Hi all! While rolling back the firmware, I felt the heaviness of the steering wheel and the sound of the tidy alarm, stopped, even without the slightest surprise, pulled out the belt and headed towards the garage. Three videos were already waiting for me in the garage. I've been waiting for this moment since I bought Patrick, and at 11,000 km I waited until the upper guide roller came up.

I put lubricants into the preserved rollers and put them in the spare parts.

Before the long-awaited replacement, I had to get acquainted with another key device of Patrick - the Viscous Coupling. Despite the censorship, I’ll tell you how the acquaintance went: this bastard didn’t want to get away with anything. I watched enough videos, read a lot of manuals, sharpened the key, put on a belt and tried to hold the pulley with it, tried to fix it with a screwdriver, but the temple clearly did not want to leave its place of residence. In general, for a long time I was haunted by the thought of the need for this unit in Patrick, you know, I was somehow fed up with the sound of a helicopter taking off (and I like revving the engine up to 6 thousand, yes) and the long warm-ups in the morning. So, such dissatisfaction and thoughts about such a wonderful removal pushed me to rid Patrick of this detail. What was done: - since I couldn’t unscrew the temple from the pulley, I removed it together with the front cover

-Bought a used cover from the 406th at a disassembly site - 500 rubles -Bought a Bosch belt 1 987 947 820 - 561 rubles

-Changed all three rollers to INA 531 0759 10 and 531 0760 10 (I bought them almost a year and a half ago - Total 1300 RUR)

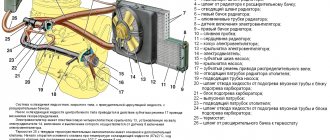

Starting... and silence! I didn't think Patrick could work so quietly! I went to work and stood in traffic for an hour. The standard one fan was set to 92 on 89 off. Of course, it is small, it turns on often, but in winter at minus -6 it is basically enough. I have come up with a plan to compensate for the fans under the hood: I use the second output from the ECU for a pair of standard fans mounted behind the radiator. I will leave the fan that is now in front of the radiator for air conditioning/reserve at critical temperatures. The firmware will allow me to configure these things easily. So far the idea has settled on buying two propellers (regular UAZ ones, only two), installation is coming soon. Let's see how they cope, I think it will be no worse than whiskey in the summer.

I had the idea of removing it for a long time, mostly interestingly described about the viscous coupling HERE

I will describe the pros and cons from the link: Disadvantages of viscous coupling

-Unstability of engine temperature, which varies depending on crankshaft speed.

- Engine load. -Difficult access to rollers and belts. -There is no possibility of forcing the engine cooling fan on. -Inconstant fan speed. It is possible that the fan blades may come off, which could result in a hole in the radiator. As a result, it becomes necessary to replace the radiator and install a new fan. On my own behalf I will add: -Constant NOISE, increasing with speed.

You go to overtake and it feels like two wings are about to come out from the sides and you can take off. There is also a high load on the front cover, which is held on by four screws and two bolts. On my Volga and with a regular lid, these screws unscrew, but here there is such an oscillatory load. Well, many write that the valve cover leak is connected precisely with this - Inconvenience during repairs - the viscous coupling fan and diffuser take up too much space - Plus, I’m not sure that it allowed the engine to fully warm up, and hence increased consumption and reduced service life Well, now what’s left after modernization:

The cooling system of the UAZ Patriot engine contains an element called a “viscous coupling” or, as it is sometimes called, a “fluid coupling” - on which the fan is located. It is necessary to protect against overheating and is activated only when the engine temperature begins to exceed operating limits.

The viscous coupling on the UAZ Patriot is designed in such a way that it is connected to the engine crankshaft not directly, but through special disks, between which there is a working fluid. When starting a cold engine, the viscous coupling spins at a very low speed, much less than the number of engine revolutions.

Then, as the engine warms up, the metal plate in front of the viscous coupling heats up from the radiator and bends outward, which releases a special ball that closes the hole in the inner disk. It turns out that the working fluid has nowhere else to go and remains between the disks.

How to remove a fan pulley on a ZMZ 409

To cool the radiator, a fan is used, driven from the engine crankshaft through a special clutch.

