The stable operation of a carburetor engine directly depends on the performance of the carburetor itself. Until recently, cars of the VAZ family were equipped with a fuel supply system using this unit. The carburetor requires periodic maintenance, which is something that almost every Zhiguli owner faces. You can do the cleaning and adjustment work yourself, just read and follow the step-by-step instructions.

- What is it for?

- Carburetor design

- Idle system

- Float chamber

- Econostat

- Acceleration pump

- Transition system

- Starting system

- What carburetors are installed on the VAZ 2106

DAAZ

- Ozone

- Solex

- Signs of a carburetor malfunction

Stalls at idle

- Dips during acceleration

Video: eliminating air leaks

- Video: fixing the stalling engine problem

- XX adjustment

Video: how to make idle stable

- Video: how to clean the carburetor

- How to remove

Video: how to remove a carburetor using the example of a VAZ 2107

Replacing the carburetor of a VAZ 2106 Zhiguli

Loosen the clamp and disconnect the corrugated warm air intake hose from the pipe.

Remove the air filter (see Replacing the air filter element).

Using a size 8 wrench, unscrew the four nuts securing the air filter housing to the carburetor. To avoid accidentally dropping them into the intake manifold, you can cover the carburetor with a clean rag.

Remove the air filter housing.

Loosen the clamp and remove the fuel supply hose.

Disconnect the tip from the solenoid valve outlet.

Using an “8” wrench, loosen the tightening of the bolt securing the sheath of the air damper drive cable.

. Use a slotted screwdriver to loosen the cable fastening screw, holding the nut with a “7” wrench.

. and remove the end of the cable from the holes.

Disconnect the crankcase gas suction hose.

Using a screwdriver with a wide blade, remove the rod from the throttle valve drive lever (see Adjusting the carburetor drive).

Disconnect the vacuum ignition timing regulator hose.

Remove the return spring.

. Using a 13mm wrench, unscrew the four carburetor mounting nuts.

Remove the carburetor from the engine.

We install a new (or washed, repaired and adjusted old) carburetor in the reverse order of removal. Be sure to replace the carburetor gasket with a new one.

ATTENTION! Do not use much force when tightening the carburetor mounting nuts. The soft metal mating surface of the carburetor body can be damaged.

How to install the unit in place

You can assemble and reinstall the carburetor in the same way as you disassembled it, performing all the steps in reverse order.

- The carburetor is installed in its place, the mounting bolts are tightened.

- The pipes through which fuel is supplied are attached. The gas cable is connected to the throttle lever.

- The wiring is attached.

- A vacuum hose is connected to the ignition distributor, and the EPHH limit switches are combined.

- After installing the carburetor, it is adjusted.

Video: installing a carburetor on a VAZ

It is not so difficult to independently remove, disassemble, clean and reinstall the carburetor in the VAZ 2107 and 2106. The main thing is not to be intimidated by the huge number of hoses, valves, parts and dirt and strictly follow the instructions.

Connecting the carburetor to the engine and other vehicle systems.

The first device we see connected to the carburetor is the air filter. The dimensions of the filter are such that it completely covers the carburetor. The filter housing is attached directly to the top of the carburetor using 4 nuts. A fuel hose is connected through a fitting located on the side of the carburetor, through which fuel is supplied from the tank using a fuel pump.

A hose is connected from the distributor (ignition system) to the Ozone. A vacuum is created in the carburetor, which rotates the contact plate in the distributor through this hose, thereby changing the ignition timing.

A wire is connected to the solenoid valve. Through it, voltage from the fuse box is supplied to the valve.

A thin cable is connected to the throttle control lever. This thrust increases the amount of produced fuel-combustible mixture, which is supplied to the engine combustion chamber. It is this thrust that acts when the driver presses the gas pedal in the cabin.

In the area of the air inlet (which is blocked by a special flap), a so-called “choke” rod is connected. This device starts a cold engine: the flap allows less air into the carburetor, thus producing a rich mixture. The rod leads to the choke handle, located inside the car, at the bottom right of the steering column.

The intake manifold, which directs the air-fuel mixture directly into the cylinders, is connected to the carburetor by a short spring and two bolts.

Engine gaskets main functions

Skoda Octavia RS Logbook Thermal gasket for the intake manifold

As in any other case, the main task of the gasket is to ensure the tightness of a particular unit, device or mechanism. The internal combustion engine is no exception.

Technical fluids constantly circulate inside this complex mechanism during operation. Moreover, these liquids are under a certain pressure. In order for the specified pressure to remain at the required level, and also to prevent leakage of liquids from the housing, tightness is necessary.

