The time has come to replace them and the owners are faced with the question of which valve stem seals are better.

Whether the owners want it or not, one day they will have to think about it, especially if the car already has a “solid” mileage. On some models, this need may arise after a long period of operation, while on others it happens more often. The replacement procedure should not be delayed, since an increase in engine oil consumption incurs additional financial costs and environmental problems.

Owners need to know which valve stem seals are better for the reason that they can navigate the offers of service centers or retail outlets and make the right choice. Today there is no total shortage of not only valve seals, but also spare parts in general. All that remains is to learn correctly, choose good quality products and distinguish fakes from originals.

Which valve stem seals are better?

The estimated service life of valve seals (aka oil seals, MSK) is 100 thousand km, but with intensive use of the car or the use of low-quality fuels and lubricants, they wear out earlier.

Signs of MSC wear are blue smoke during startup and revving on a warm engine, oil and carbon deposits on spark plugs, and increased lubricant consumption. The problem can only be solved by replacing the seals with new ones. However, if you choose low-quality ones, this will happen again faster than you would expect. If you want to know how to choose good valve stem seals with the longest service life, read the article. Here we will determine which company's valve stem seals are better by comparing products from different brands.

Tools for repair

To carry out the repair you will need the following tools:

- a set of keys;

- valve puller;

- tweezers (to pull out crackers);

- oil seal remover;

- a mandrel (or something similar for pressing, for example a piece of tube slightly smaller than the diameter of the oil seal);

- hammer;

- tin solder rod 8 mm.

How to choose quality valve stem seals

You can find out which valve stem seals are better by comparing their key characteristics. The decisive role is played by the parameters on which the service life of valve seals and the efficiency of their operation depend:

Poor quality oil seals cannot withstand the load and quickly lose their shape

In addition to the main performance qualities that determine which valve seals are better, when choosing, it is important to pay attention to secondary indicators:

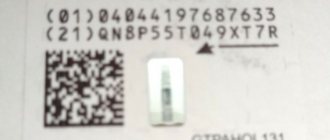

Oil seal on the right with obvious signs of a fake

The table in the next section will help you choose the best valve stem seals.

What is the crankshaft oil seal for and where is it located?

The main purpose of the oil seal is to prevent engine oil from leaking from the engine. Reliable sealing of the holes is possible due to the pressure inside the crankcase, which ensures the tightest possible pressure of the oil seal to the part. Thanks to this principle of operation, the liquid in the internal combustion engine system does not leak and does not subject the engine components and assemblies to excessive frictional loads.

The oil seal is made of heat-resistant material: fluorine rubber, silicone. Also on the outside of the seal you can see some notes; most often, they tell the driver in which direction the crankshaft is rotating. Information is necessary in order to correctly install new sealing elements

The design of the power plant determines the presence of two oil seals - front and rear. The rear rubber product is designed for installation on the part of the crankshaft that connects to the flywheel. The crankshaft end is a flange, so the rear seal has impressive dimensions and a fairly large amount of material, which ensures its long service life.

The front rubber element is mounted on the limit switch, which is the drive for the engine mechanisms. Its dimensions are smaller than the similar part at the other end, therefore the front oil seal is significantly inferior in terms of service life.

Rating of the best manufacturers of oil reflective caps

The same model of valve stem seal from different manufacturers

A review of valve stem seals with their brief characteristics, positive and negative sides, indication of conveyor applications and current prices will help you choose parts for a specific engine.

The table below contains valve seals from all the most popular manufacturers, available in Russian retail.

Valve seals: manufacturer ratings

| Manufacturer | A distinctive feature of the brand, the caps themselves | Which cars are most often installed on from the factory? | Price for summer 2022 in rubles* per 1 piece |

| Elring | Elasticity of rubber, good wear resistance, which is achieved through the selection of materials for various types of engines and high-quality casting. In addition to classic fluorine rubber, polyacrylic rubber, nitrile rubber, Teflon and other modern materials are used | BMW, Mercedes-Benz, Porsche, Toyota, Volkswagen, MAN, Iveco, DAF, Renault | From 150 |

| Victor Reinz | Good caps made of heat-resistant but flexible fluorine rubber. The original is often green in color (dark shades); it can also be black. They are distinguished by good adherence to geometry, which effectively removes excess oil and prevents its consumption. | BMW, Mercedes-Benz, VAG, Nissan, Opel, Renault, Fiat, Ford | From 150 |

| Corteco | Valve seals from one of the world's largest manufacturers and suppliers of automotive seals. They produce both domestic and discontinued models. They are made mainly from fluorine rubber, which combines elasticity and heat resistance; other fluorine-containing materials are used less frequently. | Alfa Romeo, BMW, Audi, Citroen, Ford, Fiat, Isuzu, Lancia, Iveco, MAN, Nissan, Opel, Peugeot, Mercedes Benz, Renault, Saab, Rover, Volkswagen. | From 100 |

| NOK | Japanese valve seals, factory installed on many local brands. They are distinguished by high quality workmanship and the correct selection of materials. They last a long time, and with gentle operation they last longer than the allotted resource. Often in Corteco packages you can find exactly NOK valve stem seals (as evidenced by the casting mark), because both companies belong to the same concern. | Toyota, Honda, Lexus, Mitsubishi, Nissan, Suzuki | From 150 |