Under prolonged loads and elevated air temperatures, the performance of the impeller is not enough to remove heat. Find out how to install an electric fan on a UAZ Patriot instead of a viscous coupling.

Installing an electric fan on the UAZ Patriot instead of a viscous coupling allows you to increase the air flow drawn through the radiator honeycombs and improve the temperature parameters of the power unit under conditions of increased load.

Advantages of an electric fan instead of a viscous coupling

Use an electric fan instead of a viscous coupling.

Advantages of using an electric drive for the radiator cooling impeller instead of a viscous coupling:

- ensuring the specified engine temperature regardless of the crankshaft speed;

- stable cooling of the power unit when idling (without moving or when moving at low speed);

- it is possible to force the electric motor to turn on using a toggle switch located in the car interior;

- It is allowed to install 2 fans (to increase the reliability of the design and improve airflow to the radiator).

The essence of the problem

The viscous coupling is a sealed housing filled with a viscous silicone-based working fluid. Inside the casing there are 2 disks with guide vanes; torque is transmitted by oil flows.

The characteristics of the liquid allow you to smoothly regulate the rotation speed of the output shaft and the fan impeller installed on it. The design ensures that the thermal regime of the motor is maintained at medium and high speeds.

When the engine speed drops to idle mode, the intensity of mixing of the working fluid in the clutch body decreases, which causes a decrease in the fan speed. A drop in air flow speed causes the radiator and engine jacket to overheat. The problem occurs when driving in long traffic jams or when driving on rough or swampy terrain at low speed.

An additional concern is the safety of the structure. In the center of the coupling there is a bimetallic plate that controls the bypass valve.

When the element is cooled (by the air flow from the radiator), the impeller rotates at low speed.

As the element warms up, the valve closes, and then the impeller accelerates sharply. At this point, there is a risk of injury to the driver servicing the engine. There have been cases of plastic impeller rupture (due to previous damage).

"Black box" - viscous coupling, operating principle

Years passed. One truck replaced another. Everything was spinning and did not create any problems. However, at certain moments I began to notice that the engine of my MAN began to get really hot in hot weather. There seemed to be no reason to blame the thermostat or a clogged radiator. Engine overheating began only during hot climbs, when the speed of the oncoming flow of oncoming air noticeably decreased. It became increasingly clear that the problem lay in the viscous coupling. I began to compare its rotation on a cold and warm engine. There seems to be no difference - in both cases it scrolls quite tightly. I asked all my friends who understand anything about these matters about the structure of the viscous coupling and the principle of operation, and contacted technical centers. There were a variety of opinions, but, as it turned out, no one really knows a damn thing.

How is the viscous coupling of the fan arranged?

The most likely version seemed to be that inside the viscous coupling there is a certain disk, which, under certain conditions, engages with the internal cavity of the coupling, causing it to rotate without slipping. Something like a clutch with friction clutches, but controlled by a temperature sensor. In general, after pushing around and consulting with the drivers, I decided to block it. One of the guys on the radio said that there should be some kind of bolt on its body with which this can be done. Stripped off. Looked around. No bolts. There is a spiral spring on the front cover, reminiscent of the bimetallic spiral in a window thermometer. Obviously, it is somehow connected with the viscous coupling activation mechanism. Not finding any hints of forced blocking, I decided that since such a thing still doesn’t work, then there’s nothing to feel sorry for: I’ll drill a couple of through holes, insert bolts there and fix it. So I did. The body was drilled in two places. The supposed disk was clearly visible in the resulting holes. Having inserted and tightened the bolts, I installed the viscous coupling with the fan in place. Started the engine. The blocked fan began pumping air through the radiator with a characteristic hum. Well, I think at least this way. Better than "frying" the engine. But my blocking did not last long. After about 600 km, the bolts flew out with a roar, mercilessly cut off by a disk dangling in the viscous coupling. At the same time, fragments of the disk became jammed inside the case, tearing it into pieces. With enormous force, pieces of aluminum, ricocheting from obstacles encountered along the way, broke the fan blades, the plastic diffuser, and damaged the radiator. Moreover, some sticky liquid, similar to oil, leaked out of the viscous coupling, creasing the entire engine. It turns out that this is the very working element that transmits the rotational force from the engine to the fan. I didn’t expect such a situation! Having somehow reached my home site, I again set about repairs. As they say, a bad head gives no rest to your feet. Igor, a neighbor in the parking lot, said that he had encountered similar problems. (Where were you before!?). On his Mercedes, there is a special hole in the viscous coupling for filling with working fluid. At one time, not having a syringe at hand, he filled the viscous coupling for several days - “by gravity.” The funny thing is that the liquid is very thick. So, having placed a viscous coupling near the machine and built a miniature funnel, Igor announced that everyone who passed by should add a few drops to the funnel. That's how it was done. During disassembly, I found a viscous coupling-radiator fan assembly exactly the same as mine. Outwardly, everything seems to be working, but with intense cranking, the viscosity during rotation is clearly not enough. On the advice of the “wisest”, I bought a special silicone oil with a huge viscosity for refilling these viscous couplings and a hefty disposable syringe at the pharmacy.

