In the life of motorists, a situation often arises when, when driving out onto the road and trying to accelerate, it is noted that the engine does not pull.

That is, the acceleration dynamics are very “sluggish”, the car is reluctant to pick up speed, and it feels like something is holding it back.

This problem can arise with almost any car - domestic or foreign, gasoline or diesel, with a carburetor power system and injector.

Often, a drop in traction is accompanied by additional symptoms - extraneous sounds appear when the engine is running, the engine may stall in one of the modes (usually at idle), the crankshaft speed is not stable and “floats”.

But this is not always the case; it happens that the unit behaves perfectly in all respects, but does not develop power.

Lost engine thrust: why does this happen and what should the driver do?

As a rule, during the long-term operation of a vehicle, almost every driver sooner or later notices that the engine does not pull well.

In other words, the power unit has difficulty coping with the loads, there is a loss of power, the unit needs to be cranked up to high speeds to maintain the usual pace, the car accelerates worse from a standstill, picks up speed slowly, etc. At the same time, in many cases the engine runs smoothly, does not tremble, there are no increased vibrations, extraneous sounds, knocking or noise during operation of the internal combustion engine. Let us note right away that there is a fairly wide list of possible reasons why a warm engine does not run, and there is a loss of engine power when cold and/or when hot.

In this article we will talk about why the engine does not pull, and also consider the most common malfunctions that manifest themselves in the form of loss of traction of the power unit.

The problem is that when accelerating after 2000 rpm there is a feeling that fuel stops getting into the injectors. The check is not lit, which means there are no errors. The engine is 8 valve. Can anyone tell me where to go?

The pressure in the fuel rail is low, the coolant pump is dying or the fuel filters simply need to be replaced. Well, I had a look at the injectors for spray.

how to do this in a garage? or only in a hundred?

A forum member from Rubtsovka offered you help a long time ago. You've disappeared somewhere.

the mosh valve is burnt out..measure the compression..well, a sophisticated on-board computer is desirable..

By the way, when driving in the rain, the module probably floods... because there are interruptions in 2,, 3 pots... it turns off the forces. stood .. dried .. cleared the errors and flew on. you need to think about how to isolate it from splashes, etc. did anyone have something like this?

in a garage service station. You can try to get confused yourself. You can find everything on YouTube.

sometimes it floods something, I don’t bother. Once he sneezes, the check light comes on for a minute, then goes off and it’s fine. I don’t do anything and won’t. I don’t want to bother with it.

What kind of feeling is this?) and before I actually felt like fuel was pouring like a river into the injectors?)

Describe the problem properly.

Everything should be fine there anyway, in isolation. Look at the wires and connectors. Maybe there is a crack in the MZ body?

To begin with, install the mesh in the tank, you can do it in the yard yourself (wrench 17.7 or 8, pliers, a simple screwdriver and a cross), visually compare it with the new one, and you will understand whether it is very clogged or not. Also change the fine filter (at the bottom of the tank and beam) - a trestle is needed. You can stop by for an express oil change, they will change everything there.

It should help. PS: as they wrote above, I contacted you, if anything happens, I’ll introduce you to normal repairmen (or they’ll just tell you what and how)

To begin with, install the mesh in the tank, you can do it in the yard yourself (wrench 17.7 or 8, pliers, a simple screwdriver and a cross), visually compare it with the new one, and you will understand whether it is very clogged or not. Also change the fine filter (at the bottom of the tank and beam) - a trestle is needed. You can stop by for an express oil change, they will change everything there.

It should help. PS: as they wrote above, I contacted you, if anything happens, I’ll introduce you to normal repairmen (or they’ll just tell you what and how)

What kind of key is this 17.7?)

Do you need a trestle to change the filter? He threw the rag on the ground and crawled under the car.

I’m almost ready to climb under the car on a jack.