| Goetze | German valve stem seals are often made of fluorine rubber or acrylate rubber. Teflon and other heat-resistant polymers with fluorine are used only for rare product models. | BMW, Fiat, Renault, Ford | From 100 |

| Glaser | Budget valve stem seals of good quality, originally from Spain. Elastic, they cut off oil well under normal operating conditions. Among the disadvantages is the fear of overheating. | Suzuki, Nissan, SEAT, Chrysler, John Deere, Ford. | From 50 |

| Ajusa | Inexpensive, but high-quality valve stem seals made of soft fluorine rubber. They work for 60–100 thousand km without problems, and if you regularly operate the engine in a gentle mode, even more. | SEAT, Nissan, Daewoo, Fiat, VAG and others. | From 100 |

| THO | Japanese THO valve seals combine elasticity, heat resistance, high precision performance and affordable price tags. Original parts serve the allotted 100 thousand km and even more. | Nissan Suzuki, Mitsubishi, Toyota | From 50 |

| Payen | Affordable MSCs made from high-quality fluorine rubber. They are distinguished by elasticity and at the same time have a long resource. They are also notable for the fact that they rarely become victims of counterfeits in Russia. | Ford, General Motors, Mercedes, Renault, Honda, Chrysler | From 70 |

| S.M. | Inexpensive, but high-quality valve stem seals. Viton fluorine rubber is used for production, combining elasticity and durability. | Aprilia, Audi, Bitzer, BMW, Copeland, DaimlerChrysler, Delmag, Deutz, Ducati, Ferrari, Hatz, Renault, Rotax, Voxan | From 30 |

*Not all manufacturers sell oil seals individually. They are often supplied in sets of 8, 10, 12 or 16 pieces, so the prices are approximate, based on the calculation “set price/quantity of MSK = price of 1 piece”. Exact prices depend greatly on the engine model.

Elring valve stem seals

Elring is a German manufacturer of seals for automobiles, supplying products to assembly lines of more than 50 European and Asian brands. For a number of trucks and special vehicles, its oil seals and other seals have no alternatives, so the same Elring is usually sold in branded packaging.

Thanks to the use of heat-resistant fluorinated rubber, they have a long service life, adhere well to the valve journals and effectively remove excess oil. Some oil seals use Teflon, which is a substance with one of the lowest coefficients of friction and is not afraid of heat.

Characteristics of Elring valve seals:

Victor Reinz valve stem seals

The Victor Reinz company has two homelands - the USA and Germany, as it belongs to the Dana corporation trademark (known to many car enthusiasts as a manufacturer of transmission units). Formed as a result of the merger of the German company Reinz and the American Victor.

The company has production all over the world and supplies parts to the assembly lines of many automobile factories. Its valve stem seals are distinguished by high quality, long service life and increased oil removal efficiency (reducing oil waste). In Russia, the main problem of the brand is the abundance of fakes.

Tips for selecting and using additives for valve stem seals

When a car is used for a long time, many drivers notice a sharp increase in the amount of oil consumed. At the same time, smoke with a bluish tint comes out of the exhaust pipe. Such signs indicate that it is necessary to diagnose the power plant in the near future. This is often due to poor or malfunctioning valve stem seals (VSC). Don't rush to send your car for repairs and spend a lot of money. The situation can be solved by special additives that are designed to restore these caps. It is important to consider that the use of additives for valve stem seals is not always considered correct and rational. But there are situations when additives can really help correct the current situation and prevent costly repair work in the future.

Functions of the caps

Caps, as an integral part of a car engine, are designed to prevent excess oil from penetrating into the gap formed by valve guides and valve stems. For valve stem seals, a special type of rubber is used in their manufacture. Gradually, as the vehicle is used, this material may deform and collapse. But basically there is a violation of its elasticity. Due to the loss of their original properties, the caps do not cope with their functions, oil enters in greater quantities than required. This increases oil consumption. If we talk about blue smoke, then this is a sign of combustion processes occurring in the engine.

To solve the problem of a malfunction of the valve stem seals, you can go in two ways:

- Replace the caps with new ones. Despite the apparent simplicity of these components, replacing MSCs is quite difficult. A car service will require a lot of money, and not everyone has enough experience, skills, tools or even free time to replace it themselves.

- Use special additives. This is a good way to restore the elasticity of the caps. The special composition of the additive allows rubber products to return to their previous characteristics, thereby allowing them to effectively perform their functions.

If you decide to focus on additives, then be sure to consider in more detail the issue of their use and the relevance of use for problems with valve stem seals.

When will they help

Agree that there are a lot of rumors and controversies surrounding automobile additives; opinions differ, and sometimes they are completely opposite. Therefore, you need to understand how MSC supplements help, and whether they are worth using at all. Objectively, such automotive chemistry has its positive and negative sides. But the result of the application directly depends on the literacy of the car owner himself, his attentiveness and compliance with all the instructions of the manufacturer of those same additives.

If you are one of the motorists who does not skimp on branded lubricants and buys only the most suitable oils for your vehicle, this is absolutely the right approach. The thing is that such oils are already supplied from the factory with the addition of all the necessary additives.

By adding additional additives to them, you change the properties, characteristics and capabilities of lubricants. This does not always benefit the car. Ideally, oil manufacturers should indicate in the composition exactly what additives and in what quantity they added to the motor or transmission fluid. But so far there are no such requirements.

If you do not want to be disappointed in the effectiveness of oil seal additives, then carefully read the following information.