Viscous cooling fan coupling: where it is located and how it works

The fan rotation speed changes smoothly, steplessly; a fan with a viscous coupling never turns on and off instantly

In all-wheel drive transmissions of passenger vehicles with a longitudinal engine position, a standard viscous coupling performs the functions of an ersatz differential or a special locking element that complements a conventional differential. However, from a design point of view, the device is represented by a plurality of round driving and driven plate elements with projections and holes, which are located inside a completely waterproof housing filled with dilatant liquid.

The fan rotation speed depends on the heating of the engine: the more the viscous coupling is heated, the more the inlet channel opens, and the more liquid enters the working chamber.

In the absence or insignificant volume of automobile oil inside the working chamber, free rotation of the drive disk is observed. Only in the process of gradual warming up of the engine and increasing the temperature of the antifreeze does the bimetallic plate heat up and expand, which causes the opening of the intake valve system, penetration of the working fluid into the chamber and an increase in the speed of rotational movements of the ventilating impeller. As the adhesion coefficient decreases, the difference in the rotational speed of the housing and the viscous coupling drive shaft increases noticeably, which slows down the operation of the fan impeller.

How to check a viscous coupling (using the example of UAZ Patriot)

The engine cooling system of the UAZ Patriot is equipped with a standard viscous coupling with a fan. This device provides reliable protection against overheating by turning on when the engine temperature goes beyond the established operating parameters. The viscous coupling does not have a rigid connection to the crankshaft, and starting a cold engine causes it to rotate at low speed.

It is very difficult to independently diagnose a breakdown of a viscous coupling in normal mode, but there are several ways to easily verify the functionality of such a device. To check the viscous coupling of the UAZ Patriot cooling fan, you should take a closer look at the speed of the mechanism when the engine is turned on, cold and warm.

Removing the viscous coupling

The sequence of actions when removing the viscous coupling from the ZMZ-409 gasoline power unit installed on a UAZ Patriot:

- Remove the guide diffuser located around the impeller. To secure the assembly, spacer clips are used, which are removed with the tip of a flat-head screwdriver. The deflector housing is removed upwards from the gap between the engine and radiator.

- To remove the impeller you will need a 32 mm wrench. It is possible to use a standard spanner or socket. Since the nut has a left-hand thread (to increase safety during operation), the tool rotates to the right (when viewed from the radiator of the car). To prevent the clutch from spinning, you need to press the poly V-belt by hand (into the gap between the clutch pulley and the drive wheel of the hydraulic power steering pump).

- Unscrew the impeller using a wrench or manually. Since the element is heavy, it is important not to drop the part into the gap between the engine and the radiator. If dropped, the radiator tubes may be damaged by the sharp blades of the impeller.

- It is possible to remove the coupling together with the front cover of the ZMZ-409 engine, which is attached to the front of the block and the head cover with 6 bolts. Instead of a standard part, an aluminum panel from the ZMZ-406 engine is installed, which is distinguished by the absence of fastening points for the viscous coupling. During installation, it is necessary to replace the gaskets and wipe the mating surfaces from any remaining engine oil. The bolts are tightened in the sequence specified in the power unit repair instructions.