At 17, and at 7 or 8 (unscrew the gas tank flap)

Well, yes, let them rack their brains since they don’t want to apply online)))

Yes, with this approach, it’s not at all clear how you got a computer? Previously, they didn’t know it either, and didn’t use it)))

You're doing it right. Providing a reliable support is not a problem. A guy I know got a dozen on his chest. I already wrote in my opinion, although it was a long time ago. Miraculously, he remained alive.

At 17, and at 7 or 8 (unscrew the gas tank flap)

Well, yes, let them rack their brains since they don’t want to apply online)))

It depends on what kind of car it is. The pump cover comes with keys for both 8 and 10 and just plastic on plastic tanks. The tubes come with quick releases or a 17 wrench, but it won’t hurt to hold the mating parts with a 22 wrench. It also won’t hurt to stock up on O-rings right away if the tubes are on nuts.

At 17, and at 7 or 8 (unscrew the gas tank flap)

Well, yes, let them rack their brains since they don’t want to apply online)))

If the engine is 1.6, then you don’t need a key for 17. And the nuts on mine seemed to be 10.

Gee.. Boyanya it turns out already)

Last edited by rmx116; 08/11/2016 at 06:38.

Transmission problems

Uneven running is also caused by transmission problems. Aggressive vehicle operation and neglect of maintenance will lead to jerking when starting the car. If there are no heavy loads and the driver treats the car with care, the risk of malfunctions is reduced many times over.

If a car with a manual transmission jerks at low speeds, the gearbox and all its parts have nothing to do with it. If the manual transmission breaks down, the car will not move. The problem may occur due to damage to the clutch mechanism. A worn or sticking driven disc is what causes your vehicle to jerk when changing gears.

The proper operation of an automatic transmission is largely determined by the quality and quantity of lubricant. Jerking is observed more often due to a lack of oil or the presence of foam. It is recommended to regularly check the lubricant level with a dipstick and not skimp on quality.

Power drop on a VAZ carburetor engine

To begin with, let's take VAZ cars with a carburetor power system and an 8-valve timing system - VAZ-2109, VAZ-2110, VAZ-2114, VAZ-2115.

The same power plant is installed on these cars, so the reasons are identical.

Let's go through those components, due to malfunction of which a drop in dynamics may occur.

In general, the main reason that the engine does not pull is a change in the processes in the combustion chambers - a mismatch in the proportions of the air-fuel mixture, the combustion process is disrupted, the filling of the cylinders and the removal of exhaust gases does not occur as required.

Supply system

Very often, a drop in traction occurs due to the power system. Structurally, the carburetor fuel system used on cars from VAZ-2109 to VAZ-2115 is very simple and is almost completely mechanical, so identifying the cause is not particularly difficult.

A decrease in power can occur due to:

- Severely clogged fuel filter (its throughput drops and the pump is simply not able to pump the required amount of fuel);

- Contamination of the carburetor channels (the jets and fuel channels in this element have a small cross-section and debris often clogs them);

- There is air leakage in the area from the tank to the pump (because of this, the performance of the fuel pump drops sharply);

- Damage to the fuel pump membrane (a small crack in it leads to the fact that the vacuum required for pumping fuel is not created in the pump chambers);

- The fastening of the carburetor or intake manifold is loose (due to this, air leaks around the carburetor and the proportion of the air-fuel mixture is greatly disturbed);

- The hole in the fuel tank cap is clogged (because of this, a vacuum is created in the tank and it is much more difficult for the gas pump to pump gasoline out of it);

When the engine warms up, the speed of the VAZ 2114 fluctuates

The five-door hatchback VAZ 2114 is a restyled model of the famous “nine”, which rolled off the assembly line of the car plant from 2003 to 2013. At various times, the manufacturer installed on the car power plants with carburetor or distributed fuel injection (injector) of its own making, and since 2007 the car has been equipped with an electronic engine control system. Note that all these engines have one common and very significant drawback - when they switch to idle mode, their crankshaft speed suddenly begins to “float”.

List of possible causes of power loss

Not every driver, even an experienced one, can quickly answer the question: why the thrust of the VAZ 2114 engine with 8 valves disappeared the first time.

