Hi all! I finally decided to do this. ) And I don’t regret it at all. Let's start in order. We will need: 1) Desire (there is no way without it) 2) Carburetor cleaner 3) Screwdriver 4) Ratchet with a 13 head 5) Hands growing from the right place (the most important thing) 6) Remote control gasket 7) Drilling file

Removing the remote control (I won’t quote pictures from the Murzilka, it’s described there in some detail), before doing this, open the cap of the expansion tank (to relieve the pressure). We disconnect the IAC and TPS connectors, loosen the clamps of the air hose, crankcase ventilation hose, coolant supply and discharge hoses. Using a 13mm socket, unscrew the two nuts securing the throttle assembly to the receiver and remove it from the studs.

Washing and cleaning both the throttle valve and the entire assembly is not a difficult task. But nevertheless, many car owners do not know how to clean correctly, why to clean and when to clean, and having only a little experience in car maintenance, they are afraid to climb under the hood and do anything with their own hands.

In this article we will analyze the entire procedure for flushing the throttle assembly, and I hope that the typical car owner will no longer have all the questions about performing this operation.

Adjusting the throttle valve on VAZ-2108, 2109 and 21099

The throttle valve is one of the most important elements of a car.

It is part of the intake system of a gasoline internal combustion engine and is responsible for supplying air to the engine during the formation of the air-fuel mixture. When the valve opens, the fuel mixture becomes richer, and when it closes, on the contrary, it becomes leaner. The throttle valve can be compared to an air valve. As soon as it opens, the pressure of the surrounding atmosphere and the intake system is equalized. At the moment when the “valve” closes, the opposite situation occurs - the pressure in the system drops to a minimum level.

Main types

Throttle valves can have different designs, depending on the type of carburetor:

— in carburetors of constant vacuum and with falling current, such a damper has the form of a spring;

— in a horizontal type carburetor, the throttle valve has the form of a gate located vertically. Its movement allows you to adjust the cross-section of the diffuser, in the area of which the damper moves;

— in gasoline injection systems, this unit is a separate device, the task of which is to dose air and transfer it further through the system to the manifold.

It is also worth noting that throttle valves can vary in type of actuator - the latter can be mechanical or electrical. What are their differences? Everything is simple here.

- Electrically controlled throttle valve:

— allows you to adjust XX. This is possible by moving the damper in one direction or another;

— there is no mechanical “communication” between the accelerator pedal and the damper itself.

Electronic systems are more reliable and accurate, which is why they are used in most cars. The system includes an ECU, a group of input sensors, an actuator, switches (installed on the clutch and brake pedals), and a sensor that fixes the position of the accelerator pedal. If additional options are available, the system may involve a brake system, climate control or cruise control.

- A mechanically driven throttle valve is installed only on old (including domestic) cars. Modern manufacturers have long abandoned this control option. The main difference between this system is that the throttle valve and gas pedal are connected by a metal cable.

Basic faults

Throttle valve problems are easy to identify. For example, when accelerating, you actively press the accelerator pedal, but the car is in no hurry to carry out the command. Such “dullness” is most often explained by problems with the adjustment of this unit. Of course, the remote control unit itself can also fail, but most often the problem is in the damper.

In addition, signs of a malfunctioning damper include:

— “swimming” of idle speed;

— there is no increased speed when starting a cold engine;

- setting the power unit to “cold” or “hot” can cause problems;

— if the gearbox is equipped with an automatic transmission, there may be a jerk when switching to the “Drive” position;

— the servo drive jams and wears out;

— power reduction is possible;

- fuel consumption increases.

When the first signs of a malfunction appear, set aside half an hour of your time to carry out adjustment work. For some reason, many car enthusiasts do not want to get into the carburetor for fear of disturbing or breaking something. In fact, there is nothing complicated in this work. If you strictly follow the instructions, you can correctly adjust the throttle and forget about the problems mentioned above forever.

Adjusting the throttle valve on VAZ-2108, 2109 and 21099

In this article we will deal with adjusting the throttle using the example of the most popular domestic cars - VAZ-2108, 2109 and 21099. This work must be done in two cases - if the throttle valve does not close completely or does not open completely. So let's get started:

- Prepare the tools you will need for the job - a set of wrenches and screwdrivers.

