Today our old client came to us in his white Lada Granta to replace the timing belt, roller and pump in the place with antifreeze. From the factory, this engine is equipped with a Gates timing belt with a declared service life of 75 thousand kilometers, but we change it to 60 just in case.

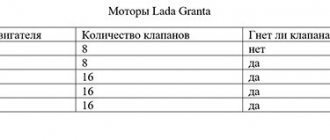

Important! When the timing belt breaks on this engine, all the valves bend. This is true for all engines produced until 2022.

I recently read that starting from 2022, this engine will be equipped with plug-in pistons; when the new Granta arrives, we’ll be sure to see if this is true with an endoscope.

Replacing timing belt Lada Granta 8 valves, timing diagram and marks

Replacing the timing belt of Lada Granta 8 valves is required once every 75 thousand kilometers. If you ignore the scheduled replacement of the belt, tension roller and sometimes the pump (coolant pump), you may end up with serious repairs to the Lada Granta engine. After all, a broken timing belt almost always leads to damage to valves, valve seats and even pistons. Therefore, the timing drive must be treated very carefully. Every 15 thousand it is necessary to inspect the belt for breaks, cracks, peeling or oiling.

Detailed diagram of the Lada Granta timing drive further.

- 1 - crankshaft toothed pulley

- 2 - coolant pump toothed pulley

- 3 - tension roller

- 4 - rear protective cover

- 5 - camshaft gear pulley

- 6 - timing belt

- A - boss on the rear protective cover

- B - mark on the camshaft pulley

- C - mark on the oil pump cover

- D - mark on the crankshaft pulley.

To replace the timing belt, we need to remove the alternator drive belt or accessory drive belt for the Grant with air conditioning. Using a “5” hexagon, unscrew the four screws securing the front upper timing drive cover and remove the plastic casing.

To avoid damage to the crankshaft position sensor, it must also be removed. With the ignition off, release the clamp of the wiring harness block and disconnect the block from the sensor connector. Use a 10mm socket to unscrew the sensor mounting bolt.

We remove the sensor from the oil pump cover boss hole and put it in a place where there are no steel filings that could subsequently disrupt the operation of the sensor.

Before dismantling the belt, it is necessary to check the engine valve timing - set the piston of the 1st cylinder to the TDC (top dead center) position of the compression stroke. Using the “17” head, turn the crankshaft clockwise by the bolt securing the generator drive pulley until mark 1 on the camshaft timing pulley aligns with boss 2 on the rear timing cover.

To ensure that the crankshaft is in the correct position, remove the rubber plug for the inspection window at the top of the clutch housing. Mark 2 on the flywheel should be located opposite slot 1 of the scale, which is visible in the window of the clutch housing cover.

Before unscrewing the bolt securing the generator drive pulley, ask an assistant to secure the crankshaft from turning by inserting a screwdriver through the window in the clutch housing between the flywheel teeth.

Using a 17mm socket, unscrew the bolt securing the generator drive pulley, remove the pulley and washer.

Reviews

| № | Positive |

| 1. | Alexander: in two years of using the car I have never changed anything. I carry out prevention systematically, as prescribed by the instructions. I believe that a moderate driving style, high-quality oil, and original parts can work wonders. |

| 2. | Kirill: at 65,000 km I tightened one rod because it started to click when it was “cold”. I haven't changed anything until now. Everything is original installed. |

| 3. | Vasily: I replaced the timing belt in a year and a half. I thought it would be difficult, but it turned out to be the opposite. I recommend that motorists carry out preventive maintenance on their own. |

| 4. | Gennady: adjusting the valve clearances on Grant is not easy, but I was able to do it myself, without outside help. Instructions and video tutorials on the Internet are always at hand. |

| 5. | Ignat: after a year of using the car, the valves began to knock. At the service station the technician said that there was no need to change it, they limited themselves to tightening it. I still ride, no complaints. |

| 6. | Vladislav: for three years of using the car, I installed all the spare parts myself and did not contact the service center. Which is what I recommend to other Grantmakers. There were no major breakdowns, they were so insignificant. Fuel and oil filters don't count. |

| Negative | |

| 1. | Victor: My timing belt fell off within the first year after purchase, which turned out to be unexpected. I installed the new one myself, the process is not complicated. |

| 2. | Ivan: at 45,000 the valves began to knock, so I took it to the service station. The master said that the second and third valves were defective. Replaced with new ones. Buy Lada Granta in 16 cl. |

| 3. | Vasily: at the second service, I replaced the timing belt at the service center. Three teeth suddenly broke off, the quality is poor. |

Removing the timing belt

You will need : remove the generator belt, the right wheel and the plastic shield of the engine compartment, prepare a “10”, “17” key, a “19” socket, and a screwdriver.

Procedure:

- Remove the plastic engine cover.

- Remove the timing drive protective cover by unscrewing the three fastening bolts.

- Timing diagram.

Set the piston of the first cylinder to the top dead center position:

- Turn the crankshaft clockwise by the bolt until the mark on the toothed pulley aligns with the antennae on the rear timing cover.

- Remove the window plug at the top of the clutch housing and make sure that the mark is not located opposite the scale slot.

- Secure the crankshaft from turning by inserting a screwdriver through the window between the flywheel teeth.

- Remove the bolt securing the generator drive pulley while holding the screwdriver. Remove the generator drive pulley.

- Loosen the tension roller nut. Remove the timing belt by turning the pulley so that the belt is loosened as much as possible.