Such tightness is ensured by gaskets, which differ in shape, and are also made of different materials, taking into account certain features (location in a certain area of the internal combustion engine, load on the gasket and degree of pressure, interaction with a specific technical fluid, temperature conditions, etc. ).

As you can see, gaskets help prevent various leaks of working fluids and lubricants from mechanisms, as well as prevent dust, moisture and dirt from entering from the outside. The use of gaskets allows you to achieve an ideal and tight fit between two surfaces, eliminating certain errors in their processing.

The gasket is able to follow the shape of the parts, and thanks to its softness and elasticity, it is possible to smooth out unevenness, roughness and other minor defects. It turns out that the solution seals the housing, seals the internal components of the motor, and prevents leaks of technical fluids.

Carburetor VAZ 2106

The carburetor is one of the most critical components in the fuel supply system to the engine of a VAZ 2106 car. It is responsible for creating the fuel-air mixture, which is necessary for the normal operation of the power unit.

Carburetor OZONE

A carburetor with the correct settings prepares a normal combustible mixture of gasoline and air (1:15). But during prolonged or intensive use, the factory settings are violated, as a result of which an enriched or lean fuel mixture constantly begins to flow into the engine. This immediately affects its operation and requires carburetor repair.

Symptoms of a problem

If the carburetor begins to produce a rich mixture, you will understand this by the following signs:

- Fuel consumption increases

- Loud exhaust is heard from the muffler and the smoke turns black

If the engine receives a lean mixture, you will understand this by the following sign:

Loud bangs are heard from under the hood.

In both cases, the engine heats up noticeably more, and its power is also lost.

If you encounter a similar problem, remember that it is a natural consequence of using the carburetor. Any element of the car requires care, regular inspection and maintenance. Therefore, the VAZ 2106 carburetor must be adjusted from time to time.

Before proceeding with the adjustment, you need to make sure that the cause of the breakdown is not the failure of any element inside the device. You need to disassemble it, wash it and clean it. And only after you are convinced that all components of the structure are in full working order, you can begin adjustment.

The easiest option is to send the car to a specialist. Carburetor technicians have a special tool - a gas analyzer. Using this device, you can achieve the most efficient system setup. However, the services of specialists in this profile are not cheap. You may want to do all the work yourself, using available materials. Next we will look at how to set up a carburetor step by step.

Blitz tips and tricks

- The efficiency of the engine and its dynamic performance depend on how the carburetor gaskets are installed, so if problems arise in the operation of this device, you must immediately begin replacing the gasket;

- It is possible to make yourself not only a product from cardboard, but if you need a homemade textolite gasket, then it is made from a sheet of textolite of suitable thickness. In this case, the material is processed using special scissors;

- If necessary, the rubber gasket for the pipe can be made of dense rubber of suitable thickness. Holes for bolts in the rubber gasket are made using a drill and twist drills, but the gasket must be securely fixed between two wooden boards;

- Before purchasing a gasket in a store, you need to disassemble the carburetor and see what the part costs;

- Thermal insulating gasket can be installed in the amount of 2 pieces, when a suitable thickness of the part cannot be found, or the textolite for self-production is not suitable for this parameter. Thermal insulation, in this case, is not compromised, and the unit can be used under normal load conditions.

Replacing the carburetor gasket or making it from cardboard will not be difficult, but you should be very careful about the selection of material, as well as the accuracy of manufacturing this part. After replacing the product, the carburetor is installed on the engine and the engine is test run, as a result of which it will be clear how correctly all repair operations were performed.

Picking apart the original gaskets led to the following conclusions: most likely they are made of dense high-quality metal asbestos mixed with black plastic similar to fluoroplastic.

I went to the local flea market over the weekend. I didn't find any metal asbestos. I found this:— Fiberboard

0.5 mm - well, very thick black cardboard.

The best option. I took a sheet - they didn’t give me less. - Electrocardboard

0.3 mm - less dense cardboard of a light brown color.

I took half a linear meter. - Fluoroplastic

0.5 mm - white FUM tape of maximum thickness, 10 cm wide. For the bottom gasket - just right. There is not enough width for medium spacers. You need at least 12 cm. I took 2 meters. Expensive. I think the thread will still be useful somewhere in everyday life.

The fluoroplastic tape was tested with a soldering hair dryer. The material calmly holds a temperature of 150 degrees, and begins to melt at a temperature of about 230 degrees. Just right for a carb! Easy to cut with nail scissors.

So I will make the bottom gasket from two materials - electrical cardboard and fluoroplastic. But the middle one will be made from fiberboard. Only to make it you need to select tubes... to punch straight holes. For these purposes, I found and put aside an old telescopic antenna. This evening I'll take it apart, cut and sharpen the tubes... I'll try to make holes with them. Maybe it will work out!

