EXECUTION ORDER

Using a 10mm wrench, unscrew the bolts of the front timing cover:

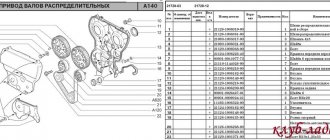

Step-by-step instructions for tensioning and replacing the timing belt on a VAZ 2109, 2108, 21099 with your own hands using a minimal set of tools. To get to the timing belt, you need to remove the protective cover. To do this, use a 10mm wrench to unscrew the two bolts on the side.

and one in the center

Removing the timing cover

To replace the belt, turn the crankshaft counterclockwise so that the mark on the camshaft pulley moves down from the rear cover antenna by two teeth.

Remove the generator drive belt, the right wheel and the right mudguard of the engine compartment. Using a 19mm socket, turn the crankshaft clockwise using the pulley bolt.

until the mark on the camshaft sprocket aligns with the mounting lug on the rear timing cover.

After removing the rubber plug at the top of the clutch housing,

make sure that the mark on the flywheel is located opposite the slot in the clutch housing cover (the coolant supply hose to the radiator has been removed for clarity).

This is how the mark should be located on the engine flywheel (with the gearbox and cylinder head removed).

We fix the crankshaft from turning by inserting a screwdriver through the hole in the clutch housing between the flywheel teeth. Unscrew the bolt securing the generator drive pulley. Remove the generator drive pulley.

Using a 17mm wrench, loosen the nut securing the tension roller.

We turn the tension roller to a position in which the belt will be loosened as much as possible and remove the timing belt.

When replacing the tension roller, unscrew the nut securing it and remove the roller from the stud.

A spacer washer is installed under the roller.

Install the timing belt in reverse order. We put the belt on the crankshaft pulley. Then we put the rear branch on the coolant pump pulley and place it behind the tension roller. We put the belt on the camshaft pulley.

By inserting a screwdriver between two screws or rods with a diameter of 4 mm installed in the hole of the tension roller, turn the roller counterclockwise, tensioning the belt. Tighten the tension roller mounting nut.

We screw the bolt securing the generator drive pulley into place and using the 19-inch head, turn the crankshaft two turns clockwise by the bolt.

We check the alignment marks of the crankshaft and camshaft.

With the generator drive pulley removed, it is convenient to control the position of the crankshaft by aligning the marks on the crankshaft timing pulley and the oil pump cover. If the marks do not match, repeat the operation to install the belt.

Dismantling

To correctly replace the timing belt, you first need to dismantle the element. The process can take quite a lot of time, although the work itself is not very difficult.

- Remove the casing covering the belt, pulleys, dismantle the tension roller and other elements related to the gas distribution mechanism.

- The cover is held in place by three mounting bolts, so removal should not be a problem.

- Remove the alternator belt. This will give you access to the desired object - the timing belt. To do this, lower the retaining bolt down a little and move the generator towards the engine. This will loosen the belt, making it easy to remove.

- Align the gas distribution mechanism to the marks. First you need to install the crankshaft in the required position. This is done by turning it and looking through the hatch on the clutch housing.

- Stop rotating as soon as the mark on the crankshaft flywheel aligns with the marks on the housing. This indicates that the piston of the first cylinder is at TDC - top dead center.

- Make sure that the mark on the camshaft gear is aligned with the mark on the metal housing.

- Having set the marks, you can begin the procedure of dismantling the old worn timing belt.

- Release and move the tension roller to the side. This will release the tension on the strap. As a result, it can be removed from its position.

- Next you need to remove the belt from the crankshaft gear. To do this, the pulley is first removed.

- There should be no problems with dismantling the pulley, since it is removed this way. First remove the right wheel, turn the steering wheel to the right and you will gain access to the side shield. The shield is removed, and behind it is the crankshaft pulley. Relevant for carburetors and injectors.

