The main function of the clutch hydraulic drive is to provide short-term separation of the flywheel and transmission when changing gears. If the VAZ 2107 clutch pedal is pressed very easily or immediately falls through, you should think about bleeding the hydraulic cylinder of the release bearing drive. To accurately identify the problem, it is necessary to check the level of working fluid in the master cylinder reservoir. You can repair the clutch without contacting a car service specialist.

- Design of the main elements of the hydraulic drive

Design and purpose of the clutch master cylinder - Replacing the master cylinder

- Dismantling and assembling the master cylinder

Video: replacing the clutch master cylinder VAZ 2101–07

- Video: replacing the clutch slave cylinder VAZ 2101–2107

- The clutch does not disengage completely (the clutch “drives”)

- Tools and materials

Video: bleeding the clutch VAZ 2101–07

In what situations should you pump

Any repair of the hydraulic drive that causes its depressurization, as well as changing the working fluid, is a direct indication for pumping. But, even if the parts or fluid have not been changed, the clutch is bled when air enters, disrupting the operation of the hydraulic drive.

Signs that the circuit is airy and the clutch needs bleeding on a VAZ 2107 are:

- pedal travel is too soft;

- difficulties and crunching when shifting gears, up to the impossibility of shifting and/or moving;

- howling or vibration when holding the clutch pedal in gear.

One of the ways to diagnose incomplete disengagement of the Zhiguli clutch is to hang the rear axle (on a lift or jacks), start the engine, engage 3rd or 4th gear and hold the clutch depressed. If the wheels begin to rotate quickly even with the pedal depressed, it means that the engine is not completely disconnected from the transmission. To correct the situation, you need to either adjust the drive or bleed the VAZ 2107 clutch cylinder.

DIY repair

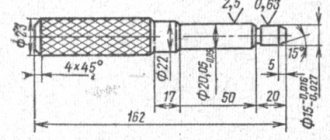

So, the part has been removed and is ready for disassembly. First, unscrew the air bleed valve and remove the retaining ring. After disassembling the part, we inspect the condition of all elements - spring, piston, pusher and sealing rubber bands. They must not show any signs of mechanical damage. Next, we wash the insides of the element. There is no need to do this with aggressive liquids like gasoline and diesel fuel. Fill a medical syringe with hydraulic fluid and use pressure to clean out the dirt inside it.

Repair

The presence of a diagram of the internal structure of the structure allows you to carry out independent repairs in case of simple malfunctions. Increased fuel and oil consumption, coolant leakage, uncharacteristic noises and knocking in the mechanism are the first indications for repair. Maintenance and replacement of worn-out components helps prolong the functioning of parts and vehicles.

How to adjust the clutch pads

In order to adjust the clutch on a UAZ, you will need to carry out the following repair work:

- Measuring with a ruler the free radius of movement of the drive pedal that turns off the mechanism. The standard value for the spring-lever type should be within the range of 35 to 55 mm, for the diaphragm type - from 5 to 30 mm.

- Measuring the full travel of the pedal after it has been lowered to the limit. The standard value must be found in the operating instructions for your model:

- for cars with a spring-lever type clutch system (Ulyanovsk SUVs of the 3151 family: 31512, 31514 and 31519) it is 18.5 cm;

- for the diaphragm type - on average 16.5 cm. So, for example, for UAZ Hunter it should be set in the range of 13-17 cm, for UAZ 3303 and UAZ 390945 - in the range from 18 to 22 cm.

Adjust the required position by changing the position using the key.

- Controlling the distance when the pedal is lowered between the partition of the motor part and the middle of the rod axis. It is necessary to achieve a value of 9.6 cm. The fork must have a free path of movement of at least 1.7 cm. Changing the length of the work basket pusher is an adjustment tool. To do this, you need to remove and screw back the pusher until the desired value is obtained.

Adjustment of the free play of the clutch pedal is required if the distance between the rotating part located on the release levers and the adjusting screws and elements of the device does not lie within the range of 50.75-52.25 mm. The screws can be removed and put back in until the correct size is established.