About the electric fan

The electric fan covers all the disadvantages that the viscous coupling had. After installing it, it will be difficult not to notice the following improvements:

From the factory, on a UAZ Patriot with air conditioning, a so-called “sparka” is installed in front of the air conditioner radiator (on the street side) - two electric fans in a plastic case. But they have little effect on the main radiator, and besides, they make a lot of noise. Therefore, if you have already decided to install electric fans instead of a viscous coupling, you can safely remove them.

Installation process

To install an electric fan, it is not at all necessary to visit a service center; everything can be done independently at home. First of all, it is necessary to select or manufacture a base for electric fans (frame or “screen”) that matches the size of the engine cooling radiator.

Pros and cons of viscous coupling

Let's start with the disadvantages, because it is because of them that owners prefer to install electric fans on the UAZ Patriot instead of a viscous coupling. And the most significant disadvantage, perhaps, is poor engine airflow at low speeds - for example, in traffic jams or when driving over rough terrain at low speed. After all, the efficiency of a viscous coupling directly depends on these very revolutions.

Besides this, there are other disadvantages:

- Additional load on the engine. The viscous coupling takes away part of the engine power, this is especially noticeable when overtaking on the highway, when the operating speed is almost in the red zone of the tachometer. Acoustic comfort also suffers - a characteristic noise and howl appears.

- There is no way to force the fan to turn on at full power, for example, in the same traffic jams.

- The clutch makes it difficult to access the idler rollers and drive belts, which significantly complicates and increases the time spent on repairs.

- There is a danger of fan blades coming off at high speeds, as well as the risk of damage to the main radiator from flying fan fragments, which may require expensive repairs with a complete replacement of antifreeze/antifreeze. Now imagine that this could happen on the highway, somewhere far from home.

- Cannot be repaired. The faulty clutch is replaced with a new one, although you can try drilling a few holes and fixing it with bolts so that it always rotates. But this repair method is only suitable for summer; in winter, the engine will take a very long time to warm up.

- A simple and fairly reliable design that can work for years without any maintenance.

- It is installed on the UAZ Patriot from the factory, so you will not have to modify anything if it is replaced.

- Does not create a load on the electrical part of the car.

As you can see, the viscous coupling has more disadvantages, so many Patriot owners eventually come to the idea of replacing it with electric fans.

DIY troubleshooting

Standard disassembly of a viscous coupling involves removing the device, dismantling the impeller, unscrewing a pair of mounting pins, draining the working fluid, thoroughly washing the inside with gasoline and drying it. After filling with new PMS-10000 silicone oil, the device is mounted back.

To troubleshoot a viscous coupling or replace it, you must first remove the device:

- Remove the fan casing by removing the pins and spacer clips.

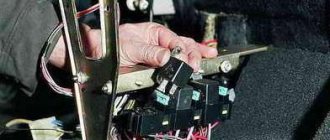

To make the key fit, its ends can be sharpened with a grinder

You need to press the belt between the temple pulley and the power steering pulley

Insert the key from above between the two blades

If the cause of incorrect operation of the viscous coupling is a leak of silicone liquid from the base, then the following actions are performed:

If there is a variety of unusual noise in the cooling radiator, the bearing will need to be replaced. For this purpose, it is necessary to drain the oil and disassemble the assembly using a special puller. After installing the new bearing, the device is mounted in the reverse order, after which new silicone fluid is poured.

A special automotive device - a viscous coupling that rotates the cooling fan using liquid - quite often fails. It is possible to fix only the simplest breakdowns on your own, so in the most difficult cases you need to contact a service center with auto mechanics who specialize in working with these types of devices.

How to remove viscous coupling

Usually, the viscous coupling from a UAZ Patriot car is not difficult to remove, although if the device has not been removed for a long time and the bolts have become sour, a hammer may be needed. So, the sequence of actions is as follows:

- First, remove the fan casing (diffuser). Using a small flat head screwdriver, remove the spacer clip pins located on the top of the diffuser and remove the clips. After this, the casing is removed from the engine compartment through the top.

The nut securing the fan to the pump hub is unscrewed. Here you can’t do without a 32 open-end wrench. Attention, the nut has a left-hand thread, that is, you need to unscrew it to the right (if you look at the front of the car).- Be sure to secure the drive belt by pressing it with your hand in the gap between the temple pulley and the power steering pulley. Otherwise, you will not be able to unscrew the nut. If even after this the nut does not unscrew, try to break it off with sharp blows on the wrench with a hammer.