To do this, you need to consider all possible sources of failure:

- debris entering the gasoline filter;

- clogged fuel pump diaphragm;

- malfunction of the sensor that controls air flow;

- poor spark plug performance;

- malfunction of the ECU (electronic engine control unit);

- dusty air filter;

- clogged injectors;

- complete wear of the clutch disc;

- insufficient compression in the cylinders.

Carburetor engine does not pull

A carburetor is a mechanical device designed to create a mixture of air and gasoline, with further supply of this mixture into the combustion chamber of the engine. Problems with a lack of engine power at the carburetor are quite common and there are many reasons for them. We will try to deal with each one.

- Engine power system

First of all, the loss of engine power may be hidden behind the power system. As a rule, the engine does not pull due to a lack or excess of fuel. The fact is that gasoline and air are mixed in a certain ratio. And if one or another element is missing, the motor will begin to work unstably and will stop developing the required power.

The ratio of air to fuel should be within 15 to 1. If the amount of gasoline exceeds the permissible parameters, then it will not burn completely, which means it will reduce engine response. In addition, such a change in ratios will seriously increase fuel consumption and subsequently lead to other engine malfunctions.

An insufficient amount of fuel even leads to “starvation”. The ignition of the air-fuel mixture will be insufficient and the piston will move slowly. All this is achieved by correct carburetor tuning, precise selection of jets and many other factors.

Setting up a VAZ carburetor begins with the selection of jets. An important condition is to have a larger nozzle for air than a nozzle for gasoline. Then the carburetor float chamber is adjusted, which should only be half filled with gasoline. After this, the car engine starts and the quantity and quality of fuel is adjusted in accordance with the technical literature for this carburetor model. If, at the same time, a stable speed is achieved within the range of 800-900 rpm, then the carburetor adjustment was successful.

Another link in the power system is the presence of clean air and fuel filters. If the filters are too dirty, then fuel or air will pass through with great difficulty, which also disrupts the composition of the mixture. Therefore, filters must always be kept clean.

Also check the throttle valve actuator. It is possible that it does not open completely. In this case, stop the engine and adjust the throttle position.

It is also quite possible that the fuel pump has stopped creating the required pressure. To do this, you need to remove it and check it. It is quite possible that the drive and its diaphragm will have to be changed. There is another very common malfunction - increased wear of the fuel pump rod. This means that when manually it pumps perfectly, but when you start the engine it works for a short time, then it loses power and the engine stalls.

- Valve assembly

The gas distribution mechanism also plays an important role in maintaining engine power. If the valves, due to wear, have lost their tightness, then gases will break through from the combustion chamber directly into the valve mechanism. All this reduces the pressure created in the engine cylinders, so the pistons move noticeably slower.

To restore the tightness of the valves, it is necessary to grind them in and adjust them correctly. The essence of the adjustment is to set the thermal gaps in their impact mechanism. The size of the gaps is indicated in the reference literature for the car engine.

In addition, the valve train must operate in synchronization with the engine crankshaft. If the opening and closing of the valves does not correspond to the position of the piston, the engine will not only pull poorly, but may not start at all.

- Ignition system

The ignition timing is perhaps the decisive factor. Sparking must occur only in strictly specified cycles, otherwise the motor will not only pull poorly, but may also overheat and operate very, very unstable. If the adjustment of the OZ was successful, but the engine still does not pull, and is completely unstable at idle, then it makes sense to check the ignition system as a whole.

On a contactless ignition system, you need to make sure that the switch is working properly. To do this, turn on the ignition and monitor the position of the voltmeter needle: first it should deviate to 12 Volts, and after a second it should rise even higher. If the Voltmeter is not provided by the design of your car, then replace the switch with a known good one and check the ignition operation again.

