The steering mechanism is a fairly important unit, on the serviceability of which depends, among other things, the life of the vehicle crew. Modern cars use a steering rack.

note

The worm mechanism is considered an obsolete design, despite its simplicity of execution. It is difficult to achieve precision control with it.

The rack-and-pinion mechanism has an open design (unlike a worm gear); lubricant for the steering rack can be supplied by the driver in a garage.

This design also has a drawback: at the slightest leak, moisture and dirt enter the mechanism, and the lubricant quickly fails.

Our material will tell you how to choose the right consumables for the steering mechanism.

What lubricant to use for the steering rack

The steering mechanism is one of the main elements of vehicles, which bears considerable responsibility for the life, health and safety of the driver.

Steering rack lubrication requires special attention, without which it is impossible to transmit steering rotation to the wheels. Indeed, during the process of friction, the metal parts of the car are constantly exposed to heat and wear out to the point of being unusable. The processing of parts makes it easier to turn the steering wheel, and if there is an electric or hydraulic booster, it extends their service life. A steering rack is a device that allows you to control the synchronous operation of the front wheels using the steering wheel.

Table

| Steering parts and components | Materials | Material requirements | Problem solving |

| Protective caps | Wet environment Low operating temperatures (T≤-40°C) | ||

| Rack and pinion | Lubricants | High loads (Pc > 3000 N) | Reduced vibrations |

| Steering shaft bearings | Lubricants | Long-term lubrication Increased loads (Рс > 2100 N) Wide operating temperature range | Extending the relubrication interval |

| Steering rod joints and seals | Wet environment Resistant to water wash-off Compatible with elastomers (including rubber) Low operating temperatures (T ≤ -40° C) | Prevent plastic and rubber parts from deforming or breaking | |

| Electric booster worm gear | Lubrication | High loads (Pc > 3000 N) Long-term lubrication Good anti-wear properties Wide operating temperature range | Extending the relubrication interval |

One of the new products for servicing steering components is grease. These are synthetic PAO greases based on calcium sulfonate. It is designed to service the steering shaft bearings. The lubricant works well under the influence of moisture, heavy loads and is compatible with plastics.

Another new product from is a mineral lubricant made on the basis of potassium sulfonate. It is used to service steering shaft bearings and other heavily loaded vehicle components. The lubricant has high anti-corrosion and water-resistant properties, works under heavy and shock loads and ensures long-term and uninterrupted operation of components.

The use of lubricants that do not meet the requirements listed in the table leads to premature wear of steering parts and assemblies, which is one of the reasons for its jamming.

The steering mechanism of any car bears a huge responsibility. The life and safety of both road users and others depends on its serviceability. Like most mechanical components, the steering system requires careful maintenance. It is especially important to know how to lubricate the steering rack

.

What is a steering rack and why is it needed?

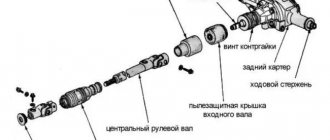

The essence of the steering mechanism is to transform the steering torque into linear movement of the steering rods. The main element of this mechanism is the steering rack. In it, with the help of a gear and a rack, steering rotation is transmitted to the wheels. The gear is attached directly to the steering shaft. As it rotates, its splines cling to the teeth of the rack, pushing it in a certain direction. The rack, in turn, drives the steering rods, which are rigidly fixed at its ends. Steering tips are attached to the opposite ends of the rods, which transmit the turning force to the wheels.

By understanding the operating principle of the vehicle control mechanism, it is easier to prevent its premature failure. It is also important to know what maintenance is needed, how to lubricate the steering rack, and how to care for it. You also need to consider the overall lifespan of your vehicle. After all, with every thousand kilometers traveled, the vulnerability of its parts and components becomes more and more noticeable. And accordingly, he needs to pay more attention.

Why do you need steering rack lubrication?

As in any mechanisms, processes of interaction between metal parts take place in the steering rack. Such contact does not occur without the occurrence of a friction effect. As a result, the temperature of the parts increases and their wear also increases. In order to reduce the negative effect of friction, lubricant is used. Also, a lubricated steering rack makes it easier for the driver to turn the steering wheel. If the steering mechanism is supplemented with an electric or hydraulic booster, then their service life is noticeably extended. But before you lubricate the steering rack

, it must be disassembled and the remaining old grease must be carefully removed. Only after this can the rack be filled with new lubricant and reassembled. Regular repetition of the above procedure will ensure long-term and trouble-free operation of the steering rack.

