All modern cars are equipped with an electrically operated throttle valve. Instead of the usual cable. What is the difference between an electronic throttle and a mechanical one?

The electronic throttle valve is controlled by the KSUD unit (engine management system controller). The opening and closing of the valve is driven by an electric motor built into the throttle body.

How does the Lada Vesta electric throttle work at idle speed?

The electronic throttle of the Lada Vesta does not have a separate IAC (idle speed regulator), which was installed in the mechanical throttle. Idle speed in the electronic throttle is controlled by the main damper; it opens the cross-section of the throttle pipe exactly as much air as the engine needs to operate at idle speed.

The controller controls the crankshaft speed at idle speed. The actuator that meteres the incoming air into the engine is the throttle valve, the opening angle of which at idle is set by the controller depending on the temperature of the coolant, the consumers turned on (air conditioning, seat heating, fan, etc.) In addition, to maintain the idle speed, the controller controls OZ and fuel supply. It is worth remembering that when driving a car with the accelerator pedal released in 1st, 2nd or 3rd gear, the specified idle speed differs from the specified speed of a stationary vehicle and depends on the temperature of the engine coolant. The state of the engine at idle speed can be determined by the parameters of the current idling correction, (“Desired change in torque to maintain idle speed (integral part)”% and the desired change in torque to maintain idle speed (proportional part)”%) and the torque adaptation parameter (“ Idle speed adjustment adaptation parameter "%). The torque adaptation parameter is determined only on a warm engine, but is used as an additive throughout the entire temperature range of engine operation.

Refinement of a new electronic gas pedal

There are two options for modifying the pedal:

On the lever of the removed pedal module, you can saw off a protrusion 2-3 mm thick, and then the amplitude of movement of the pedal will increase, acceleration can be carried out by hitting the lever “to the floor”.

The second option with which you can modify the part is to change the internal design. For this:

- Before removing the module, start the engine, place a ruler next to the part, and measure the position of the edge of the pedal.

- Smoothly lower the lever until you hear the growl of the motor.

- Record the idle distance of the part.

- Turn off the engine, tighten the handbrake, remove the negative from the battery.

- Remove the gas module.

- Using a Phillips screwdriver, remove the cover securing screws and the cover itself.

- Using the same screwdriver, remove the rheostat slider mount and set it aside.

- Remove the board - you will see springs underneath.

- Hold the spring with a screwdriver and remove it.

- Measure the distance between the support pad and the rubber in the body, while moving the pedal to the idle value.

- Place material under the platform with a thickness equal to the distance obtained in the previous step.

- Assemble the module and install it in place.

- Perform the check - start the engine. The idle speed should remain at the same level. If this is not the case, disassemble the module and remove several layers of padding.

Electric throttle of Lada Vesta when pressing the gas sharply.

The interaction takes place between the electronic accelerator pedal, the engine control unit and the electronic throttle valve.

To reduce engine load and fuel consumption when driving. If you sharply press the gas pedal to the floor, the throttle will not open completely, as it did with a cable drive, but will open smoothly in accordance with the tachometer speed. That is, protection from fools. If you drive 40 km/h in fourth gear and press the gas pedal to the floor, the electronic throttle will not open 100% and will not put more load on the engine. Thus, the car will not accelerate, but will force the driver to switch to a lower gear.

The clutch and brake pedals have sensors that are activated when the pedals are pressed.

OWNERS' REVIEWS

Owners of LADA XRAY who independently performed the throttle valve zero adaptation procedure note that the car stopped twitching and acceleration became smooth.

Some reviews from Drive2.ru:

I don’t know about others...But it REALLY helped me!

Not long ago I got into an Xray and thought that I had forgotten how to drive a manual transmission! There were jerks with almost every shift. Yesterday I read the post and after work I spent 5 minutes on this procedure... And lo and behold, he stopped twitching! Today, driving around the city was absolutely fantastic... even the consumption dropped... but I think it’s due to the change in pedaling... So I definitely recommend doing it. It really works! This morning I did this operation and the car drove much better, especially at low speed. Why is this not done during pre-sale preparation? I’ve been suffering with this problem for half a year, but here it’s 3 minutes! I even wrote to AvtoVAZ, they sent me... to the dealer.) Now, after carrying out the above mentioned manipulations, I’m driving for the second day without twitching! In the morning I carried out these manipulations at an ambient temperature of -10 and an engine temperature of 50 degrees. The car is unrecognizable - all the twitching is gone. Acceleration became smooth, and fuel consumption seemed to drop slightly. I rode all day long.

Electronic throttle device for Lada Vesta.

The electronic throttle system uses two throttle position sensors. TPS are part of the electrically driven throttle valve.

The TPS is a potentiometric type resistor, one of the terminals of which is supplied with a reference voltage (5 V) from the controller, and the second is supplied with ground from the controller. From the pin connected to the moving contact of the potentiometer, the TPS output signal is supplied to the controller. The controller controls the position of the throttle valve electrically, in accordance with the position of the accelerator pedal. Based on the TPS readings, the controller monitors the position of the throttle valve.