First of all, pay attention to the cleanliness and tightness of the contacts in the distributor. If everything is in order, you can move on. Start the engine and pull out the high-voltage wires one by one. After each wire, listen to how the motor operates. If it starts to work even worse, then there is a spark in this cylinder. If the engine operation has not changed, this means that you have found a faulty spark plug or high-voltage cable. This assumption can be verified by replacing the element with a known good one.

Incorrect use of spark plugs also affects engine performance. Most often, the difference between spark plugs lies in the gaps between the electrodes. The gap size must correspond to the engine, the season of operation of the vehicle and the spark plug model.

Check the ignition distributor. It is quite possible that a resistor located in the rotor circuit burned out. Another problem is the loose contact of the contact carbon. Try replacing it or the spring.

The last ignition problem is the unclear operation of the octane corrector. In the absence of the required vacuum, the special plate does not return to its original position. In addition, there is increased play in the system. Fix it and replace any faulty parts. Check the hose for leaks.

- Compression rings

The last and most terrible malfunction is the occurrence of compression or oil scraper rings. These elements are designed to reduce friction of the piston against the walls of the engine cylinder and remove residual oil so that it does not enter the engine combustion chamber.

Failure of the rings entails a violation of the tightness of the combustion chamber, and therefore the cylinder compression is seriously reduced. This can be determined by increased oil consumption and the corresponding color of the exhaust gases. In this case, only serious engine repair will help.

- Faulty exhaust system

The exhaust part of the car also plays an important role in creating the required pressure in the engine cylinders. If this pressure difference between the inlet and outlet is disturbed, the engine thrust may noticeably decrease. In this case, check whether the exhaust system is dirty: the pipes must be removed and inspected. Pay special attention to the exhaust pipe. If there are any holes in it, it will lose its seal and become unusable.

If there are any extra holes or damage in the resonator, pipes or muffler, they must be replaced without fail.

Elimination methods

To correctly find the problem and fix it, the motorist should have knowledge of the design of the engine and its systems, as well as have the tools. A very indispensable element is time and hands growing from the right place. So, now you can begin to analyze the processes aimed at troubleshooting the problem.

Sensors and ECU

Many car repair mechanics recommend checking the software and meters, of which there are quite a lot in modern cars, before getting into the mechanical part.

So, first you should connect to the electronic engine control unit and carry out diagnostics using special software. The vehicle owner will need a USB-car cable, called K-line or OBD II, a tablet and the appropriate software.

After connecting and identifying the automotive equipment, it is worth carrying out diagnostic operations. If a software failure is detected, it must be removed and the system restored to functionality.

Also, the diagnostics will show which of the sensors has lost its functionality.

Which sensors are responsible for the normal operation of the engine, and their failure can lead to tripling of the power unit:

- Idle speed regulator. If this meter fails, then the engine will run cold. In this case, the engine will not only stall, but also have difficulty starting.

- Mass air flow sensor. Quite an expensive part in any car. Often, it does not fail, but the measuring grid becomes clogged. To restore operation, you need to clean the mesh.

- Crankshaft position sensor. It measures the number of engine revolutions, thereby regulating the supply of the amount of fuel mixture.

- The coolant temperature sensor affects the operation of the system indirectly, but can affect and create artificial tripping.

Fuel and its supply components

An integral element in the formation of the air-fuel mixture is fuel. So, not enough of it leads to the formation of a lean mixture, but too much of it leads to a rich mixture, which can flood the system.

The first thing you need to start diagnosing is the pump and filter. Clogged elements can lead to insufficient fuel reaching the injectors. The gasoline pump is located under the rear sofa, where it is quite easy to reach, but the filter element is mounted on the bottom behind the right rear wheel.

An injector is a fuel element that sprays fuel. The clogging of this unit affects the amount of fuel injected into the combustion chambers. Therefore, it is necessary to carry out diagnostics quite often. This is done using a special stand. If necessary, it is worth replacing the elements.

Air

Air supply elements are quite important because they directly affect the formation of the air-fuel mixture. So, a clogged throttle valve or its jamming will cause the car to suffocate, which will lead to the effect of tripping or it will stall. To clean this unit, it is necessary to dismantle the entire throttle valve. The part is cleaned using carburetor cleaning fluid.