In real conditions, the use of additives is justified only in situations where the rubber seals, which are the caps, have minor defects or damage. That is, when not drops of oil pass through them, but entire streams, you should not expect a miracle from the additive. She won't help. Therefore, you cannot count on the omnipotence of auto chemicals.

The principle of operation of additives for valve stem seals is that auto chemicals soften rubber products, they swell, restore their geometry and do not allow excess amounts of lubricant to penetrate through them. If the cap is cracked or partially collapsed, then you do not need an additive. You will only be wasting money, for which it is better to contact a good car service for a complete replacement of the MSC. And the real benefit is achieved by pouring the additive into the oil when the caps have just begun to gradually wear out, but have not led to serious changes in engine operation. They are used for minor deformities or as a means of prevention.

Features of additives

First, remember that there are no special separate additives for softening exclusively valve stem seals. These are universal additives that are used for problems with:

- caps;

- oil seals;

- gaskets;

- other rubber seals.

Additives are used to extend the service life of products, soften their structure and restore the original functionality of sealing various engine elements. High-quality compositions are able to restore the elasticity of even those elements that have become very rough, hardened and worn out, but not destroyed. Additionally, MSC additives allow you to gently clean the channels and lubrication system of the car. This has a positive effect on the operation of the power plant. Carbon deposits are eliminated, slag formations are removed, and various products of oxidative processes are removed.

That is, one such additive has a complex effect. There is no need to pour in a whole scattering of all kinds of additives to affect each individual unit or mechanism. This saves money and does not greatly change the composition of the engine fluid in the car.

Selection of softening additives

The selection of suitable additives aimed at restoring valve stem seals is somewhat complicated by the wide range of similar products on the market. Manufacturers offer a whole range of additives, each of which is aimed at performing specific tasks. Among them, compositions designed to restore the elasticity of valve stem seals and other rubberized sealing elements are deservedly popular.

To help you navigate the proposals a little, we will introduce you to some of the most popular, effective additives that have earned recognition among car owners. Not surprisingly, they all represent famous brands. A low-quality additive does not stay around for long, but quickly disappears from the shelf as soon as negative reviews about it appear. This is a calculation for quick profit. Famous companies that value their own reputation are not interested in reducing interest in their products. Therefore, they are trying to apply new technologies and use current developments in the field of automotive chemistry. As a result, we get, although more expensive, high-quality and truly useful supplements.

- Liqui Moly;

- Xado;

- Wagner;

- Hi-Gear.

These are popular brands that offer their solutions to the problem with valve stem seals. Therefore, we will consider them separately.

Wagner

The product that is needed in this case is called Oil Stop. A time-tested, quality product that performs well in restoring various seals in a car. An important advantage of the drug is the lack of exposure to chemicals that are part of motor oil. The product immediately gets onto the gaskets, caps and seals, expanding their original volume. This drug is widely used in eliminating leaks of lubricating fluids and in hydraulic systems.

Hi-Gear

A wide-range manufacturer that produces all kinds of automotive chemicals, including additives for restoring the elasticity of rubber gaskets. In our case, you should pay attention to two options for auto chemical products:

- HG 2246;

- HG 2243.

These are two modern high-tech additives that prevent oil oxidation, restore the original properties of engine oil, and increase compression. Practice and testing by car enthusiasts have clearly shown that the substances behave very well when interacting with rubber elements. The ability to restore rings and caps even if they are moderately deformed is noted. None of the competitors have been able to achieve this, which makes Hi-Gear one of the first choices for car owners.

To get the maximum benefit from the drugs, the manufacturer advises pouring them into cars with average or high mileage. On relatively new cars, using the additive will not give a noticeable effect, although for preventive purposes it will not hurt.

Ukrainian manufacturer of auto chemicals, which has managed to gain worldwide popularity. From a small enterprise in Kharkov, Xado has turned into a brand recognizable far beyond Ukraine, with high quality and reasonable prices. If the oil scraper rings suffer from carbon deposits that have formed on them, Hado will be almost the best solution in the current situation. It is important to carefully read the manufacturer's instructions. Do not fill the mixture more than normal or ahead of time. If you overdo it, or uncontrollably pour auto chemicals into your car, even with good intentions, it will not lead to anything good.

Liqui Moly

Another world-famous brand that has not only a well-developed advertising department, but also high-tech equipment. Entire laboratories and a huge staff of specialists are working to create new products that will meet all international standards, requirements and meet the needs of car owners themselves.

The main player in eliminating problems with valve stem seals is an additive called Oil Verlust Stop from the manufacturer Liqui Moly. Now this additive is widespread throughout the world, which makes it easy to purchase a bottle of Liqui additive in almost any automotive chemical store. This drug is a universal remedy for solving the problem of engine oil leaks. With its help you can cope with minor ailments of oil seals, rubber gaskets and valve stem seals.

The most significant positive effect of Liqui Moly is the protection of valve stem seals and rings from waste products of lubricants. This allows the material to return to its former elasticity and functionality. All of the above additives are actively used by car enthusiasts and specialists when repairing various vehicles. This once again proves their high degree of effectiveness.

Just don’t place high hopes on additives. This is not a panacea, but simply a preventive and partially repair remedy. With their help, you can solve the problem for a while and delay mandatory repairs. In case of severe damage, when the valve stem seals can no longer perform their functions at all, not a single additive will help solve the problem without interfering with the design itself. Therefore, it is better to carry out preventive measures, use high-quality oils and add appropriate additives as necessary.