- Make sure the throttle valve really needs adjustment. For this:

— loosen the fastening clamp with a screwdriver and discard the thick air hose from the damper pipe;

— loosen the fastening clamp (again with a screwdriver) and discard the second hose, which is connected to the large branch of the crankcase ventilation;

— ask an assistant to sit behind the wheel of the car and press the accelerator pedal all the way;

— at the moment of pressing, carefully observe the behavior of the damper and its final position. With the accelerator pedal depressed as much as possible, the throttle “curtain” should be fully open;

— give the command to the adjustment partner to release the gas pedal;

- check the position of the damper again (if everything is normal, then it should return to its place and close completely).

In a situation where the throttle lock does not fully open when the accelerator pedal is fully pressed and does not close when the pedal is released, adjustment is necessary:

— loosen the cable locknut and unscrew the adjusting nut. Look at the damper. Make adjustments until the throttle valve is fully open when the accelerator pedal is depressed.

— loosen the lock and tighten the adjusting nut. Achieve complete closure of the remote control.

When performing work, be careful with the throttle cable. If handled carelessly or over-tightened, it may break. Such a problem will significantly add to your work (you will have to replace the cable).

Conclusion

Adjusting the throttle valve on VAZ cars of the 2108-21099 series is a matter of 20-30 minutes. It is very important to diagnose the problem in a timely manner. The work itself is very simple and accessible even to novice car enthusiasts. The main thing here is to familiarize yourself with the design features of the carburetor, get an assistant, set aside some time, prepare the tool and believe in yourself. Good luck.

Causes of pollution and how to deal with them

There are several reasons why the throttle body becomes dirty over time. By avoiding their appearance, you will automatically extend the time between cleaning it. Reasons mentioned include:

- Using low-quality gasoline . If there is sediment in it, it will definitely get into the throttle assembly, where it will turn into carbon deposits. Therefore, try to fill in high-quality gasoline and refuel at proven gas stations.

- Clogged fuel filter . If you do not change the fuel filter in time, then there is a possibility that pieces of dirt from it will get into the fuel system, including the throttle assembly.

- Dust and dirt getting into the intake system . This can be caused by various reasons - clogged air filter, damage to the integrity of the air duct, various mechanical stress.

- Crankcase gases with oil dust . They are the main cause of oil deposits on the valve. They can enter the combustion chamber through the valve cover from the crankcase ventilation system. The situation is aggravated by the fact that they carry oil dust. It is this that burns and remains as sediment on the surface of the throttle valve.

Read also: How much speed is removed from the body

Clogged fuel filter

Change the air and fuel filters on time, fill with high-quality gasoline, and prevent dust from getting into the car's fresh air ventilation system. All this will save you from the need to clean the throttle valve ahead of schedule.

Do-it-yourself cleaning of the throttle valve of a VAZ 2109-15

Over time, the throttle assembly becomes dirty and requires cleaning. Do-it-yourself cleaning of the VAZ 2109-15 throttle valve according to the manufacturer’s recommendations should be done every 50-60 thousand km.

Below we will look at the symptoms of a dirty throttle valve.

1. While driving, when the “neutral” is turned on, the engine rapidly loses speed to 400-600 and stalls or returns to normal with difficulty.

2. Possible problems with “cold” or “hot” start.

Cleaning algorithm

Now we will give a step-by-step algorithm for properly cleaning the throttle valve.

- First of all, you need to get to the damper itself. The design is different in different engines. But as a rule, to do this you need to remove the air duct that runs from the damper to the air filter.

- Dismantle the damper. To do this, unscrew several mounting bolts (2-4 pieces), and also disconnect the necessary connectors (for example, the connector from the absorber purge valve).

- To clean, you must use a carburetor cleaner. There is a wide variety of them, and in auto stores you can easily find a product in accordance with your preferences and capabilities (we will talk about them later).

- Using a rag and the mentioned product, you must thoroughly wipe the damper outside and inside.

- You also need to clean the protective grille (if your car has one).

- Assembly of the unit is carried out in the reverse order.

