2013 was the year of birth of the Lada Kalina 2, which was almost completely modernized compared to its predecessor. The car has become popular not only in the regions of the Russian Federation, but also in countries far and near abroad. The car belongs to the small class, but has quite good capacity.

Lada Kalina 2 or VAZ 2192 is equipped with a line of power units with a displacement of 1600 cm3. They differ not only in power indicators, but also in the number of valves in the cylinder head. There can be 8 (engine 11186) or 16 (engines 21126 and 21127), the timing mechanism is driven by a toothed belt.

Checking and replacing the timing belt of a Lada Kalina car

Depending on the engine configuration, a timing gear drive can be installed with an automatic timing belt tensioner or with a tension roller.

In the latter case, it is necessary to regularly (when performing maintenance, every 15,000 km) check the condition and tension of the timing belt, and change it every 75,000 km.

If there is an automatic tensioner, there is no need to check and adjust the timing belt tension.

In addition, in such a drive the service life of the belt itself is significantly increased. This does not exclude failure of the tension mechanism or oil leakage through the shaft seals.

Oil getting on the timing belt leads to a significant reduction in its service life.

Breaking teeth on the belt will result in poor valve timing and possibly serious engine damage.

A broken belt will inevitably cause the engine to stop.

Taking all this into account, on engines with an automatic tensioning mechanism, it is advisable to check the condition of the timing belt, and if defects are found on it, replace it.

Checking the timing belt with automatic tensioner

We prepare the car for work.

Using a 5 mm hex wrench, unscrew the four bolts securing the front upper timing belt cover.

Remove the cover from the engine

Rotating the crankshaft (by the pulley mounting bolt or by the flywheel ring gear, through the inspection hole in the clutch housing), we check the condition of the belt by external inspection.

Make sure that the marks on the tensioner match.

The belt must be clean - without dirt or oil on its surface.

It is necessary to replace a belt with tears, cracks, delaminations, cut or worn teeth, abrasions to the cord, or oily ones. Oil leaks should be eliminated as soon as possible.

After inspection, install the cover.

Replacing a timing belt with an automatic tensioner

Removal

We prepare the car for work.

Remove the upper front timing belt cover.

If you are removing the timing belt not for replacement, use a marker to mark the direction of its rotation. When assembling, it should be installed in accordance with the mark.

Remove the front right wheel and place the car on a reliable stand.

Remove the right side of the engine mudguard.

Remove the generator drive belt.

Using a 17 mm socket wrench, turn the crankshaft until the marks on the camshaft pulley align with the mark on the rear timing belt cover.

This position will correspond to the position of the crankshaft at TDC on the compression stroke of the first cylinder.

It is not allowed to rotate the crankshaft by the camshaft pulley bolt.

When performing the following operation, the crankshaft can be held with a slotted screwdriver by the flywheel ring gear by removing the rubber plug installed in the upper part of the clutch housing.

Also, the crankshaft pulley bolt can be unscrewed if an assistant shifts into high gear and presses the brake pedal.

However, the crankshaft may turn slightly. Therefore, it is necessary to re-check that all marks match.

Using a 17 mm socket wrench with an extension, unscrew the crankshaft pulley mounting bolt and remove the pulley.

Using a 5 mm hex wrench, unscrew the three bolts securing the lower front timing belt cover.

Remove the limit washer from the crankshaft.

Using a 15 mm wrench, turn the automatic tensioner mounting bolt half a turn counterclockwise to loosen the tension on the timing belt.

Remove the timing belt.

After removing the belt, check the condition of the tension roller

Installation

We put on a new belt, laying its branches in accordance with the drawing, and making sure that the mark on the crankshaft toothed pulley is located opposite the boss made on the oil pump housing.

We put the belt on the camshaft pulley so that the front branch is tensioned.

Without letting the belt loosen, we put it on the pump pulley and on the tensioner pulley.

If the camshaft has turned, then loosen the belt and reinstall it by turning the incorrectly installed camshaft (permissible mismatch of marks within one tooth of the camshaft pulley).