Measure the distance from the plate to the heads of each claw screw; it should not differ from each other by more than 0.2 millimeters. Tighten the adjusting screws to set the distance with the required difference. Fixation of each claw screw occurs by pushing the edges of the claws into the grooves of the screw shanks.

The diaphragm spring connection does not require free play adjustment and does not require adjustment of the mechanism release system. The correct dimensions of the gaps and strokes are ensured by the design features.

The principle of adjusting the clutch of UAZ 3303

A familiar classic

UAZ cars have been popular in Russia for decades. They have always been distinguished by high maneuverability, reliability and good control quality. The UAZ model range is constantly expanding, developing and improving. Everyone knows that cars are assembled from several thousand parts, and when the car is in use, it may be necessary to replace any, perhaps even the smallest part, which nevertheless plays a very large role in the life of the car.

Requirements for clutch brake fluid

Except for the basic requirements - viscosity and boiling point - brake fluids must also meet some others:

- No negative impact on rubber parts. Rubber cuffs are located between the hydraulic drive pistons and cylinders. The tightness of these connections increases provided that the rubber increases in volume under the influence of brake fluid by no more than 10%. After pouring the composition, such parts should not lose strength, ductility, or deform.

- Lubrication of friction pairs. The level of wear of pistons, brake cylinder surfaces and lip seals depends on the lubricating properties of the composition.

- Resistance under the influence of temperature changes. In the range from -40°C to +100°C, clutch brake fluids must maintain their performance properties, not delaminate, and not settle on components and parts.

The composition should be replaced on average once every 2-4 years, and the frequency depends on the condition of the brake system and the car as a whole. Simply put, the older the vehicle, the more often it is advisable to change the brake fluid. If the composition changes color before the deadline, it is changed immediately.

We recommend watching this video about bleeding the clutch:

Design

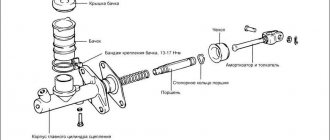

Unlike front-wheel drive foreign cars, on all-wheel drive UAZ Patriot vehicles the clutch slave cylinder (its adjustment is at the end of the article) is hydraulic and is controlled using fluid pressure, and not a cable. The design of this element includes several components. This:

- Frame. It is made of plastic or metal.

- Piston (working rod).

- A valve that releases air when the clutch system is bleeding (adjusting).

- Retaining ring.

- O-rings. Made from durable rubber.

- Return spring.

- Pusher. It affects the previous element.

When should you not restore?

In some cases, repairs will not work. The working cylinder is replaced if the housing is damaged (cracks) or there is a large hole inside it. The latter may occur due to a faulty or defective rod. In case of any of these malfunctions, the UAZ clutch slave cylinder is replaced entirely with a new one. The cost of the element is about five hundred to six hundred rubles. The clutch master cylinder costs a little more - 750 rubles. The repair kit can be purchased at a price of 150 to 200 rubles. The amount is not impressive, so if you have limited time, it is better to immediately replace the element with a new assembly. After the clutch slave cylinder is installed, the UAZ needs to be “pumped”. This way we will eliminate all existing air pockets in the lines and adjust the normal pedal travel.

Review of Manufacturer Prices

| Name/catalogue number of brake fluid | Price in rubles |

| DOT4 250ml TRW PFB425 | From 145 |

| DOT5.1 250ml TRW PFB525 | From 180 |

| DOT4 500ml TRW PFB450 | From 220 |

| DOT5.1 500ml TRW PFB550 | From 220 |

| DOT5.1 ESP 500ml TRW PFB750 | From 220 |

| DOT4 1L TRW PFB401 | From 220 |

| DOT5.1 1L TRW PFB501 | From 220 |

| DOT4 ESP 1L TRW PFB440 | From 220 |

| DOT4 ESP 1L TRW PFB440 | From 220 |

| DOT4 5L TRW PFB405 | From 220 |

| *prices are as of May 2022 | |

Purpose of the container

The design of the domestic VAZ 2107 car uses a hydraulic braking system, consisting of drive and actuator mechanisms, as well as lines in the form of tubes and hoses, and a reservoir filled with liquid. This liquid substance acts as a drive source, and it is called brake fluid - an acid that is hygroscopic. It is poured into a transparent plastic container under the hood, but more on that.

