved by replacing the boot. This is possible if the CV joint itself has not yet worn out due to exposure to contamination;

- If the damaged boot is not detected in time, the grenade will be completely worn out within literally 200 kilometers;

- If the CV joint fails, a strong crunching sound appears when cornering and accelerating. Such a symptom indicates the need to urgently replace the CV joint;

- The cost of new grenades is quite affordable; they are available at any auto parts store. But you should purchase those that meet the technical requirements of the VAZ 2109;

- If you have at least a little experience in repairing cars yourself, it is quite possible to replace a grenade with your own hands.

Old and new element

Causes of CV joint failure

Unlike other cars, it is especially difficult for the VAZ-2109 to keep the grenade boot in working condition for a long period.

The main reasons for its failure, first of all, can be unfavorable climatic and external factors. As a result, cracks will form on the parts, and further operation will be impossible. If, after you heard a suspicious crunch in your VAZ-2109, you came to the garage and found traces of grease on the hinge, then you immediately need to completely replace the CV joint along with the boot, since the parts of this mechanism cannot be interchanged.

Types of CV joints

Before you begin repairs, you need to find out exactly how the unit is designed.

The pair of drives on the VAZ 2109 is equipped with a total of 4 CV joints.

CV joint type

Peculiarities

There are 2 of them. They transmit torque to the axle shaft from the gearbox

There are also two of them. Installed on the ends of the axle shafts and transmit torque directly to the wheels

Outer

This arrangement of grenades allows the wheels to rotate during turns and constant operation of the suspension system. To put it simply, the outer CV joints are responsible for transmitting torque when cornering, and the inner ones are responsible for the vertical movement of the wheels. These are collisions with bumps, holes, roll in turns, etc.

Interior

Replacement

If problems arise with grenades, you should determine which ones have problems. Next we will look at how to change the drive and how to remove it. Additionally, we recommend watching the repair manual video.

The procedure for replacing inner and outer CV joints differs from each other, therefore each stage should be considered separately.

Let's start with the internal.

Inner CV joint

Rubber boots are a vulnerable element of the grenade design. It is not uncommon that by replacing the boot, washing the grenade with gasoline and applying new lubricant, it is possible to solve the problem. If the wear of the CV joint is insignificant, such measures can replace a full repair.

But if you discover the breakdown late, you will have to completely replace the inner CV joints.

- Apply the handbrake and install chocks under the wheels.

- Unscrew the hub nut using a wrench and a socket. Carefully remove the punching elements from the nut with a punch. This way you will be able to preserve the carving on the garnet. The nut itself will need to be replaced with a new one during reassembly.

- The main thing here is to unscrew the nut, lowering the wheels to the ground. Otherwise, you risk breaking the differential and other gearbox components.

- Raise the car using a jack on the desired side, first loosening the wheel nuts. Remove the wheel.

- Drain the gearbox oil. This can be done earlier, at your convenience.

- Release the steering knuckle from the ball joint at the bottom. To do this, unscrew a pair of mounting bolts.

- Since you have already removed the hub nut and unscrewed the ball joint from the steering knuckle, proceed to removing the splined part of the grenade. To do this, pull the brake disc and strut assembly towards you. She has a decent ride. Just remember to turn the steering wheel all the way so that the tip of the steering wheel extends as far as possible.

- Pry the inner grenade with a pry bar, which will allow you to remove the drive.

- Having taken out the CV joint, look at the condition of the oil seal in the gearbox. If you find traces of leaks, be sure to replace the element.

Interior

Replacing the internal CV joint of a VAZ 2109 is carried out if the following parts and tools are available:

- Vise;

- A set of keys;

- Hammer;

- Jack.

First of all, completely remove the drive from the car and secure it in a vice. To remove the boot, you will need to remove the CV joint clamps. After this procedure is completed, you can begin to remove the part itself. Using a hammer, give the part a few firm blows to force it out of the mount. At the end of this part there is a plastic tip. It must be carefully removed for subsequent installation on a new “grenade”.