- If your VAZ 2109 has an injection engine, you will need to fix the crankshaft to remove the pulley. It is not difficult to do such a procedure. Insert a long screwdriver into the special hatch where the flywheel mark is located. This will lock the crankshaft in the required position, so you can easily unscrew your pulley.

- On a carburetor VAZ 2109, fixation should be performed directly on the pulley.

- Before you begin removing the timing belt, examine the condition of the water pump and tension pulley. You should also check whether the axis of the tension roller and timing gear are in good condition.

- If there is damage, defective elements must be replaced.

- Check the current condition of the camshaft and crankshaft seals.

Crack on the strap

Experts agree that when replacing the timing belt, the rollers and pump should also be replaced. But this is a recommendation, not a requirement.

Before you buy Remote washer VAZ 21080100613010, read the important information!

We sell spare parts from official dealers and distributors of the VAZ brand.

Using the part number (21080100613010) and the VIN number of the car, you can clearly determine whether this spare part fits your car or not. If you are not sure about the applicability of a part, you can first consult with our manager.

tel.

tel.

Our manager can also select, if possible, an analogue of the spare part VAZ 21080100613010 and answer other questions, for example, about delivery times.

Pickup

For clients living in the cities: Lyubertsy, Zhukovsky, Zheleznodorozhny, Pavlino, Lytkarino, Oktyabrsky, Ramenskoye, Tomilino, Kraskovo.

And also the districts of Moscow: Novaya Nekrasovka, Kozhukhovo, Nekrasovka, Vykhino, Zhulebino, Kotelniki, Novokosino, South-Eastern Administrative District.

It will be convenient for pickup at one of our stores located at:

Moscow, Tashkentskaya street, 28с1

Moscow region, Malakhovka village, Bykovskoe highway 37/14

For residents of Omsk and the region, the store is located at

Omsk, st. Dekabristov, house 155

Delivery to regions

Carried out by DPD, more than 300 pick-up points in Moscow and the region, 1800 throughout Russia, as well as targeted delivery to your door.

Step-by-step replacement instructions

Why does the alternator belt whistle when starting the engine or air conditioner?

The VAZ 2109 car is designed in such a way that if repair work is necessary, it can be carried out by the car owner himself. The process of changing the tensioner roller is quite simple, and it will take no more than 1.5 hours.

Step-by-step instructions for carrying out technical work on the timing system:

- Park the car. It is best to use a garage with good lighting.

- Next you need to turn off the engine. Wait about 10 minutes for the engine to cool down.

- Using a ratchet wrench, unscrew the timing belt cover.

- Use a special wrench to loosen the belt tensioner.

- Then unscrew the drive pulley.

- Turn the belt half a turn, during which you carefully remove it.

- Next, using a spanner, you need to loosen the bolt that secures the position of the tensioner.

- Then release the tensioner from the pressure in the spring.

- Next, you need to replace the spacer rings and washers, if such are used in the engine of your modification.

- Replace tensioners.

- Once the rollers have been installed and their position has been adjusted, you can begin reinstalling the timing belt.

- It is necessary to align the shaft and generator gear so that the mark in the form of a strip on the gears is directed towards the clutch generator.

- Then you can put on the timing belt.

- Then adjust its tensioner. If the vehicle is equipped with a modified timing belt, the owner will have to adjust all the tensioners at the same time, tightening them half a turn clockwise. Then move counterclockwise to the next one. Continue this way until all the rollers are tightened.

- After assembly is completed, you need to start the engine.

- Then you need to observe the movement of the belt. If there is play in it, it moves with distortions, makes noise, or creaks, then additional adjustments need to be made.

- After the test start, you need to start the engine again and let it run for about 10-15 minutes. Then turn off the car engine and check the battery charge level. If its voltage is normal, then all work has been completed correctly.

roller with a hidden spring roller with an external spring design

If, after the work carried out, the car owner has no complaints about the operation of the engine, then the process of replacing the timing rollers in the engine is over.