By turning the crankshaft two turns (by the flywheel crown or by screwing the pulley mounting bolt into the shaft), we verify by matching the marks that the relative position of the shafts is not disturbed. If necessary, aligning the marks, repeat the installation of the belt.

After aligning all the marks, we install the parts removed from the car in place.

Checking the timing belt with tension roller

The timing belt should be checked during vehicle maintenance - every 15,000 km.

To complete the work, you will need a wrench to tension the timing belt.

We prepare the car for work.

Using a 10 mm wrench, unscrew the three bolts securing the front timing belt cover.

Lift the cover vertically up and then remove it from the engine.

Rotating the crankshaft, visually check the condition of the belt.

The crankshaft can be rotated with a 17 mm spanner by the bolt securing its pulley or with a large slotted screwdriver by the flywheel teeth. To do this, remove the rubber plug from the hole in the clutch housing.

The belt must be clean, without dirt or oil on its surface.

A belt with tears, cracks, delaminations, cut or worn teeth, or abrasions down to the cord must be replaced.

With two fingers we try to turn the belt 90° in the area between the crankshaft and camshaft pulleys, applying a force of 15 - 20 Nm (1.5 - 2.0 kgf.m).

If the applied force is not enough to turn the belt to the required angle, the belt will be overtightened; If the belt can be turned to a greater angle, then the belt is not tensioned enough.

Excessive belt tension, oil and dirt on it will shorten the life of the belt, and also accelerate wear on the tension roller and coolant pump bearing.

Belt tension should be adjusted on a cold engine.

Use a 17 mm wrench to loosen the nut securing the tension roller.

Necessary tools and accessories

To work, we will need a set of keys and sockets, as well as a 5-point hex and a key for the tension roller. The entire procedure takes approximately one and a half hours.

The Kalina engine is very similar to the eighth.

Replacing a timing belt with a tension roller

1. Remove the front timing belt cover.

2. Remove the front right wheel and engine mudguard.

Using a 17 mm socket wrench with an extension, use the pulley mounting bolt to turn the crankshaft until the mark on the camshaft pulley aligns with the protrusion of the rear timing belt cover.

Remove the rubber plug installed in the upper part of the clutch housing.

Using a 17 mm socket wrench, unscrew the crankshaft pulley mounting bolt; in this case, an assistant uses a screwdriver inserted through the opened window between the teeth of the flywheel ring to keep the shaft from turning.

We unscrew the nut securing the tension roller and loosen the tension of the toothed belt as much as possible.

Remove the timing belt from the pulleys.

Rotating the tension roller, we check its condition. A roller that has play and makes a lot of noise when rotating is replaced.

Installation

We check the alignment of the marks on the crankshaft toothed pulley and on the boss on the oil pump housing.

We also make sure that the mark on the camshaft pulley matches the protrusion of the rear timing belt cover.

We install a new belt in the following sequence: without allowing the toothed pulleys of the crankshaft and camshaft to rotate relative to the marks, put the belt on the crankshaft pulley; Having slightly tensioned the right branch of the belt, we put it on the camshaft pulley; we pass the belt from the inside of the tension roller and put it on the coolant pump pulley.

Adjust the belt tension.

We tighten the bolt securing the crankshaft pulley and, turning the engine crankshaft two turns, make sure that the marks on the pulleys and the engine match. If necessary, reinstall the belt.

We install the crankshaft pulley in place and tighten its fastening bolt to a torque of 97.9 - 108.8 Nm (9.9 - 11.1 kgcm).

Reinstall the front timing belt cover, alternator belt and parts removed during disassembly.

Source

How to change the timing belt on the Lada Kalina

In the gas distribution system, the belt is of particular importance. It is he who is responsible for the possibility of connecting the crankshaft and camshaft. In addition, without this drive, synchronous operation of the pistons in the cylinders and the intake/exhaust valves is impossible. The timing belt turns the camshaft pulley exactly half a revolution of the crankshaft pulley.

Quality and reliability are especially important in engines where the piston and valve group are a single unit, for example, like Kalina’s. Why should every car owner know how to change the timing belt on Kalina? The valves and pistons are located in the same block, but thanks to the belt they do not touch. Accordingly, when they break, the pistons hit the valves, which leads to expensive engine repairs.