Before replacing, all fasteners, and the CV joint itself, must be lubricated with a special lubricant. Next, carefully put the new part back onto the drive. To do this, use a hammer and a wooden block so as not to damage the part.

Next comes the installation of the boot. It must be installed at a distance of approximately 20 mm from the “grenade”. After installation, secure with clamps.

Possible causes of crunching

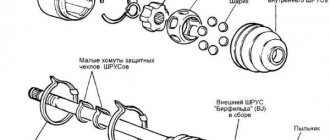

An experienced driver can by ear determine the location of a car malfunction. This quality comes with age. However, it is very difficult to confuse the crunch of a grenade with another sound. Let's figure out what a CV joint is. On the outside it is made in the form of a bowl, and on the inside the body has semicircular grooves. There are six of them.

In the internal space there is a spherical fist (clip) with 6 grooves and a splined connection for the axle shaft. Rotation occurs through the force that the cage transmits to the body through the balls located in the separator. The balls, moving along the grooves, change the angle between the axes.

- low-quality or defective products, including counterfeit ones, have been identified;

- low-quality lubricants are used or they are absent;

- boot damage;

- driving on bad roads or aggressive driving style.

Each part has its own production resource. And over time, play appears in the hinges. The rolling of the balls, now more free, produces a sound reminiscent of crunching. It may appear when turning, sharp acceleration, or overcoming obstacles.

There are 2 grenades installed on the drive wheels (internal and external): the first transmits rotation from the gearbox, the second - from the axle shaft to the wheel hub. Therefore, if an extraneous sound occurs, you need to determine which CV joint is making the sound (located on the left or right, inside or outside).

Methods for diagnosing CV joints

Grenade structure: 1 - body with outer clip; 2 - separator; 3 - inner race; 4 — balls (6 pcs.); 5 — drive shaft; 6 — retaining ring; 7 — corrugated cover; 8 — cover clamps

How to determine which grenade is damaged and needs to be replaced? There are several diagnostic methods.

- First, let's try to determine the crunch of the external grenade. The car is stationary. We pull the axle at the hinges one by one and listen. A knocking sound appears, which means there is play in the CV joint, which indicates that the grenade is damaged.

- Now let the car drive on a flat area. To install, what kind of grenade crunches, how to proceed, you need to turn the steering wheel all the way to the right, then do the same to the left. There was a crunch when you turned to the right, which means the right outer grenade is faulty, a crunch when turning left means the left outer grenade.

- If the internal grenade malfunctions, the question arises: which one, how to determine the failure? To do this, we choose a road surface with bumps and holes so that the wheel drops as low as possible, and drive the car straight. We listen to the sounds, alternately driving either the left or the right front wheel into the hole, and by ear we determine which grenade is crunching.

- Raise the car on a lift. Engage first gear so that the wheels can rotate while suspended. If the grenade malfunctions, you will hear a hinge crunch.

We found out what, how and in what place a grenade “clicks”. All that remains is to start replacing the damaged CV joint. This can be done at a car repair shop or you can carry out the repair yourself if you have the appropriate experience. There are three basic rules, when followed, the car’s drive will last a long time.

- Avoid jumping off.

- Do not accelerate by turning the steering wheel.

- Inspect the anthers periodically.

The CV joint wears out quickly under significant loads and dirt. Take care of your car.

Front-wheel drive cars have in their design such elements as constant velocity joints, or, in short, CV joints. On the VAZ-2109, replacing these elements is quite simple, but you will need a little experience and special tools. Without this, repairs are unlikely to be possible. It is also advisable to purchase new elements in advance - depending on what financial capabilities you have, you can buy complete drives or separate CV joints (they are also called grenades for their external resemblance to this weapon).