Malfunctions after replacing timing rollers

In most cases, after replacing the timing belt tensioners, the car owner does not encounter any problems. However, as practice has shown, malfunctions can manifest themselves after some time.

Malfunctions and solutions:

Fault 1: The battery does not charge well; after several hours of inactivity, the car does not start. Voltage drops are also observed in the on-board electrical network.

Solution: Most likely, when installing the timing belt, the driver incorrectly adjusted the position of the shaft gears in relation to the generator gear. As a result, malfunctions in the on-board network began to appear. They arise due to the asynchronous operation of the gears described above. To eliminate this problem, you just need to debug the position of the shaft gears and the generator. After additional configuration, the problem goes away.

Malfunction 2: After replacing the rollers, the timing belt cracked or even broke.

Solution: In most cases, this problem occurs when a modified timing panel panel is installed. Such breakdowns occur due to the fact that the position of the rollers was not calibrated, as a result of which the belt was overtightened. To eliminate this problem, remove one of the rollers, then put on the belt. After this, install the removed roller back on the panel. Then adjust its position. The adjustment itself must be carried out using a special wrench, which must be used to tighten additional screws on the tensioner. When adjusting the position of the roller, you should also rotate the belt to ensure that there is no excessive pressure on it.

If any other problems occur in the engine after replacing the rollers, a simple solution would be:

- Checking the position of the drive gears. Most likely, due to inaccurate alignment of the shaft when replacing the roller, the generator gear came loose. In this case, it needs to be tightened.

- If the car owner cannot independently solve the above problems, then it is necessary to contact the official VAZ car repair service.

Despite everything, I would like to emphasize that the VAZ 2109 car, although it is the brainchild of the domestic automobile industry, can serve its owner for many years with proper care.

When do you need to change timing rollers?

Most motorists cannot determine in time that the timing belt rollers need to be replaced. It's not the motorists' fault. After all, most of them are accustomed to the fact that the on-board computer informs the driver about the need to replace consumables. It processes data received from various sensors. If necessary, displays a corresponding notification on the dashboard.

In most foreign cars, it is the on-board computer systems that monitor the general condition of the engine. But in this case, the car owner will have to monitor the technical condition of the consumables. The VAZ 2109 does not provide any kind of on-board computer. Everything is the old fashioned way here!

Therefore, you should listen to experienced owners of a car of this model! They recommend replacing rollers when the following symptoms appear:

- When the engine starts, a whistle is heard, after which the smell of melted rubber may come from under the engine compartment shield.

- At high engine speeds, a sharp drop in speed may occur. In ordinary cars, this may indicate some kind of malfunction in the gearbox. However, in the VAZ 2109, this indicates an idle rotation of the rollers, during which the shaft rotation speed drops.

- While driving, a metal grinding sound is heard from under the hood. This happens because the rollers are jammed. As a rule, this happens when they are over-tensioned, or the spacer rings and washers are worn out. In this case, you will also have to replace the rollers, since if such parts are damaged, the roller itself is damaged. Therefore, you will have to replace them with a set. There is an important thing to consider here: additional timing roller parts are not sold separately. They can only be purchased complete with a set of rollers.

- Also something to consider! In the case of an installed modification shield, the motorist will have to spend a much more impressive amount than 3,500 - 8,000 rubles.

- If noise is heard when the engine is running, and when removing the protective casing, the owner sees that when the engine is running, the belt moves not only in a circle, but to the sides along with the roller, then an urgent replacement is necessary.

- If you hear a squeaking sound when starting the engine, then most likely the cause will be either excessive tension on the rollers or damage to their bearings. In this case, it is necessary to urgently remove and check. If during inspection it is discovered that the bearing moves with play, or lubricant is leaking from it, then it must be replaced. Fortunately, the cost of bearings varies from 145 rubles to 356 rubles.

- If, when inspecting the engine, oil smudges are found on the belt, it means either the bearing is leaking or the attachment rings have ruptured. As a result, lubricant from the roller bushings got onto the belt.