Read also: Blaupunkt gta 5350 connection diagram

An easy way to clean your throttle body

The correct way to clean the throttle body

Throttle valve, potentiometer, idle speed controller

Gasoline is used as fuel in the internal combustion engines of VAZ-2109, VAZ-2110 and other models produced or produced by the Volzhsky Automobile Plant. However, in the cylinders it does not burn on its own, but in a mixture with air. The throttle valve is needed to prepare the air-fuel mixture in the required proportions. It is located behind the air filter in front of the intake manifold.

Basically, the throttle valve is an air valve that regulates the amount of air entering the engine. The principle of its operation is to change the cross-section of the air channel. When it is fully open, air flows freely into the intake manifold. To determine the opening angle, a throttle position sensor is used, which is connected to the engine control unit. Based on the signals transmitted by the sensor, the control unit issues a command to increase the amount of fuel injected, the working mixture is enriched, and the engine operates at maximum speed.

The smaller the throttle opening angle, the less air enters the manifold, and the lower the engine speed.

Throttle valve device

The design of the throttle body is not as simple as it might seem at first glance. Among other things, it is also part of the engine cooling system. It has channels for coolant circulation. It is also equipped with pipes, one of which is connected to the engine crankcase ventilation system, and the second to the gasoline vapor recovery system.

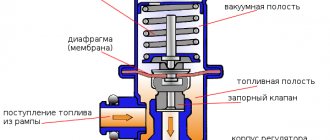

Idle speed control

The idle air control is an electromechanical device whose task is to maintain a certain crankshaft speed when the throttle valve is fully closed. For example, while the engine is warming up or the load changes, when additional equipment is turned on. The design of the idle speed controller is as follows: inside the housing there is a stepper electric motor, to which a spring-loaded conical needle is connected. When the engine is idling, the needle, moving back and forth, adjusts the cross-sectional area of the bypass air channel through which air passes when the damper is fully closed.

The throttle valve can have two types of drive:

- mechanical, like VAZ-2109, VAZ-2110, VAZ-2114;

- electric, which is used on most modern cars.

Mechanical drive

For the VAZ-2109, VAZ-2110 and other outdated models of the Volzhsky Automobile Plant, the throttle valve is connected to the gas pedal via a steel cable. The mechanical drive has a very simple design and low cost, so it is still used on many inexpensive cars.

Electric

If the throttle valve is equipped with an electric drive, then there is no direct connection between it and the gas pedal. The principle of operation of an electric damper does not change, but its design is much more complex. Simplified, such a node works as follows. The force of pressing the gas pedal is recorded by a special sensor, which transmits this information to the engine control unit, the throttle opening angle is determined by the throttle position sensor, and also transmits the corresponding signals to the control unit. The controller constantly compares these values and sends commands to the electric motor to increase or decrease the damper opening angle.

The main distinguishing feature of the electric throttle valve is the absence of an idle speed control. When the engine is idling, the throttle valve does not close completely; its opening angle is set by the control unit in accordance with the operating parameters of the power unit. The electronic throttle, unlike the mechanical one, has not one position sensor, but two. If one sensor, also known as the throttle potentiometer, fails, the throttle assembly will still work.

Throttle position sensor

This sensor is a potentiometer. When you press the gas pedal, the position of the damper and the voltage supplied to the controller changes. When closed, the voltage is 0.7V, when fully open it is 4V. In accordance with these data, the sensor controls the fuel supply.

If a malfunction of the position sensor occurs, the controller will not be able to correctly determine the position of the damper. This results in the following malfunctions:

- in all engine operating modes, the speed begins to fluctuate; at idle, the speed will be increased;

- when you switch off the gear (neutral) while driving, the engine may stall;

- Sometimes the CHECK light may come on.

To check the functionality of the position sensor, you can use a multimeter. With the ignition on, the probes are connected to connectors B and C. Changing the position of the damper should lead to a change in voltage.

» alt=»»>

Knock sensor

Very often, the knock sensor of VAZ 21099 and 210115 fails, thereby disrupting engine operation. After all, its main task is to determine the moment of fuel microexplosions.

Any motorist knows that good proper operation of the engine depends on optimally selected ignition timing angles; ideally, they are different for each engine operating mode. This is why there is an ECU, whose main task is to set these angles as ideally as possible using a knock sensor. It is he who can accurately determine that the ignition timing is set incorrectly. The ECU program is written to set the ignition timing as large as possible in order to prevent the engine from going into the detonation zone.