======Results: I abandoned fiberboard in favor of PMB paronite. The tape still flows under pressure and temperature. The only way out is to take strictly grade 4 fluoroplastic (high-temperature, from Dupont “Teflon”) and 2-5 mm thick. It should be taken into account that this lifts the carb and displaces its fastenings.

Material? Where to find?

As far as I remember, paronite can be used for these purposes. You choose a certain thickness and use punches to “create” holes. Cuts well with simple scissors. Heat resistant. Used on Soviet cars in garages

The fact is that I have at least two gaskets on my Solex carburetor. And one can be said to divide the carburetor in half and many people make it from cardboard, but it costs a penny in the store.

But the gasket that separates the carburetor from the manifold is most likely made of paronite.

And it’s really not easy to buy such a gasket. My car came from the factory without such a gasket, there was only one liner, and only then did I order such a gasket from the factory.

This is exactly what you can make yourself from paronite, and this was done before my eyes. And this process is not complicated, the main thing is that you have a suitable paronite plate.

Replacing the Solex 21083 carburetor on a VAZ 2106

To carry out work on replacing the Solex 21083 carburetor, you need to prepare gasket material made of paronite, a fuel supply hose about 80 cm in length, a carburetor rocker and the Solex product itself. A set of motorist's locksmith supplies will be useful for the job.

Installing a Solex 21083 carburetor on a VAZ 2106:

- We clean the power compartment to prevent contamination of the motor and power system.

- We disconnect the cables and ties of the carburetor device, the fastenings of the fuel wires and hoses of the heating complex.

- We remove the bracket holding the casing covering the throttle valve drive cable.

- We clean the manifold platform for attaching the carburetor.

- Apply a layer of sealing lubricant to prevent air from entering the system.

- We place the gaskets in the following sequence: thin, then thick, then again thin gasket. A large cross-section gasket is used to remove heat and prevent heat transfer to the carburetor device.

- We mount the Solex on the seat, removing the front part of the product for ease of operation.

- We install the rocker on the side of the over-valve cylinder head cover.

- We pull the cable from the throttle drive of the carburetor valve and set the required length of the cable and then connect it to the carburetor device.

- We install the updated gasket and lock the front carburetor cover.

- We connect the hoses of the heating and distribution ignition system.

- Connect the tee to the fine fuel filter element and connect the return hose to the fuel system.

- We connect the reverse valve to the “return” hose, and then connect it to the carburetor device.

- We connect the return type spring to the axial element of the rocker, which is located on the cylinder head casing.

- We mount an additional spring element for the throttle drive of the carburetor valve for the period of running-in of the product (if necessary).

- Connect the idle air solenoid valve to the relay connector.

- Restore the original position of the air filter housing and connect the gas outlet hose.

- This completes the Solex installation.

It is important to choose the right model of Solex carburetor for the VAZ 2106, the price of which is quite reasonable for Russian car enthusiasts. It all depends on the size of the power plant

In some cases, it is advisable to install the Solex 21073 product, but you should know that when using such a modification of the carburetor, the dynamics of the vehicle improves, although fuel consumption also increases in direct proportion.

In a VAZ 2106 car, adjustment begins with correcting the fuel level in the float chambers. For all the different methods of arranging the “return” (directly into the fuel tank or tapping into the gas line in front of the pump), the following steps must be taken:

- We place the vehicle on a level surface, start the engine, warm it up, test it at all speeds and turn off the power plant.

- We remove the fuel hose from the carburetor device, and do this carefully so that fuel does not get into the chambers, because The float level will be incorrect.

- We dismantle the front cover of the Solex together with the accelerator cable, after which we use a caliper to measure the distance from the fuel level to the cut of the product body (should be 24 mm in both chambers) with an error of 1 mm. Due to a possible system error in the vehicle horizon, you can take the arithmetic average value based on measurements in the carburetor chambers.

- Based on the measurements taken, we bend the tongue of the float in the required direction, after which we check, after assembling the product, for the transfer of fuel from the chambers.

- Next we adjust the idle speed.

This work is carried out on a power plant heated to operating temperature. The peculiarity is that the mixture quality regulator is equipped with a red arrow, and the mixture quantity regulator is equipped with a blue arrow. Otherwise, the adjustment is of a normal nature, only the value is set by the quantitative regulator to 9000 instead of 800 on previous models.

Installation procedure

The Solex carburetor is absolutely suitable for mounting on the VAZ 2106 engine. Since the device itself is different, you will need to purchase some additional parts in order for the installation to be successful and the engine to work properly. The parts list includes the following items:

- 2 paronite gaskets and 1 paper;

- 1 meter of hose for fuel supply;

- Carburetor, always with a slide;

- A set of keys, screwdrivers and other locksmith supplies.