The container in question on the seven is made of soft and impact-resistant plastic. It is almost impossible to break the tank, but it is easy to damage it with a sharp tool. The reservoir is filled with fluid, which goes to the master cylinder. The piston moves in the cylinder when the middle pedal is pressed, thereby increasing the pressure in the system. When the pressure increases, the working cylinders are activated, in which the pistons move under the action of a liquid substance.

From a brief description of the principle of operation of the brake system on the VAZ 2107, it is clear that the reservoir plays a fundamental role. It ensures an uninterrupted supply of working substance to the main cylinder of the system. If lines or operating mechanisms are damaged, the tightness of the system is compromised. Due to the fact that the tank has transparent walls, it is possible to identify system malfunctions easily and quickly. To do this, you need to open the hood and look to see if the container is full.

How to change the tank

Before replacing the brake fluid reservoir, you need to understand its location. The reservoir is located on the driver's side under the hood. When you open the hood, you need to look at the wall closest to the cabin, where there will be two plastic tanks next to each other. The first reservoir, which is located to the left, is a container for brake fluid. Next to this tank there is another tank of a smaller volume - this is a container for a similar substance, which is used in the clutch system.

Vehicle owners should be aware that brake fluid must be replaced every 40 thousand km. If the car has mileage above this indicator, then the quality of the mixture deteriorates, which can cause brake failure at any time. In addition to replacing the mixture every 40,000 km, it is also necessary to periodically monitor the level of brake fluid in the reservoir and, if necessary, top it up.

Replacing the tank may be necessary in rare situations when its integrity is compromised. These are rare cases, however, they are appropriate, for example, when repairs are being carried out and the tank structure is accidentally touched. Instructions for replacing the tank are as follows:

- At the initial stage, you need to disconnect the connector of the sensor, which is activated when the brake fluid level decreases.

- Unscrew the tank cap.

- Pump out the composition from the reservoir using a syringe or bulb.

- Using a screwdriver, loosen the clamps that secure the rubber hoses.

- Disconnect the rubber hoses.

- Unscrew the bracket that secures the tank.

Now you can dismantle the device and install a new tank in its place. The assembly process is performed in the reverse order of removal. After replacement, the brake fluid is filled and the system is bled (air removed).

What kind of service is this?

Like any other part of the car, the clutch requires constant maintenance. Changing the clutch fluid, changing the engine oil or replacing the brake fluid is a simple but very important procedure to ensure the normal operation of this mechanism.

The clutch in a car is necessary to temporarily disconnect the engine crankshaft from the gearbox. This procedure is needed to change gears. This mechanism also allows you to move off smoothly without significant jerks. Untimely replacement of brake fluid in the clutch hydraulic drive or untimely change of oil in the transfer case leads to disruption of these functions, which significantly complicates the operation of the vehicle. Using the example of the “classics” we will analyze this procedure.

Replacing brake fluid in the clutch

Only brake fluid is poured into the clutch drive due to its special properties, due to which it resists compression. This helps to avoid depressurization, leading to complete breakdown of the mechanism. When you fill the fluid, the main thing is not to mix up the brake and clutch reservoirs. The latter in the “classic” is closer to the wing.

Replacing clutch fluid is carried out in several steps:

- Before starting work, it is recommended to wipe the tank to remove dirt and dust.

- Unscrew the lid and set it aside in a visible place.

- Call an assistant while you unscrew the cylinder fitting with a wrench. Take the container, point it to the desired location and ask an assistant to press the clutch pedal until all the liquid has drained.

- Once all the liquid has been pumped out of the tank, ask an assistant to stop his actions. At this time, tighten the fitting yourself to the initial position.