An important element is the air filter. If it has not been changed for a long time or it is clogged ahead of time, then a tripping effect may be created. To eliminate the malfunction, you need to replace the dirty part with a clean new element.

Sparking

The last component that is involved in the normal operation of the engine is the spark generator. This unit includes: spark plugs and high-voltage wires.

Often, due to improper operation of the injection system, the spark plugs will either burn out or be flooded with gasoline, which makes it impossible to ignite the fuel normally, since there is no space between the contacts.

To diagnose and fix the problem, you need to unscrew the elements. To do this, remove the tips of the high-voltage wires from the spark plugs. And then, using a spark plug wrench, unscrew the elements. So, by examining each candle you can determine what condition it is in.

If there is no spark plug tester to check the spark, then you should turn to the “old-fashioned” method and do it by car.

With high-voltage wires everything is simpler. They should be removed from the engine compartment. To do this, disconnect the tips from the spark plugs, and then from the ignition coil. The elements are checked using a multimeter. On the tester you need to set a resistance “measurement” and measure each wire. The indicator should be around 5 ohm. If the deviation is too large, the wire must be replaced.

Messages 17

1 Topic by Tehnix04 2014-01-28 18:01:47

- Tehnix04

- User

- Offline

- Registered: 2009-04-08

- Messages: 44

- Reputation: [ 0 | 0 ]

Topic: Poor momentum

The car is 21083, 2002, injector, when accelerating it is very blunt (as if an anchor is being dropped when you press the gas pedal), the revolutions float, especially when stopping at a traffic light, the idle drops almost to zero, then to the set 800 and back, after a while it stabilizes! The candles are white! At the moment, another working one has been replaced or installed: ignition module, spark plugs, air flow sensor, fuel pump, fuel filter and air filter. Please help, I’ve been suffering for a month!

2 Reply from hamlet 2014-01-28 20:28:34

- hamlet

- User

- Offline

- Registered: 2008-11-20

- Messages: 1,503

- Reputation: [ 14 | 0 ]

Re: Poor acceleration

As I understand it, the mixture is lean. Have you checked the air leaks? Spray a little spray on likely places, if the speed changes, then look for a hole. P.S. the program could not grunt?

3 Reply from Tehnix04 2014-01-29 07:12:26

- Tehnix04

- User

- Offline

- Registered: 2009-04-08

- Messages: 44

- Reputation: [ 0 | 0 ]

Re: Poor acceleration

As I understand it, the mixture is lean. Have you checked the air leaks? Spray a little spray on likely places, if the speed changes, then look for a hole. P.S. the program could not grunt?

Actually, it happened suddenly, I was driving - I stopped - after a couple of hours I started it - I couldn’t drive anymore! What possible places for suction can you tell me?

4 Reply from hamlet 2014-01-29 08:18:32

- hamlet

- User

- Offline

- Registered: 2008-11-20

- Messages: 1,503

- Reputation: [ 14 | 0 ]

Re: Poor acceleration

First, we exclude the vacuum seal: with the car running and idling, we sharply press the brake pedal several times: if the speed rises sharply and then drops almost to zero, then we look for a hole in the hose, and if it drops sharply, then the vacuum seal membrane is leaky. Possibly leaking from the hose fitting. If the changes in the boots are insignificant, then the vacuum is working properly. Has the suction sound changed? Look at the 2 fittings on the receiver (one, in my opinion, goes with a hose to the RTD, and the other to the adsorber). Pinch these hoses with pliers: when the speed jumps, you’ve found it.

HP-shku for receiver joints, hoses, etc. etc., while monitoring changes. maybe this will happen. There were cracks in the corrugation and breathers. If I remember again, I’ll write

Analysis of the causes of poor engine traction and possible repairs

Fuel filter dirty

This may be due to low-quality gasoline (containing various small debris) or infrequent cleaning of the fuel tank. In this case, you will have to completely replace the entire filter system.