Now, you can get to work. Before installing the Solex on a VAZ 2106, clean the area where the Ozone carburetor connects to the engine. This is done so that when removing, debris does not get into the engine. Next, disconnect all the hoses and cables.

Next, unscrew the fastenings and remove the “Ozone” from the engine. Before installing the carburetor from the VAZ 21083, clean the mounting location. Afterwards, apply sealant and lay the gasket. The gaskets should be in this order: thin, thick and thin.

When the seat is ready, disassemble the Solex into two parts. This will make it easier for you to install it. First of all, install the rocker from the carburetor VAZ 21083 to 2106, as this is the key element required to begin the installation. You can already install the Solex on it.

Now, connect all the cables and hoses. We start with the throttle cable. It must be set to the required length, which is enough to connect it. Next in line is the fuel system hose. Before installing it, it is worth considering that on the VAZ 21083 it is longer than on the 2106, so you will need a pre-prepared meter hose. Place one of its tips on the outlet of the fuel system, and the second on the inlet to the carburetor. Before putting on the second end, it is better to cut it so that it does not dangle freely in the engine compartment. Also, remember, the longer the hose, the more fuel it will contain, and therefore the weight. This can cause it to become disconnected and possibly even cause the engine to catch fire.

Connecting and setting up the rods

Next, we connect one end of the return flow to the fine filter, do not forget to install a valve in it. Place the other end on the carburetor. We put all the springs in their places (they do not need to be replaced with new ones). Once all the hoses and cables are in place, you will need to worry about the idle speed. To do this, install a solenoid valve.

The final touch is to put on the top part of the carburetor and tighten the fastening nuts. Now, your Solex is ready for use.

Which carburetor is better for VAZ 2106

Since carburetors of the SOLEKS and WEBER families were completely copied from foreign-made analogues, their reliability is beyond doubt. It is enough to regulate and clean these units every 60 thousand kilometers, and there will be no problems with the supply of fuel to the engine of your car.

But the most popular are the devices of the OZONE family. They need to be adjusted and cleaned twice as often. In addition, they have many different diaphragms, which often break. The most common breakdowns of melon units are incomplete opening of the second chamber and malfunction of the accelerator pump.

Do-it-yourself carburetor idle adjustment

To solve the problem of how to adjust the idle speed on a VAZ 2106, you need to stock up on a set of driver’s tools, although one screwdriver is enough for this technological operation. On the Internet you can watch the “VAZ 2106 idling” video clip about carrying out adjustment work to stabilize the idling speed of the vehicle.

To adjust the idle speed of the “six” carburetor, a number of preparatory conditions must be observed. These include:

- The operation is carried out only on the motor that has reached operating temperature (about 90 degrees Celsius).

- The clearances of the timing valves and ignition contacts (with a contact system) must correspond to the required dimensions.

When adjusting the idle speed of a VAZ 2106 carburetor on a cold engine, the required result cannot be achieved. If there is no idle speed, it will appear only if the correct adjustment conditions are met.

If the VAZ of the “sixth model” stalls at idle, then to find out how to adjust the idle speed, you need to use the following algorithm:

- The process of adjusting the idle speed on a VAZ 2106 car is carried out using two screws for adjustment, the first is the quality screw, the second is the quantity of the mixture.

- In accordance with the factory parameters, the quantitative adjusting screw is locked with a sealed limiter sleeve. To carry out adjustments and when there is no idle speed on the VAZ 2106, the seal is removed and adjustment work is carried out.

- Using a high-quality screw, we achieve a value of 900 rpm, checking the value with the tachometer readings.

- Using the quantity screw, we use a gas meter to set the carbon monoxide value in the range of 0.6-1.3 percent. The circular movement of the adjusting screw changes the number of rotations of the crankshaft of the power unit.

- In this situation, we re-fix the required crankshaft speed parameters with the first screw. If everything is done correctly, then when you sharply press and lower the accelerator pedal, the rotation value should remain stable.

- If all operations are performed correctly, there should be a smooth increase in engine speed and the unit should operate stably.

If the idle speed floats or the VAZ 2106 engine operates spasmodically, that is, jerkily and unevenly, then the unit settings need to be restored. Upon completion of the setup, the power plant should produce stable speed.

You need to know how to set the idle speed of the VAZ 2106 in order to adjust the carburetor. You can perform this procedure quite quickly with your own hands, if, of course, you have an idea of what a carburetor consists of and the functions of its main components. But first things first, let's start with the saddest thing - the case when suddenly there is no idle speed and the engine starts to stall.