- Fill with new fluid and check the cap for defects. If they are present, this may cause a lack of tightness and replacement of the lid.

Design and features of tanks at GCS

Tanks of this type are made of plastic, parts are divided into two types:

- Installed on the top of the cylinder body;

- With installation on the end of the cylinder.

In the first case, the container has a cylindrical, conical or complex shape, its lower part does not have a bottom, or the bottom is a small-width collar. At the top of the tank there is a thread for a plug. The plug itself has a hole in the upper part to equalize the pressure in the tank. At the bottom of the plug there is a reflector - a rubber or plastic corrugated part (or a part in the form of glasses inserted into each other), which prevents the working fluid from flowing out through the hole during sudden changes in pressure in the main fluid circulation system and while driving over uneven roads. The reflector additionally serves as a plug gasket. There may also be a mesh filter under the lid to prevent large contaminants from entering the system when filling liquid.

The tank is installed on the main circulation pump through a bypass fitting, and two types of installation are possible:

- External installation with fixation with a bandage (clamp);

- Internal installation with clamping with a threaded fitting or a separate screw.

The first method is used to install tanks on the upper part and on the end of the cylinder head, the second - only on the upper part of the cylinder body. In this case, tanks mounted on the upper part of the main body are used only when the cylinder is installed horizontally, and mounting on the end can be used on the main body with any inclination.

When installed externally, the lower part of the tank is put on the corresponding protrusion or end of the main fluid center, and is fixed with a bandage; a tight fit is ensured by a coupling bolt. Typically, one or two rubber O-rings are placed under the tank to seal it.

During internal installation, the lower part of the tank is installed on the corresponding protrusion on the cylinder body (through a gasket), and a fitting with a wide collar is screwed in - due to the collar, the tank is pressed against the body of the main fluid pump and is firmly fixed to it.

As a rule, the reservoir is held on the cylinder body only by a band or bypass fitting, but sometimes additional fixation is used using two screws and brackets.

DIY replacement

First you need to drain the remaining liquid in the system. This can be done using a syringe. This operation is necessary to flush out dirt from the hydraulic drive system. On some models, access may be blocked by the cooling system expansion tank. For convenience, remove the container’s fastening nuts and remove the hose. It should be unscrewed with a 10mm wrench. Next, we dismantle the metal tube that comes from the clutch master cylinder. It can be copper or aluminum. After this, we remove the main cylinder, having previously unscrewed the two fastening nuts with a 13mm wrench. Using a 17 socket, you need to remove the hose that comes from the working cylinder. Next we will need the key for 13 again.

Frequent malfunctions and their causes

The clutch system of a UAZ vehicle is characterized by various malfunctions: the clutch is strengthened, the mechanism does not disengage, slips or does not pump. Timely maintenance, replacement of worn parts, lubrication and monitoring of the liquid level in the tank, diagnostics of all systems and components of the mechanism help to avoid such problems.

The operating instructions provide basic information about the operation of transport units, their preparation for operation, the rules and frequency of monitoring the functionality of the units, the main malfunctions and the decoding of error codes. Following the manufacturer's recommendations will extend the life of the equipment. Simple breakdowns can be fixed yourself.

For more complex system malfunctions, it is recommended to contact a service center.

The first category of reasons relates to the problem when the system cannot start completely when the pedal is lowered. The algorithm of actions is as follows:

- Lack of free play on the pedal. Repair measures consist of adjusting the shutdown drive.

- A malfunction in the pressure plate movement design requires replacement of the part or removal of the cause of the jam.

- Defective pressure springs, reduced force. Purchasing new spare parts will help correct the situation.

- Oil getting on the friction surface of the discs. It is necessary to rinse and wipe the elements dry with gasoline.

- Prolonged slippage causes overheating. The mechanism will cool down on its own after some time.