DIY car repair and maintenance

Step-by-step plan for replacing CV joints (grenade)

So, the grenade (both internal and external) on front-wheel drive models of domestic “cars” (God forgive me) starting from the VAZ 2108 and ending with at least 2115 is the same (well, maybe from different manufacturers and different service life of the final ). The same principle applies to Priora, Kalina and Grant.

Greetings, dear visitors! I want to devote this article to replacing the external grenade. If you follow the sometimes unclear terminology (which I don’t always like) - replacing the constant velocity joint, i.e. CV joint. I try to write my articles in everyday language, in which people ask for information.

Signs of CV joint malfunctions

Most often, the outer CV joint of the VAZ-2109 is replaced, since its resource is approximately three times less than that of the internal one. But the repair algorithm is generally similar.

Even to install new boots, you will need to completely dismantle the drive - it’s much more convenient to work this way. To determine if grenades are damaged, you need to do the following:

- Turn the steering wheel to the left all the way.

- Drive away and listen for any extraneous sounds.

- Turn the steering wheel to the right all the way, then drive off again and listen to the sounds.

If a characteristic crunch appears, you need to change the grenade. It is useless to repair it - these elements cannot be restored. If both CV joints are faulty - internal and external, then it will be easier to install a new drive assembly. At least there won't be any problems knocking down old grenades.

Basic procedure

First of all, you should put the car on the parking brake and secure the rear wheels with blocks. After this, while the car is on the ground, the hub nut is loosened. You will first need to remove the protective cap. It should also be taken into account that this nut is tightened quite tightly, so you will have to make a significant effort. At this point you can loosen the wheel bolts.

Next, you need to raise the front of the car by placing the body on supports. After this, you can unscrew the wheel bolts completely, removing the wheels, and remove the hub nut stop washer. The next step is to disassemble the steering rod, or rather its tip. The fastening bolts of the lower part of the steering knuckle support are screwed together, after which it is necessary to turn the steering wheel in the direction from which the replacement is being made until the extreme position is reached.

Next, the spitz end of the outer CV joint of the VAZ 2109 is pulled out from the hub, after the steering knuckle and strut have been pulled out. The next step is to press out the inner CV joint secured in the gearbox, for which it is better to use a pry bar.

It is important to pay attention to the fact that if it is necessary to carry out work on all CV joints, it is recommended that after removing one drive, install a retainer in the box, which can be an old similar part of the inner CV joint. Otherwise, the gears will shift, due to which the CV joints will not be able to be installed in place

If traces of oil were observed in the area of the gearbox during operation of the vehicle, then the seals on the CV joints will also need to be changed. Next, you need to clamp the drive shaft with a vice, remove the clamps from the hinges and unscrew the boots if they are intact. It is enough to cut off torn anthers with a knife.

The CV joints are knocked off the shaft with a hammer and drift, with the main forces being applied to the hinge cage. The same is done for the outer CV joint.

If you only need to replace the anthers, then the joint should be washed with gasoline to get rid of old grease and traces of dirt.

The new boot is placed on the shaft, but it is important to keep in mind that the right shaft is longer than the left. In addition, it is better to immediately replace the lubricant in the CV joint, making sure there is enough of it

Drive diagnostics

But a crunch can also appear when other suspension elements - balls, rod ends, bearings - are destroyed. Therefore, before replacing the CV joint on a VAZ-2109 with your own hands, do a complete diagnosis of the suspension and chassis. It is quite possible that it is not only grenades that will need to be repaired. In general, the diagnosis looks like this:

- Place the car on a viewing hole, overpass, or lift. It needs to be secured securely so that it does not roll off.

- Using a mounting spatula, check the drive play - if it is large, you can hear the balls knocking when moving, you will need to change the element.

- At the same time, check the condition of the ball joint - their reliability is not very high, and the roads leave much to be desired.

- Visually inspect the condition of the anthers on all grenades - they determine how long the drives will last.

Replacement instructions and Video!

