In the VAZ 2114 injection engine, one of the most important systems is the power supply system. This definition refers to the supply of fuel to the injectors and then into the manifold intake pipe to create an air-fuel mixture. It is not pure gasoline that is injected into the cylinders, but a mixture mixed with air in a certain amount.

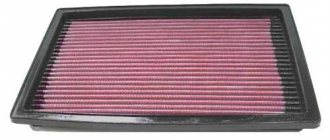

Air filter VAZ 2114

Diagram and order of air movement in the VAZ 2114 injection engine

In an injection car engine, the air movement pattern is somewhat different from that of a carburetor internal combustion engine. Since the injection is controlled electronically, the system has built-in sensors connected to the on-board computer.

- The air driven through the cooling system fan enters a panel-type air filter, unlike the round, large-sized one that was on carburetor engines; this filter is small-sized, but effective in terms of cleaning and creating normal air flow. The fact is that injection engines are very responsive to the quality of the air entering the intake pipe.

- At the outlet of the air filter, between the filter and the corrugated hose of the intake pipe, there is a mass air flow sensor. The mass air flow sensor is designed to measure the amount of air that the engine sucks in, in kg/hour. If it overestimates the readings at low throttle, then the engine operates unstably at idle, stalls after a sharp application of gas, and even problems with starting are possible. If it underestimates the readings at high speeds, then traction drops and fuel consumption increases.

- After the sensor, the air enters the corrugated hose of the intake pipe and is supplied to the receiver. There are several more sensors in front of the receiver, such as the idle speed control and the throttle position sensor. The receiver itself is a mandatory accessory of an injection engine and is designed to accumulate air and compensate for fluctuations in the air mass. There are different receiver designs, including sports ones. It is believed that with the installation of such a design it is possible to achieve a significant increase in engine power. Air is taken from the receiver through a hose to the fuel pressure regulator located on the fuel rail.

The main air mass from the receiver enters the intake pipe of the engine intake manifold.

Modifications

- VAZ-2105 - 1.3 l. carb. VAZ-2105 engine with 4-speed Checkpoint.

- VAZ-21050 - 1.3 l. carb. VAZ-2105 engine with 5-speed Checkpoint.

- VAZ-21051 - 1.2 l. VAZ-2101 carburetor engine with 4-speed gearbox.

- VAZ-21053 - 1.5 l. carb. engine VAZ-2103 or injection VAZ-2104 with 5-speed. Checkpoint.

- VAZ-21054 is a small-scale modification produced for the traffic police, the Ministry of Internal Affairs and the FSB with an additional gas tank and battery.

- VAZ-21055 - 1.5 l. diesel VAZ-341 produced by Barnaultransmash, small-scale modification for taxis.

- VAZ-21057 (Lada Riva) - an export version of the VAZ-21053 with right-hand drive, produced in 1992-1997 for the UK.

- VAZ-21058 is an export version of the VAZ-21050 with right-hand drive, produced in 1982-1994 for the UK.

- VAZ-21059 - 1.3 l. rotary engine VAZ-4132 with a power of 140 hp.

| 2105 | 21051 | 21053 | 21055 | 21059 | |

| Performances | Four-stroke, gasoline, carburetor, four-cylinder | diesel | rotary | ||

| Body type | sedan | ||||

| Number of doors | 4 | ||||

| Places | 5 | ||||

| trunk volume, dm 3 | 345 | ||||

| Overall dimensions, mm : | |||||

| length | 4130 | ||||

| width | 1620 | ||||

| height | 1446 | ||||

| own weight, kg | 995 | ||||

| payload, kg | 400 | ||||

| Wheelbase, mm | 2424 | ||||

| Front wheel track | 1365 | ||||

| Rear wheel track | 1321 | ||||

| Drive wheels | rear | ||||

| Ground clearance to floor pan | 182 | 182 | 182 | ||

| Clearance to rear axle beam | 170 | ||||

| Clearance to front suspension beam | 175 | ||||

| Engine | 2105 | 2101 | 2103 | 341- diesel | VAZ 4132 |

| working volume, cubic meter cm | 1290 | 1198 | 1452 | 1524 | 1308 |

| Max. power, kW (at rpm) | 46,8 (5600) | 43,2 (5600) | 37(4600) | 103 (6000) | |