Signs and reasons for replacing the timing belt Lada Kalina

The advantage of the 8-valve engines of the VAZ 2108 and subsequently the Samara 2 family was that when the timing belt breaks, the pistons do not meet the valves and do not bend them. Lada Kalina engines are structurally different from the previous model. And a break leads to the need for repairs.

Replacement frequency

It is regulated by the manufacturer. Usually this is about 80,000 mileage, but given the low quality of components, it is recommended to reduce this period to 50,000 km. In general, the best option would be a timely visual inspection of the part to determine the degree of wear. The first sign of wear will be microcracks, which are clearly visible on a tensioned belt.

If microcracks are found, there is still time to replace it in the near future. Because of this, the belt does not break immediately, since inside it is reinforced with thin and durable steel threads. This provides the belt with the ability to repeatedly withstand heavy loads and maintain its properties for as long as possible. Another sign of wear can be loose tension due to stretching. In this case, the engine will start to run noisily, and the dynamic characteristics will also weaken.

Many motorists, as well as auto repair shop workers, recommend replacing the water pump (pump) and the tensioner roller along with the belt.

The fact is that their wear is often not visually observed, and yet the process of replacing them is quite labor-intensive. Therefore, it is better to change these elements immediately, especially since manufacturers produce kits consisting of a belt and a roller. Some make parts with reinforced metal cord. They are somewhat stronger than regular ones and last longer, but they are also more expensive.

Wear factors

Despite the fact that the manufacturer recommends changing the belt no later than 80,000 kilometers, it is impossible to determine the exact frequency, since this is influenced by several factors. The following points influence the degree of wear.

If a car is purchased from the secondary market, it doesn’t hurt to ask the former owner in advance when exactly the belt was changed. It’s even better to play it safe and replace it along with other consumables that should definitely be replaced on a used car.

Signs of critical belt wear

Signs of wear are distinguished: direct and indirect.

Direct signs of wear include:

- presence of cracks on the belt surfaces (external and internal);

- chips on the inner surfaces of the teeth;

- longitudinal sections on the outer surface;

- presence of heavy contamination;

- visible runout and stretching of the timing belt;

- extreme cases - belt breakage, “licking” of teeth.

The listed signs can be detected by visual inspection. In most cases, this requires removing the belt cover. In some car models, this requires “hanging” the engine and carrying out a series of dismantling works. Therefore, before deciding to diagnose the condition of the belt drive, it is necessary to evaluate indirect signs of wear, which include:

- misfires in engine cylinders;

- detonation, especially at the moment of shutdown;

- uneven idle speed.

These signs can be examined using computer diagnostics. The most effective diagnostic result is achieved by studying the ignition angle in dynamic mode (with the engine running). Typically it should be within plus or minus five degrees. In this case, the ignition timing when the engine rotates at idle speed should not change significantly.

Timing belt tension on Kalina

This Lada has two types of engines. On a 16-valve internal combustion engine, an automatic timing belt tensioner is used, and on an engine with 8 valves, a tensioner roller is installed. In the case of a roller, the tension should be checked every 10-15 thousand kilometers and replaced after 75,000 kilometers.

On a 16-valve engine, you do not need to tighten it yourself; there is an automatic mechanism for this. The belt in such motors lasts longer. But, on the other hand, it is possible that the tensioner may fail or oil may get onto the teeth due to a faulty crankshaft oil seal. Breakage or wear of its teeth will lead to disruption of the gas distribution mechanism and subsequent repair of the internal combustion engine. Therefore, you should not rely only on the automatic mechanism and periodically check the wear status of the part during maintenance.

To carry out the procedure for tensioning the timing belt on a drive with a tensioner pulley, you will need a special wrench. The algorithm of actions is as follows.

To adjust the tension, you will need to cool the engine and use a 17mm spanner to loosen the tensioner roller fastener. Next, you will need a special key with which you need to turn the roller to the right or left (to tighten or loosen), after which, holding the key in the desired position, tighten the roller fastening nut. After this, the tension level is assessed again. If necessary, the procedure is repeated. If the belt is tensioned as required, you can put on the protective cover and secure it with three fastener bolts.