How to replace a CV joint with your own hands and tips for prevention

The reason for replacing a part of the internal CV joint on your VAZ-2109 may be the sound of a “crunch” heard when turning on the highway. A part of constant velocity joints - CV joint, like any car component, has a tendency to wear out. You can check the condition of the CV joint by bleeding the drive axle shaft. If you feel noticeable play or find damage to the CV joint cover, this part will have to be replaced.

A CV joint can only be disassembled and repaired if you are very poor and have solid technological skills. In all other cases, it is recommended to replace this part as a whole, assembled. Damage to the CV joint can be caused either by natural wear or as a result of foreign objects getting inside after its cover is damaged. It is worth noting that the components of this assembly are not mutually interchangeable. Also, a sign of the need to replace the CV joint may be traces of grease on its cover or on the area connecting the gearbox and the drive half of the axle. Let's look at how the operation to replace a CV joint on a VAZ 2109 model is performed:

Before starting work on changing the CV joint, remove the entire front drive assembly of your wheel.

https://youtube.com/watch?v=2z8-KwRUqLU

Fix the removed axle shaft in a prepared vice. This way you will get ample access to the parts of the fastening clamps (internal and external) of this unit. Remove the mounting clamps.

Move the protective cover towards the inner end of the axle shaft and turn the cover over to the reverse side.

The entire CV joint must be removed from the axle shaft using a knockout device. Force must be applied to the clip of the part being removed.

Please note that there is a plastic plug at the end of the inner end of the axle shaft. Do not forget to check its presence when reassembling the unit, when you install the drive shaft in its place

Check the presence and level of lubricant in the CV joint assembly being placed. Its quantity should be about 80 cm3. If the amount of lubricant is low, replenish it.

It is necessary to install the CV joint assembly without hitting it very hard with a hammer through a wooden spacer. The direction of influence should be directed towards the outer end of the axle shaft. The signal for the end of the impact will be the fixation of the CV joint assembly. During installation, do not allow dirt to enter the CV joint assembly.

Before installing the CV joint protection cover, use a flat blade screwdriver to press out its edge. Once air gets inside, the cover will expand.

When installing the boot of the inner CV joint, maintain a distance of 21 centimeters between the near edge of the boot and the inner edge of the shank. Tighten the fixing clamps using special pliers.

Repair tool

To independently remove CV joints on a nine or any other car, you need to have the following tool on hand:

- A socket wrench for “30” or a socket with a strong wrench.

- Hammer and chisel.

- Balloon wrench.

- Set of spanners and sockets.

- Penetrating lubricant such as WD-40.

- Capacity of at least 5 liters.

- Marker or metal scriber.

- Jack, support and wheel chocks.

You may also need a grinder, drill, drill bits, and other attributes. The work can be complicated if the drives have never been removed - the threaded connections become dirty, which complicates disassembly.

Preparatory work

Before replacing the CV joint boot or the grenade itself, you need to perform several preparatory steps. Without this, withdrawal is impossible. Please note that you cannot remove both inner joints at the same time - this will lead to destruction of the differential mechanism.

If the bevel gears fall off, you will have to remove the gearbox and completely disassemble it. Preparation includes the following steps:

- Complete or partial drainage of oil from the gearbox. When removing the internal CV joints, oil will spill out; to prevent this from happening, it is necessary to drain at least 2/3 of the total volume.

- Unlocking the front wheel hub nut (or both, if two drives need to be repaired).

- Loosening the hub nut and wheel bolts. The hub must be unscrewed using a 30mm wrench with a large lever.

- Removing the wheel after installing the side to be repaired on the jack and support.

Having completed the preparatory work, you can begin directly replacing the VAZ-2109 CV joint.

Removing the hinge

It is advisable to treat all unscrewed bolts and nuts with WD-40 a day before replacing the outer hinge, thus significantly reducing the effort spent on unscrewing these elements. If this is not possible, we process the bolts and nut immediately before starting repair work.