- Unscrew the nut a little and, holding it with a wrench, rotate the fan impeller to dismantle it. Keep in mind that the fan weighs a lot, so do everything carefully.

- Remove the fan and remove the viscous coupling by unscrewing the four mounting bolts around the perimeter.

Electric Fan Installation

Replacing viscous couplings with electric fans begins with purchasing or making your own metal support frame for electric motors, which is then placed on the inside of the radiator.

On some vehicles equipped with an air conditioning system, an additional air conditioning heat exchanger with electric fans (installed on the outside of the radiator) is used. It is not recommended to remove the elements as they are controlled by the air conditioning controller to keep the air inside the vehicle cool.

For cooling, 2 fans from the Gazelle or from the “classic” VAZ models are used. When purchasing an impeller, you should consider the direction of air flow created by the blades. Additionally, it is necessary to replace the sensor in the thermostat housing, which activates the operation of the electric motors.

There are several types of sensors that are triggered at a liquid temperature of +87...+97°C. An additional toggle switch for manually turning on the engines is located in the car interior (on the dashboard or center console between the seats).

It is allowed to use fan units from Nissan X-Trail SUVs, which are equipped with a 4-channel patch cable. The devices are connected to the power unit control controller and to a temperature sensor (with a response threshold increased to +95...+97°C).

Installing an electric fan is very simple.

The signal from the control unit turns on the impellers with an operating capacity of 40% of the maximum value. With a further increase in temperature, a sensor located in the thermostat housing is triggered, allowing the fans to be switched to maximum air supply.

There have been cases of using a fan from Hover (catalog number 1308100K00V1), which is equipped with additional resistance to obtain 2 speeds of rotation of the impeller. The product is supplied with a plastic frame, which is installed on the UAZ Patriot radiator with minor modifications.

Before installation, you will need to cut down 2 support brackets, which are placed on the lower edge of the plastic diffuser. For mounting, standard holes on the radiator are used, intended for installing the original guide casing.

Features of refilling the ZMZ-409 cooling system. Viscous coupling repair.

Coolant is drained from the ZMZ-409 engine cooling system to replace it or flush the system through two taps or plugs. One of them is located on the lower radiator tank, the other on the left of the cylinder block. When draining, the lever or handle for controlling the interior heater tap must be set to the “open” position.

Features of refilling the ZMZ-409 cooling system. Viscous coupling repair.

Due to air entering the UAZ Hunter cabin heater and connecting hoses after draining the coolant, it is impossible to fill the full amount without starting the ZMZ-409 engine. Therefore, refilling the engine cooling system is carried out in the following order:

— close the coolant drain taps (plugs). — set the lever or handle for controlling the interior heater valve to the “open” position. — fill the radiator 10-15 mm with coolant. below the neck and the expansion tank is 3-4 centimeters above the “Min” mark. — start the engine, after reducing the liquid level in the upper radiator tank, add coolant to it and close the radiator cap. — turn off the engine, let it cool, bring the coolant level in the expansion tank to normal and close the expansion tank cap. — perform 2-3 cycles of warming up and cooling the engine and again bring the coolant level in the expansion tank to normal.

Installing an electric fan on a UAZ Bukhanka

The clutch allows you to reduce fuel consumption, reduce fan noise, and promotes better warm-up of a cold engine.

The viscous clutch is removed if it malfunctions, if the clutch does not turn on or does not turn on completely.

You will need a 32 key.

View of the viscous coupling assembled with the fan

To make it easier to unscrew the coupling, unscrew one pin

Unscrew the coupling shaft from the fan drive hub

Please note that the connection between the coupling and the hub has a left-hand thread

Remove the viscous coupling assembly with the fan

Unscrew the four nuts securing the fan to the coupling

Remove the fan from the coupling

Install the fan and clutch in reverse order

UAZ Patriot - viscous coupling replacement

In the UAZ Patriot there is an element called a “viscous coupling” or, as it is sometimes called, a “fluid coupling” - on which the fan is located. It is needed to protect against overheating and is activated only in this case, when the motor temperature begins to go beyond the operating limits.

