It often happens that you blame the car for engine failure, low-quality fuel that was filled at a gas station, although in fact the input shaft speed sensor in the automatic transmission simply failed. Damage can be mechanical, destruction of the seal of the housing, or internal, oxidation of contacts. But first things first.

Write in the comments, has this device already failed?

Automatic transmission input shaft speed sensor

The automatic transmission is equipped with two speed sensors.

- one records the number of rotations of the input shaft;

- the second one measures it.

Attention! For automatic transmissions of variable-wheel drive vehicles, the sensor measures the number of rotations of the differential gear.

The input shaft sensor is a magnetic non-contact device based on the Hall effect. Consists of a magnet and a Hall integrated circuit. This equipment is packaged in a sealed case.

Information from these sensors goes to the electronic control computer of the machine, where it is processed by it. If any malfunctions are observed either with the sensor, or with the crankshaft or differential, then the automatic transmission goes into emergency mode.

If the ECU does not find any problems according to the sensor readings, and the car speed drops or does not pick up, the Check Engine light is on, then perhaps the fault is in the automatic transmission input shaft sensor itself. But more on that later.

Read

Basic malfunctions and repairs of Mazda 3 automatic transmission

Now I will talk about how the input shaft sensor works.

Principle of operation

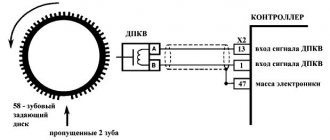

As I already wrote, the device records the number of shaft revolutions after switching to one of the automatic transmission gears. The working process of the Hall sensor is as follows:

- During operation, the electromagnetic sensor creates a special electromagnetic field.

- When a wheel protrusion or a gear tooth of a “pulse wheel” installed in it passes through the sensor, this field changes.

- The so-called Hall effect begins to operate. In other words, an electrical signal is generated.

- It is converted and sent to the automatic transmission electronic control unit.

- Here it is read by a computer. A low signal is a trough, and a high signal is a ridge.

The “impulse wheel” is a regular gear installed in the device. The wheel has a certain number of protrusions and depressions.

Where is

The sensor for measuring the speed of the automatic transmission output shaft is installed on the machine body next to the air filter. Devices for measuring the number of rotations of the input and output shafts differ according to the number specified in the catalog. For Hyindai Santa vehicles they have the following catalog values: 42620 and 42621.

Attention! These devices should not be confused. There is a lot of information on the Internet about these devices, but often inexperienced writers do not distinguish between them and write as if they were one and the same thing. For example, information from the last device is needed to adjust the lubricant pressure. These automatic transmission sensors have different proportions between the speed and the signals that come from them.

It is these devices that immediately communicate with the automatic transmission control unit. The devices themselves are repairable. You just need to check if there are any cracks on the body.

Read

Repair and replacement of automatic transmission Volkswagen Passat b6

Next, I will tell you about diagnosing problems with the input shaft rotation speed sensor.

Diagnostics

If you are a new car enthusiast and don’t know how to check, and where to start looking for errors in the device, I advise you to ring the contacts and measure DC or AC signals. For this you use a multimeter. Use the tool to determine voltage and resistance.

Diagnostics can also be carried out by the shocks and jerks that the driver feels when switching the selector lever to mode “D”. A faulty sensor gives incorrect signals about rotation measurements and, accordingly, weak or too high pressure is created, which causes failures in speed gain during acceleration.

Experienced mechanics include monitoring the appearance of errors on the dashboard monitor as a visual type of diagnostics. For example, the following lights on the monitor may indicate problems with the input shaft sensor:

- "Check Engine";

- The “Hold” lamp blinks.

The automatic transmission can start emergency mode, or only engage 3rd gear and nothing else.

If you check with a scanner with a laptop in your hands, the following error “P0715” will be displayed. In this case, you need to either replace the automatic transmission input shaft sensor or replace the damaged wires.

Let's sum it up

As you can see, the automatic transmission shaft speed sensor is a simple element, and the quality of operation of the automatic transmission as a whole directly depends on its serviceability. If any malfunctions and deviations from the norm are noticeable (the car accelerates poorly, the “check” light comes on, the HOLD indicator blinks, gears shift hard and roughly, the shift timing is shifted, delays are observed, etc.), then as part of a comprehensive automatic transmission diagnostics One should not exclude possible malfunctions of the automatic transmission input shaft speed sensor.