How can I lubricate the steering rack?

It is necessary to lubricate components and parts of automotive mechanisms with oils and lubricants recommended by the vehicle manufacturer. But even with ideal lubrication, the main factor in the reliability of the unit is the conditions in which it operates. If the hinge is protected hermetically from moisture and dirt, it will work for a long time. And the quality of the lubricant will not fundamentally affect the service life. If the protective seals are broken, then even with ideal lubrication the service life of the parts will be very limited. Water and dirt entering the protection will turn the lubricant into an abrasive mass.

One of the conditions for reliable operation of the steering rack is its tightness. Also, it is necessary to fill it with lubricant to capacity. This extends the service life of both the rack and pinion mechanism and the lubricant itself. Therefore, it is advisable to check that there is a sufficient amount of lubricant even on a new car. Another important requirement for steering lubricants is their resistance to low temperatures. After all, hardened lubricant in the steering mechanism can have a bad effect on the car’s handling.

Video about lubrication of the steering rack

Advice from professionals.

The steering rack bears a lot of responsibility for safe driving. Therefore, professionals advise paying special attention to it. Timely lubrication of the steering rack extends its service life, but not indefinitely. Also, wear is possible in other steering parts. The following symptoms that appear in the steering mechanism should cause increased concern in the driver:

— The steering wheel play has increased;

— There is a knocking sound in the steering wheel;

— The force required to turn the steering wheel has increased;

— Lubricant leakage from the steering rack is noticeable.

In such cases, you should immediately contact a car service center to diagnose the steering. This event will allow you to timely identify the problem area and eliminate the malfunction. This way you will prevent more dangerous consequences of possible problems.

What types of lubricants are there?

Different lubricants have different physical-chemical, mechanical, lubricating, anti-wear and other properties. As a rule, lithium greases are suitable for the steering mechanism. Their performance characteristics meet the requirements for ideal lubricants. This group of lubricants includes Litol-24, Fiol, Severol (for especially low temperatures), Tsiatim and others. These lubricants have good water resistance, conservation properties, and have antioxidant additives.

The steering mechanism is one of the main elements of vehicles, which bears considerable responsibility for the life, health and safety of the driver. Steering rack lubrication requires special attention, without which it is impossible to transmit steering rotation to the wheels. Indeed, during the process of friction, the metal parts of the car are constantly exposed to heat and wear out to the point of being unusable. The processing of parts makes it easier to turn the steering wheel, and if there is an electric or hydraulic booster, it extends their service life.

A steering rack is a device that allows you to control the synchronous operation of the front wheels using the steering wheel.

How to lubricate the steering rack?

A wide variety of lubricants are sold in stores.

But how to choose the one that is most suitable. All lubricants differ in their base, which is determined by the thickener. Based on this property, the following types of lubricants are divided:

- calcium and graphite (solidol). This type of lubricant has performance characteristics that satisfy many car enthusiasts and a relatively low price. But at the same time, solid oil does not tolerate low temperatures;

- complex calcium. This lubricant is more resistant to low temperatures, but absorbs moisture and is prone to heat strengthening;

- sodium and sodium-calcium. Unfortunately, this type of lubricant is not at all resistant to moisture, so it is not so common. But it can withstand a high temperature range;

- lithium It is gaining popularity due to lithol, which is used on all parts and components of the car and has a low cost on the market. The only drawback of the lubricant is its gradual squeezing out of parts as a result of liquefaction. It is this material that is best given preference when processing the steering rack;

- barium and hydrocarbon. They are resistant to water, have good preservation properties, but contain a large amount of soap, are difficult to produce on an industrial scale and do not withstand low temperatures;

- copper. Withstands extremely high temperatures and operates under high pressure, often used in tire fitting work. But it does not withstand moisture well.

How to lubricate the steering rack?

It is impossible to change the oil or lubricant of the rack without dismantling it. And for this it is absolutely not necessary to send the car to a service center. Before applying new lubricant to mechanism parts, you must first get rid of the old one by first disassembling the part. You need to prepare the lubricant and a couple of clamps in advance, and then get to work. It is important that the lubricant is also suitable for the materials from which the anthers are made.

- First you need to lift the left side of the car, turn the steering wheel to the right and remove the wheel.

- Then clean the surrounding area a little.

- Loosen the reusable small tie on the right boot and cut the large inner disposable tie.

- By sliding the corrugation up the shaft, you can see the presence of lubricant.