Don’t be lazy; in this case, it’s best to conduct a detailed inspection of the rollers, belt, shaft gear, and generator gear. It will take about 30 minutes and can save you up to 50,000 rubles. Since ignoring problems with the timing system can completely damage the engine.

The cost of restoration work on the model 2109 engine varies from 45,000 rubles to 78,000 rubles.

modified timing shield

a conventional timing panel is a variant of a modified timing system panel

There are also cases of installing a special double chain instead of a rubberized belt. As a rule, for the operation of this type of system, the installation of a turbine is necessary. Otherwise, it will not have enough power to rotate the chain. Since the chain requires 0.56 times more power to operate than a standard engine produces.

As you can see, the modified timing shield is slightly wider than the usual one. This change in design is due to the presence of an additional number of timing belt tension rollers. As a result, the size of the shield increases.

The modified shield is installed in the form of an overhead panel on the engine. In this case, all gears are removed. Their bushings are inserted into special grooves on the panel. Then the gears return to their place. The panel itself is fixed with 5-8 bolts, depending on the model.

To avoid serious problems and any malfunctions in the engine, you should replace the rollers on the VAZ 2109 in a timely manner. The manufacturer recommends updating these consumables at intervals of 40,000 - 50,000 kilometers.

The actual condition of the rollers must be checked every 19,500 kilometers.

Compliance with intervals:

- checks;

- replacements.

Allows you to extend:

- timing belt service life;

- the operation of the entire engine as a whole.

It is worth considering the following things that affect the wear of timing rollers:

- use of low-quality bearings;

- the car owner uses rollers from one manufacturer and bearings from another;

- use of low-quality lubricant for roller bushings;

- excessive tension on the rollers, as a result of which excessive pressure is exerted on them - this can lead to their breakage;

- use of parts made from low-quality materials.

Delivery:

— We work only on the territory of Ukraine. The goods are not sent to Russia and Belarus.

— Delivery of goods to the regions is carried out using courier services: Nova Poshta, Ukrposhta. Responsibility for forwarding services lies with service representatives. For exact information about terms, costs and other questions, please contact the service representatives directly. We provide indicative information only.

— Order completion times can vary from 1 to a maximum of 5 working days, depending on the availability of goods in the store.

— The parcel stays at the Nova Poshta office for 5 days, regardless of the type of payment for the goods from the buyer, after which the automatic return of the parcel will be issued and the cost of shipping will be calculated to the sender.

Original solution

In most cases, adjusting the timing belt involves adjusting the spacer washer installed under the NTZ roller. Experienced craftsmen and motorists advise inspecting this very washer, checking to see if it is placed backwards.

Indeed, the amateurism of service station workers in some cases is simply infuriating. Mechanics who have been practicing even for several years may simply not notice the adhesive on the spacer washer, pointing to the correct side. Yes, it is applied with acrylic varnish and may not be noticeable, but if you look closely, you can see it.

Distance washers

What is the function of the spacer washer? The main reason for the belt slipping, as was written above, is not the misalignment of the crankshaft, but the initial unevenness of the working surface. Knowing this, AvtoVAZ designers and mechanics initially came up with the idea of leveling the seat with a spacer washer. And they put it on acrylic glue.

All this is understandable, but why couldn’t AvtoVAZ solve the problem with the internal combustion engine in some other way? It turns out that our inherent laziness and unwillingness to work to the end are also evident here.

According to the standard, all engines assembled at AvtoVAZ must be tested on the assembly line. If a problem with the belt slipping is discovered, the power plants are sent for modification to special workshops, where Uncle Vasya and Uncle Kolya simply install spacer washers to save time. Simple and ingenious, and the manufacturer no longer cares what happens to the engine after a long run when the belt is replaced. The main thing is to provide a factory warranty, and an obviously defective engine can be presented as completely working. These are the pies.

Therefore, if auto mechanics are struggling and puzzling over the problem of a belt slipping, and cannot come up with anything, it is quite possible that the engine is simply from the category of defective ones and modified by Uncle Vasya.