In this case, the replacement itself can be done on your own in a garage. The main thing is to separately study in the manual all the necessary information regarding the installation location, features of removal and subsequent installation of the automatic transmission input shaft sensor.

The main sensors in an automatic transmission: the purpose and operating principle of automatic transmission sensors. Malfunctions of automatic transmission sensors, signs.

What is automatic transmission emergency mode? Why does the automatic transmission go into emergency mode: the reasons why the automatic transmission goes into emergency mode, diagnostics.

Why the automatic transmission kicks, the automatic transmission jerks when changing gears, jerks, jerks and impacts occur in the automatic transmission: the main reasons.

Automatic transmission slipping when changing gears: the main reasons why an automatic transmission slips. Box diagnostics, troubleshooting.

Automatic transmission ECU: how the electronic control unit of an automatic transmission works and works. Malfunctions of the automatic transmission ECU, repair of the control unit.

How an automatic transmission works: classic hydromechanical automatic transmission, components, controls, mechanical part. Pros and cons of this type of gearbox.

The Volkswagen Polo Sedan was equipped with a classic automatic transmission (Aisin 09G) and 7-speed DQ200 0AM 0CW robots with two clutches. One clutch is responsible for engaging odd-numbered gears, the second – even-numbered gears. When the car is moving, one clutch is engaged, and on the second shaft the gears of the next gear are already prepared for operation. When conditions arise for shifting gears, the ECU sends a signal - the first clutch opens and the second closes. At the same time, the transmission of torque is not interrupted, and the car moves extremely smoothly, switching is almost imperceptible. Otherwise, diagnostics and, if necessary, repair of the Polo sedan 1.6 automatic transmission in Moscow at DQDL are required.

The world's first 6-speed automatic transmission 09G (Aisin TF-60/61SN) - since 2003 it has been used for almost all front-wheel drive VAG models with engines from 1.4 to 2.0 liters. Developed by the Japanese company Aisin on the instructions of VAG, which took upon itself the design and settings of the electrics, ECU and aggregation with the engines of its cars. 09G is designed for torque up to 280 N/m. The first real competitor to manual transmissions and DSG, the settings and shift speed allow you to drive aggressively and close to the limiting moments.

One of the common problems with the 09G is the torque converter. It operates with a wide "slip mode". The locking pressure is supplied not by a conventional solenoid valve, but by a PWM solenoid. This mode increases efficiency, but at the same time accelerates the wear of the torque converter friction lining several times.

In the summer, to combat rapid lining wear, sensors on some machines notify the TCM ECU when a critical temperature of 130° has been reached and the “slip mode” may be canceled.

If you maintain cleanliness and oil temperature in this automatic transmission up to 100 g, then it will run forever. Change the oil as usual every 60 thousand km (even more often if driving aggressively). The 09th series is sensitive to the correctly set ATF oil level, which is checked at t=40°±5° at the level of the overflow tube in the sump; the filter does not change with an oil change, because To do this you need to disassemble the automatic transmission.

How does 09G fail?

- The torque converter clutch engages with slipping starting from 3rd speed, without waiting for the speed of rotation of the engine shaft and transmission to equalize. At the same time, it actively wears out and contaminates the oil with hard and sticky powder. This aggressive suspension enters the channels of the valve body and solenoids, clogs the spools, and prevents the springs and solenoids from working. In addition, it wears out all sliding surfaces. It is expressed in shocks, delays in turning on and off the packages, and there is a difference between working in cold and hot oil.

- The plungers and valves jam and do not provide enough oil pressure to one of the packages, leaks and oil flows form in worn areas, and the pressure in the clutch packages critically decreases. Which is already expressed in the wear of the clutch clutches and the box feels like it “does not pull.” Repair of the valve body consists of cleaning and replacing critically worn valves and batteries with repair ones.

When is DSG 7 repair required?