- Next, lubricate, sparing no material, the rail and the boot itself from the inside. Turn the steering wheel all the way a couple of times and add more lubricant. Reinstall using a pre-purchased clamp.

- Carry out the same operation on the left side.

The lubricant change procedure should be repeated regularly so that the steering mechanism serves you for many years. To process parts, use only lubricants and oils recommended by the manufacturer.

The main condition for the longevity and reliability of the rack is its tightness, since in the event of a violation of the protective seals, neither the quality nor the properties of the lubricant will play a special role in the operation of the unit.

It is very important to fill the rack with lubricant to the very end, this will ensure precise control and a long service life of the mechanism and the lubricant itself. It is also worth filling the substance into the anthers, at the same time checking their integrity. If you find the slightest cracks or tears in them, you need to urgently replace them. Otherwise, the steering rack will “leak”. After all, the direct purpose of the boots is to protect the steering mechanism from dirt, dust, moisture and lubricant leakage from the crankcase. Such damage can lead to rapid wear and failure of the mechanisms.

Even on a new car, it is recommended to check to ensure that the required amount of the substance is present.

When the question is what is the best way to lubricate the steering rack, it is very important to pay attention to resistance to temperature changes. A frozen lubricant will not have any positive consequences.

Steering rack repair is not a rewarding task. If you replace some of its components, the effect will be short-lived. Therefore, the best solution when the mechanism wears out is to install a completely new steering rack.

Basics of selecting power steering oil

Kalina steering rack repair

Currently, there are a large number of different lubricants on the market used in power steering.

Power steering oils

Within the framework of a review article, it is not possible to list all types of oils used in hydraulic boosters. Let us consider only the general rules for selecting a suitable liquid.

- All oils for hydraulic amplifiers are divided into mineral, synthetic and semi-synthetic.

Today, mineral liquids are the most common. There is a rule: if the operating instructions do not specifically state the possibility of using synthetics and semi-synthetics, then only mineral-based oils can be used. Reverse interchangeability is also undesirable (that is, with recommended synthetics, it is better not to fill in mineral options), but is considered safer. - It is guaranteed to be safe to mix only liquids with the same or similar chemical compositions.

Often information about interchangeability is indicated on the packaging. Colors of power steering fluids As for color, there is an unspoken rule: red and yellow fluids can be mixed. Greens cannot be mixed with others, but only with each other. However, there is an exception here for the greens. Green power steering oils can be synthetic or mineral. Therefore, relying only on color is undesirable.

- In the short term, in case of a forced replacement rather than a planned one, you can temporarily fill in any oil. For example, in a situation where the return hose has come off and the liquid has leaked out, you can fill in absolutely any oil for a short period of time. The power steering pump will quickly fail when running dry.

Therefore, less harm will be caused by the wrong oil than by operating the power steering system without any lubrication at all. But before further filling with suitable oil, you will definitely need to flush the system.

How to replace the fluid in the power steering and not make a mistake in choosing the right lubricant? The general answer is extremely simple: read the car's operating instructions.

Alarming symptoms

No matter how often you change the steering rack lubricant, unfortunately, it cannot extend the life of all parts of the mechanism indefinitely. Therefore, if the following factors are detected, it is recommended to immediately stop using the vehicle and contact a service center.

- Increased steering play.

- Turning the steering wheel requires more effort than before.

- Traces of steering rack lubricant leakage were found.

Knocking and extraneous sounds in the steering mechanism. They usually appear when making a sharp turn or turning the steering wheel, or when hitting protruding parts of the road. To make sure that the cause is in the rack, you need to:

- place the car on a flat surface;

- get out of the car and open the hood;

- unscrew the wheel until it stops in both directions;

- Listen carefully to where the sound comes from when you turn the steering wheel sharply.

Timely diagnostics will protect your car from possible future serious breakdowns and sudden expenses.

Steering rack lubricant: the choice depends on the type of steering mechanism

The steering mechanism is a fairly important unit, on the serviceability of which depends, among other things, the life of the vehicle crew. Modern cars use a steering rack.

The rack-and-pinion mechanism has an open design (unlike a worm gear); lubricant for the steering rack can be supplied by the driver in a garage.

This design also has a drawback: at the slightest leak, moisture and dirt enter the mechanism, and the lubricant quickly fails.

Our material will tell you how to choose the right consumables for the steering mechanism.

What lubricant should I use for the steering rack?

Technologically, the unit consists of several parts, each of which requires maintenance:

- The actual steering rack. It is a set of a spur gear connected to the steering shaft and a horizontal plate with mating teeth. When the shaft turns, the rack moves in a horizontal plane.