You'll be lucky if this happens close to home. But if you’re on the road, it’s not good enough. On my own behalf, I’ll add that several times I had to remove and disassemble the carburetor while standing on a narrow highway, shying away from passing trucks and highlighting it with a flashlight. A good habit is to take a thermos and a flashlight on the road.

The most common breakdowns

However, the most common devices are the OZONE family of devices. They need to be cleaned and adjusted twice as often. In addition, they have a lot of different diaphragms, which break every now and then. The most common breakdowns of these units are incomplete opening of the second chamber, as well as malfunctions of the accelerator pump.

- Popping sound when you press the accelerator pedal, as if something is shooting into the carburetor.

- Similar pops, but now it shoots into the muffler.

- The idle speed is either too high or too low (floats).

- The car thinks for a long time when driving on the highway. When you press the gas pedal all the way, it does not accelerate at all or accelerates too slowly.

- When you shift into 2nd or 3rd gear and press the accelerator pedal, the car first slows down and then jerks forward with a sharp increase in speed.

The detonation problem may be associated with a violation of the ignition timing angle. In any case, you should first try to eliminate detonation by adjusting the carburetor. In 90% of cases this helps.

The symptom described in point 3 indicates the need to adjust the idle speed. The situation indicated in paragraph 4 indicates that camera drive 2 is faulty. Eliminated by replacing broken parts. The symptom described in paragraph 5 indicates a breakdown of the accelerator pump - the diaphragm or spring must be replaced.

Carburetor malfunctions, their causes and methods of elimination

According to the recommendations of experts, the VAZ-2106 carburetor must be subjected to maintenance at least once every 30 thousand km. mileage Thus, you will be able to promptly identify and eliminate various types of malfunctions in the form of torn diaphragms, breakdown of the accelerator pump, or incomplete opening of the second mixing chamber.

How to determine that the carburetor of a VAZ-2106 car has failed and needs to be restored? To do this, you just need to pay attention to the signs indicating this, described below:

- The presence of popping sounds when you press the gas pedal - the cause of the problem is micro-explosions of the air-fuel mixture, known as detonation. If detonation is observed in the intake manifold, one should conclude that the mixture is too lean, and popping noises in the muffler indicate too much gasoline in the combustible mixture. In both cases, the carburetor should be adjusted, although often the reason lies in a violation of the ignition timing.

- The engine is running unsteadily (the speed is floating) - if you notice this “symptom”, it means that you need to adjust the idle system.

- While driving, the engine does not pick up speed or picks up speed too slowly when you press the accelerator pedal - the presence of this problem may indicate that the drive of the second mixing chamber has failed.

- Slow, jerky increase in revolutions when upshifting and pressing the gas - if you encounter such a problem, then the accelerator pump needs repair.

You can perform carburetor cleaning and repair operations yourself

Next, we will tell you in detail how to clean the carburetor and perform all the necessary repair operations yourself.

Carburetor 2106

The standard option used on the Six engine is the “Ozone” sample. This is a two-chamber carburetor, with a falling air flow, emulsion type. The technical characteristics of the engine, when running, produced 75 horsepower, and the maximum speed was 155 km/h. Acceleration time to hundreds is 16 seconds.

The engine response is good, but when you press the gas pedal sharply, the car first chokes and then starts to move. This was explained by the fact that in the Ozone float chamber, the fuel level was insufficient, and during sharp acceleration there was not enough of it.

VAZ 2106 car owners were racking their brains over the question of which carburetor is better to install so that the engine's throttle response increases, while having minimal losses. Most opinions agreed that installing a Solex with a VAZ 21083 would be the best option.

Bottom line

After installation, the characteristics of the Six engine will acquire several pros and cons.

The advantages are that the engine will be more responsive, the maximum speed will increase (up to 160 -165 km/h), and the acceleration time to the first hundred will be reduced (instead of 15 seconds - 13). The modernization will not significantly affect the rated power, increasing it by 5 - 10 hp.

The only downside is fuel consumption. With normal, non-economical driving in the urban cycle, it will increase by 1 - 1.5 liters.

The general conclusion is this: installing this carburetor is a necessary thing, because for the price of 1 - 1.5 liters per 100 kilometers, you will get more driving comfort.

Before you begin removing the carburetor on the VAZ 2106, you must first remove the air filter. After this, it is necessary to completely remove its body, since it will also interfere. First, as usual, I will give a complete list of the necessary tools that will be needed to replace the carburetor:

- Open-end wrench 13

- crosshead screwdriver

- Heads for 8 and 10

- Ratchet handle or crank

- Small extension cord

BRIEFLY ABOUT THE FEATURES AND DEVICE OF THE “SIX” CARBURETTOR UNIT

Before adjusting the carburetor on a VAZ 2106, it doesn’t hurt to know its design features. After 1980, Ozone and Solex began to be installed on Tolyatti cars. The purpose of the unit’s operation is to prepare a combustible mixture before feeding it into the car’s cylinders. Down to the subtleties, this is not a driving school, we will not disassemble the design, it is enough to familiarize yourself with the main components that ensure optimal operation of a carburetor internal combustion engine:

- Fuel dosing system.