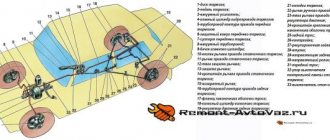

The principle of operation of the VAZ 2107 clutch drive

The clutch is engaged and disengaged using the release bearing. Moving forward, it presses on the spring heel of the basket, which, in turn, retracts the pressure disk and thereby releases the driven disk. The release bearing is moved by the clutch on/off fork. This fork can be pivoted in different ways:

- using drive hydraulics;

- flexible, durable cable, the tension of which is automatically adjusted.

The clutch is engaged and disengaged using a release bearing, which presses on the spring heel of the basket, thereby retracting the pressure plate and releasing the driven disc

The operating principle of the VAZ 2107 clutch hydraulic drive is quite simple. When the engine is running and the clutch pedal is in the up position (depressed), the clutch and flywheel rotate as a unit. Pedal 11, when pressed, moves the rod with the piston of the master cylinder 7 and creates brake fluid pressure in the system, which is transmitted through tube 12 and hose 16 to the piston in the working cylinder 17. The piston, in turn, presses on the rod connected to the end of the clutch engagement fork 14 Rotating on the hinge, the other end of the fork moves the release bearing 4, which presses on the spring heel of the basket 3. As a result, the pressure disk moves away from the driven disk 2, the latter is released and loses traction with the flywheel 1. As a result, the driven disk and the gearbox input shaft stop. This disconnects the rotating crankshaft from the gearbox and creates conditions for changing gears.

Find out how to diagnose the clutch yourself: https://bumper.guru/klassicheskie-modeli-vaz/stseplenie/stseplenie-vaz-2107.html

When is clutch bleeding required?

The operation of the clutch system is based on the laws of physics - the properties of hydraulic/brake fluid to compress/decompress under load. If air gets into the system, its properties change. As a result: the hydraulics stop responding to pressure or react late, which leads to jerks and jolts when pressing the pedal.

Signs of “airing” of the system

If the following symptoms appear, it's time to change the hydraulic fluid:

- the pedal is depressed too easily, but the gear does not change;

- the pedal moves normally, but the gear engages with vibration or delay;

- the clutch pedal “sticks” to the floor, slowly returning to the top position.

Even one of these signs is enough to check the system.

“Sinking” can also be caused by a broken return spring.

Before bleeding the clutch, find out that the spring mechanism is not the cause of the malfunction.

In what cases is the clutch hydraulic drive pumped?

Bleeding of the clutch and braking systems is mandatory if:

- The liquid used has already served its purpose

. Changes in physical and mechanical properties over time are the norm. The recommended period of use for hydraulics is 1-2 years (as a rule, the period is indicated on the container).

The liquid loses its properties, even if stored in an airtight container.

the clutch or brake system is being repaired

. When cuffs, seals, seals are changed, leaks are eliminated, depressurization occurs. Result: leakage of working fluid and airing. Needs replacement.

It is easy to speed up new bleeding if you loosely tighten the fastenings of the clutch mechanism units. Air leaks freely through the micro-holes.

Clutch/braking system components are severely worn

.

In case of wear of parts, only bleeding is not enough, because the cause of airing does not disappear. To fix the problem, you must first repair or change the functional elements, and then change the working fluid.

Types of Clutch Master Cylinders

All GCS have a fundamentally identical design and principle of operation, but are divided into several varieties according to the location and design of the reservoir with the working fluid, the number of pistons and the general design of the housing.

According to the location and design of the tank, the cylinders are:

- With an integrated reservoir for working fluid and a remote tank;

- With a remote tank;

- With a reservoir located on the cylinder body.

| Clutch master cylinder with integrated reservoir | Clutch master cylinder with remote reservoir | Clutch master cylinder with reservoir mounted on housing |

The first type of GVC is an outdated design that is rarely used today. Such a mechanism is installed vertically or at a certain angle; in its upper part there is a reservoir with working fluid, the supply of which is replenished from a remote tank. Cylinders of the second and third types are more modern devices, in one of them the tank is remote and connected to the cylinder via a hose, and in the other the tank is installed directly on the cylinder body.

Based on the number of pistons, GCS are:

- With one piston;

- With two pistons.

| Single piston clutch master cylinder | Clutch master cylinder with two pistons |