Position of the Lada Vesta electronic throttle when starting the engine.

When the ignition is turned on, the controller sets the damper to the pre-start position, the degree of opening of which depends on the coolant temperature. In the pre-start position of the throttle valve, the output signal of TPS 1 should be within 0.58...0.70 V, the output signal of TPS 2 within 4.30...4.42 V. If you do not start the engine within 15 seconds and do not press the pedal accelerator, the controller de-energizes the electric throttle drive and the throttle valve is set to the 6-7% throttle opening position.

In the de-energized state (LIMPHOME) of the electric throttle valve drive, the output signal of TPS 1 is within 0.70...0.75 V, the output signal of TPS 2 is within 4.25...4.30 V. Further, if no action is taken for 15 seconds the check (“learning”) mode will begin 0 - the throttle valve position is completely closed and the throttle valve opens to the pre-start position, and then the electric throttle valve drive will again switch to de-energized mode.

At any throttle position, the sum of the TPS 1 and TPS 2 signals should be equal to (5±0.1) V. If a fault occurs in the TPS circuits, the controller de-energizes the electric throttle drive, stores its code in its memory and turns on the alarm. In this case, the throttle valve is set to the 6-7% throttle opening position.

When and how to do it yourself

When to do it

adaptation of the throttle valve zero and adaptation of the misfire diagnostic function:

- After replacing the ECU controller or resetting the controller using a scan tool.

- After replacing the throttle assembly.

Throttle zero adaptation procedure

:

- When the car is stationary, you must turn on the ignition, wait 30 seconds, turn off the ignition, wait until the main relay turns off.

Adaptation will be interrupted

, If:

- the engine turns over;

- the car is moving;

- the accelerator pedal is pressed;

- engine temperature is below 5 °C or above 100 °C;

- Ambient temperature is below 5 °C.

Adaptation procedure

Misfire diagnostic functions:

- warm up the engine to operating temperature (parameter value “Coolant temperature” = 60.90 °C);

- accelerate the car in 2nd gear until higher crankshaft speeds are reached (parameter value “Engine crankshaft speed” = 4000 min-1) and perform engine braking (“Engine crankshaft speed” = 1000 min-1);

- Perform engine braking six times in one trip.

The adaptation procedure is specified in the technological instructions (TI 3100.25100.12056) for Lada Vesta (download) and XRAY (download).

How to adapt and train the electronic throttle of Lada Vesta.

If the electronic throttle body or ECM is replaced, or the controller is reset using the scan tool (Function Test; ECU Reset with Initialization mode), the Throttle Zero Adaptation procedure must be performed.

To do this, with the car standing, you need to turn on the ignition, wait 30 seconds, turn off the ignition, and wait until the main relay turns off.

Adaptation will be interrupted if:

- the engine turns over;

- the car is moving;

- the accelerator pedal is pressed;

- engine temperature is below 5 °C or above 100 °C;

- Ambient temperature is below 5 °C.

If the electric throttle actuator is de-energized, the throttle valve is held in the Limp home position (6-7%) using direct and return springs.

Code P0122 Low signal level of the Lada Vesta throttle position sensor.

Code P0122 is entered if:

- ignition on;

- the throttle position sensor signal voltage (ADC parameter “ Throttle sensor voltage 1 ”) is less than 0.25 V for 0.12 s.

The malfunction indicator lights up 5 s after the fault code appears.

Description of checks.

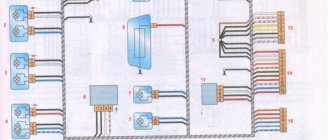

The sequence corresponds to the numbers on the card.

- Using a diagnostic tool, it is checked whether code P0122 is active at the time of diagnosis. If only code P0122 is detected, then the fault must be looked for in the signal circuit of TPS A. If codes P0122 and P0222 are detected at the same time, then the fault must be looked for in the power circuit of TPS A and TPS B.

- The circuit is checked from contact “X1.2/G2” of the controller to contact “3” of the electronic protection device.

- The controller is checked: when you bridge contacts “3” and “5” of the block to the EDS using a probe, the TPS A signal on the diagnostic device should change.

- The circuit is checked from contact “X1.2/E3” of the controller to contact “5” of the electronic protection device.

- The controller is checked: pin “5” of the block to the EDS should receive a reference voltage of 5 V from the controller.

Superficial intervention or deep cleaning?

There are two ways to clean the throttle valve. The first is a superficial intervention that does not require complete removal of the entire device. And the second is a complete cleaning, which must be performed in cases where your car’s engine is not working well.

To perform the first type of cleaning, you will need a pre-purchased cleaning product and a fine brush. Open the hood, remove the corrugation, it goes from the air filter housing to the throttle valve. You will see a valve - it is easy to recognize by its completely round shape. Treat it with a chemical and let it sit for a few minutes, then remove the dirt with a brush. If necessary, use a rag. Repeat the procedure several more times until the flapper valve turns a bright color. This work can be carried out once every 3–5 thousand kilometers, fortunately, it does not take much time.