- Steering ends (rods). These are ball joints that transmit force from the rack to the steering knuckles of the front wheels.

- Power steering. May have an electric or hydraulic drive. Designed to reduce the effort on the steering wheel when turning the car.

Serious force is generated at the points of contact of the teeth. The value does not depend on the amplifier: it only helps the driver operate the steering wheel. The load on the gears is not only strong, but also variable.

That is, the vector quickly changes direction in a short time. Under such conditions, the working oil film breaks, exposing bare metal.

The ideal option is liquid lubricant, like in an engine crankcase. The interacting parts are either “bathed” in an oil bath, or the working fluid is constantly supplied to the friction zone.

But the design of the steering rack housing cannot ensure tightness, and the liquid lubricant will instantly leak out. The boots on the steering tips protect against dirt getting inside, and not against leaks.

This means that the lubricant must be consistent. Such a composition will be retained inside the mechanism, but at the same time it will not independently spread over the surface of the gear joint in the event of extrusion from the load.

Manufacturers compromise by creating lubricants with mutually exclusive properties:

- on the one hand, high viscosity ensures a strong and sticky oil film on the working surface;

- on the other hand, the compositions are quite fluid and fill voids well.

The best option: lithium-based consistency oils.

The best lithium greases for steering racks have the following qualities:

- Heat resistance. Preservation of plasticity in the winter season, down to a temperature of -50°C. The steering mechanism remains flexible and does not make driving difficult. The drop point is well above the limit that can occur inside the steering rack. The mechanism is unlikely to heat up even to +100°C.

- The viscosity itself, at the level of a paste-like consistency, is the main advantage of these compositions.

- Thanks to lithium, good adhesion is formed, which does not decrease with temperature changes.

- Protects internal parts of the steering mechanism from corrosion. If the seal of the anthers is broken, moisture and reagents from the road surface invariably get inside. Metal can only be preserved with high-quality lubricant.

- Chemical neutrality is required. The mechanism can consist of steel, copper, aluminum and composite materials. This is especially true for lubricant for the steering rack with power steering. The piston system contains rubber or silicone seals and O-rings. The lubricant should not destroy them, otherwise the hydraulic booster will fail.

- Restoration of worn surfaces. Compositions with lithium additives at the molecular level restore worn surfaces on the gear-rack pair.

- Zero hygroscopicity and good water-repellent properties. The steering rack is located under the bottom of the car and is constantly exposed to water and dirt.

Lubricant for a steering rack with electric power steering should have the same properties, except that neutrality with the rubber seals is not required. Lithium greases have good dielectric properties, so lubricating the electric power steering cannot harm its motor.

Table 1. Main characteristics of sealing lubricants produced by Dow Corning and

| Replacing the steering rack of a VAZ 2114 Type of material | Brand | Base oil | Filler | Load-bearing capacity (welding load), N | Working range temperature, °C |

| Plastic lubricant | EFELE SG-311 | PJSC* | — | — | -60…+120 |

| EFELE SG-391 | PJSC | Composition of white solid lubricants | ≥ 2000 | -40…+160 | |

| EFELE SG-393 | Silicone | PTFE | — | -40…+160 | |

| PJSC | Composition of white solid lubricants | 3924 | -40…+149 | ||

| PJSC | Composition of white solid lubricants | 2200 | -50…+140 | ||

| PJSC | PTFE | 3140 | -60…+130 | ||

| PJSC | PTFE | 5500 | -50…+150 | ||

| PDMS | — | 1600 | -50…+190 | ||

| PDMS | PTFE | 1180 | -40…+200 | ||

| PFMS | — | — | -65…+175 | ||

| FS | PTFE | 3924 | -40(-31)…+232 | ||

| Compound | PDMS | Silica gel | — | -40…+204 | |

| PDMS | Silica gel | — | -40…+200 | ||

| Paste | PJSC | PTFE | 5500 | -50…+150 | |

| Mineral | Composition of white solid lubricants | 4800 | -25…+125 |

*Interpretation of abbreviations: PAO – polyalphaolefin; PDMS – polydimethylsiloxane; PFMS – polyphenylmethylsiloxane; FS – fluorosilicone; PTFE – polytetrafluoroethylene.

Synthetic greases EFELE SG-311 and EFELE SG-391 with NSF H1 food grade approval are based on PAO oil. They are compatible with plastics and elastomers, resistant to water and have excellent anti-wear properties.