Valve seals for VAZ 2107 which are better

Unread message VladiZlav » Wed Jul 16, 2008 20:35:17

Unread message Alex » Tue Jul 29, 2008 9:29:39 AM

Unread message VladiZlav » Tue Jul 29, 2008 11:50:15

Unread message Alex » Tue Jul 29, 2008 11:51:55

Unread message by serega » Wed Nov 26, 2008 8:03:20 AM

Unread message by Andreys » Fri Jan 08, 2010 19:15:32

Unread message byran » Fri Jan 08, 2010 20:13:55

Unread message by Andreys » Fri Jan 08, 2010 20:59:26

Unread message by Serega73 » Sat Jan 09, 2010 12:04:39

Unread message Motorist » Fri Feb 19, 2010 16:25:12

Unread message JET » Fri Feb 19, 2010 17:11:04

Unread message Motorist » Fri Feb 19, 2010 17:54:19

Unread message JET » Fri Feb 19, 2010 17:57:50

Unread message IZoneD » Tue Feb 23, 2010 13:35:59

Good day)))

Maybe someone has come across this question. In general, it's time to replace the caps. At the store today they said that the Audi caps fit on the VAZ. They say that I often ask them about the classics, they suit them perfectly. I don’t know whether to believe it or not and whether it’s worth buying. the price is 40 rubles per piece (320 rubles) relative to “GOETZE” which costs 250 rubles.

How is the crankshaft oil seal replaced?

To successfully complete the task, you first need to arm yourself with all the necessary tools and prepare an inspection hole in the garage to perform a whole range of work.

Developments from the following manufacturers are recommended for purchase:

| Name | Manufacturer | Price |

| Victor Reinz | Germany | 350 rubles |

| Elring | Germany | 300 rubles |

| Ajusa | Spain | 650 rubles |

| Espra | Spain | 250 rubles |

| Goetze | Germany | 600 rubles |

Screwdrivers, wrenches, sockets, and new seals should be on hand. All work comes down to separate replacement of the front and rear crankshaft oil seals.

Changing the front oil seal

Access to the front crankshaft oil seal largely depends on the specific make of the car, so before carrying out all the work, it is advisable to read the operating instructions with all the necessary information. For owners of domestic cars, in particular the VAZ brand, all work comes down to the following steps:

It is advisable to treat the junction of the oil seal with the crankshaft with machine oil and apply the substance to the outer surface of the seal and the output end of the shaft.

Changing the rear oil seal

This type of work requires a lot of time and effort from the car owner. To get to the rear oil seal, you need to disassemble the cardan and disconnect the box and clutch housing. The next steps are as follows:

Which valve stem seals are better for the VAZ 2107

The combustion chamber of a car must be protected from the entry of foreign substances and elements into it. The valve stem seals are responsible for this, the task of which is to prevent excess oil, chips and other “garbage” from entering the combustion chamber during the movement of the car’s valve stems. If the valve stem seals no longer cope with their tasks, they must be urgently replaced to avoid carbon deposits on the engine elements, as well as increased oil consumption. In this article, we will look at what signs indicate wear of the valve stem seals, why they wear out, and how to replace them without removing the cylinder head.

Tips for selecting and using additives for valve stem seals

Functions of the caps

Caps, as an integral part of a car engine, are designed to prevent excess oil from penetrating into the gap formed by valve guides and valve stems. For valve stem seals, a special type of rubber is used in their manufacture. Gradually, as the vehicle is used, this material may deform and collapse. But basically there is a violation of its elasticity. Due to the loss of their original properties, the caps do not cope with their functions, oil enters in greater quantities than required. This increases oil consumption. If we talk about blue smoke, then this is a sign of combustion processes occurring in the engine.

To solve the problem of a malfunction of the valve stem seals, you can go in two ways:

- Replace the caps with new ones. Despite the apparent simplicity of these components, replacing MSCs is quite difficult. A car service will require a lot of money, and not everyone has enough experience, skills, tools or even free time to replace it themselves.

- Use special additives. This is a good way to restore the elasticity of the caps. The special composition of the additive allows rubber products to return to their previous characteristics, thereby allowing them to effectively perform their functions.

If you decide to focus on additives, then be sure to consider in more detail the issue of their use and the relevance of use for problems with valve stem seals.

When will they help

Agree that there are a lot of rumors and controversies surrounding automobile additives; opinions differ, and sometimes they are completely opposite. Therefore, you need to understand how MSC supplements help, and whether they are worth using at all. Objectively, such automotive chemistry has its positive and negative sides. But the result of the application directly depends on the literacy of the car owner himself, his attentiveness and compliance with all the instructions of the manufacturer of those same additives.

If you are one of the motorists who does not skimp on branded lubricants and buys only the most suitable oils for your vehicle, this is absolutely the right approach. The thing is that such oils are already supplied from the factory with the addition of all the necessary additives.

By adding additional additives to them, you change the properties, characteristics and capabilities of lubricants. This does not always benefit the car. Ideally, oil manufacturers should indicate in the composition exactly what additives and in what quantity they added to the motor or transmission fluid. But so far there are no such requirements.

If you do not want to be disappointed in the effectiveness of oil seal additives, then carefully read the following information.