Rice. 3 - Place of treatment with WD-40

Rice. 4 - Areas of treatment with WD-40

Set the car's steering wheel straight, engage first gear and apply the parking brake. For those for whom it does not work, I suggest reading this article. Under the front wheel, in which the outer joint is changing, we install two bricks, as shown in the figure below, to prevent rotation and scrolling. Use an impact screwdriver to loosen the nut. Using a “30” socket with a long handle, unscrew the hub nut, turning the wrench counterclockwise, regardless of which side the CV joint is being replaced from (!).

Rice. 5 — Unscrewing the hub nut

Having removed the nut, unscrew it and remove the washer. Then loosen the wheel bolts and jack up the front wheel. We place stump or bricks under the front side member so that when the jack is removed, the front wheel still remains raised a few centimeters above the ground. Now you need to hang the other front wheel in the same way. This is necessary in order to break the transmitted force from one suspension to another through the transverse stability beam. Then unscrew the wheel bolts and remove the wheel from the side we need. The result should be the same as in the figure below.

Rice. 6 — Hanging the front wheels using bricks

Now, using the “16” head, you need to unscrew the two bolts securing the ball joint to the steering knuckle. It’s not very convenient to do this without a hole, but it’s quite possible.

Rice. 7 — Unscrewing the ball joint bolts from the steering knuckle (body elements have been removed for clarity)

Next, move the strut to the side so that the outer hinge comes out of the hub.

Rice. 8 — Output of the outer hinge from the hub

We loosen the clamps of the CV boot and remove them, and cut the boot itself so that it does not interfere. To remove the outer joint from the shaft, you need to use a flat (slotted) impact screwdriver to crawl between the retaining ring and the joint separator, and use a lever to pull it off the drive shaft, while holding the shaft with the other hand, as shown in the figure below.

Attention! Never pull the drive shaft towards you, as it may come out of the inner joint!

Rice. 9 — Removing the CV joint using a screwdriver

Rice. 10 — Installing a screwdriver between the retaining ring and the hinge separator

If you did it as shown in the figure, the hinge should be easily removed from the shaft. Replacing the locking half-ring is completely optional if its external integrity is intact. Then we take out a set of new outer CV joint and get ready for installation.

How to remove the drive

In order to remove the drive assembly, you need to perform the following steps:

- Completely unscrew the nut on the outer joint to free the hub.

- Remove the nuts from the bolts that secure the strut to the hub steering knuckle. This will allow you to move the hub to free the joint. But it will be much more efficient not to unscrew the nuts on the strut, but to disconnect the ball joint.

- If you unscrewed the ball joint, you need to remove the tie rod end pin from the hole in the strut knuckle. This is done using a special puller.

- Now you need to pull the outer joint out of the hole in the hub. How to do this depends on the situation. You can use a thin drift, but without fanaticism, so as not to damage the mechanisms. You should also not hit the CV joint axle with a hammer - this will cause the edges to flatten and make it impossible to remove the element.

- After you pull out the outer joint, you can proceed to the inner one - to remove it from the hole in the gearbox, just apply a few light blows with a small chisel. You can also use a mounting spatula.

That's all, now the drive has been completely removed, you also need to learn how to remove the CV joint on a VAZ-2109.

How to remove a vaz shruz

Having determined that it is the external grenade that is broken, we begin to remove it.

How to unscrew the hub nut on a VAZ?

First of all, unscrew the hub nut. To do this, take a 30mm head and a lever, the larger the better. We put bricks under the wheels to prevent the car from rolling (simply putting it in gear is not an option, the wheel will spin) and begin to unscrew the hub nut.

In this matter, the more you weigh, the better, since I very often lacked my weight and leverage of about one and a half meters. I got out of the situation in the following way: I stood completely on the lever, as close to the edge as possible, thereby giving maximum tension to the nut, and hit the lever with a hammer. Usually this method helped me unscrew even the most soured wheel nuts.