- Mechanisms for controlling throttle valves and enriching the mixture.

- Idle system.

- Accelerator pump and econostat.

- Float chamber.

A chamber with a float and a needle valve is responsible for the stability of the fuel level. Next, gasoline, flowing through the spray tube, enters the chamber, where it mixes with air from the inlet pipe. The amount of mixture is adjusted by the throttle valve, which is connected to the accelerator pedal.

Precise adjustment allows you to prepare the correct mixture of gasoline and air in a ratio of 1:15. During long-term operation of the car, the settings get lost and you have to think about how to adjust the carburetor on a VAZ 2106 on your own. The adjustment technology is the same for both Solex and Ozone.

WHEN IS ADJUSTMENT NEEDED?

Adjusting the carburetor unit is no more difficult than adjusting the clutch drive on a VAZ 2107, since it only involves adjusting the jets. In some cases, they need to be cleaned of resins and other contaminants; the presence of contaminants is felt by power dips in the process of accelerating. Many car owners claim that Ozone carburetors are not a very good option and recommend replacing them with Solex.

However, the signs that the device has begun to prepare an enriched mixture and needs to be adjusted are the same for both types of units:

- Increased fuel consumption.

- Frequent overheating of the motor.

- Black smoke from the exhaust pipe and pops.

- Loss of power.

The preparation of a lean mixture is characterized by the following characteristics:

- Popping sounds in the carburetor.

- Loss of power.

- Engine overheating.

Of course, you don’t always need to immediately grab a screwdriver and turn the adjusting screws - perhaps it’s something else. For example, when the idle speed floats, air may leak through the intake manifold gasket, or there may be a breakdown of the brake booster diaphragm. But even the reasons listed are not all the options, so specific recipes for eliminating certain problems cannot be given. The issue should be addressed comprehensively, taking into account the connection between vehicle systems.

Tenderloin - gasket

Cutting the gaskets is done as follows.

The paronite sheet, under which it is necessary to place a sheet of plywood, is lightly pressed with the head and the spindle is turned on at a speed of 3 - 4 rpm. When lowering the spindle with the mandrel, the cutting rollers, rolling along the paronite, cut out the gasket. During cutting, under the action of a compressed spring, the pressing head, remaining motionless, tightly presses the paronite sheet. This mandrel allows you to cut gaskets with a diameter of up to 300 mm. The gaskets are cut using both tools on a wooden backing. To reduce friction, the cutting edges must be moistened with soapy water during the cutting process.

Cutting the gaskets is done as follows. The paronite sheet, under which it is necessary to place a sheet of plywood, is lightly pressed with the head and the spindle is turned on at a speed of 3 - 4 rpm. When lowering the spindle with the mandrel, the cutting rollers, rolling along the paronite, cut out the gasket. During cutting, under the action of a compressed spring, the clamping head, remaining motionless, tightly presses the paront sheet. This mandrel allows you to cut gaskets with a diameter of up to 300 mm.

The gaskets are cut using both tools on a wooden backing. To reduce friction, the cutting edges must be moistened with soapy water during the cutting process.

| Recommended length (in mm) of pipes with flanges. |

Gaskets are cut out on drilling machines using special devices, as well as in cutting dies on driven mechanical and hydraulic presses.

| Cutting mandrel for cutting gaskets. |

Cutting out the gasket is done as follows: a sheet of gasket material is attached to the faceplate of the lathe. Depending on the width of the gasket, the corresponding transverse feed of the cutter is set. The transverse feed of the caliper is turned on. The cutter, moving from the center to the periphery, cuts out the gasket along the Archimedes spiral.

| Universal tool for making round gaskets.| Circular saw for cutting discs and spacers.| Roller shears (zig machine. |

Cutting out large gaskets can also be done using universal disc shears adapted for circular cutting, or using zig machines equipped with a special device for this purpose.

The gaskets are cut using a compass cutter or chisel; Rubber gaskets are cut out with a knife. Such gaskets provide a significantly worse seal and require significantly more material to manufacture. If there is a new gasket prepared, they begin to unscrew the flange connection, for which purpose the corresponding section of the pipeline is first turned off from work; place a bucket under the unscrewed flange connection to drain the liquid contained in the pipeline into it; the flanges are thoroughly cleaned of the remnants of the old gasket, two adjacent bolts are inserted; a new gasket, pre-treated accordingly, is inserted between the flanges; a correctly cut gasket will take the proper position if its edge touches both adjacent flange bolts; After applying the gasket, install the remaining bolts, put on the nuts and tighten them. The nuts on the bolts are tightened gradually, in sequential order, no more than 1/2 turn at a time.