In real conditions, the use of additives is justified only in situations where the rubber seals, which are the caps, have minor defects or damage. That is, when not drops of oil pass through them, but entire streams, you should not expect a miracle from the additive. She won't help. Therefore, you cannot count on the omnipotence of auto chemicals.

The principle of operation of additives for valve stem seals is that auto chemicals soften rubber products, they swell, restore their geometry and do not allow excess amounts of lubricant to penetrate through them. If the cap is cracked or partially collapsed, then you do not need an additive. You will only be wasting money, for which it is better to contact a good car service for a complete replacement of the MSC. And the real benefit is achieved by pouring the additive into the oil when the caps have just begun to gradually wear out, but have not led to serious changes in engine operation. They are used for minor deformities or as a means of prevention.

Features of additives

First, remember that there are no special separate additives for softening exclusively valve stem seals. These are universal additives that are used for problems with:

- caps,

- oil seals,

- gaskets,

- other rubber seals.

Additives are used to extend the service life of products, soften their structure and restore the original functionality of sealing various engine elements. High-quality compositions are able to restore the elasticity of even those elements that have become very rough, hardened and worn out, but not destroyed. Additionally, MSC additives allow you to gently clean the channels and lubrication system of the car. This has a positive effect on the operation of the power plant. Carbon deposits are eliminated, slag formations are removed, and various products of oxidative processes are removed.

That is, one such additive has a complex effect. There is no need to pour in a whole scattering of all kinds of additives to affect each individual unit or mechanism. This saves money and does not greatly change the composition of the engine fluid in the car.

Selection of softening additives

The selection of suitable additives aimed at restoring valve stem seals is somewhat complicated by the wide range of similar products on the market. Manufacturers offer a whole range of additives, each of which is aimed at performing specific tasks. Among them, compositions designed to restore the elasticity of valve stem seals and other rubberized sealing elements are deservedly popular.

To help you navigate the proposals a little, we will introduce you to some of the most popular, effective additives that have earned recognition among car owners. Not surprisingly, they all represent famous brands. A low-quality additive does not stay around for long, but quickly disappears from the shelf as soon as negative reviews about it appear. This is a calculation for quick profit. Famous companies that value their own reputation are not interested in reducing interest in their products. Therefore, they are trying to apply new technologies and use current developments in the field of automotive chemistry. As a result, we get, although more expensive, high-quality and truly useful supplements.

- Liqui Moly,

- Xado,

- Wagner,

- Hi-Gear.

These are popular brands that offer their solutions to the problem with valve stem seals. Therefore, we will consider them separately.

Wagner

The product that is needed in this case is called Oil Stop. A time-tested, quality product that performs well in restoring various seals in a car. An important advantage of the drug is the lack of exposure to chemicals that are part of motor oil. The product immediately gets onto the gaskets, caps and seals, expanding their original volume. This drug is widely used in eliminating leaks of lubricating fluids and in hydraulic systems.

Hi-Gear

A wide-range manufacturer that produces all kinds of automotive chemicals, including additives for restoring the elasticity of rubber gaskets. In our case, you should pay attention to two options for auto chemical products:

- HG 2246,

- HG 2243.

These are two modern high-tech additives that prevent oil oxidation, restore the original properties of engine oil, and increase compression. Practice and testing by car enthusiasts have clearly shown that the substances behave very well when interacting with rubber elements. The ability to restore rings and caps even if they are moderately deformed is noted. None of the competitors have been able to achieve this, which makes Hi-Gear one of the first choices for car owners.

To get the maximum benefit from the drugs, the manufacturer advises pouring them into cars with average or high mileage. On relatively new cars, using the additive will not give a noticeable effect, although for preventive purposes it will not hurt.

Ukrainian manufacturer of auto chemicals, which has managed to gain worldwide popularity. From a small enterprise in Kharkov, Xado has turned into a brand recognizable far beyond Ukraine, with high quality and reasonable prices. If the oil scraper rings suffer from carbon deposits that have formed on them, Hado will be almost the best solution in the current situation. It is important to carefully read the manufacturer's instructions. Do not fill the mixture more than normal or ahead of time. If you overdo it, or uncontrollably pour auto chemicals into your car, even with good intentions, it will not lead to anything good.

Liqui Moly

Another world-famous brand that has not only a well-developed advertising department, but also high-tech equipment. Entire laboratories and a huge staff of specialists are working to create new products that will meet all international standards, requirements and meet the needs of car owners themselves.

The main player in eliminating problems with valve stem seals is an additive called Oil Verlust Stop from the manufacturer Liqui Moly. Now this additive is widespread throughout the world, which makes it easy to purchase a bottle of Liqui additive in almost any automotive chemical store. This drug is a universal remedy for solving the problem of engine oil leaks. With its help you can cope with minor ailments of oil seals, rubber gaskets and valve stem seals.

The most significant positive effect of Liqui Moly is the protection of valve stem seals and rings from waste products of lubricants. This allows the material to return to its former elasticity and functionality. All of the above additives are actively used by car enthusiasts and specialists when repairing various vehicles. This once again proves their high degree of effectiveness.

Just don’t place high hopes on additives. This is not a panacea, but simply a preventive and partially repair remedy. With their help, you can solve the problem for a while and delay mandatory repairs. In case of severe damage, when the valve stem seals can no longer perform their functions at all, not a single additive will help solve the problem without interfering with the design itself. Therefore, it is better to carry out preventive measures, use high-quality oils and add appropriate additives as necessary.

Why are valve stem seals needed?