| Max. power, l. With . | 63,6 | 58,7 | 71,1 | 50,3 | 140 |

| Max. torque, Nm (at rpm) | 92(3400) | 85 (3400) | 103,9(3400) | 92,0 (2500) | 186 (4500) |

| supply system | carburetor | carburetor | carburetor | ||

| KP | |||||

| Number of gear stages | 5 or 4 | 4 | 5 or 4 | 5 | 5 |

| Gearbox ratios: | |||||

| I | 3,67 | 3,67 | 3,67 | 3,636 | 3,636 |

| II | 2,1 | 2,1 | 2,1 | 1,95 | 1,95 |

| III | 1,36 | 1,36 | 1,36 | 1,357 | 1,357 |

| IV | 1 | 1 | 1 | 0,941 | 0,941 |

| V | 0,82 | 0,82 | 0,784 | 0,784 | |

| reverse | 3,53 | ||||

| Final drive ratio | 4,1 | 4,3 | 4.1 or 3.9 | 3,9 | 3,9 |

| Maximum speed, km/h | 145 | 142 | 150 | 125 | 180 |

| acceleration to 100 km/h, s | 18 | 20 | 17 | 23 | 9 |

| Fuel consumption, l/100km: | |||||

| fuel consumption at 90 km/h | 7,5 | 5,8 | 9,5 | ||

| fuel consumption at 120 km/h | 10,1 | 8,0 | 12,5 | ||

| fuel consumption in the urban cycle | 10 | 6,7 | |||

| Fuel tank capacity, l | 39 | ||||

| Front brakes | disk | ||||

| Rear brakes | drums | ||||

| Braking distance loaded from 80 km/h | 38 | ||||

| Parking brake drive | cable | ||||

| Clutch drive | hydraulic | ||||

| Front suspension | independent | ||||

| Rear suspension | five-rod | ||||

| Steering | worm - roller | ||||

| Smallest turning radius | 5,6 | ||||

| The weight of the towed trailer is storm. | 600 | ||||

| Towed trailer weight without brakes | 300 | ||||

| Max, roof rack weight | 50 | ||||

| Maximum lift without acceleration | 34 | 34 | |||

| Resource until the first cap. repair, km | 150 000 | ||||

| Cold start temperature, C | -25 | ||||

| Tires | 13″ | 13″ | 13″ | 165/70R13 175/70R13 | 13″ |

| Dashboard | 2105 | ||||

| Seats | 2105 | ||||

| Rear window defroster | + | + | + | + | + |

| Cooling fan | mechanical | mechanical | mechanical | ||

| Bumpers | aluminum | ||||

| Exterior mirrors | left | ||||

| Seat upholstery | is . leather | ||||

| Headlining | film | ||||

| Door trim | unified |

* – as you master it ** – installed on special equipment

Design and purpose of the VAZ 2114 air filter

The main purpose of an internal combustion engine air filter is to most effectively clean the incoming air mass from dust, moisture and dirt. In addition to trapping harmful particles, the filter must provide as much air flow as possible. These are two main requirements for the VF, which are reflected in the form of specific parameters in the product data sheet.

The panel-type VF housing is made of plastic; rows of paper filter elements are placed in it. They are sealed using special polymer rings. When air enters the filter, it is heavily contaminated, foreign particles settle on the walls of the filter elements, and over time they accumulate so much that air begins to flow in limited quantities and engine power decreases.

Automotive publications, such as the magazine “Behind the Wheel,” periodically analyze the effectiveness of air filters offered by manufacturers and car dealerships. For the main indicators they take the longest operating time and the lowest resistance to air flow. Based on the results of one of these analyses, you can pay attention to several foreign and domestic brands and find out, among other things, how much an air filter for a VAZ 2114 costs:

- “MANN” made in Germany, its code is C 22117, the average price is 250 rubles.

- “HENGST” made in Germany, its code is E 22 L, the average price is 200 rubles.

- “BIG” made in Russia, its code is GB 9597 C, the average price is 100 rubles.

- “AF” made in Russia, its code is 2112-1109080-02, the average price is 80 rubles.