One more nuance: if the outer walls of the head come into contact with the walls of the hub, it is better to lubricate the head with mining or lithol, or, in extreme cases, with silicone grease. Thanks to this trick, the head will not bite in the hub.

How to remove a grenade?

The hub nut is unscrewed, now we remove the wheel, unscrew the two bolts that hold the ball joint, disconnect the suspension arm and the hub, move it to the side of the car while lightly tapping the grenade, remove it from the hub. At this point, two options are possible:

- The grenade is already broken.

- Replacing the grenade due to its crunching sound.

In the first case, you simply remove the outer part of the CV joint from the shaft, then the retaining ring from the drive shaft and knock off the cage with a hammer.

In the second case, removing the CV joint becomes more difficult. You need to deflect the grenade relative to the shaft at the maximum angle so that the bearing balls and their cage are visible.

Now use a hammer to break the jumpers of the cage between the bearing balls and take out the balls one by one. When you take out the last ball, you can remove the body of the grenade, and then its inner part sitting on the shaft, after first removing the locking ring from the shaft.

Of course, you can simply try to knock the grenade off the shaft, but due to the locking ring this will be problematic.

That's it, the CV joint is completely removed. Now let's start installing the new part.

- Jack;

- Wheel bolt wrench;

- Power wrench;

- Ratchet driver;

- Steering and ball pin remover;

- Head at seventeen, thirty;

- Magnet;

- Hammer;

- Oil collection container;

- Mounting lever;

- Vise;

- Slotted screwdriver;

- Dull wire cutters;

- Engine cleaner in aerosol;

- The extension is sharpened to a cone;

- Torque wrench.

- Loosen the wheel bolts, jack up and remove the wheel.

- Remove the cap and unscrew the hub nut using a 30 mm socket. When unscrewing the nut, ask an assistant to press the brake pedal. You can also remove the nut while the car is on its wheels.

Use a magnet to remove the washer that is placed behind the hub nut.

Unscrew the nut securing the steering joint to the shock absorber. Head nut for seventeen. Use a puller to squeeze your finger out of your ear. If you don’t have a puller, you can hit the end of the eye where the finger is inserted several times with a hammer. Unscrew the two bolts securing the ball joint to the steering knuckle and move it to the side.

Remove the outer grenade from the splined part of the wheel bearing.

Place a container to collect the oil and remove the internal grenade from the manual transmission. To remove the grenade, insert the mounting lever into the cut in the drive housing and manual transmission. Next, tap the lever with a hammer until the grenade moves.

Pull the inner grenade out of the box and remove the drive shaft.

Remove the boot from the grenade by opening the clamps in advance. The clamps can be opened with a slotted screwdriver.

Grab the slotted part of the grenade with one hand and use a hammer to hit the outer body of the grenade with the other hand. After two or three hits the grenade will be in your hand.

Remove the old boot from the shaft and clean the spline part of the old grease. Fill the new CV joint with grease and, if necessary, replace the retaining ring on the shaft. Place the boot on the shaft with the narrow side facing inward.

Replacing CV joints

The most important thing now is to knock down the old hinge (or both, if you are also changing the internal one). To do this, you will need to firmly clamp the drive itself in a vice so that the hinge to be removed is directed downward. Apply sharp and strong blows with a hammer to knock down the hinge. If you are only replacing the anthers, try to carry out all work carefully so as not to damage the elements.

But if troubles arise when replacing a VAZ-2109 CV joint and the old joint does not want to come loose, you will need to take extreme measures. Using a grinder, you need to cut the outer casing to free the entire inner part. After this, you will have access to the retaining ring on the drive, removing which you can completely disassemble the element.

Installing new hinges is done in the reverse order. First, install the anthers, then the locking ring and put on the grenade. Gently hit it through the wooden spacer so that it locks onto the ring. The drive is installed without any special features.