The gasket for the frame of the seat cushion of a truck (size 430 X 880) is cut out of waterproof cardboard 2 mm thick in a knife stamp (Fig.

| Hydraulic device for spreading flanges.| Gasket replacement device. |

A variety of tools are used for cutting gaskets. The device is inserted into the drill chuck.

| Hydraulic device for spreading flanges. |

Carburetor adjustment: setting the fuel level

The level of fuel in the float chamber affects the composition of the mixture in any operating mode of the carburetor, the toxicity of exhaust gases, the dynamics of engine operation and fuel consumption. Work order:

Unscrew the carburetor cover mounting screws and install it in a vertical position. A prerequisite for its installation is light contact between the float tongue and the needle ball. Using a special gauge, measure the gap between the bottom surface of the float and the plane of the cover (taking into account the cardboard spacer)

It is important that the gap is 6.5+0.25 mm. If the gap size does not match, the value is corrected by bending the float tongue. Finally, check the float stroke, which should be 8.0+0.25 mm.

Adjusting the float system

Before you begin this work, you need to make sure that the needle valve is working reliably.

- We take a measurement between the float and the gasket. This distance should be 6.5 millimeters. A slight deviation of 0.25 millimeters is allowed. You can also simply use a suitable drill bit to measure.

- The clearance is adjusted by changing the angle of the float tongue.

- Turn the float all the way. We measure the distance to the gasket in this position. It should be equal to 8 millimeters. Using the tongue we achieve the desired value.

How is a carburetor repaired and flushed?

Many problems can be eliminated by flushing the carburetor, but for it to be effective, the unit must be removed from the car. After which you will need to disassemble it to the required level so that you can gain access to absolutely all elements of the mechanism.

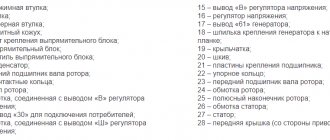

Parts of the carburetor body 2107-1107010 in the diagram: 1 - rod of the pneumatic drive of the second throttle valve; 2 — pneumatic drive housing; 3 - diaphragm; 4 — pneumatic drive cover; 5 — fuel jet of the transition system of the second chamber; 6 — fuel nozzle body; 7 — small diffuser of the second chamber; 8 — accelerator pump nozzle; 9 — screw valve of the accelerator pump; 10 — main air jet of the second chamber; 11 — emulsion tube of the second chamber; 12 — main air jet of the first chamber; 13 — emulsion tube of the first chamber; 14 — main fuel jet of the second chamber; 15 — main fuel jet of the first chamber; 16 — accelerator pump adjusting screw; 17 — fuel jet of the idle system; 18 — fuel nozzle body; 19 — return spring of the accelerator pump; 20 — accelerator pump diaphragm; 21 — accelerator pump cover; 22 — small diffuser of the first chamber; 23 — lever return spring; 24 — three-arm air damper control lever; 25 — connection rod with the throttle valve; 26 — throttle valve return spring bracket

Repair consists of the following steps:

- Dismantling the device.

- Flushing, which includes cleaning and purging of carbon deposits and adhering dirt.

- Replacement of faulty parts.

Important: You need to remove the carburetor if you are 100% sure that the problem is in the carburetor, because the problem in other components of the car’s fuel system is also possible

Where does carburetor repair on a VAZ 2106 car begin?

Do-it-yourself repair of a VAZ 2106 carburetor begins with its removal. To do this, you will need to remove the air filter, which will still have to be replaced with a new one, and dismantle its housing.

It is recommended to first seal the openings in the chambers with rags to prevent small objects from getting into them. After this, the hose going to the brake vacuum is removed from the pneumatic valve, the choke installation cable is unscrewed and the rod is removed from the gas pedal lever that controls the throttle valve.

If you have the latest Solex carburetor, then the wires from the throttle valve, air damper and economizer are disconnected, providing forced idle.

Next, remove the fuel supply and return hoses and the ventilation pipe. After disconnecting all suitable and supply elements, you can begin to remove the block itself. To do this, you need to unscrew the 4 fastening nuts and carefully remove the device from the studs. It is highly recommended to plug the hole in the collector with a soft rag.

Step-by-step instructions for removing the carburetor

For your convenience, I have compiled detailed step-by-step instructions for removing the carburetor from the photo:

Important to remember: Be sure to replace the gasket under the carburetor with a new one. To avoid air leaks

Spare parts included in the carburetor repair kit for the VAZ 2106:

- Trigger diaphragm

- Jet body

- Idle jet - 2 pcs.