The DSG 7 gearbox has a distinctive feature: it uses dry clutches and, as a result, it has a small volume of oil (1.7 liters, poured in doses), which is only required to lubricate the mechanical part (it is not used to cool the clutch). Efficiency increases and, accordingly, fuel consumption decreases. The cost of repairing a DSG 7 for the consumer is relatively low, since it is rare that both the mechatronics and the clutch break down at once.

The latest generations of DSG 7 are more reliable, but the weak points are still the same - the clutch and mechatronics. It is with them that box repair is most often associated.

What does a DSG 7 repair consist of?

Replacing the DSG 7 clutch

The clutch itself is a fairly reliable mechanism, but over time they still wear out. In this case, the DSG 7 Skoda Yeti clutch is replaced. On a 6-speed gearbox, which, as is known, is a wet-type gearbox, this procedure is carried out much less frequently (about once every 150-200 thousand km, subject to moderate use, although cars with mileages of about 300 thousand km arrived quite often) than in a dry type gearbox, where replacing the clutch with a DSG 7 may be necessary starting from 25-30 thousand km.

You should also know that the clutch responsible for odd gears wears out faster, because it is responsible for the operation of 1st and reverse gears (increased load). Constantly driving in traffic jams also negatively affects the clutch life.

Initially, manufacturers of 6 and 7 speed DSGs provided the possibility of replacing clutches in the gearbox and, accordingly, produce repair kits. After this procedure, clutch adaptation is required. We provide a 1-year guarantee for this work (replacement+adjustment+adaptation+installation).

Repair and replacement of mechatronics DSG 7

In the vast majority of cases, problems with a dual-clutch transmission begin with the mechatronics (it actually controls the switching process). On DSG 6, on average, everything happens later than on DSG 7.

Problems with it may arise due to fur. wear of the solenoids (jerks appear). In this case, usually a complete replacement of the mechatronics is not required, but only the solenoids are changed.

The second problem area is the mechatronics electronic control unit; problems usually arise with it due to overheating (when started on a cold system, the system goes into emergency mode). If the unit cannot be restored, then it is replaced and then reprogrammed for the desired machine. We reprogram DQ200 DQ250 mechatronics for a specific car.

Typical symptoms of malfunctions

Basically, a harbinger of problems is the appearance of jerks and jolts when starting to move and when switching to lower gears (downshifting). In a worse case scenario, the gearbox does not turn on and, accordingly, the car does not drive. In most cases, the box goes into emergency mode, which does not go away when the errors are reset (not always). You shouldn’t leave it to chance, as the rule always works - the sooner, the cheaper it is to repair the mechatronics of DSG 7 Polo Sedan 1.4 0AM 0CW, etc.

What to do if mechatronics repair is not possible?

This happens quite often (usually after accidents). It needs to be replaced with a used one, repaired or new, and then reprogrammed for the desired car. We have used, repair mechatronics for DSG 7 in stock. On the spot we will reprogram it for the desired vehicle within 20 minutes. The cost of work is indicated in the table (see above).

Mechanical part DSG 7

There are also problems with it.

Wear of bearings produces noise when moving, which increases with the number of revolutions and speed. It can be solved by opening and then replacing the set of bearings.

The shift fork is destroyed - even gears and reverse gear disappear. It goes into emergency mode.

Destruction of the needle bearing on the input shaft, leakage of the input shaft oil seal. For those who change the clutch, it is strongly recommended to replace these 2 parts.

Location of automatic transmission sensors using the example of Hyundai Santa

The measured speed of rotation of the automatic transmission input shaft is converted into electric current. Information can be transmitted by either direct or alternating voltage, proportional to the rotation speed.

Speed meter

A common malfunction is mechanical damage to the housing, as a result of which the device ceases to be sealed. The cause of destruction lies in prolonged exposure to temperature or poor quality manufacturing. Repair in this case consists of replacing the sensor with a new one.

Under the influence of an aggressive environment, the contacts in the assembly oxidize. This causes the signal to disappear and an incorrect value may be sent to the ECU. To eliminate the problem, you can clean the contacts. In case of severe oxidation, it is recommended to replace the device with a new one, since as a result of removing plaque, the protective coating is erased and the contacts are damaged at an accelerated pace.