EFELE SG-393 sealing grease with food grade NSF H1 approval is based on PTFE-thickened silicone oil. It has high sealing properties, is operable in water, steam and chemically aggressive environments and is compatible with plastics and elastomers.

Synthetic PAO greases Molykote G-1502 FM with food approval NSF H1 (Fig. 4), Molykote EM-60L (Fig. 5), Molykote G-2003, Molykote YM-102 are characterized by a wide range of operating temperatures, compatibility with plastics and elastomers , high water resistance.

Molykote EM-60L (Fig. 5) and Molykote YM-102 contain highly dispersed PTFE in high concentrations, which allows these lubricants to provide the lowest friction and high load-bearing capacity. These greases are most common in valve manufacturing for water and gas supply systems.

Molykote PG-21, Molykote G-5032 and Molykote 55 O-Ring greases contain silicone oils (PDMS, PFMS) and have a high viscosity index. This allows them to be used equally effectively both at low (up to -65 °C) and high (up to +200 °C) temperatures. Lubricants based on silicone oils are more resistant to chemical attack and oxidation. In many cases, low friction in metal-polymer systems can be ensured by lubricants with silicone base oils, even without an antifriction filler in their composition.

If the working medium in the pipeline is petroleum products (kerosene, diesel fuel, etc.), then it is necessary to choose fluorosilicone lubricants with a polytetrafluoroethylene thickener. Molykote 3451 and Molykote 3452 greases are resistant to liquid hydrocarbons, isopropanol, methanol, toluene and other chemically active substances that dissolve conventional lubricants.

Dow Corning 4 and Molykote 111 silicone compounds (Figure 6) are the most versatile sealing compounds. They simultaneously function as lubricants and sealants. Possessing high sealing properties, resistance to steam, water, oils, alkali and acid solutions, methanol and ethanol, they simultaneously keep the joints mobile and effectively reduce friction in them. Compounds are used in ball valves for gas and water supply, as well as in chemical production.

Molykote DX Paste and Molykote E Paste are lubricating pastes for solving the most acute problems in metal-polymer friction pairs. These lubricants are capable of operating under extremely high loads. The highly dispersed PTFE filler contained in the pastes fills micro-irregularities in the surface and forms a lubricating film on it with very low friction.

Which lubricant is better, we analyze the manufacturers

Any experienced driver who repairs cars himself in a garage will list the magic list:

Moreover, these can be both names and “common nouns”. The main issue is the composition of the additives.

Calcium, sodium-calcium and graphite lubricants are not suitable for steering racks. They cannot withstand low temperatures and absorb moisture. The situation is similar with copper lubricants.

Barium and hydrocarbons resist moisture, but at low temperatures they turn into ordinary soap (in consistency). So that leaves lithium.

Among domestic manufacturers we can highlight:

- . While maintaining recipes proven over the years, new technologies are used.

- Gazprom and Rosneft produce good quality Litol-24.

- Import manufacturers are represented by well-known companies Molykote and EFELE.

It is difficult to single out any manufacturer for the top step of the pedestal; they all meet the standards. For car enthusiasts, it is not the choice of a specific brand that is important, but the timeliness of lubrication. Otherwise you will have to change the steering rack

How to lubricate the steering rack

The exact parameters must be indicated in the instructions supplied by the automaker; you must follow them. But external factors are also taken into account, including climatic conditions.

For example, some lubricants are not suitable for cold climates with sub-zero temperatures. To improve properties, additives are added - they increase frost resistance, oxidation resistance, moisture resistance and other characteristics.

Among the various types of lubricants, those made on a lithium basis are considered suitable for the steering rack. They can last for a long time and do not dry out much when exposed to oxygen. They are not afraid of water; if moisture gets in, the composition retains its original properties.

A viscous substance is produced by thickening petroleum oils with lithium soap. Lubricants are distinguished by their degree of viscosity, and they also come in different colors. The most commonly used types of lubricants are:

- Fiol - available in varying degrees of viscosity.

- Cyatim 201 is a domestic development and is in wide demand due to its affordable cost. It has an operating temperature range from -60 to 90 degrees.

- Severol is frost-resistant, designed for regions with cold climates.

- Litol-24 - at a temperature of -20 degrees, the viscosity of this product is halved.

It is better to choose the level of frost resistance with a margin, otherwise the mixture designed for -25 degrees will freeze in a sudden frost of thirty degrees. But first of all, it is important to follow the recommendations of the car manufacturer. As a last resort, the recommended product is replaced with an analogue of similar composition.