The VAZ 21099 knock sensor, the injector of which has not been cleaned and diagnosed for a long time, fails very quickly, especially if it is a semi-handicraft fake, of which there are more than 80% on the market. After all, it is equipped with a very sensitive element that works on the principle of the piezoelectric effect. This device is mounted directly on the cylinder block.

If the knock sensor of a VAZ 21099, 210115 or other car brands fails, then the engine begins to overuse fuel, overheat and stall, it loses traction and the timing belt wears out greatly. The VAZ 21099 knock sensor is considered broken, the injector of which begins to produce the following tricks:

- the motor is troublesome;

- the car loses dynamics;

- when starting from a standstill and on an ascent, the check engine of the on-board computer lights up;

- The check engine lights up when the car accelerates quickly.

You can buy a VAZ 21099 knock sensor at any auto store for up to 200 rubles, or install a Volgov one, which costs up to 500 rubles and has unsurpassed quality.

Do not skimp on the knock, idle or throttle sensors of the VAZ 21099. And then the injector will be able to serve you faithfully for many years.

Why is it necessary to modernize the throttle valve on VAZ-2109, 2110, 2115

Spare parts stores sell throttle assemblies with valves of increased diameter (52, 54 and 56 mm) for VAZ-2109, 2110 or 2115 cars. According to the sellers, by installing such a valve instead of the standard 46 mm one, the car owner will receive significant advantages: the car becomes more responsive to the gas pedal, problems with idle speed disappear, the car's dynamics improve, and this is especially noticeable if you replace the standard air filter with a zero-resistance filter. The main argument that they try to convince car owners is that the engine requires more air to operate efficiently, for which it is necessary to replace the standard throttle assembly with an improved one. They even give figures: the diameter of the VAZ-2109 or VAZ-2110 receiver is 53 mm, and a damper with a diameter of 46 mm allegedly “strangles” the engine.

Many VAZ-2109 and VAZ-2110 owners succumb to persuasion and replace the standard device with an improved one. After this, indeed, the engine works better and the car drives more dynamically. The reason for the improvements actually turns out to be much more prosaic: instead of the old, dirty throttle body, which had long been in need of thorough cleaning, the owner installed a new one. As a result, the engine returned to normal operation, which is perceived by the owners as the promised responsiveness and agility of the car.

Adjusting the throttle valve on VAZ 2108, VAZ 2109, VAZ 21099

Welcome! Today we will adjust the throttle valve on injection vehicles VAZ 2108, VAZ 2109, VAZ 21099.

When do you need to adjust the throttle valve on a VAZ 2108-VAZ 21099? The throttle valve is subject to adjustment when: 1) It is not fully opened. 2) Or when it is not completely closed.

What is needed to adjust the throttle valve on a VAZ 2108-VAZ 21099? 1) Screwdrivers. 2) Wrenches.

How to check whether the throttle valve needs adjustment on a VAZ 2108-VAZ 21099? 1) First, disconnect the air hose, which is marked with the letter “A”, from the throttle valve pipe, and also, together with it, disconnect the hose of the large branch of the crankcase ventilation, which is marked with the letter “B”.

Note! For information on how to properly disconnect the air hose from the throttle valve, see the article “Replacing the throttle valve on a VAZ 2108, VAZ 2109, VAZ 21099”, in the section: “ removal ”, in paragraph “2-3”!

2) Then put one person behind the wheel of your car and ask him to press the gas pedal all the way.

3) At this time, look at what position your throttle valve is in.

Note! The throttle valve must be fully open!

4) Then ask your assistant to take his foot off the gas pedal. 5) At this time, check what position the throttle valve is in; it should be completely closed.

Note! If the throttle valve does not open completely, or does not close completely, then adjust it!

Cleaning without removal

Also, many car owners are interested in the question of how to clean the throttle valve without removing it. Such methods do exist, but you must immediately understand that high-quality cleaning is only possible by dismantling the damper .

To do this, you will need a special product - an intake tract cleaner. You can use different brands. You can also use EGR valve cleaning fluid, WD-40, and solvents for cleaning.

So, the procedure without removing the node :

- As in the previous algorithm, you need to remove the air duct to get to the damper.