The problem is also solved simply: the washer, firstly, is placed on the correct side, and, secondly, it is sharpened on a sharpener or grown on one side. If you do everything correctly, the belt will move clearly and evenly along the middle of the flywheels the first time, and will not jump off anywhere.

Replacing the timing belt on a VAZ 2109

Gasoline car engines provide for the supply of a fuel mixture to the cylinder while the piston is at top dead center. Synchronization of the rotation of the crankshaft (controlling the piston group) and distribution shaft (controlling the timely flow of the combustible mixture into the combustion chamber, exhaust gas removal) shafts of VAZ cars is carried out using a special transmission element

Mechanical wear of an important structural part causes unstable operation of the motor, loss of power, breakdown, expensive repairs, and possible replacement of the unit. The article answers the question: how to independently replace the timing belt (gas distribution mechanism) on VAZ 2109 cars

When is it necessary to replace the timing belt on a VAZ 2109

Initially, power units used a chain drive, which was distinguished by reliability, durability, and ease of maintenance. The transition to the use of a belt drive made it possible to reduce operating noise, cost, and weight of the product. The belt is a three-layer structure.

The inner working side contains nylon teeth and is in contact with the gear. The main, middle layer consists of fiberglass cords, characterized by high strength, resistance to mechanical and temperature loads, and exposure to aggressive environments. The outer, rubber, protective five-millimeter shell gives the item elasticity and flexibility.

The service life of the product is determined by the manufacturer, operating conditions of the vehicle, quality, and regularity of maintenance.

The reasons for the breakdown may be:

- discrepancy between the guaranteed service life established by the manufacturer and the actual service life (manufacturer’s defect, counterfeit);

- malfunction of oil seals (leakage of lubricating and cooling liquids out);

- damage to protective casings (cracks, bending), allowing contamination, dirt and foreign elements getting under the teeth;

- bearing failure, cessation of rotation of the tension roller;

- the pulley and gears must rotate strictly in one plane, distortions will cause abrasion and destruction of the product (bending the roller pin causes serious problems);

- jamming of the coolant pump, crankshaft, camshaft;

- errors during installation of the gas distribution mechanism (excessive or insufficient tension, pulley misalignments, avoidance of marks);

- defects in the teeth of drive gears (chips, burrs).

Under normal vehicle care conditions, replacing the timing belt on a VAZ 2109 is carried out after fifty thousand kilometers. The lubrication of the tension roller bearing is designed for the same motorcycle mileage. There is an opinion among car owners: it is advisable to change the timing belt and tensioner simultaneously with changing the engine oil. The event will cost several orders of magnitude less than a major overhaul of the power unit in the event of an emergency.

Signs indicating the need to remove the front cover of the protective casing and inspect the transfer unit.

- loss of power, engine malfunctions;

- black smoke from the exhaust pipe;

- extraneous noise on the right side of the engine compartment;

- problems when starting the engine;

- increased vibration of a running car.

Preparatory operations

Changing the pump and roller is a prerequisite so that after a thousand kilometers you don’t have to disassemble everything again. But it’s up to you to decide for the pulley, the price is 150 rubles per pair. There were cars where a slightly bent pulley caused the belt to slip and gradually wear out, reducing its service life. On this car the belt was worn down in half.

Replacement interval

We recommend that you periodically check the condition of the belt to avoid annoying consequences and not have to look for someone to take it to a repair shop. Replace every 40,000 kilometers.

And here is the patient himself.

We unscrew the three ten bolts securing the protective timing cover and remove it.

Next, loosen the nut thirteen that secure the generator and unscrew the tension bolt ten.

We take the generator to the engine and remove the belt.

Set the top dead center

Remove the engine protection and drain the antifreeze. We set the camshaft mark by turning the crankshaft clockwise. The ebb on the pulley should be opposite the bend of the protective cover fastening.