Measuring the rotation of the automatic transmission output shaft

I wrote earlier about the sensor for measuring the rotation of the output shaft of an automatic transmission, comparing it with the device that records the rotation speed. Now let's talk about its malfunctions.

A malfunction of the output shaft speed sensor is indicated by error P0720. The box ECU receives a signal from the device and decides what next speed to turn on. If there is no signal from the sensor, the automatic transmission goes into emergency mode or an experienced mechanic diagnoses error 0720 with a scanner.

Read

Diagnostics and repair of automatic transmission selector position sensor

But first, the driver may complain that the car is stuck at one speed and does not change gears. There are failures in acceleration.

Write in the comments if you had problems with devices for determining the rotation speed of the input and output shafts, what errors the automatic transmission gave you.

What does P0721 mean?

On vehicles with an electronically controlled transmission, the output speed sensor is located at the end of the output shaft directly in front of the drive axles. This allows the sensor to read the shaft speed. This is necessary, first of all, to determine the moment of gear shifting and control the activation of the torque converter and the electronic pressure regulator inside the transmission.

If the PCM or ECM (transmission control module or engine control module) detects a problem with the output shaft speed sensor, trouble code P0721 will appear. It should be noted that even if the sensor is faulty, it will still be able to operate using values received from other sensors to control torque converter operation, shift timing, and determine electronic governor pressure.

Gear shift detection

Now you know everything about the sensors that monitor the rotation speed of the input and output shaft. Let's talk about another very important device - a device for determining gear shifts. It is located next to the selector. The choice of speed and the ability of the driver to engage one or another gear depend on it.

This device monitors the position of the gear selector linkage. But sometimes it breaks down and then the driver observes:

- incorrect indication of the selected gear on the dashboard monitor;

- the letter of the selected gear is not displayed at all;

- switching between speeds occurs in jerks;

- delayed gear shift response. A car, for example, can stand for some time before moving in a given mode.

All these malfunctions occur due to:

- drops of water getting inside the housing, immediately breaking the seal;

- dust on contacts;

- wear of contact lamellas;

- contact oxidation or contamination.

To correct errors caused by improper operation of the sensor, the device must be disassembled and cleaned. Use regular gasoline or kerosene to clean contacts. If you need to solder the loose contacts, then solder them.

Read

Location and adjustment of the adjusting bolt of the Ford Focus 2 automatic transmission

Use a penetrating lubricant to clean the contacts. But experienced mechanics and I do not recommend lubricating the surface with Lithol or Solid Oil.

Causes of malfunctions

There are a number of reasons that directly affect the performance of the device, but do not require its replacement:

- Dirty or worn contacts;

- Moisture getting on the wires;

- Oxidation.

In order to correct the situation, it is recommended to use gasoline to clean the contacts and, if necessary, use soldering of wires.

In other cases, it is necessary to replace the device with a new one. To do this, you can use specialized centers or deal with the issue yourself.

The device is replaced on cars every 100 thousand kilometers. Its cost is about 1000 rubles, but if you don’t want to buy a new one, you can always try to repair the device.

Features of obtaining data on the position of selectors in some car models

The following vehicle modifications have repairable sensors:

- Opel Omega. The slats on the devices for determining the position of the selector levers are thick. Therefore they rarely fail. If they crack, then light soldering reconnects the contacts;

- Renault Megane. Car owners of this car may experience a jammed input shaft sensor. Since the board is packaged in fragile plastic, which very often melts under high temperatures;

- Mitsubishi. Input shaft sensors on Mitsubishi automatic transmissions are famous for their reliability. To correct their poor performance, you need to disassemble it and blow it with air and clean the contacts with kerosene.

If cleaning or blowing the automatic transmission input shaft sensors does not help, you will have to replace it. Have you ever replaced such devices? If not, then sit down comfortably. I'll tell you how to do it yourself.

How does a mechanic diagnose a P0721 code?

First, the mechanic will remove and inspect the output shaft speed sensor. If any teeth are worn or missing, your mechanic will replace the necessary parts. The mechanic will also check the resistance of the sensor and repair or replace it if necessary. After repairing or replacing the sensor, the error code will most likely disappear.

If the error code persists, the mechanic will check for loose or damaged wires and connectors. Dirty terminals can also cause this error code to appear. If your vehicle is equipped with a transmission fluid temperature sensor, your mechanic will check its resistance.