For a 16-valve engine equipped with an automatic tensioning mechanism, a similar procedure is not provided.

Choosing a timing repair kit for Lada Kalina

The quality of the belt and roller is very important, since the smooth operation of the engine depends on it. The issue should be approached with all responsibility. On the other hand, this is a consumable item, which means you still have to change it.

The Lada Kalina is equipped with a timing belt with number 21126-1006040 from the factory. The original is considered one of the best and is highly reliable, on average it lasts for 50,000 kilometers. The cost varies depending on the region: 1,000–1,500 rubles. There are a large number of analogues on the modern market, which are usually cheaper.

But there are also more expensive examples. The following brands became the most popular:

The most affordable analogues are considered to be belts from manufacturers such as Master-Sport, Hofer and some others. On average, their cost does not exceed 1 thousand rubles. It is also equally important to choose a high-quality tensioner roller, since belts are usually changed together with them in pairs. There is also a lot of variety here.

The original roller installed from the factory has a catalog number 21126-1006135.

The average price, depending on the region, is no more than 700 rubles. The market for analogues is much more diverse, and accordingly, their prices vary from 400 to 2,000 rubles. More often than others, car enthusiasts choose brands such as Gates, Pilenga, Trialli, Master-sport and others. On average, their service life is about 50,000 kilometers +/- 5,000, it all depends on the quality.

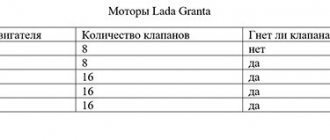

About engines

Depending on the configuration, one of four modifications of the power unit was installed on the car. Two of them had 8 valves in the cylinder head, two had 16 valves per engine. The cylinders are arranged in one row, the block is cast from cast iron. Three engines have a working volume equal to 1600 cm 3, one of them VAZ 11194 was made with an engine capacity of 1400 cm 3. This engine, just like the VAZ 21126 , has 4 valves per cylinder, that is, there will be 16 of them in the cylinder head Thanks to some modifications, the engines comply with Euro 3.4 standards.

Timing diagram

The engine with a displacement of 1400 cm3 was not produced for long, since the appearance of Kalina 2 was conceived only for power units with a displacement of 1600 cm3. Manufacturers guarantee a service life of engines of more than 200 thousand km. Both engines can be moderately boosted without significantly reducing their service life.

Are the valves bending?

This question worries many owners of Kalina and other VAZ cars with front-wheel drive. This is due to the fact that when there is a break in the valve drive or the teeth of the drive belt are cut, the pistons hit the valve heads. In the best case, the car gets bent valves, but bending connecting rods, damaged pistons, and burst valve guides are also possible. Such a malfunction will entail previously unforeseen costs for engine overhaul.

Don't let drivers be misled by the recesses in the piston heads; they do not save the engine from damage. In this case, only compliance with all recommendations of the engine manufacturers, the use of high-quality spare parts and other consumables, and timely replacement of worn parts can help.

Rules for replacing the timing belt and roller

Since there are two types of engines on Kalina, it is logical to start with the 8-valve one as it is simpler in design.

Replacing the timing belt on an 8-valve engine

To work on replacing an 8-cylinder internal combustion engine, you will need the following set of tools:

First, you need to remove the generator drive belt, and then unscrew the three bolts securing the cover under which the timing drive is located. The further algorithm of actions is as follows.

But it is impossible to completely remove the part until the generator drive pulley is removed.

To do this, loosen the wheel bolts and lift the right front side on a jack, and then remove the wheel. This will give you access to the pulley fastening nut, but sometimes you have to put in a lot of effort to unscrew it. At the same time, you need to hold the crankshaft from turning and unscrew the nut. To prevent rotation, you can insert a flat-head screwdriver into the inspection window on the clutch housing (where the flywheel mark is placed). Now you can unscrew the nut and remove the pulley, and then completely remove the timing belt.

The tensioner roller is almost always replaced in tandem with the belt, so you should unscrew the nut securing it, and then remove the roller. There will be a puck under it, which under no circumstances should be lost. During installation, the washer is inserted into the roller, only after which it can be installed on the stud.