Unscrew the crankshaft pulley mounting bolt. We put the assistant in the cabin and force him to engage fifth gear and press the brake. And at this time we easily and naturally unscrew the bolt using a 19 meter head and a pipe of one and a half meters. It must be screwed properly, and some craftsmen lubricate it with sealants and then wait for kind words addressed to them.

Replacing the tension roller is done as follows:

1. Remove the faulty roller, then install a new roller in its place and tighten using a special wrench according to the instructions described above.

2. Adjustment of the timing belt tension using a tension roller is carried out according to the instruction manual.

Replacing the VAZ 2110 timing belt has been successfully completed, start the engine and make sure that everything is in order. There is nothing complicated about how to replace a timing belt, so there is no need to pay for something that you can easily do yourself, so you can save money while gaining valuable experience.

Some information about the tension roller

The tension roller is an important mechanism in the timing belt, which affects the quality of tension of the belt drive and connects the crankshaft to the generator. Therefore, not only the operation of the timing belt, but also the voltage of the on-board network and the battery charge depend on its serviceability.

The purpose of the roller is to maintain tension at a normal level. When the mechanism is overtightened or loosened, there is a risk of the following problems:

- excessive noise when starting the power plant (for example, whistling or squeaking of a belt);

- a decrease in voltage level, which causes a number of malfunctions in the operation of on-board equipment and disrupts the battery charging cycle;

- roller jamming. In this case, it will be impossible to continue driving.

Adapter washer for timing roller VAZ 2108-2110 7mm (from old to new)

— If your order is sent with prepayment, its packaging will begin after the money is credited to our account/card.

— The indicated prices are selling prices for the goods and do not include shipping, delivery, additional packaging from the carrier (muffler, windshield, subframe, etc.).

— The cost of delivery/shipping is paid by the buyer in all cases.

— If the order amount is less than 150 UAH, cash on delivery delivery (payment upon receipt of the goods) is not possible. In this case, you need to pay for the order before shipping (this can be done to our current account, which is opened in Privat Bank through bank branches, through Privat24 applications and in any other convenient way).

— Cash on delivery also provides for an advance payment in the amount of 80 UAH. (For this we should thank the people who do not pick up parcels from delivery service offices. And now honest people are experiencing the inconvenience. To our deepest regret and sympathy.)

— You can pay with VISA and MasterCard cards on our website through the LiqPay and WayForPay services.

— Only Ukrainian Hryvnia is accepted for payment.

— Your insurance when paying by card is the results of our work - these are our long-term reviews, which are moderated by the Prom and Bigl.ua sites and cannot be corrected by us. Over the past four years, our customers have rated us "excellent" in 99% of reviews.

— For our regular customers who have placed 3 or more orders, orders can be sent without prepayment and without restrictions on the minimum order amount.

— In cases where we received an order from you, which you immediately paid for and we have no additional questions for you regarding delivery, your order can be sent without a clarification call to your phone.

— The management of the auto store reserves the right to change the terms of payment/delivery or not to fulfill your order at all to prevent conflict situations.

— In case of refusal to receive parcels already sent from the store’s warehouse, subsequent orders are sent on the basis of full prepayment.

— Refunds for any reason are made within 3 business banking days.

— Some items are shipped ONLY upon prepayment.

— Refunds, the reason for which is not related to the work of the store (buyer’s mistake, changed his mind, already bought, etc.) are made with a commission of 5%.

Timing belt for VAZ 2109 engine

Previously, the gear device was quite rare and caused some mistrust among car enthusiasts. In modern cars, such a drive is no longer uncommon. And there are a number of objective reasons for this:

- toothed belt drive is less noisy;

- simplicity of design and light weight;

- service costs less.

But, as it turned out, the belt has many disadvantages. Firstly, it is fragile (it often breaks). Secondly, with prolonged use, sagging is observed, associated with squealing. Thirdly, if you tighten the belt, its teeth will “stick together” over time, which will lead to the need for replacement and unstable operation of the power unit.