About the “nulevik” resource

But as for frameless “zeros”, they must be cleaned. This is done once every 10 thousand kilometers. But you need to know how to do it correctly. You cannot simply remove and wash the part under water. It won't have any effect.

First, the element is treated with a special impregnation (dry, without soaking). Next, you need to wait a while (usually 10 minutes) and rinse the element in water. It is not necessary to re-impregnate it. Once dry, the element is ready for reuse.

But please note that the FNS should be installed only after it has completely dried, otherwise water will get into the cylinders. To speed up the process, you can use a hairdryer at home. If you do not change the air filter on a VAZ-2114 for a long time, it may develop the following problems:

If you do not change the air filter on a VAZ-2114 for a long time, it may develop the following problems:

- Reduced engine power.

- Increased fuel consumption.

- Acceleration failures.

- Unstable engine operation at idle.

- Long engine warm-up.

When the filter is clogged, the machine stops “pulling” normally. Of course, the car owner will not like this. Therefore, you need to be guided by mileage. After 10 thousand, the car needs to change both the oil and the air filter.

The procedure for replacing the air filter of a VAZ 2114 engine

On a VAZ 2114, the air filter needs to be replaced after a mileage of 10-15 thousand kilometers, but not more than 30 thousand kilometers. Moreover, replacing the air filter on a VAZ 2114 should be done regardless of the visual condition in which it is. Some experts recommend blowing out the VF with a stream of compressed air instead of replacing it. As a temporary measure, this measure can be taken into account. But only as a temporary one. It is necessary to change the VF, because the performance of the car depends on its condition. The car's operating instructions will tell you how to replace the air filter on your car.

To increase engine power, some experts recommend installing a so-called zero-resistance filter instead of a conventional filter. Before deciding on such a replacement, you need to weigh the pros and cons. The fact is that in this case it is necessary to carry out some modifications to the intake system, carry out chip tuning and a number of other measures. You need to know how to properly install the air filter on a VAZ 2114.

In addition, a zero-resistance filter requires additional care and a lot of time can be spent on this. It needs to be impregnated with a special composition, and very carefully so that the impregnation does not get on the mass air flow sensor, otherwise it will produce incorrect data and this will lead to engine malfunctions.

Nulevik should be regularly cleaned and washed in a bucket.

So, how to install an air filter on a VAZ 2114.

- Before you start replacing the VF, you need to prepare. Buy a filter and prepare the necessary tools, as well as a rag for wiping the filter housing and its insides. The price of a VAZ 2114 air filter ranges from 80 to 250 rubles.

- Open the hood and disconnect the battery.

- Disable mass air flow sensor.

- Wipe the air filter housing with a rag.

- Unscrew the four screws with a Phillips screwdriver and lift the cover.

- Pull out the air filter and wipe the inside of the housing.

- Place a new air filter to replace the old one and close the cover, not forgetting to check the presence of a rubber gasket that ensures a tight fit of the cover to the body.

- Tighten the four screws and connect the mass air flow sensor.

The installation of the VAZ 2114 air filter has been completed and, according to established experience, this procedure takes from 10 to 15 minutes.

Replacement frequency, what oil to fill

According to the manufacturer's regulations, service changes of engine oil on the VAZ 2105 are carried out after 8,000-10,000 kilometers or at intervals of 1 year.

But some car owners consider this interval to be a little too high, recommending that it be shortened taking into account operating conditions. It is recommended to use semi-synthetic with a viscosity of 10W-40 as a lubricant. The following motor oils are most popular among model owners:

- Lada Professional 10W-40

- Lukoil Genesis Advanced 10W-40

- Shell Helix HX7 10W-40

- Total Quartz 7000 10W-40

From this list, anyone can choose based on preference, price or love for the brand.

When using this car in winter, you should select oil taking into account the climate zone, as well as the recommendations of AvtoVAZ. Viscosity 5W-40 will allow you to operate the car down to -30°C, and 0W-40 up to -35°C.

If you use motor oil of different viscosities for winter and summer, but of the same brand and manufacturer, then flushing is unnecessary.