- With the damper closed, spray the surface with cleaning liquid and remove the cleaned dirt using a rag.

- Open the damper and remove dirt from the side surface.

- Make sure that the cleaning agent gets into all channels. The cleaning procedure is similar using a rag.

Let us repeat once again that for proper cleaning, the throttle valve must be removed from the car. And when installing it back, it is advisable to replace the damper gasket with a new one. Fortunately, its price is low.

It should also be remembered that in most cases, after cleaning the throttle valve, it is necessary to perform actions to “train” it . This procedure is carried out either using a computer (by connecting it to the car's ECU), or by manipulating the ignition and gas pedal. In this case, it is impossible to give universal recommendations, since they can differ significantly for each manufacturer and even model. Remember this!

How to adjust the throttle valve on a VAZ 2108-VAZ 21099?

The throttle valve does not open fully:

1) In order to adjust the position of the throttle valve, slightly loosen the cable nut under the letter “B”, and at the same time tightening the nut under the letter “A”, ensure that the throttle valve opens completely.

The throttle valve does not close completely:

1) Slightly loosen the nut under the letter “A”, and then tighten the nut “B” until the throttle valve is completely closed.

Important! 1) Handle the throttle cable carefully so as not to damage it!

For newbies! Question: Where is the throttle valve located in the injection engine on the VAZ 2108, VAZ 2109, VAZ 21099? Answer:

You may also like

What you need to know when buying a used car

Since 1998, the VAZ 21099 began to be equipped with injection engines, which are a priority to buy. Once you own a used car, you will often need to repair it yourself. There is nothing wrong with this; changing the knock sensor of a VAZ 21099, whose injector has begun to act up, will not be difficult. Most operations do not require special training or special knowledge - you can do everything yourself by watching a video from YouTube or reading step-by-step instructions on the Internet.

The best way to check the condition of the engine is to measure the compression in the cylinders. For 21099, the best result will be 13 units, and if it is less than 10, then a major engine overhaul will be required. It is worth considering the fact that the difference in readings when measuring in different cylinders should not exceed 1%. It is not advisable to buy a car with a dirty, oily engine, as this indicates serious damage. Beware of cars with ECU problems, since a failed VAZ 21099 or 21115 throttle sensor can ruin your nerves for a long time, you will get tired of looking for the cause of the breakdown.

Terminals in the engine compartment require additional care

After purchasing a VAZ 21099, it is advisable to treat all electrical contacts on the engine compartment terminals, including the fuse box, with a special agent. Experts advise that when buying a used VAZ, do not change the antifreeze and oil immediately, but take a closer look - maybe the car you bought does not need it.

Advantages of purchasing a VAZ 21099:

21099 also has disadvantages:

Thus, the VAZ 21099 throttle sensor is afraid of moisture and fails after 5,000 kilometers, in particular the idle speed sensor is a “ninety-ninth” problem.

Considering that this model was produced in the Russian Federation until 2004, and in Ukraine until 2011, it is quite difficult to find a used car without problems. However, if you are not afraid of the prospect of doing small repairs yourself, this budget option will be ideal.

Replacement of battery cable terminals on all VAZ vehicles

32 comments

What should I do, I can’t adjust the throttle properly, it’s just not adjustable?

Hello Semyon! What do you mean not regulated? Could you be having problems with your throttle cable? The first thing to do is check the throttle cable itself for defects, it may simply be that it is stretched, that’s all! If this is the case, then replace the cable (see “Replacing the throttle cable”)

Thank you very much Oleg, it really turned out that my throttle cable was pulled out, this morning I replaced it with a new one and everything was fine)

Hello. The problem is the following: the damper does not close completely, the on-board computer shows 1%. even if the throttle pin is completely unscrewed. Pressing with your finger, it closes, but when you press the gas it goes back down. Please tell me if it is possible that the throttle valve is defective and the internal dimensions were not observed during production. Dpdz new

Hello, Alexander! It is necessary to rinse until the jam is eliminated.