Engine operation involves non-stop operation of the elements of the vehicle's gas distribution mechanism. To reduce their wear due to friction, oil is supplied to the timing gear, which should not end up in the combustion valve, otherwise the stable operation of the engine will be disrupted. When the valves operate, the oil seals take on the task of removing excess oil and act as an obstacle, preventing oil from entering the combustion chamber.

The valve stem seals are designed quite simply, and we can name 3 main components of which they consist:

It is worth noting that over the last decade, valve stem seals have changed a lot in terms of the materials used. Since their failure can lead to big problems, manufacturers strive to use the most durable and wear-resistant materials that are resistant to aggressive environments.

Why are they installed in engines?

All rubbing couples in engines receive a certain portion of lubricant to reduce friction, and the task of oil seals is to reduce its entry into the combustion chamber to a minimum. Such a pair in the cylinder head is the guide sleeve and the valve stem. It is impossible to make this connection without a gap, so valve seals are used for sealing. They are made from special oil-resistant reinforced rubber. The upper part of these seals is pressed against the valve stem by a spring.

There was a time when PTFE was widely used for these, but nowadays it is rarely used in the production of these replacement parts. Instructions for car repair and operation recommend that when replacing, install only those parts that were installed by the manufacturer. Today, this recommendation is often violated, since the use of high-quality materials and modern technologies makes it possible to create products that are in no way inferior, and sometimes even superior in their characteristics, to the original caps.

Service life of valve stem seals

It is easy to guess that valve stem seals need to be changed from time to time.

The valve performs more than 1000 strokes per minute, and on each valve, the valve stem seals must remove excess oil to prevent it from entering the combustion chamber. It should also be taken into account that the temperature in the operating area of the valve stem seals is high, and the environment itself is aggressive: oil and exhaust gases. Due to the influence of a host of factors, valve stem seals begin to deteriorate over time - the rubber of the cap cracks, peels off, and loses elasticity. Over time, the spring begins to press the cap less tightly against the walls, which is why oil begins to enter the combustion chamber. On average, the service life of good quality valve stem seals is 100,000 kilometers. If the car has been idle for several years, it is recommended to replace the valve stem seals before you start using it, since during inactivity they have time to dry out greatly.

Preparatory work

Before starting work, it is necessary to wash the engine compartment of the machine. This must be done carefully so as not to wet the sensors, pads, and elements of the ignition system. Before washing the engine compartment, you must disconnect the ground wire from the battery.

It is advisable to carry out the work in a garage - this will help to avoid dust getting on the timing parts during assembly. It is also necessary to secure the machine with the handbrake and turn on neutral speed so that you can turn the crankshaft during operation.

Valve stem seals

Valve seals @ Niva 4×4

Nivovodov Club. Founder - Ermolov Alexey Igorevich, aka ALER

NIVA-FAQFAQ mapSpare parts catalogArtNivaFrom adminForum rules

Niva 4×4 / Niva equipment / General technical section

Reg.: 02/03/2009 Messages: 2541 From: M.O. Fryazino Age: 33 Car: VAZ 2121 1994 1.7i

I don’t have any leaks, sometimes I notice something like this...

Reg.: 02/28/2013 Messages: 35 From: Russia Tambov region Age: 39 Car: VAZ 21213 1996

It's most likely that you have oil pressing from the rear axle through the breather. Look at the bridge, it probably shows signs of oil leakage. The caps have nothing to do with it.

Indeed, the rear axle seal is leaking.

don't run from a bullet, you'll die tired

Reg.: 11/05/2007 Messages: 5136 From: Novosibirsk Age: 36 Car: Fora, 212180 2002 carb

So, the procedure came, I went shopping, in the GAZ company store I took from the 406 engine (the seat is 8 mm, like ours) MC caps Kirovo-Chepetsk, fluoropolymer, everything as it should be... at the same time I went to the JIEMA officials in Novosibirsk, bought 10 pieces originals by weight of RESERVE caps Samara (allegedly) began to inspect, the Reserve is a reserve and does not smell at all, there are no rezerve inscriptions on the original, hmmm well, okay... so the procedure goes on, I refer to this https://www.chevy-niva .ru/viewtop…f558bb0732395917a04e036056aded02 1-2-4 cylinders I install Kirovo-Chepetsk from the 406 engine, heat the cap with a hair dryer at a temperature of 100 degrees, remove the spring, push it through the mandrel not completely... on cylinder 3 I put “reserve originals by weight” same procedure! everything is fine, wonderful... I rode about 100 km with annealings of 4500-5000 km, I come to the garage, so 1-2-4 spark plugs are wonderful, dry, 3 spark plug is not like a thread, it’s all covered with oil and is leaking all the way from it... I was upset, I thought that the cap came off! I had to go through it, opened the 3rd cylinder - hmmmm everything is in place, they fit tightly, the collet only pulled it off the guides 2-3 times, oh how! I also installed a Kirovo-Chepetsk from a 406 engine on the 3rd cylinder, drove it today for about 150 km with annealing for 4000-5000 km... as a result, all 4 spark plugs are of excellent quality in appearance, dry, there is no hint of oil in the cylinders! It was not possible to find the original reserve! If necessary, I can take a photo of the supposedly Rezev and Kirovo-Chepetsk caps on an MS DSLR, if interested! and as always a rhetorical question! Officials can also trade on the left, it turns out. It’s all sad, and then we’re surprised at the VAZ Amno, like the Subara doesn’t eat, etc. So if the quality of the sealing cuffs is such, the rings will immediately coke... I’ll use it and write down what’s what Added after 5 minutes 3 seconds:

Reg.: 06/24/2012 Messages: 743 From: Russia. Cool. Age: 36 Car: Niva 21213.1995

I also took in bulk, supposedly vases, light brown, pressed them onto the guides until the end, as described in the FAK. after replacing it stopped smoking, but the threads of all the spark plugs remain in the oil a little bit, after changing the caps I didn’t remove the threads of the spark plugs/heads, the spark plug itself is clean, the oil doesn’t go away when driving quietly, if you anneal it to 5000 then the level drops, the problem turns out to be approximately Is it the same as on your internal combustion engine with 3 spark plugs? those. Do the caps still let oil through?

Officials can also trade on the left, it turns out.

It turns out that way, unfortunately.

Rear SC

The procedure for replacing the rear motor assembly is noticeably more complicated than the front one, so not everyone will decide to carry out such work on their own. We recommend that you consult first and watch training videos.

To replace the rear AC, you will have to spend a little more time and effort. The work is not easy, but with the right approach, a positive result can still be achieved.

The basis for successful replacement of front and rear joints is patience, attentiveness and perseverance. If you rush, rush, nothing good will come of it, and you will have to go to a service station and pay a lot of money.

Signs of wear on valve stem seals

If you recognize the wear of oil seals at an early stage and replace them in time, you will be able to avoid serious engine problems. The primary signs of oil seal failure are as follows:

When the signs of wear on the valve stem seals described above occur, you need to urgently inspect them, as well as check the gas distribution mechanism and valves. If there are signs of severe wear on the valve stem seals, they need to be replaced, otherwise:

Carbon deposits on engine components are a direct path to a quick overhaul. Timely replacement of valve stem seals with new ones will help avoid this.

When is it time to replace

Over time, the sealing material of the valve stem seals becomes hard. As a result, it loses its elasticity, which leads to oil leakage into the cylinder. The same problem occurs when the piston rings are faulty.

The caps are changed in cases where oil leaks occur without visible places. Watch how the exhaust behaves while driving. Brake the car sharply with the engine, and then also sharply press the gas pedal. If this leads to the appearance of thick smoke from the muffler, then it is time to replace the seals.

How to replace valve stem seals without removing the cylinder head

If the problem with wear of the valve stem seals was detected in a timely manner by the driver, he can replace them without removing the cylinder head. In a situation where the solution to the problem has been delayed, it will be necessary to dismantle the parts to remove carbon deposits from the pistons and valves.

Depending on the car model and engine, the process of replacing valve stem seals will vary. But we can distinguish several main stages common to all machines:

The valve pusher springs are dismantled - “de-stressed”;

If there is a possibility that the valve stem seals have been faulty for a long time, you will need to remove the cylinder head and carry out a full replacement, including cleaning the engine elements from carbon deposits.

( 432 votes, average: 4.51 out of 5)

Related Posts

Injectors: how to check and clean without removing them from the engine

Plastic, metal, aluminum gas tank - which is better?

Front SC

We recommend starting with the front one, since this oil seal is the easiest to replace. Even a car owner without much experience can handle it. Once you learn how to change it, you will most likely be able to replace the rear crankshaft oil seal yourself. But it is better to act according to the circumstances.

The steps for replacing the front oil seal are as follows:

Since replacing the AC requires serious dismantling work, it is not superfluous to simultaneously check the condition of other units, replace the oil, filter or other parts.

Niva valve stem seals, replacement interval

The AvtoTAZ operating manual recommends replacement after 50 thousand km. This is about 2-3 years of average mileage. The D'Artagnans argued until they were hoarse on the motorists' forum that if these are the same caps that we put on the "Germans", then they can be changed no earlier than after 100 thousand. The answer is simple, precisely because “at the Germans”))). What the plant is doing now and calling it engines is sabotage and sabotage. On any other car, the maximum valve-guide gap should be up to 0.04. To avoid incidents associated with bad metal valves and guides, the factory makes this gap more than 0.1 mm, that is, 10 acres. With such “tolerances and fits”, valve stem seals simply do not last more than 50 thousand. Therefore, the plant carefully and gently makes a backing for itself.

Source

When is it time to change?

The car crankshaft has two oil seals: front and rear. They are dense elastic rings in a hard cage.

Their purpose is to prevent dust and dirt from entering the crankcase and to prevent oil leakage. The service life of the sealing rings is 150 thousand kilometers. But consumables may wear out sooner. The reason for this may be:

You can diagnose the replacement of oil seals by the oil stains that appear on the engine and gearbox. An oil leak can cause the timing belt to break, causing damage to the valves. In this case, it may be necessary not only to replace the valves, but also to overhaul the engine.