Fuel pump diaphragm clogged

The cause of the blockage, as a rule, is low-quality gasoline. To clean it, just remove the diaphragm and rinse it thoroughly or blow it with air.

Malfunction of the sensor that controls air flow

This is the most common reason why the VAZ 2114 does not work.

- Engine idle speed is too high or low;

- intermittent engine idling;

- disturbed acceleration dynamics. The car becomes uncontrollable and often freezes.

It is worth periodically checking the operating condition of the air flow meter to avoid wasting time and money diagnosing the engine.

Air filter dust

The more the filter is clogged with dust, the less air flows to the engine, therefore, the thrust decreases. What can be done in this case? Ideally, the filter should be replaced with a new one, but if this is not possible, you should remove the filter, tap and blow to remove large debris (flies, dry leaves, insects).

conclusions

Maintenance, which should be carried out according to the manufacturer’s recommendations, will avoid many problems. The only question is where to go, at the “Kulibins”, or at specialized service stations equipped with the necessary equipment and equipment. The choice is up to the vehicle owner. The sooner the prerequisites for the failure of a particular part are identified, the less financial losses there will be in the future . It should be remembered that timely maintenance increases the safe operation of the vehicle.

vote

Article rating

The injection engine does not pull

Why does the car not pull if the injection systems are equipped with feedback and can self-regulate in a “closed loop”? Unfortunately, the possibilities for self-regulation are not as wide as we would like.

The first enemy of injection systems is insufficient fuel pressure. When fuel consumption is minimal, the correction margin is sufficient for idling. But as soon as you put a load on the engine, the correction will jump to the maximum threshold, but the injectors will still be “underfilled”.

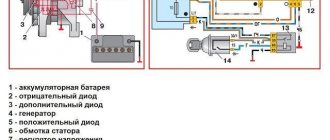

The pressure in the fuel rail is set by three components: the fuel pump itself, the pressure regulator and a set of filters (coarse and fine). The performance of a working fuel pump is several times greater than the engine needs at maximum flow rate - this is done so that pump wear affects the engine’s operation as little as possible. That’s why a fuel pressure regulator is used, which dumps “excess” fuel either immediately at the pump outlet or from the fuel rail after the fine filter.

In the first case, the fuel rail is called drainless (16-valve VAZ engines, modern foreign cars), in the second - drain. The difference between these systems is the location of the regulator and its operation. On drain ramps, pressure regulators are controlled by the vacuum in the intake manifold; the pressure in the ramp changes depending on the load (at 3 bar, normal for a VAZ, at idle it is 2.3-2.4 bar, take this into account when diagnosing!). On drainless ones, the pressure is maintained constant relative to the atmosphere and is 3.5-4 bar, depending on the car model. An exception is direct injection systems, where the operating pressure ranges from 20 to 70 bar.

Something else useful for you:

The resistance of fuel filters has no effect when measuring fuel pressure “in the plug” (the pump is forcibly turned on with the engine off, when there is no fuel flow in the ramp) and minimally at idle. But under load, an excessive increase in filter resistance reduces the fuel supply to the rail, which will lead to a loss of speed. Therefore, measure the pressure at idle and under load (for example, by hanging the drive axle and braking the wheels in gear). In cases where the idle speed is normal, and problems occur while driving, measuring the pressure only at idle speed (idle) is pointless.

Exception stages during verification:

- Remove the coarse filter (“mesh” at the inlet). This is a known problem for a number of cars - for example, on the second generation Focus.

- Replace the fine filter.

- Measure pressure under load.

- On engines with a drain ramp, clamp or otherwise plug the return line to eliminate the influence of the fuel pressure regulator. On engines with a drainless ramp, the RTD is installed in the fuel pump module; here it is easier to temporarily install a plug washer made of polyethylene or other material under it that is not destroyed by gasoline.