Purpose of the timing belt

The timing belt is made of rubber and has teeth with serrations on the inside. Its main task is to ensure synchronous rotation of the crankshaft and camshaft drives. Thanks to the belt, a lower camshaft speed is achieved: it is two times lower than the crankshaft speed. Unfortunately, the part does not last as long as the chain, and wears out before 60 thousand kilometers. It is recommended to replace the belt, even if there is visually no visible damage or signs of wear.

https://youtube.com/watch?v=aIOMGBmM3SM

A broken belt completely disables the engine, making it impossible to move the car. On 8-valve engines with a volume of 1.5 liters (the injector and carburetor have the same systems), a broken belt does not lead to the valves being deformed; in common parlance, the valves are bent on the valve cover.

There may be several reasons why the drive breaks.

- Natural wear of the belt or manufacturing defects (poor quality material).

- The ingress of oil and dirt, as a result, peeling of the rubber and breakage.

- The coolant pump is jammed and antifreeze is leaking.

- Tensioner pulley problem.

- Seized camshaft or crankshaft.

In order to avoid the financial costs of eliminating problems when the timing belt breaks, it is necessary, if possible, to monitor the operation of the timing belt:

- do not neglect the established regulations and promptly change consumables (belt, roller, pump, etc.);

- listen to the sound of the engine and if suspicious noises occur, immediately look for the cause;

- Check the belt tension regularly and tighten if necessary;

- monitor the warning lights on the dashboard (the oil pressure warning light indicates a malfunction);

- Avoid oil leaks; if there are any, look for the cause of the leak.

However, monitoring the condition of the belt and other drive elements is problematic due to the protective casing. To solve this problem, it is recommended to make a small inspection slot in the casing cover.

This way you can monitor the condition of the belt. And if there are cracks, scuffs and other damage, replace the drive in a timely manner, without waiting for it to break at the most inopportune moment.

How to tension the timing belt correctly

The optimal tension of the timing belt is very easy to check. Using a little force, you need to unscrew the belt. If the angle at which it is twisted is 90 degrees, then tension is not required.

After replacing any timing element, you will need to tighten the belt. To do this, you need to put it on the toothed pulleys of the crankshaft and camshaft drive and use a tensioner roller to make the tension optimal. After this, you need to crank the engine several times. This can be done with a wrench by turning the camshaft pulley mounting nut. Next, you need to look at the location of the alignment marks on the flywheel and gear - they must match exactly. If there is no match, the belt is removed again. And the pulleys are installed according to the marks, after which the tensioning procedure is repeated.

It happens that even a correctly tensioned belt begins to slip after starting the engine. The reason for this is deformation of the roller pin. It needs to be replaced.

Installing a new timing belt

We check that all marks match.

We first place the belt on the crankshaft and pump. Then we tighten the right descending branch of the belt and put it on the camshaft pulley and tension roller. We check all the marks again and tighten the belt with a roller. The tension is considered sufficient if, with the force of two fingers, you can twist the longest branch of the belt by a maximum of 90 degrees. It’s easier to take the right branch of the belt with two fingers and twist it, if more than 90 is not very bad, but less is very bad. An overtightened belt will wear out quickly and will also reduce the life of the pump.

We place the bottom protective plastic cover. And on the crankshaft pulley we mark the twentieth tooth after skipping two teeth. We count counterclockwise.

This mark corresponds to the top dead center of the first cylinder. We put the pulley in place and the mark should be against the crankshaft position sensor. More precisely, against the small iron core of the sensor. Sometimes it gets into the gap between the teeth, this is considered acceptable. We tighten the pulley in the same way as we unscrewed it, with the help of a partner.

We turn the crankshaft two turns and check the marks; this is where our mark on the pulley comes in handy.

If everything is in trouble, we collect everything that we took apart. As they say in smart books, install the parts in the reverse order of removal. Don't forget to add antifreeze.

We start the car, accept congratulations from family and friends and head off to adventure.