01/26/2022 80 547 117 117 Sensors

Author: Ivan Baranov

The main signs of a malfunction of the mass air flow sensor are loss of engine power, difficult starting, “floating” engine speed. To find out the exact cause of the flow meter failure, you need to visually inspect the device and then test it with a scanner (via Openidag), a voltmeter or a motor tester.

[Hide]

What does a faulty air flow sensor cause?

Operating an engine with an inoperative/faulty flow meter causes detonation of the fuel mixture in the combustion chamber. This affects the operation of the crank mechanism (crank mechanism) and destroys the piston surface, which can cause a “wedge” in the engine.

What indications should a working mass air flow sensor give?

The voltage of the analog-to-digital converter (ADC) of the flow meter when the engine is not running should be 0.996 V. Indicators of 1.016 and 1.025 V are acceptable, but if they reach more than 1.035 volts, it means that the sensing element of the mass air flow sensor is clogged.

It is important to know

To accurately determine the degree of deviation of the operating flow meter values from normal values, it is necessary to evaluate the engine operation at different speeds.

For example, for an injection 1.5-liter VAZ 2111 engine, if it is in good condition, at idle (860–920 rpm) the correct readings are 9.5–10 kg/hour, and at 2 thousand rpm - 19 –21 kg/hour. If the flow meter at 2 thousand rpm shows about 17–18 kg, then the car will drive stably. If the values are from 22 to 24 kg/hour, then the vehicle will move steadily, but the fuel consumption per 100 km will be approximately 10–11 liters. In addition, the car will have difficulty starting in cold weather due to fuel overflow when the engine warms up.

Symptoms of a problem

The mass air flow sensor is located in the air duct near the air filter. It is designed to determine the amount of incoming air. Depending on its readings, the control unit will show how much fuel is needed to form a high-quality fuel mixture. The normal ratio is 1:14. Therefore, the quality of the fuel-air mixture depends on the correct readings of the flow meter.

The high-quality operation of the mass air flow sensor depends largely on the cleanliness of the air filter. Therefore, if symptoms of a malfunction of the mass air flow sensor appear, you should first check the air filter before making repairs. The flow meter is usually beyond repair. If it is faulty, it is replaced with a new device. But its cost is quite high, so you should first make sure that the causes of the problems are in the sensor and not in other malfunctions of the machine.

The signal for diagnosis is the following symptoms of a malfunction of the mass air flow sensor:

- Check Engine appears on the instrument panel;

- an error is displayed indicating a low level of the mass air flow sensor signal;

- the engine is bad, accelerates very slowly, stalls, its power drops;

- high level of fuel consumption;

- the engine is unstable at idle;

- the engine stalls when changing gears;

- The rpms are either high or low.

There are other symptoms of a “dying” sensor. For example, it may have cracks in the corrugated hose that connects the throttle body to the sensor. If the engine stalls, there may be a power problem or damaged wiring. This is a signal to check the electrical wiring. If malfunctions are detected, the machine's electrical system must be repaired.

In addition to the above possible signs of failure of the mass air flow sensor, you should diagnose the sensor signal level.

A low signal level may mean the following:

- Mass air flow sensor is not connected;

Disconnected sensor connector - open circuit in the sensor connection circuit;

- the mass in the chain breaks, oxidation appears;

- signal wires are broken or incorrectly connected;

- Engine control unit malfunction.

You should not draw conclusions about a malfunction of the mass air flow sensor, relying only on the symptoms listed above. A complete diagnosis of the engine and machine should be carried out, since signs of a flow meter failure may appear if other devices malfunction (for example, due to a clogged air filter). Then you need to repair these devices to restore the car's functionality.

DMRV error code

The following errors may indicate a malfunction in the operation of the mass air flow sensor:

- P0100 - damage to the electrical circuit connecting the sensor. To eliminate the breakdown, you need to check the wiring for integrity, since accidental disconnection of the connector or damage to the electrical contacts is possible.

- P0102 - the vehicle control unit began to receive a low signal, which was recorded at the input of the mass air flow sensor power line. To eliminate the cause of the breakdown, it is necessary to check the electrical wiring and the insulating layer of the cable; oxidation of the contacts of the wiring connector (the so-called chips) is possible.

- P0103 - critically high signal detected at the input of the mass air flow sensor power line. If the cause of the malfunction is not the wiring, then a visual inspection and cleaning of the flow meter will be required or it will have to be replaced with a new one.

Equipment operation

For 1 stroke, the ratio of the volume of incoming gasoline and air is 1 to 14. Under such circumstances, the engine performs its job perfectly. Under unfavorable circumstances, excessive fuel consumption or a decrease in power can be observed. The peculiarity of the sensor’s functioning is to measure the incoming air, and then it must inform the on-board computer about this. As a result of receiving the data, the computer sets the amount of fuel that needs to be provided to the engine. You can control the incoming air yourself. During the period of increased pressure on the accelerator, the amount of arriving air increases. If the sensor functions smoothly, then there will be much more fuel. It follows from this that when driving slowly without jerking, air consumption will be less, and along with it, gasoline consumption will also decrease. So, let's move on to the structure. A platinum cable with a diameter of seventy microns can be seen inside the measuring tube, but the throttle valve is located in front of it. Previously, at the end of work, the wire always became dirty, and therefore the manufacturers included a function for heating the wires in the electronic control unit. Within one second after the motor is turned off, the surface heats up to a thousand degrees, due to which all remaining dirt disappears. While maintaining the good condition of the sensor using all possible methods, the nuance cannot be ruled out that the next malfunction will lead to a complete change of equipment. It is extremely difficult to repair the sensor, and a complete replacement is often necessary, but there is always a way out.