Replacing the CV joint and boot on a VAZ-2109 - what is needed for this and how the replacement is carried out

Hello, dear car enthusiasts! Greetings to all car enthusiasts, happy owners of the VAZ “Nine”! With the start of VAZ's production of eighth and ninth series vehicles, a change in priorities occurred on the domestic passenger car market.

The rear-wheel drive “classics” now have worthy competitors, whose chances of getting higher positions in the sales rankings increase every day.

A more modern design, an economical and dynamic engine and, of course, front-wheel drive, became the distinctive features that allowed the new models to become the object of dreams of thousands of car enthusiasts.

The new car required car service technicians and their owners to gain knowledge and completely new skills in repairing components that were not found on previous models. One of the most mysterious parts that is often a dead end is the VAZ 2109 CV joint.

CV joint 2109 – the basis of front-wheel drive

Thanks to the fact that the front wheels became the drive wheels, the “Nine” gained excellent maneuverability and significantly reduced fuel consumption. For all good things, sooner or later you have to pay.

The ability for the front wheels to be driven was given by a special device - CV joint 2109. Constant velocity joint - this is how the mysterious set of letters is deciphered.

Internal CV joints of the VAZ 2109 transmit rotation from the gearbox to the axles, at opposite ends of which external CV joints are installed. They are the ones who spin the wheel and allow it to turn.

The importance of CV joints cannot be underestimated

In this regard, it is important to constantly take care of their condition

Constant operation of a car requires, in relation to CV joints, the implementation of several simple rules, namely:

- periodically inspect the condition of the CV joint boots and internal lubrication;

- immediately replace the VAZ 2109 CV joint boot if it is damaged;

- If such signs as impacts or “crunching” of the CV joint appear, the CV joint must be immediately replaced with a VAZ 2109.

What is needed to independently replace the CV joint on a VAZ 2109?

In order for the repair work to go smoothly, you need to be properly prepared. It should be noted right away that it is only at first glance that replacing the VAZ 2109 CV joint boot or the hinge itself (both external and internal) seems like a difficult undertaking.

Having carried out the procedure of replacing the CV joint or boot once, any car enthusiast will be able to repeat everything, as they say, with his eyes closed.

Preparation for CV joint repair includes the following steps:

- purchasing a new CV joint, boot, lubricant, clamps and other accessories, which, as a rule, are included in one repair kit;

- the car is installed on an overpass or inspection hole, but in addition, a jack and “goats” should be prepared for the safety of the repair work being carried out;

- You should have a set of standard tools on hand, including: socket wrenches with extended handles or attachments, a hammer, brass or wooden spacers.

You need to start by putting the car on the parking brake and fixing the rear wheels with stops. After the hub nuts and wheel bolts are loosened, the front of the car is raised and placed on racks so that the wheels are suspended.

The wheel must be removed, as well as unscrew the hub nut and remove the lock washer. The preparation ends by unscrewing the two bolts securing the lower ball joint to the steering knuckle.

How is the outer CV joint of a VAZ 2109 replaced?

Before we begin describing the repair process, we note that regardless of whether it is necessary to replace one CV joint or both, and also how many boots need to be replaced, the shaft with two CV joints must be removed.

First, let's look at how to do this. Having turned the hub using the steering wheel, using gentle blows through the spacer, knock out the axle shaft of the outer CV joint from the splined joint of the hub.

Then, using a pry bar, you can remove the inner CV joint. All. The shaft with CV joints is ready for repair. If CV joints are removed from both sides at once, it is strongly recommended to insert old hinges into the gearbox mounting sockets so that the gears do not move.

For convenience, the shaft is clamped in a vice. Now you can remove or cut off the old boots and lightly hit the CV joint body with a hammer to remove it.

A similar algorithm of actions will always be used if it is necessary to replace the CV joint boot or the hinge itself.

If one CV joint is being repaired (changed), you should never be too lazy to disassemble, wash and re-lubricate the second one. It is better to change the anthers at the same time.

The shaft is installed in the reverse order.