Starter replacement and installation procedure

If the car does not start and the problem lies in the starter, it will need to be dismantled. Moreover, it is best to do this on a lift or on an inspection pit. This will greatly simplify the work. It is also worth carefully reading the photos of the dismantling process in advance. The algorithm includes the following main stages:

it is necessary to disconnect the warm air supply hose to the air filter housing;

the air intake is removed;

the heat-insulating shield is removed from the engine;

then the lower bolt securing the starter is unscrewed;

then two more lower bolts are unscrewed;

the blocks with wires from the starter are disconnected;

Next you need to unscrew the nut securing the wire to the contact relay;

Then the starter can be removed without any effort.

After dismantling, you can inspect the engine Bendix splines and try to rotate the shaft by hand. This will allow you to verify the performance of the bearings or establish their significant wear.

It is important to carefully study the starter in advance. After removal, it is advisable to inspect it and lubricate the threaded connections. This will avoid various problems in the future.

This will avoid various problems in the future.

Reinstalling the starter is carried out in the usual way, in reverse order. If possible, threaded connections should be lubricated with graphite lubricant. This will avoid future problems associated with unscrewing.

It is important to perform all procedures carefully

Solex

Immediately after the DAAZ, without retreating a step, comes the Solex model. This is one of the heaviest carburetors in terms of installation. Removing this device from the engine is not a problem, but installing it on the 2107 engine requires a lot of work.

The Solex circuit is the same as the others, but its design is somewhat different. To install it on a car, you will need to purchase some additional parts: a throttle cable from a VAZ 2108, a return tee, a longer fuel hose and a return valve from the G8. Design features of the Solex included 2 chambers with increased volume. This enabled the engine to perform better, namely: increase acceleration speed, rated speed and power. Of course, with such an improvement in performance, there was one drawback - increased fuel consumption. Therefore, the Solex was considered more amateur than for everyday use. Just like Ozone, it had modifications 1107010 and 1107010 - 20. It can be installed on both the VAZ 2107 and 2105.

LADA

This is one of the most famous domestic car brands in the world, which was developed and launched in the 60s, which is still in production and production. During the Soviet years, Lada was the largest manufacturer of cars, most of which were exported to Western Europe. Let us remind our readers that the first Lada models were developed on the basis of Italian Fiat cars. In appearance, some Zhiguli models were very similar to cars of the Italian brand.

However, despite their similarities, the first Lada cars were not actually Italian Fiats. This was really our Russian car, the external design of which was “written off” from famous Fiat cars.

Yes, of course, Lada is not a BMW or a Mercedes. But the company's management did not expect to rely on so-called sophistication and power. The main goal of the management was clear, to produce a simple and reliable car that could deliver citizens from point “A” to point “B”, offering the driver of the car optimal maneuverability and comfort on the road.

Not many global automakers can boast of producing such models, which were first introduced to the car market more than 40 years ago. For example, AvtoVAZ only recently removed the VAZ-2105 and VAZ-2107 models from serial production. The old classic in its various versions (models 2101, 2102, 2103 and 2104) sold 20 million copies worldwide. It was only in 2012 that the company’s management decided to completely stop the production of older car models.

The most popular model of all the classic Zhigulis was the VAZ-2105 model, which was created on the basis of the 124 Fiat model of 1966. The AvtoVAZ classic was valued among the population for its low cost and simple design.

From the very beginning she was the main partner. Nowadays, the general partner of the plant is the group. Today the automobile company has updated its product line. These days on, Lada Kalina, Lada Largus, Lada Priora and the Niva 4x4 SUV. Serial production of the new Lada Vesta and Lada X-Ray models will also begin very soon.

| VAZ 2101 | VAZ 2102 | VAZ 2103 |

| VAZ 2104 | VAZ 2105 | VAZ 2106 |

| VAZ 2107 | VAZ 2108 | VAZ 2109 |

| VAZ 21099 | VAZ 2110 | VAZ 2111 |

| VAZ 2112 | VAZ 2113 | VAZ 2114 |

| VAZ 2115 | Lada Kalina | Lada Priora |

| Lada Granta | Lada Largus | Lada Vesta |

| Niva 4×4 | Lada X-Ray |

Coal option

There is a lot of information on the Internet about how to make it yourself, as well as how to extend the life of what you already have. What enterprising car owners don’t do: they put nylon stockings on it, stuff it with napkins and foam rubber, vacuum it, etc.