Now you can install the belt. First it is put on the teeth of the crankshaft gear, and then at the top - on the camshaft drive toothed pulley. In this case, you need to be more careful and not allow the crankshaft pulley to roll without the camshaft pulley, otherwise you will have to re-set the marks.

After this, you can put it on the water pump drive and tensioner roller. If all the belt teeth fit snugly against the pulleys, you can use a special wrench to tighten the timing belt. The belt should not be loose or, conversely, overtightened. If the tension is insufficient, it will deviate from straight-line movement, and if the tension is too strong, the tensioner roller will begin to hum.

Replacing the timing belt on a 16 valve engine

The Kalina is equipped with an engine similar to the one on the Priora. Therefore, replacing a part on these cars, including Kalina 2, is almost no different. To work you will need the following set of tools:

As on an 8-valve engine, the alternator drive belt is removed first, followed by the timing cover. After this, the protective cover is removed from the car. The further replacement procedure is as follows.

The new one is easy to install. Installation begins from the bottom, namely the crankshaft gear. Then you need to pass it through the support roller and put it on the right camshaft gear, and then on the left. If the marks are lost, you need to set them again according to the instructions and start installing the belt from the very beginning.

All that remains is to put the strap on the pump gear and install a new tensioner roller. Using a special key, you need to tighten the strap. To do this, use a key to turn the roller counterclockwise until the slot on the outside and the protrusion on the inside of the roller coincide. If these marks coincide, it means that it is tensioned, and further adjustment of these parameters falls on a special automatic mechanism for tightening or loosening. To tighten the roller fastening nut, it is better to use a torque wrench, tightening with a force of no more than 41 Nm and no less than 34 Nm.

After installation, it is recommended to additionally check the alignment of the marks by turning the crankshaft several times.

If the marks are not knocked off, you can install the generator pulley and tighten the nut with a force of at least 110 Nm. All that remains is to install the protective cover and start the engine; there should be no strange sounds. This completes the replacement of the timing belt on Kalina 16 cl. completed.

How to independently determine that it is time to change the belt

As mentioned above, a part can wear out much earlier than expected. You should be especially careful when buying a used car. A motorist can determine belt wear independently, but depending on the design, inspection may not be possible without the use of special tools. Taking into account the fact that a part always wears out to varying degrees, it is not worth neglecting to assess its condition, even if the time for the proposed replacement has not yet arrived.

A number of signs of wear that indicate replacement:

- cracks or other defects on the inside and outside of the product;

- longitudinal sections along the length of the part;

- worn teeth;

- severe contamination of the consumable;

- oil leakage, contact with the product;

- Belt breakage is a critical case.

The question of how to check the timing belt should be approached based on the characteristics of the mechanism. The above signs of wear can be noticed visually, but most often this requires dismantling the protective cover of the part. Some car brands require the engine to be suspended for this purpose. Diagnostics should be carried out unambiguously if signs hinting at wear are noticed, these are interruptions in the functioning of the car’s heart:

- detonation of the power unit;

- misfires in the cylinders;

- Rough idle.

Computer diagnostic research can accurately identify these signs. The most effective way is to check the ignition angle with the engine running (normal deviation is up to five degrees), but at idle it should not change significantly.

Replacing a timing belt requires certain skills and appropriate tools. Often during installation it is necessary to adjust the ignition timing. Many control systems block the motor from starting at an incorrect angle in order to prevent destruction of the mechanism.

Causes of breakage and consequences

There are several factors why a part fails. Here are just the main ones.

| Factors |

Why is this happening

It is also important to change parts on time. The consequences of untimely replacement may vary. If the timing belt breaks on a Kalina with an 8-valve engine, the valves do not meet the pistons, which means the consequences are not as catastrophic as when the belt breaks on an internal combustion engine with 16 valves.

Untimely replacement can cause the following problems:

Every car owner should periodically inspect the timing belt and know the signs indicating the need for replacement. You can do it yourself. This way, you will be able to avoid serious troubles in time that will lead to expensive and time-consuming repairs.