- Measure the pressure again: if it has increased, then the RTD needs to be replaced, otherwise the pump needs to be replaced.

The second reason for “underfilling” is clogged nozzles. Even with normal filter operation, the formation of deposits on the nozzles is inevitable over time. At home, you can only evaluate the shape of the spray pattern by removing the ramp and cranking the engine with the starter (Attention! This procedure is a fire hazard!). A clean nozzle should “dust” evenly, and not produce separate streams or pour to the side. You can evaluate the performance of injectors and compare it with the nominal one only on a bench.

Loss of dynamics is also a consequence of excessively enriched mixture. The fuel pressure regulator cannot be blamed here (the performance of the pump, even when operating without an RTD, is not so high that the correction margin of the injection computer does not cover the enrichment). It is much more likely that the injectors are leaking (again, checked on a bench) or the failure of the sensors that are used to calculate the injection time.

Here the undisputed leader is the mass air flow sensor - an accurate but sensitive device. As the air flow sensor gets dirty and ages, the readings become higher and the car begins to consume significantly more fuel. As a result, the over-enrichment of the mixture can no longer be corrected by the lambda probe. But such a malfunction is immediately visible: the car will begin to smoke, the spark plugs will be covered with black soot. On engines with an absolute pressure sensor, failure of the air temperature sensor is more likely (here it is a separate unit, while in the mass air flow sensor it is built-in).

On cars with an electronic throttle, it is worth checking the operation of the servo drive by removing the pipe from the throttle and allowing it to release gas. The throttle should open evenly, without pauses or wedging, indicating problems with the drive gearbox or critical contamination of the damper (the axle, overgrown with carbon deposits, becomes wedged in the housing).

Malfunctions of the power supply system, ignition and impaired mixture formation

While problems with spark plugs and filters can be identified on the road, more serious problems associated with the power and ignition system are much more difficult to diagnose and fix on site. In cases where the engine does not pick up speed, and jerks and dips are noted when pressing the gas pedal, it is necessary to check and adjust the carburetor or injector.

Let's focus on the more common electronic injection. The list of main malfunctions of modern injection internal combustion engines includes:

- malfunctions, decreased performance or contamination of the fuel pump mesh filter;

- malfunction of injection nozzles;

- problems with ECM or ECU sensors;

- ignition system malfunctions;

- air leaks and leaking fuel lines;

Often, on many cars, problems are associated with the fuel pump, which is located in the gas tank, as well as with the specified regulator. To measure fuel pressure, a pressure gauge is connected to the rail; the obtained values are compared with those recommended for a particular engine. If the pressure is below normal, then the culprit may be either the fuel pump or the pressure regulator.

The regulator's task is to discharge excess fuel into the return line at a time when the pressure is higher than normal. If the settings are incorrect or the regulator itself is leaking or faulty, then the fuel will be discharged into the return line ahead of time. To check this, air is pumped in with a compressor or pump, and the pressure in the rail increases. If the regulator operates earlier than the recommended pressure, the element must be adjusted or replaced.

If the gas pump does not pump gasoline or the required pressure is not created, it is necessary to remove the device from the tank, clean or replace the mesh on the pump. If the situation does not change, then the pump is faulty and needs to be repaired/replaced.

As for injection nozzles, these elements must not only open and close in a timely manner, but also supply fuel to the cylinders in full. The shape of the spray pattern is also important. For this reason, the injectors must be checked and cleaned regularly to ensure that the fuel is sprayed evenly.

- ECM sensors (mass air flow sensor, air pressure sensor, etc.) send a signal to the ECU, thanks to which the controller takes into account how much air the engine consumes. Based on these data, the unit determines how much fuel needs to be supplied through the injectors to form the required fuel-air mixture, taking into account a particular operating mode of the internal combustion engine.

If the sensors do not work correctly, the ECU may supply the wrong amount of fuel. As a result, the engine does not pull and the car does not drive as it should. You can use a multimeter to check the sensors, but the best way is to conduct computer diagnostics of the engine.