The service life of the mechanism is affected by operating conditions. The hinge must remain sealed to prevent dust and moisture from entering it. When the seals are damaged and do not fit tightly, even an ideal lubricant cannot improve the safety of the parts. The lubricant mixture mixed with dirt particles only increases wear.

When to and when not to lubricate the rack

You can determine the malfunction of this unit with 100% accuracy by contacting the nearest service station. But it is also possible to independently identify the need for lubrication. To do this, you need to listen to the car while driving and pay attention to extraneous sounds.

If there are knocking noises in the steering gear area, one of the most likely causes is a lack of lubrication. Often the sound appears only when driving on rough roads outside the city. But using this method does not provide a complete guarantee, because the reason may not be in the rack at all.

When the steering wheel stops turning, this indicates that the steering mechanism has become jammed. Such a breakdown is possible, for example, when the teeth bite due to insufficient lubrication. You cannot ignore it, since the car’s controllability and road safety depend on the serviceability of the steering wheel.

Teeth on the steering rack

Often drivers decide to lubricate the rack if the manufacturer used little lubricant. After purchasing a new car, it is recommended to check this unit, even if there are no visible problems. This measure is simply necessary if the steering wheel has to be turned with force. But you shouldn’t lubricate the rack when you don’t have a suitable product at hand.

When applying lubricant, it is important to completely fill the gaps and turn the steering wheel so that the mixture is evenly distributed. For this reason, a syringe is used for injection, which can be purchased at a pharmacy. It allows you to pump a lubricating substance into hard-to-reach places.

In cold weather, a lubricant that is not suitable for the temperature range will freeze. As a result, the steering wheel will stop turning; in order to move, you will have to warm up the engine for a long time. Then a crunching sound is possible when turning the steering wheel, so as not to damage the anthers, you will have to be careful when driving.

If you start making sharp jerks, the mechanism may be damaged. On vehicles with power steering, the hose may rupture and the power steering pump may fail. Of course, you can continue to operate the vehicle, but it is better to change the lubricant to one suitable for sub-zero temperatures.

Causes of leaks

There are several common reasons why the steering rack leaks:

- The main thing is driving with torn rubber covers. Moisture penetrates through the holes and gets onto the shaft, causing corrosion. The rusty surface becomes rough and begins to rub the seal lip. The slightest gap is enough for oil to escape under pressure.

- Failure to comply with the rules for handling the hydraulic booster. Holding the steering wheel in the extreme position for a long time leads to an increase in pressure inside the chambers and squeezing of the seals. If the driver constantly repeats the mistake, oil leaks from the rack will inevitably appear.

- Adding unsuitable hydraulic fluid or other composition that destroys the rubber of the seals.

- Long-term operation without replacing fluid that accumulates debris and small chips. In this case, the oil seal leaks due to abrasion.

- Critical wear of the hinge joints of the steering tips with the shaft. Due to the dangling rod, air and moisture penetrate under the boot, causing corrosion. The process then proceeds according to the scenario described in the first paragraph.

Steering rack repair is possible, and the cost of the event depends on the degree of wear. In some particularly advanced situations, the unit cannot be restored.

How to lubricate the steering rack

The longer a given unit is in use, the more attention must be paid to maintenance. If there are serious problems, it is better to completely disassemble the mechanism. Only with complete disassembly can you lubricate the rack as efficiently as possible. To carry out the work you will need the following tools:

- set with keys and sockets;

- nail polish or marker;

- syringe;

- hose connected to the syringe;

- WD-40 product.

First, the steering wheel is placed in the middle position and the position of the shaft is marked with nail polish or a marker. If this is not done, during subsequent assembly it will be difficult to understand what position the shaft was in. To get to the steering rack, you need to remove the interfering parts in the engine compartment.

If the mechanism is equipped with power steering, you will first need to pump out the fluid from it. This operation can be performed using a syringe with a hose connected to it. Next you need to install the jack and remove the front wheel.

Then you need to unscrew the stabilizer link and the lateral stability arm.

Now you can remove the protective boots and steering rods. After this, the locking nut and bolt are unscrewed, which holds the steering shaft.

The shaft is knocked up using a hammer, having first removed the retaining ring.

Now you can remove the seals, it is important to remember that the top one is secured with a locking pin. This pin can be knocked out with a hammer.

Disassembling the rack

It is better to disassemble and reassemble the steering rack cleanly, without sand and dust. If abrasive particles get inside, the surfaces and seals will quickly wear out, and the rack will leak. Secure the rail in a bench vise; if you don’t have one, place clean cardboard or other material in the disassembly area.