Difficulties in case of malfunctions, check

The characteristics of the damage are different. It is not difficult to determine a defect if you carefully observe the signals that indicate it:

1. For example, Check Engine - this inscription can be seen on the panel. It symbolizes various damages and sensor failure is no exception.

2. Fuel consumption has increased.

3. Loss of power.

4. Control dynamics have disappeared.

5. Difficulties with the functioning of a heated motor.

Of course, this is not the entire list. It is also necessary to clean the sensor in case of other ailments. For example, oil flows down the engine crankcase ventilation and enters the air filter or onto the surface of the air duct. Thus, it disrupts the performance and provokes damage to the mass air flow sensor. Even when dust and dirt get into areas of equipment, ailments can be seen. Manufacturers are trying to create a device that is very durable when operating at different temperatures and does not accumulate dirt. In modern times, you can find approximately 50 types of sensors.

This type is the most relevant, we have already talked about it. An integral part of the design is a heat exchanger. From it come 2 platinum plates through which current passes. One plate is working, and the other is for reserve. Because one of the plates is different in temperature, air is directed to cool one of them, trying to compare the temperature. In order to compare temperatures, an extremely large amount of current should be supplied to the non-working plate. Only this data affects the response of the control unit and the release of gasoline. It is very bad if, at the time of testing with a multimeter, a low signal is given.

Just a few years ago, platinum-coated silicon wafers began to appear on the market. Not very popular today.

The pitot tube is an integral part of the installation. In the middle there is a thin plate that is gently attached. Under the influence of air, the plate bends, but the potentiometer device records its bending, changing the resistance data. The control unit takes information from the potentiometer readings and then decides how much fuel is required.

Checking and repairing at home

There are eight ways to independently check amplitude and frequency mass flow sensors.

Method No. 1 - disabling the air flow meter

The method consists of disconnecting the sensor from the fuel system of the car and checking the functionality of the system without it. To do this, you need to disconnect the device from the connector and start the engine. Without a mass air flow sensor, the controller receives a signal to switch to emergency operation mode. It prepares the air-fuel mixture only based on the throttle position. If the car moves faster and does not stall, it means that the device is faulty and requires repair or replacement.

Method No. 2 - flashing the electronic control unit

If the standard firmware has been changed, then it is unknown what reaction of the controller is programmed in it in case of an emergency. In this case, you should try to insert a 1mm thick plate under the throttle stop. The turnover should increase. Now you need to pull out the chip from the air flow meter. If the power unit continues to work, then the cause of the malfunction is the firmware.

Method No. 3 - installing a working sensor

Install a known good part and start the engine. If after replacement it begins to work better, the motor does not stall, then replacement or repair of the device is required.

Method No. 4 - visual inspection

To do this, use a Phillips screwdriver to unscrew the clamp holding the air collector corrugation. Then you need to disconnect the corrugation and inspect the internal surfaces of the air collector corrugation and the sensor.

Inspection of duct corrugation

There should be no traces of oil or condensation on them, the surfaces should be dry and clean. If you do not take care of the air filter and change it rarely, then dirt can get on the sensitive element of the sensor and cause it to break. This is the most common malfunction. Traces of oil may appear in the flow meter if the oil level in the crankcase is high, or if the oil sump of the crankcase ventilation system is clogged. If necessary, you need to clean the surfaces using special cleaning products.

Method No. 5 - checking the mass air flow sensor with a multimeter

To do this, you need to turn on the tester in a mode in which constant voltage is checked. The limit value for measurements should be set to 2V.

DMRV operation diagram

Sensor pinout:

- The yellow wire is located closer to the windshield. It serves as an input for a signal from the flow meter.

- The white-gray wire is the sensor voltage output.

- The black and pink wire leads to the main relay.

- The green wire is used to ground the sensors, that is, it goes to ground.

The wires may have different colors, but their location is unchanged. To check, you need to turn on the ignition, but do not start the car. The red probe from the multimeter must be connected to the yellow wire, and the black one must be connected to ground, that is, to the green wire. We measure the voltage between these two outputs. Multimeter probes make it possible to connect without disturbing the insulation of the wires.

On the new device, the output voltage ranges from 0.996 to 1.01 V.