- Remove the tension roller by unscrewing the nut securing it.

Have you noticed that the timing belt is eating or slipping? The reason may be a defective belt, rollers, or a pin that is overtightened.

Review of Manufacturer Prices

| Catalog items | Price, rub.) |

| Tensioner roller for internal combustion engines 1006120 0021647 | From 550 |

| Timing belt 1006040-10 | From 1500 |

| Automatic tension roller 1006226 | From 800 |

| Timing belt 1006040 | From 1500 |

| Roller key – 67.7812.9573 | From 350 |

| 67.7834.9525 | —/— |

| Timing belt GATES 5521 | From 1100 – 1400 |

| BOSCH 1987949095 | —/— |

| DAYCO 94089 | —/— |

| CONTITECH CT527 | —/— |

| Finwhale 1006040 | —/— |

| GATES 5670XS | —/— |

| CONTITECH CT1164 | —/— |

| QUARTZ QZ-5670XS | —/— |

*prices are current as of October 23, 2018.

How to install and tension the timing belt

- Place the timing belt on the crankshaft pulley.

- By tensioning both branches of the belt, we put the rear branch on the pump pulley and wind it behind the tension roller.

- We put the front branch on the camshaft pulley.

- Tension the timing belt by turning the tension roller counterclockwise and inserting a screwdriver (as in the photo).

- Tighten the bolt securing the generator drive pulley and turn the crankshaft by the bolt 2 turns clockwise.

- We check the coincidence of the crankshaft and camshaft marks. If the marks do not match, repeat the operation to install the belt.

Features of disassembling a 16-valve engine

As for the 16-valve engine, the sequential disassembly is completely identical to that described, with the exception of one point - installing the marks. Since this engine uses two camshafts, the marks must be aligned on both, and do not forget about the marks on the flywheel.

Also, during disassembly, in addition to the tension roller, you will also have to dismantle the bypass roller, since it also needs to be replaced.

After removing the belt, you should also check the play of the bearings on the pump. If it is significant, then it is better to replace it immediately. Otherwise, it may quickly fail after replacing the belt and the need to re-disassemble the drive, since the pump is replaced only after dismantling the drive.

Note that after removing the belt, it is important to ensure that you do not accidentally turn one of the shafts while installing a new one.

Replacing the timing belt without special tools

The method can be used if there is no need to change the rollers.

- Cut off half of the old timing belt with a utility knife.

- Remove half of the old timing belt.

- We put a new timing belt on the crankshaft pulleys.

- We cut the second half of the old timing belt and remove it.

- Pull the new timing belt onto the crankshaft pulleys until the end.

Where can I buy

: Timing belt kits at low prices are available in our online store (Timing belt category).

Share on social networks:

Found an error? Select it and press Ctrl+Enter..

Source

Installation of all shafts according to marks

First check that the gear is in neutral.

There is a rubber cover on the crankcase body closer to the clutch assembly. It needs to be removed. The point is to achieve alignment of the marks on the flywheel and in the scale slot. When this is done, fix the flywheel with a screwdriver.

Of course, it is easier to perform such an operation with two people. Know that the desired position of the shaft corresponds to the alignment of marks AB and CD (see figure).

The crankshaft itself must be rotated to the right using a 17 or 19 key (motor 11183).

The meaning of this is illustrated in the photo. The alternator belt must be removed.

The alternator belt blocks access to the timing drive parts. You will have to loosen the fastening and remove this belt.

Use a 13mm wrench to loosen the lower mounting bolt. Then unscrew the upper fastening nut and remove the bolt. The generator casing is pressed against the engine and the structure is secured with wire. The belt can now be removed. Installation of the alternator belt is carried out in the following sequence:

1

.

Secure the generator; 2

.

Throw the belt over the pulleys, as shown in the photo; 3

. Having engaged 5th gear, roll the car back.

Please be aware that reusing the alternator belt is a last resort. It would be better to buy a new part.

How to determine that a break may soon occur

Urgent replacement of the timing belt for a Granta car of 8 and 16 cl. may be necessary if the following phenomena occur:

- Decrease in vehicle power. A poorly tensioned or worn drive can make the engine difficult to start and reduce power output.

- Incomprehensible noises from the timing belt on the Grant, emanating from the engine compartment. Clunking, ticking or strange rustling noises often indicate that the Granta timing belt is damaged and rubbing against the casing or other parts under the hood

- Visible damage. The part may have abrasions, cracks and “shaggy” areas that are visible to the naked eye.

If, upon careful inspection, it is discovered that the teeth on the Grant timing belt have been cut off or at least one of the other listed problems, it is necessary to urgently replace the part with a new one, which is quite possible to do yourself.

Imported analogues

Various components are suitable for replacing belts “2108-1006040-10”:

- GATES – 5521 or 5521XS;

- BOSCH – 1 987 949 095;

- DAYCO – 94089;

- CONTITECH – CT527;

- Finwhale - 2108-1006040.

The timing belt “21116-1006040” can be replaced with another part:

- GATES – 5670XS;

- CONTITECH – CT1164;

- QUARTZ (Germany) – QZ-5670XS.

Usually the choice is made in favor of GATES products. The letters "XS" in its catalog mean "reinforced". Grantovods have already told us in detail about the timing of replacing the timing belt, its selection, and signs of wear in the material:.

Original timing belt and fake

Attention! Components from GATES (England) are most often counterfeited! From the photo you can understand what the main difference is. Beware of fakes.