Procedure for disassembling the steering rack

- Remove the clamps and pull off the tie rod boots.

- Securely fix the rack body and unscrew the steering rods (there are grooves for an open-end wrench on the threaded coupling).

- Unscrew the lock nut and the adjusting mechanism nut, remove the washers and the pressure sleeve from the mounting socket.

- Unscrew the drive shaft housing or nut (a special wrench may be needed) and remove the shaft from the housing.

- Pull out the rack gear rod.

- Remove the sealing collars, bushings and fluoroplastic rings from the rack body.

How to lubricate the steering rack without removing it

Since removing the entire assembly is difficult, many people refuse such a complex method. But the rail can be lubricated without removing it. First you need to remove the protective casing from the motor cover. Now you need to find the steering rack boot and cut off the casing on which it rests with side cutters.

You need to check the condition of the boot and rod. If there is little or no lubricant on the surface, then you need to apply it. For this purpose, it is convenient to use a syringe or a rod bent in the shape of the letter “L”.

The viscous mass must be packed between the body and the rod. Next, the boot is installed; to secure the parts, you need to use ties of the appropriate size. Then you need to turn the steering wheel to the right and lift the car with a jack to get to the rack. All that remains is to check the boot on the wheel side.

The process of pumping lubricant is discussed in detail in the video:

Even without lubrication, the car will be able to drive, but the mechanism will wear out quickly, and at sub-zero temperatures the steering wheel will not turn. Therefore, you should regularly check that there is sufficient lubricant. The main thing is to know the temperature range at which the car will be operated. It is not necessary to contact a specialist, because any motorist can lubricate the mechanism if desired.

How to lubricate the steering rack? Service is sacred

Some time of operation of the car is enough for its owner to become interested in how to lubricate the steering rack.

Owners of used cars, both domestic and foreign, face this problem more often. If this operation is not performed on time, it will lead to accelerated wear of this unit. Paying due attention to this mechanism means ensuring road safety, since it is this unit that bears enormous responsibility for the stability and behavior of the car on the roads. Owners of not only domestic cars, but also foreign cars will be interested in knowing how to lubricate the steering rack, since the operating principle and design features of these units are largely similar. These units contain parts made of plastics and light alloys that need lubrication, otherwise they will quickly become unusable. But in addition to understanding that the assembly needs to be lubricated, you also need to know what kind of lubricant can be used for this.

Diagnostics

Error codes

c1044 - incorrect sequence of the rotor position sensor (RPS)

c1621 - incorrect voltage 5V

c1622 - speed signal circuit failure

c1011 - car engine speed signal circuit, no signal - the signal from the idle sensor (or the standard tachometer through a voltage limiter) is divided by 4 and applied to the tachometer input,

c1022 - error, voltage of the main output of the torque sensor - it is possible that the shaft cover has rubbed the insulation and the middle, green wire shorts to ground

A little about the structure of this node

The main task for any design of devices that control a car is the transmission and transformation of the rotational movement of the steering wheel into translational movements of the steering tips. The main element of such devices are steering racks. Its design necessarily includes a rack and pinion. It is with their help that the rotational movement of the steering wheel is transmitted to the wheels.

The gear is connected to the steering wheel; when it rotates, its teeth cling to the same teeth on the rack and push it in the direction the driver wants. From the rack, these movements are transmitted to the steering rods; they are installed at both ends of this device. These rods are connected to the steering ends. They are designed to transmit steering movement to the front wheel pins.

Only by studying and understanding how this mechanism works can you avoid its failure ahead of schedule.

It is important to know and understand the principle of maintenance, what time limits are allocated for this, what lubricants can be used for this without fear of harming this device. The timing of routine maintenance is affected by the mileage of the vehicle at the time of maintenance and the condition of the parts of this unit. The longer the period of use of this mechanism, the more careful the approach to maintenance should be.

Components of the amplifier. Types of power steering

In general, the main task of an amplifier in a passenger car is to increase safety, and only then to ensure comfort.

The power steering device includes several main components:

- pump;

- distributor;

- power cylinder;

- connecting pipelines.

Power steering elements

The equipment used two types of hydraulic boosters:

- Combined (integrated).

- Separated.

The combined type is distinguished by the fact that the distributor and cylinder are integrated into the steering mechanism, which makes it possible to significantly reduce the metal consumption of the structure and make it more compact. Thanks to this, it has become widespread, including on passenger cars.