Oleg, thank you for responding, I forgot to add that I completely removed the throttle valve and washed it with carburetor cleaning fluid about two months ago, but then there were problems with floating speed and stalling engine, recently I just changed the throttle valve, the problem with floating speed disappeared, now only when the throttle open by 1% when cold, if you start it in this state, then most likely the car will stall or will not hold speed, after pressing the pedal once, it will go to zero percent and no longer bother. Sorry if something is not clear, I tried to describe the essence as clearly and in detail as possible

And I apologize, I wrote it wrong, the damper sticks after pressing with your finger, and when you press the gas (I mean pressing from under the hood, not on the pedal), you just feel the jam. And here’s another thing: now the throttle valve is on one bolt, because having screwed it by two, the throttle is open by 3-4%, which is why I suspect that there is a defect in the throttle valve

I completely forgot, the throttle valve is not factory, I bought a new one more than a year ago

Hello, Alexander! Separate the TPS from the throttle pipe and look separately at what is sticking - the damper or the sensor. It is also possible that you have a TPS of the wrong model that fits this throttle pipe. As far as I know, there are at least 3 variants of TPS, they look very similar.

Hello, Oleg! Thank you so much for your help, I will definitely look into this and follow your advice, thanks again and good luck! If possible, in the future I will definitely write about fixing the problem

Hello, Alexander! We were glad to help. We would appreciate your feedback!

Hello, Oleg! You were right, it was the TPS. I bought another one again, no more problems. Thanks again and good luck

Hello, Alexander! I am glad to help. Contact us.

There is also a problem with dpzd. You start it when it keeps the speed stable and as expected. As soon as you press the gas, it holds all 1500 revolutions and does not release. If you press on the gas again it slowly releases. I already changed the sensor.

Hello, Ramil! Are you sure the damper isn't sticking? In general, check the sensor number when purchasing, they look the same, but differ in parameters. By the way, if you have any problems with idle speed, you should start by flushing the XX regulator and the XX channel. Then read errors about misfires and correct them. Only then watch the TPS and everything else.

Hello, my car is a VAZ 2109 with an injector (before this I had trouble running) and it won’t start. This happened yesterday when I was driving home while driving, the car stalled and started and won’t start, the starter turns the fuel sensor, there is a spark, I can’t figure out what’s wrong

Hello, Shyngys! What does “fuel sensor trip” mean? Write clearly, specifically, in generally accepted terms, since I can perceive what you mean in your jargon in a completely different way. In general, most likely your timing belt has broken or one of the timing gears has turned on the shaft.

My problem is this: the car won’t start when it’s cold, especially now in the cold. Tighten (pull) the throttle cable and it starts. And, accordingly, as the engine warms up, the speed increases. That is, once the engine is warmed up, you have to turn the cable back to normal. Oleg, if you can, tell me what is the reason and how to treat it?

Recommended Method

Level control technology includes a number of stages:

- We dismantle the housing of the air filter element. To do this, unscrew the fastening nut of the housing cover, unclip the latches, remove the cover, take out the filter and tighten the 4 nuts that secure the housing to the carburetor.

- Raise the body and disconnect the rubber pipes. We move the body to the side.

- Loosen the clamps securing the fuel pipes going to the carburetor and disconnect them.

- Remove the wire suitable for the idle speed solenoid valve;

- Disconnect the drive cable of the air damper (the “choke” handle);

- Unscrew the 5 screws securing the carburetor cover;

- Having removed the cover, we immediately determine the fuel level in the chambers by lowering a ruler or caliper into one of them until it stops (using its depth gauge). If the measurement shows a level of 25-26 mm, it corresponds to the norm and no adjustment is required;

If the amount of fuel in the chamber is lower or higher than normal, we perform a visual inspection and a series of measurements on the floats, and if necessary, we correct their position.

To carry out adjustment work, place the removed carburetor cover on a flat horizontal surface with the floats facing up.

First, we look at the position of the elements from above. The outer side surfaces of the floats are parallel to the special imprints on the gasket. Deviations can cause the floats to touch adjacent elements and surfaces, causing the fuel level to be incorrect. If necessary, adjust the position of the floats by bending their mounting arms. The next step is to measure the gap between the floats and the gasket. A rod with a diameter of 2 mm is useful here - this is how much the specified gap should be.

If it does not correspond, we bend the tongue of the floats, with which they act on the locking needle. After this adjustment, we check the total height of the floats, which is normally 34 mm. If this is not the case, check the gap again, adjust it if necessary and measure the height again.