Sparco24 › Blog › Installing 16V camshafts

In this article we will look at the installation of sports and tuning camshafts on VAZ 2112, 21124, 21126 and 11194 engines. First, you need to remember that engines 2112 and 21124 have their own timing belt drive and are incompatible with the timing belt of engines 21126 and 11194 - this worth considering when purchasing split gears. Engine gears 21126 and 11194 have rounded teeth, so the belt, pump, lower crankshaft gear and camshaft gears have their own. To install the camshafts you need to do the following:

1. Disconnect the TPS, IAC and mass air flow sensor connectors, loosen the clamps holding the inlet pipe on the receiver, loosen the ventilation clamp for the crankcases of the cylinder head cover and dismantle the intake pipe assembly with the mass air flow sensor;

2. Unscrew the nuts that secure the receiver to the cylinder head; it is most convenient to do this with a ratchet with a 13-mm socket;

3. Remove the receiver assembly with the throttle;

4. Remove the timing belt cover using a ratchet and a short 8mm socket;

5. Loosen the bolts of the camshaft gears;

6. Set the crankshaft position to TDC of cylinder 4, aligning the mark on the flywheel and, loosening the tension roller, remove the belt from the camshaft gears;

It will be useful How to choose and change the oil in a nissan qashqai variator: reviews and tips

7. Completely unscrew the bolts of the camshaft gears and remove the gears themselves. Be careful - the keys for fixing the gears on the camshafts can fly out and, due to their small size, can easily get lost;

8. Using a ratchet and a 8mm socket, unscrew the timing cover bolts and remove it. Using the same tool, unscrew the bolts of the bed and also dismantle it;

9. Remove the standard camshafts, not forgetting to remove the keys that secure the gears;

10. Remove the hydraulic compensators using a magnet. It is advisable to number the hydraulic compensators by wells in order to install them in their places. If the camshafts are not full-base, install the included bearings on the valve stem;

Camshafts 2112 lift 11.8/11.8 mm Sport

7,800 rub. Club price 7,500 rub. 11. Place new camshafts and check them for rotation in bed. If the cams cling to the hydraulic compensator wells slightly, use a sharpened screwdriver or chisel to carefully modify the edges of the wells to rotate the camshaft cams. To ensure that this procedure is as safe as possible and that shavings do not fall into the wells, it is recommended that before processing the well, fill it with cotton wool or a piece of cloth; after processing, this should be removed and the well should be blown out. If the camshaft cams do not turn at all, and the wells need to be thoroughly modified, it is strongly recommended to dismantle the cylinder head, modify the wells using a drill or machine, wash it and install it back, otherwise, in the case of rough return, excess chips can clog the oil channel or, by over-modifying the well, worsen the performance of the hydraulic compensator by reducing oil pressure;

12. Clean the surface of the bed from sealant on both sides; the seats of the bed bolts must be blotted from oil using a thin screwdriver and a piece of cloth so that when tightening the bolt you do not pull out the thread (remember that oil does not compress, and if the bolt has nowhere to twist - it will begin to pull the threads out of the cylinder head), apply new sealant to the lower plane of the bed;

13. Having aligned the new camshafts with the veneer grooves vertically upward, place the bed and tighten its bolts, starting from the central holes towards the timing belt and pump;

14. Place the split gears on the camshafts and tighten their bolts, put on the timing belt; Guided by this article, set the valve timing recommended by the manufacturer; Clean the cylinder head cover, apply new sealant and close the cylinder head cover, tighten it with bolts, starting from the center and moving away to the sides of the timing belt and pump; Repeat the installation operations of the receiver, timing case and sensor connectors in reverse order.

Attention! To achieve the maximum effect from installing camshafts, it is mandatory to change the ECU program online

Main signs and causes of faulty valves

Replacement of all valves on a Priora with 16 valves can occur either when they are bent or when they burn out. They can burn out due to poor quality parts or poor quality of the mixture used.

If the vehicle engine overheats too quickly, then sooner or later the working surface of all valves begins to burn out (wear out). Another point is that the valves and their mechanisms have a return spring. If the return spring begins to wear out, the valve will begin to hit the piston during operation. In this case, the result will be the same as a damaged timing belt.

It is important for the vehicle owner to correctly diagnose problems with valves. The very first sign of an emerging problem is a decrease in the level of engine response, which manifests itself in a noticeable decrease in vehicle power.

In some cases, tapping sounds are heard.

A common symptom of valve problems is black smoke coming out of the exhaust pipe. This problem is combined with increased engine oil consumption. The machine may also operate unstably when idling. It is difficult to diagnose this problem, since it is difficult to accurately determine the cause of the breakdown without disassembling the engine.

Why do they need to be replaced?

The only reason for removing them and installing new parts can be wear of the edge of the valve seals, which is used to compress the valve stem. During engine operation, they perform a huge amount of work, experience high temperature loads and exposure to an aggressive environment. This cannot but affect their resistance and durability. Most of these spare parts are based on rubber, which, under the influence of all these negative factors, begins to harden, the working edges begin to crack, wear out and wear out.

This leads to a gap for engine oil to penetrate into the working chamber, resulting in “dirty” exhaust and increased lubricant consumption. You should not be afraid that replacement will be very frequent; manufacturers have learned to produce good products whose service life is 100,000 km, or even more. But unfortunately, there are still many such machines for which replacement happens more often than usual.

About the reasons for replacement

There are many reasons for such a replacement; let's look at some of them. An example is the cost of “native” products; the price of individual copies can range from $5 per piece or more. There are also situations when one of the oil seals may be damaged during assembly, and you need to look for a replacement. This is where knowledge of the characteristics of manufactured spare parts can come to the rescue in order to select a replacement.

We can talk for a long time about the advantages and disadvantages of such products of domestic and imported production. We tried to tell you which valve stem seals are better in accessible words. In conclusion, I would like to note that, unfortunately, the quality of domestic products is still inferior to foreign caps.