The split type was used on a number of trucks. Its peculiarity lies in the fact that the power cylinder is a separate element that interacts with the steering drive. But because of this decision, the power steering design turned out to be more cumbersome, so it is not used on passenger cars.

Pump

From the name of the amplifier it is clear that the main working element in this mechanism is liquid. Since it is incompressible, when pressure is created, a force can be obtained that will perform the required function.

And this pressure is created by the pump. In a simpler mechanism scheme, the pump is belt driven from. This design element can be gear (less common type) or rotary (also called blade). Most often, the second option is used on cars.

The design of a rotary-type power steering pump is very simple. Its main elements are a housing with supply and outlet fittings and a shaft, at one end of which a drive pulley is installed, and at the other - a rotor with blades. This rotor is located in a specially shaped chamber - the stator (its role is played by the housing). Due to this shape of the stator, liquid is pumped, which is then supplied to the outlet fitting leading to the distributor.

Power steering vane pump

The disadvantage of a pump driven from the crankshaft is that the pressure generated varies depending on engine speed. Because of this, the force created by the power steering at low speeds is insufficient, and at high speeds it is excessive, which leads to the appearance of an effect such as an “empty steering wheel” (“feedback” of the steering control is absent, so the information content of the steering control is very small).

Operating principle of gear and rotary pumps

To eliminate this drawback, the power steering pump device includes a pressure regulator that maintains it at a given value. It functions very simply - when the pressure is exceeded, the regulator, moving, opens a bypass channel between the supply and outlet channels and part of the pressure is released.

Distributor

Liquid under pressure created by the pump is supplied to the distributor. The task of this component is to distribute fluid flow depending on the steering position. The most widely used valve in passenger cars is the rotary type spool valve. This unit is an intermediate link between the column shaft and the steering gear.

Rail distributor device

The distributor consists of two elements - a shaft and a rotary spool. These elements are mounted on a torsion bar, which connects the column shaft and gear.

The distributor is approached by a supply fitting from the pump, a return line (through which the liquid returns to the pump) and two terminals leading to the power cylinder.

Distributor operating diagram

The essence of the distributor's operation is this: when the steering wheel rotates, the resistance coming from the wheels leads to twisting of the torsion bar, which in turn ensures the rotation of the spool relative to the distributor shaft. Because of this, some channels open and others close, that is, a redistribution of the fluid flow occurs.

Cylinder

The power cylinder acts as an actuator. In the combined type of power steering, it is completely integrated into the steering mechanism. The piston is the steering rack, which additionally has a washer with seals, and the cylinder is the housing. The piston divides the cylinder into two chambers connected by pipelines to the distributor.

What is it for?

Many devices, including steering ones, have units in which parts made of different materials interact. This relationship is never without friction. Probably, many drivers remember from a school physics course that in places of friction there is always an increase in temperature in the area of work of the rubbing pairs. In these places, the process of wear of parts accelerates.

In order to somehow reduce this wear and significantly extend the service life of such components, various types of lubricants are used.

In addition, lubrication reduces the amount of effort required to turn the steering. This fully applies to mechanisms with electric and hydraulic drives. In some cases, to carry out such work it is necessary to remove it from the machine, completely disassemble it, clean it, wash it, and only then apply new lubricant.

What is used for lubrication?

Recommendations for performing such operations are usually carefully prescribed in the operating instructions for the machine. This takes into account the design features of the unit, the region of use of the vehicle, and other important aspects of its operation. The most effective lubricants for such mechanisms are products that are made on a lithium basis.

Such products include Litol-24, Fiol, Tsiatim

Severol

is well suited for areas with severe frosts . During their manufacture, additives are added to the composition to increase moisture resistance, wear resistance, counteract oxidative processes, and maintain conservative properties. We told you how to lubricate the steering rack, but in addition to replenishing the lubricant, you should pay attention to the condition of the steering protective covers. Sand, dirt and other foreign objects get into breaks and cracks, which greatly accelerates the wear of rubbing pairs.

A few words about types of devices

The differences in such mechanisms can be easily seen by owners of cars that have driven different models. They can immediately point out not only external and design differences, but also the sensations when driving a car. Today, several types of such mechanisms are installed on cars, they can be like this:

- Mechanically driven devices;

- Hydraulic driven mechanism;

- A unit based on an electric drive.

Today, the most modern devices are electrically driven racks, but the most widespread are still devices with mechanics or hydraulics as a drive. The electric drive and hydraulics in this device are designed to reduce the force on the steering wheel when the driver rotates it.