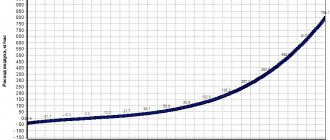

During operation, this voltage gradually increases and by its value one can judge the wear of the flow meter:

- if the sensor is in good condition, the voltage is from 1.01 to 1.02 V;

- in satisfactory condition - from 1.02 to 1.03 V;

- the sensor resource ends if the voltage is in the range from 1.03 to 1.04 V;

- a value in the range from 1.04 to 1.05 indicates a near-death state; if there are no contraindications, then you can continue to use the sensor;

- if the voltage exceeds 1.05 V, the mass air flow sensor requires replacement.

Indications of the ADC of the flow meter

Diagnostics of the mass air flow sensor "Tseshkoy" is not complicated and can be done with your own hands.

If there is dirt on the removed sensor, you can clean it yourself. You can use WD-40 to wash it. To clean the mass air flow sensor, you must first remove the pipe from it, and then dismantle the device itself. Inside the device there is a mesh and several wires - sensors.

They need to be sprayed with cleaning agent and washed. Then let the liquid dry. If dirt remains, the procedure should be repeated. You need to clean the pipe with the same product. It must be free of dirt and oil stains. After replacing the air filter, all parts must be returned to their place. After the cleaning procedure, the functionality of the device can be restored to 80%, the error about the reduced sensor signal level disappears (the author of the video is “24 hours”).

Flushing the sensor will help avoid costly repairs.

Method number 6 - checking with a scanner

Test method:

- Install a diagnostic program on your phone (smartphone), tablet or laptop computer (for example, Torque Pro, Opendiag, BMWhat, OBD Auto Doctor).

- Connect your mobile device or laptop to the diagnostic connector located on the vehicle's electronic control unit using a special cable, Bluetooth channel.

- Launch the diagnostic utility on your phone (smartphone) or computer.

- Wait until the program finishes scanning all vehicle components. As a result, the utility will check the serviceability of each vehicle unit.

- Decipher the error codes that the program will show after the diagnostics are completed.

To perform this method, testers are used:

- K-Line 409/1;

- Scanmatic;

- ELM (ELM) 327;

- OP-COM.

Method No. 7 - checking by Vasya the Diagnosticist

To identify a malfunction of the mass air flow sensor without removing it from the car, you need to:

- Install a program called “VASYA diagnostician” on your laptop (laptop) and run it.

- Connect the adapter to the vehicle's diagnostic port.

- Select the item “Electronics 1” or “01 – Engine electronics” from the “Control unit” tabs to connect to the vehicle’s control unit.

- Go to “Custom Groups”.

- Select 211, 212 (passport value) and 213 (current value).

- Compare current indicators with passport data. If the deviations are high, then it is necessary to replace the mass air flow sensor.

Method No. 8 - using a motor tester

Good to know

This method is used to test frequency-type flowmeters.

To check the mass air flow sensor with a motor tester (oscilloscope), you need to connect it to the sensor (depending on the car brand) and start the engine.

Mass air flow sensor check parameters:

- transient time when the ignition is on;

- air consumption readings at idle and a sharp increase in engine speed;

- voltage in the sensor network.

It is important to know

The output data is individual for different types of engines. Before diagnosis, you should check the current indications with an official representative.

Replacing the air flow sensor

To replace the sensor with your own hands, you need to prepare a shaped screwdriver and a “10” key.

The replacement procedure consists of the following steps:

- First you need to turn off the ignition and open the hood.

- Then you need to disconnect the negative terminal on the battery.

- At the next stage, you need to loosen the clamp with which the corrugation is attached to the mass air flow sensor.

- Next, remove the corrugation from the pipe.

- Then you need to bend the comb and disconnect the sensor connector.

Disconnecting the sensor connector - Then, using a key set to “10”, you need to unscrew the sensor mounting bolts to the air filter housing.

- Now you can remove the mass air flow sensor.

- Installing the sensor yourself is carried out in the reverse order.

Thus, if the car stalls and has all the signs of a breakdown of the mass air flow sensor, then before you start repairing it, you should check the level of its signal, it should not be low, perform a full diagnosis of the car and repair all faulty components and parts.

It is important to undergo regular vehicle inspections and perform timely maintenance, then the parts and components will last longer.

Sensor restoration

Before starting work on the car, it is necessary to deactivate the ignition and disconnect the plug with wires from the regulator.

What will you need?

To carry out the procedure you will need:

- rags;

- set of wrenches;

- cleanser;

- a screwdriver if its use requires dismantling the flow meter.

Selecting a cleaner

Products that can be purchased at the store to clean the controller:

- WD-40. A universal product that can also be used for cleaning.

- Liqui Moly. The use of such a composition is relevant for working sensors. The product is universal and can be used on both diesel and gasoline engines.

- Alcohol.

- Cleaning agent for carburetor engines.

- Liquid key. This product is sold as a spray.

- Air Senso Clean.

Do not use cotton swabs or compressed air to clean the device. It is important that the cleaning agent does not contain acetone or ether.

Algorithm of actions

| Image | Step |

| The user must remove the hose connected to the sensor; to do this, use a wrench to unscrew the screws securing the device to the air filter housing. The dismantling algorithm may differ depending on the design features of the car. | |

| |

|