The viscous coupling on the UAZ Patriot is designed in such a way that it is connected to the engine crankshaft not directly, but through special disks, between which there is a working fluid. When starting a cool engine, the viscous coupling rotates at a very low speed, even lower than the number of engine revolutions.

Then, as the engine warms up, the iron plate in the front part of the viscous coupling heats up from the radiator and bends outward, which releases a special ball that closes the hole in the inner disk. It turns out that the working water has nowhere else to go and remains between the disks.

Replacing an electric fan — UAZ Patriot

Replaced the air conditioner fan today. They work in "spark" But the replacement backfired.

First, remove the radiator grille.

Remove the plastic from the radiator and unscrew the air conditioner radiator.

Unscrew the fan. Three large screws.

Unscrew the top radiator mount.

Unscrew and remove the air filter and use a stick to press out both radiators. The most important thing is not to crush anything.

It was not possible to squeeze this pie much; the air conditioner line was in the way.

We put our hand between the pies and try to unscrew the nut that holds the fan blades. I've been fiddling with this problem for a long time)))) Next, unscrew the oil cooler (if you have one)

And we take out the motor.

Why did I bother to change the motor: I had suspicions that the bearing was broken. the blades were shaking a lot. And that was the reason. Old motor.

The cotter pin was simply bent. Old impeller, view from the back.

Then we assemble everything in reverse order.

And now the results: The new engine turned out to be complete shit. There is no balance on the impeller itself, strong vibration in the cabin. It’s good that this motor works in pick-up mode and turns on extremely rarely.

Apparently we will have to revive the old engine.

| HALK # May 12, 2022 at 10:42 am 0 |

| Local # May 12, 2022 at 7:47 pm 0 |

| Local # May 21, 2022 at 2:16 pm +1 |

| I repaired the old one, there was no vibration. To begin with, I found a nail of the required diameter at the dacha, even a little smaller. And cut it to the required length. Then I just glued it to the motor Then I took everything apart and assembled it as I wrote above. Vibration and other imbalances. as it was not. Now everything is smooth |

Service

Maintenance of power units of all types for the “Loaf” is given in the same way. All these engines were developed on the basis of the legendary ZMZ 402, and therefore the maintenance for them is approximately the same.

For representatives of UMZ 417 and 421, engine maintenance is carried out almost similarly. Thus, scheduled maintenance is carried out every 15,000 km. Maintenance includes changing the oil and filter. To change the oil, you will have to unscrew the drain plug and wait for the lubricant to drain. Then, the plug is screwed in and oil is poured through the filler neck. The oil filter is changed when there is no oil in the engine.

Maintenance also includes checking all systems for oil leaks and malfunctions. Every 30,000 km the valves must be adjusted, and every 20,000 km the air filter element must be replaced.

The essence of the problem

Let's start with the fact that the engineer of the Ulyanovsk Automobile Plant equips UAZ Patriot SUVs with radiator cooling fans, which are driven by a viscous coupling.

A viscous coupling is a mechanism presented in the form of two flat disks. Viscous coupling allows you to transmit torque using a special silicone-based fluid.

The operating principle consists of several plates mounted on the driven and drive shafts. They rotate in a container with liquid, which changes its properties when heated. When the liquid is mixed while the drive shaft rotates, it changes its properties (expands) and thereby creates pressure in the chamber. As a result, the disks of the driven shaft engage, causing it to move.

But personally, I do not support the idea of replacing the viscous coupling with an electric fan

A viscous coupling is needed in a UAZ. It always spins and provides some kind of cooling. Would you say that it consumes too much horsepower for its low efficiency? Well, okay, but it is absolutely energy independent. The fuse will not blow in it, the wiring will not fray. It just exists and is always spinning.

My thesis is simple, there should be a viscous coupling, and an additional electric fan should help it

I didn’t think much about a technical solution. On the first Patriot, an additional electric fan was installed from the factory. Its radiator is the same, it matches the Bukhanochka absolutely. You just need to take the Patriot Carlson, buy it and install it.

Is it efficient enough?

Enough. Repeatedly tested in Altai, the Urals and Mongolia. There were times when I wanted to have not one, but two such fans, but that was a couple of times, when in July, when at exactly noon, when in the heat of the day, when on a steep mountain pass.