For more detailed cleaning of the throttle valve in a VAZ 2110, you need to completely remove the entire injector mechanism. It is also recommended to replace the gasket and O-ring, which are included in the throttle valve repair kit, which is easy to buy at any auto store. Before starting cleaning work, remove the terminals from the battery.

Then disconnect all air pipes connected to the throttle body. After this, remove the fastenings of the throttle cable and unscrew the throttle valve itself. It is attached to two bolts that are screwed into the engine housing.

Electronic sensors must be disconnected carefully to avoid damaging them.

After that, take a chemical and treat the entire body and all the grooves of the throttle body. Do this until you completely get rid of the dirt. You can also clean the air flow meter sensor. To do this, carefully treat its hairs with a cleaning product and remove the dirt with a brush. Give the entire device time to dry completely before reassembling. Do not forget to change the gasket and ring, which are located in the corrugation

Also pay attention to whether all air pipes are intact. Perhaps some require replacement with new ones

For maximum effect, you can also replace the air filter.

Diagnostic information on the electronic throttle valve of Lada Vesta.

If a fault is detected in the TPS A circuit, the engine control system will operate in emergency mode until the end of the current trip.

The following emergency modes are possible: - limiting engine power if the TPS B circuit is working; — de-energizing the electric throttle drive and limiting engine speed (2500 rpm) if the TPS-A and TPS-B circuits are faulty.

The diagnostic tool in the “Signal Monitoring” mode displays the signals TPS A (ADC parameter “Throttle sensor voltage 1” ) and TPS B (ADC parameter “Throttle sensor voltage 2” ) in volts.

When the throttle valve is opened, the TPS A signal increases, the TPS B signal decreases.

With the throttle valve fully closed, the TPS A signal should be in the range of 0.30…0.58 v, the TPS B signal should be in the range of 4.42…4.70 v. The sum of the TPS A and TPS B signals should be equal to (5±0.1) V at any throttle position.

A mechanical failure occurred with the owner of a Lada Vesta.

I drove for a little while after buying the car and during kickdown the car did not pick up speed and went into emergency mode, to which an acquaintance of the former owner said it was drizzling, the ABS sensor took my word for it, but in vain. And at 130,000 km I was already forced to urgently go to the service center to look for the fault; in the end, the reason turned out to be in the throttle valve because... Manufacturers made plastic gears on them and over time they ground down and broke off in some places.

SUBSCRIBE TO NEW ARTICLES VIA VK GROUP!

Subscribe

Cleaning methods

There are two ways to clean the throttle valve for a VAZ 2114 car:

- Superficial;

- Deep.

Each of them deserves separate consideration.

Surface cleaning

The easiest way that does not require virtually any knowledge in the field of car repair and disassembly. There is no need to disassemble the damper itself, because this option is preferred by almost all beginners who are just beginning to learn the joys of self-repair.

The procedure for superficial cleaning of the throttle valve is as follows:

- Remove the corrugation from the throttle valve;

- Treat interior surfaces with your chosen cleaning product. Better than WD40;

- Go over the knot with a brush. Just don’t use metal ones;

- Wipe off any accumulated dirt with a dry cloth;

- Carry out similar activities on the reverse side of the damper;

- Reinstall all removed items.

Let’s say right away that this method cannot be called effective. It’s not called superficial for nothing. This tells us that all the internal components of the unit will still remain dirty. Therefore, the symptoms are unlikely to disappear.

Deep flushing

In most cases, you will not be able to fix the problem without deep cleaning. Plus, it is still recommended to check the throttle position sensor on the VAZ 2114, since the reason for the violation of the proportions of the air-fuel mixture may lie in it.

From a set of materials and tools you will need:

- The almighty WD40;

- Crosshead screwdriver;

- Dry rags;

- Throttle valve gasket (for 1.5 liter engine);

- Receiver O-ring (for a 1.6-liter engine);

- Spanners;

- Two M13 bolts;

- Ear cotton swabs.

A fairly inexpensive set, each item from which will be useful to you. Therefore, it is better to immediately collect everything you need and get to work.

- Remove the entire throttle assembly. To do this, remove the corrugation from the filter, turn off the antifreeze pipe (here you will need M13 bolts to close the pipes). There is no need to drain the antifreeze, as many recommend. Just try to disconnect the pipes as quickly as possible and plug the holes with bolts.

- Now the adsorber pipe is removed.

- You have completed the most difficult stage, so it will be easier further. Remove the assembly fasteners, disconnect the cable from the gas pedal. This will allow you to remove the throttle body.

- After removing the unit, disassemble it into parts. The first are two sensors - TPS and IAC. They must be thoroughly cleaned using the products indicated in the previous section. If you don't have WD40, use alternative solutions.

- Rinse the damper thoroughly from all sides, blow out the holes, which will allow all internal components to dry properly.

- Now all you have to do is assemble the assembly in reverse order. This is not difficult to do if there are no problems with disassembly.

- Don't forget the gaskets or rings. There is no point in cleaning them from dirt, so immediately replace the old ones with new ones. Do not confuse which element is suitable for which VAZ 2114 engine size. Many people manage to put the ring where the gasket should be, or vice versa.