Replacing the automatic transmission input shaft sensor

Attention! In rare cases, drivers of the 2nd generation Renault Megane, and other vehicles, may not notice any changes in the operation of the automatic transmission. The gradual increase of this problem will lead to the fact that the car may go into emergency mode somewhere in the middle of busy traffic. This will lead to an emergency situation. Therefore, it is important to take your car to a service center for maintenance on time.

Repair and replacement of a damaged output shaft speed sensor is carried out as follows:

- Open the hood and remove the air filter to get to the device.

- Disconnect it from the connectors.

- Check the housing for leaks. If everything is fine, then open the device.

- Check the voltage and resistance of the device.

- If the gear teeth are worn out, replace it with a new one.

- Check the contacts and clean them.

- If the device is in poor condition, replace it and install a new one.

- After all procedures for installing a new one have been completed, check the automatic transmission for errors with a scanner.

- If the errors persist, check the terminals and wires. They can be chewed by mice or cats.

- Replace them if necessary.

Read

Lexus automatic transmission repair

After the components and wires have been replaced, start the car and shift the selector lever through the gears, pick up speed up to 40 km/h. See how the switching occurs, whether the letters on the monitor behave adequately for the gear that is switched on.

If everything is normal, then you were able to diagnose the problem and fix it. If not, then contact your nearest service center.

What are the symptoms of a P0721 code?

When this error occurs, the Check Engine light will come on. Other symptoms include speedometer malfunction, engine misfire, delayed shifting, inability to shift gears, and hard shifting. You may also hear noises, such as crunching, grinding or crackling noises, or feel resistance when shifting gears. In some cases, the engine may stall when the car is stopped.

It should be noted that in rare cases, drivers may not notice any signs of a P0721 code at all.

Technical description and interpretation of error P0715

This diagnostic trouble code (DTC) is a generic transmission code. The P0715 code is considered a common code because it applies to all makes and models of vehicles. Although the specific repair steps may vary slightly depending on the model.

Trouble code P0715 is displayed when the powertrain control module (PCM) detects a malfunction in the circuit for the turbine speed sensor, known as "A". The "A" designation is generally reserved for OBD-II equipped vehicles that use multiple input or turbo speed sensors.

The sensor is located near the rear of the torque converter (on the transmission input shaft). It is installed either with a bolt or screwed directly into the transmission housing.

There are special grooves on the transmission main shaft that run close to the end of the sensor. When the grooves pass the sensor, the circuit is interrupted and an electronic pulse is generated. This pulse is received by the PCM as a waveform pattern, which it recognizes as the turbine speed input signal.

On which cars is this problem most common?

The problem with code P0715 can occur on different machines, but there are always statistics on which brands this error is most often present. Here is a list of some of them:

- Alfa Romeo

- BMW (BMW X3, BMW X5)

- Chery (Chery QQ)

- Chrysler (Chrysler Crossfire)

- Daihatsu

- Dodge (Dodge Intrepid)

- Fiat

- Ford (Ford Kuga, Mondeo, Taurus, Focus, Explorer)

- Honda (Honda Jazz, Prelude, SRV)

- Hyundai (Hyundai Santa Fe, Sonata, Elantra)

- Kia (Kia Magentis, Sedona)

- Mazda (Mazda 3, Mazda 6, Demio, Protégé, Tribute, Surname, MPV)

- Mercedes (Mercedes Sprinter, w203, w211)

- Mitsubishi (Mitsubishi Outlander, Galant, Lancer, Montero, Pajero)

- Nissan (Nissan Beetle, Qashqai, Note, Teana, X-Trail)

- Opel (Opel Astra, Vectra)

- Renault (Renault Duster, Megan)

- Skoda (Skoda Fabia)

- Subaru

- Suzuki

- Toyota (Toyota Camry)

- Volkswagen (Volkswagen Golf, Jetta, Passat, Tiguan)

With fault code P0715, you can sometimes encounter other errors. The most common ones are: P0122, P0160, P0446, P0700, P0707, P0716, P0717, P0720, P0722, P0730, P1529, P2207, P3007.