It is absolutely impossible to do any of the above, since the filter elements operate in a hot and humid environment and also absorb fats. Therefore, it is not known how nylon or foam rubber will behave in this situation.

In order to make a cabin filter with your own hands, you will need:

- The frame is from an old one.

- Metal mesh.

- Universal carbon material.

- Sealant or hot glue, knife or other cutting tool.

- First you need to cut out the old filter element, then install a metal mesh in its place. It will then be a support for new material

Such a mesh can be purchased at a regular market or at a car dealership. It is most often used to decorate air intake grilles.

Instead of mesh, you can use any other material, but it is very important that the final structure is rigid and durable

- Then, from the universal material purchased in advance (by the way, it can be purchased at M.Video at a fairly low price, about 300 rubles), we cut out a piece identical to the old one.

Read more: Pedestrian crossing outside the populated area rules

The entire procedure will take no more than an hour. And in the future you will only have to replace the canvas, since you have already placed the frame in the frame. You can use your remaining piece of carbon sheet again to replace the material in the frame.

This example describes the case of replacing a filter cloth in a plastic frame; in some modern cars the frame is made of pressed cardboard or, in general, there is none, in this case you will have to additionally add structural rigidity.

Compression check

After checking the compression, you can breathe a sigh of relief or worry, since the cost of the repair depends on the result.

Impaired compression often causes the presence of oil in the VF, and also causes a number of other problems.

Compression check

To work you will need:

- Compressometer;

- A rag in oil, which you will use to determine the compression stroke;

- Adapter for spark plug holes. It is used when checking the combustion chamber for leaks;

- Compressor.

Now let's start checking.

- Warm up the engine to operating temperature, then turn off the fuel supply.

- In the case of a carburetor, you need to remove the hose, clamp or squeeze it with something, or lower it into a container.

- If you have an injector, remove the fuel pump fuse, start the engine and let it run. As soon as the fuel in the fuel rail runs out, it will stall on its own.

- Disconnect the ignition system by removing the center wire from the distributor (on the carburetor). The crankshaft position sensor at the injector must be disconnected.

- Remove all debris from the spark plug wells so that it does not end up inside the cylinders. Unscrew the spark plugs.

- Insert the compression gauge fitting while an assistant starts the engine. The starter should rotate the engine until the pressure gauge needle stops in one position.

- By analogy, measurements are carried out on each cylinder, the results are recorded on paper.

- To calculate ideal compression, use the formula - 1.2 * Compression ratio.

See your owner's manual for the compression ratio of your engine. Please also note that measurements may have some error.

What you need to know about verification

- If the indicator is 12 atmospheres, this indicates that your engine is almost in perfect condition.

- When checking the compression on a cold engine, the compression readings will be significantly lower. Perform the test only on the engine at operating temperature.

- If the battery is partially discharged, the test data will also not be accurate.

- The increase in compression occurs due to the combustion of oil in the cylinders.

What the results say

We take the paper where you wrote down the data of the check, carried out according to all the rules, and study what is wrong with the motor.

- Indicators in the range of 0-4 atm indicate a high probability of burnout of the piston, head gasket or valve.

- Compression of 4-6 atmospheres indicates that the piston rings or the partition between them have broken.

- If you get about 8-10 atm in each cylinder, the cylinder-piston group is worn out. Major repairs will soon have to be carried out.

- 12-12.5 atm - these are the indicators that occur in a new, run-in power unit.

- If the car has serious mileage, and the check data shows numbers equal to or exceeding the norm, oil has probably entered the cylinders due to wear of the cylinder-piston group or valve liners.

Obviously, the presence of oil in the filter does not bode well. But the problem can still be prevented if measures are taken in time.

KAMAZ

The Kama Automobile Plant produces vehicles under the Kamaz brand. The company specializes in the production of heavy vehicles and other automotive equipment. This company was founded in 1969. The first mass production of cars began in 1970. Today it is not only one of the best automakers of trucks in our country, but also one of the best automakers of trucks in the world. For a long time, Kamaz vehicles have remained the undisputed leaders and winners in the regular Paris-Dakar races.

Thanks to these races, its cars have gained a reputation as safe, reliable and powerful cars. Currently, this automobile plant produces 260 trucks per day. Produces 93 thousand 600 cars per year.