We begin to look for something similar to the Patriot Carlson. Here it is, my dear one, being sold on Bazashop for a little over three thousand. But without wires for switching. Some wires are sold nearby, but do they fit here? This is a UAZ, there are a thousand modifications of them!

You need to take the kit. So that the fan itself, the wires, and all sorts of tubes are there right away.

Found. Here he is, dear. A little different from purely patriotic, but the meaning is the same. I ordered it as a gift for the New Year, bought it and threw it in the garage to age. I didn't even open the box. Why put it in winter? Summer...maybe it won't come at all.

Summer came suddenly. Yesterday and the day before yesterday, weather forecasters hinted at snow, and today - hellish plus 25. The heat is unbearable, it’s scorching, it’s a thrill! We need to quickly install an additional fan.

The box, as expected, contained the propeller itself, wires for connection, a coolant temperature sensor and a tee to fit into the pipe.

Installation is simple. In my case, even very simple; The oil cooler has been plugged for a long time, hanging purely for show.

You need to unscrew the oil cooler and screw in the fan. If for some strange reason you don’t want to part with the oil cooler, you’ll have to add another stage and screw it back on.

I really didn't want to remove the radiator for this. But this was not necessary.

Let's end the idle chatter and begin the installation.

Unscrew the oil cooler. It is convenient to turn the upper bolts from above, and the lower ones (forever your KO) from below.

To rotate from below, the loaves have a tricky door. The car was designed very conveniently.

We unscrewed the oil cooler and threw it into the pile, which is waiting for a trip to the purchase of ferrous and non-ferrous metals.

Good good! You love useless oil coolers, I get it. You don’t have to throw it away, but carefully put it aside for later reinstallation on top of the electric fan, all the fasteners are provided there for this purpose.

Unscrew the corners. We throw it in the same pile as the oil cooler.

What remains is a bare radiator, on the ears of which we will mount an additional electric fan.

We run to the store and buy a handful of M8 bolts and the same nuts. The original bolts that we unscrewed are a bit short, and the manufacturer did not include normal ones in the kit. Let's write a minus into his karma for this.

Adding four bolts and four nuts to the kit is a trifle, but how nice it would be. You wouldn’t have to crawl out of the hole, look for nuts that aren’t very useful in storage, wash your hands, run to the store...

Using a hammer and an anvil, the nuts take their place in special grooves. Now they are not simple nuts, but mortgages.

In order not to break out the lower mountings of the radiator, slightly loosen the bolts. The radiator becomes a little more movable, which is required to fit the fan.

Then everything is even simpler. We screw the fan to the ears. The manufacturer says in the instructions that the fan should be installed with the wire facing down. But for the life of me, it’s impossible to stage it like that! I installed it with the wire facing up. I hope there is nothing criminal in this.

We cut the upper pipe and insert a tee for the temperature sensor.

Our motto is cut seven times and try on once. I didn’t have time to think, maybe it would be better to put the sensor in the lower pipe, since everything was already installed. I hope this will be okay too.

We connect the wiring according to the male-to-female type, so you don’t get confused. We place the relay on a conveniently protruding bolt, and throw two ground contacts there.

Actually, everything is ready. You can test the device and check its functionality. First - in a kettle with boiling water. Then - to the mountains. I hope I can get away somewhere this summer.

Congratulations to everyone on May Day! As they say, we will fan the world fire on the mountain for all the bourgeoisie!

Congratulations to everyone on the upcoming Victory Day! Clear skies above everyone! So that we don’t need to travel to Europe in tanks, but only in motorhomes built on the basis of the UAZ Bukhanka.

Key for removing viscous coupling on UAZ Patriot ZMZ 409

Key for removing viscous coupling on UAZ Patriot ZMZ 409

Post by lexmak » May 28, 2022, 02:51 pm

Any factory key for 32 with a thickness of no more than 9 mm. Found in nature.

Well, that's all.

Key for removing viscous coupling on UAZ Patriot ZMZ 409

Post by igorstrong » 06 Jun 2022, 07:30

Key for removing viscous coupling on UAZ Patriot ZMZ 409

Post by lexmak » 06 Jun 2022, 17:49