Hello, readers of the blog RtiIvaz.ru. Today we will look at how to replace the timing belt of a Kalina with an 8-valve engine.

To begin with, here is a diagram for installing the timing belt of Kalina with an 8-valve engine:

FIGURE 1 Timing drive Kalina 8 Kl and location of marks

As can be seen from the schematic image, first of all, you need to correctly set the marks on the camshaft and crankshaft pulleys.

In the photo below, please see the position of these marks:

FIGURE 2 Crankshaft pulley on Kalina 8 Kl

FIGURE 3 Camshaft pulley 8 valve Kalina

STAGE 1

We drive the car into the inspection hole and lift the front right wheel with a jack. We remove the wheel and, opening the hood, let the engine cool. It is desirable that the engine temperature is approximately 60 degrees Celsius. Before getting to the Kalina timing belt, you need to remove the generator belt and its drive pulley on the crankshaft.

The generator drive device is shown in the photo below:

FIGURE 4 Installing the generator belt for 8 valve Kalina

As can be seen from the photo, the generator belt is tensioned using a roller. To remove the poly V-belt, you need to loosen the tension on this roller. To do this, you first need to loosen the rod locknut with a wrench (19). We loosen the lock nut and use a wrench ( we tighten the rod itself until the belt loosens and it becomes possible to remove it. Now it’s time to get to the generator drive pulley on the crankshaft. To do this, you need to go down into the pit and remove the engine “boot” protection on the right side. Also you need to remove the flywheel protection, which is secured with three bolts (10) from the bottom of the engine, on the gearbox housing. We remove the protection and, by inserting a flat-head screwdriver between the teeth of the ring gear and the gearbox housing, we will lock the flywheel. This is necessary so that when the bolt is unscrewed, the crankshaft does not turn. Bolt ( the key 17) is tightened very tightly, so to unscrew it, you will need to apply some force. To do this, it is better to use a socket with the same size and a pipe as a lever. After tearing off the bolt, unscrew and remove the generator drive pulley.

To remove the poly V-belt, you need to loosen the tension on this roller. To do this, you first need to loosen the rod locknut with a wrench (19). We loosen the lock nut and use a wrench ( we tighten the rod itself until the belt loosens and it becomes possible to remove it. Now it’s time to get to the generator drive pulley on the crankshaft. To do this, you need to go down into the pit and remove the engine “boot” protection on the right side. Also you need to remove the flywheel protection, which is secured with three bolts (10) from the bottom of the engine, on the gearbox housing. We remove the protection and, by inserting a flat-head screwdriver between the teeth of the ring gear and the gearbox housing, we will lock the flywheel. This is necessary so that when the bolt is unscrewed, the crankshaft does not turn. Bolt ( the key 17) is tightened very tightly, so to unscrew it, you will need to apply some force. To do this, it is better to use a socket with the same size and a pipe as a lever. After tearing off the bolt, unscrew and remove the generator drive pulley.

STAGE 2

We leave the pit and remove the upper plastic engine protection. It is attached to the engine with four clips; you just need to carefully pull it off from each clip in turn. Next, remove the timing belt protective cover of the Lada Kalina. To do this, you need to unscrew the three mounting bolts with a wrench (10). One of them is located in front of the casing, and the other two are on the side. Having unscrewed the bolts, we removed the casing, and the entire gas distribution mechanism drive opened in front of us (see photo).

FIG.5 Timing drive Kalina 8 Cl

Now the crucial moment has come! It is necessary to install the entire Kalina timing belt drive strictly according to the marks. To do this, you need to take a socket head (19), preferably with an extension, and screw back the bolt that we unscrewed when removing the generator drive pulley.

Which belt is better to buy?

The main supplier that supplies timing belts to Lada Kalina is the RTI plant from Balakovo. The quality of its products has been tested by many years of cooperation with the VAZ plant, and there is no doubt.

At the same time, imported components are also installed. Gates products have proven themselves well, guaranteeing a belt mileage of 200 thousand km or more. You can use the services of other well-known companies with global experience, the main thing is not to run into a well-disguised fake.