- Main air jet - 2 pcs.

- Main fuel jet - 2 pcs.

- Needle valve assembly

- Accelerator pump diaphragm

- Filter element

- Carburetor cover gasket

- Starter gasket

- Return spring

- Accelerator pump diaphragm spring

- Idle speed screw (adjustment needle)

- Ring sealing

- For R/K 2105-10, 2105-20, 2106, 2107-10, 2107-20:

- Acceleration pump nozzle

- Spray Valve

- Sprayer gasket - 2 pcs.

- Screw M5x0.8x20

- Screw M4x0.7x15

Correct selection

Fans of tuning VAZ classics and simply wanting to improve its performance characteristics most often opt for Solex

.

Initially, models from front-wheel drive cars DAAZ 2108 and 21083

. It is impossible to install them on classics without minor modifications. Let's look at such works in more detail.

When choosing a device for your car, you need to take into account the engine displacement. For engines with a volume of 1.3 liters, the DAAZ 2108 fits well, and for 1.6 - the DAAZ 21083. These devices differ in the diameters of the cross-sections of the diffusers, as well as the fuel and air nozzles. To install any of these models on a classic engine, you must additionally prepare the following components. A new set of gaskets for the carburetor, a piece of hose to ensure its heating, a tee to the fuel system, a valve and a set of rods for the gas pedal.

To get the most out of this idea, it would be advisable to replace the ignition system with an electronic one. Now let's look at the procedure for installing the carburetor:

- On a cold engine, you need to remove the standard device along with the gaskets;

- The next step is to install new gaskets. The first is paronite, then plastic and then cardboard on top;

- A new Solex is placed on top of these gaskets, but the fasteners are not yet clamped;

- Under the nuts closest to the engine on the carburetor, place a bracket from a set of rods for the gas pedal;

- The double-arm pedal drive lever, which is removed from the valve cover, should be placed on the bracket;

- The rod on it, the one that is shorter, is replaced with a new one from the purchased kit, and if necessary, the length is adjusted;

- The pedal return spring should be placed closer to it;

- Now you need to ensure heating of the device; to do this, connect it to the outlet pipe on the intake manifold.

Afterwards, vacuum intake for the ignition distributor and crankcase ventilation are provided. Before installing the device on the car, it is advisable to check and, if necessary, adjust the fuel level in the float chamber. It remains to pave the way for the return of excess fuel to the tank. To do this, you need to install a tee in front of the fuel pump; the valve at the outlet of the carburetor is connected to the tee. After a little adjustment, you can try it out.

Those owners who purchase a Solex modernized as a classic will have much fewer problems with modifications and adjustments; it has an index of 21053 and works well with a 1.5-liter engine. It is difficult to answer the question about the carburetor for the VAZ 2109, since its Solex is in its place and copes with the task assigned to it. However, you can find variants of cars with Webers, or devices from foreign cars.

Articles on the topic

:

- “How to adjust a Solex carburetor”;

- “Selection of types of jets for Solex 21073 carburetor.”

It is, of course, up to the owner to decide whether this or that alteration is necessary. In this article, we tried to explain in simple words which carburetor is best installed on the VAZ 2106, 2107 and 2109. The choice of a specific model depends on the requirements that the owner puts forward for the new device. Some people want to achieve maximum fuel economy, while others want to improve the dynamic characteristics of the car. Based on this, you should select a carburetor.

How does the Ozone carburetor work?

The VAZ 2106 “Ozone” carburetor is a two-chamber emulsion-type device with a falling flow. The first chamber is intended for the dosing system and enrichment device, in the second the mixture of fuel and air is created in the required ratio. What is the operation scheme of the Ozone carburetor?

The fuel pump directs fuel into the float chamber through a needle valve, which maintains the required level. Through the nozzles, the fuel enters the first and second chambers, and then into the emulsion wells, where it is mixed with air, also entering through the nozzles. The created mixture is supplied to the carburetor diffusers.

Immediately after the engine starts, the idle channel is closed by an electromagnetic valve, then at idle speed gasoline flows from the first chamber. As the fuel moves through the nozzle, it mixes with air. When the throttle valves open more (when you press the gas pedal), the resulting mixture goes into the carburetor float chambers, through the transition holes. Through the econostat, the mixture enters the atomizer, which directs it into the combustion chamber of the engine.

General view of the Ozone carburetor

Adjusting the starter

This type of setting can be performed directly in the car; you just need to remove the filter cover in advance.

- The first step is to unscrew the plug under which the adjustment screw is located.

- If the carburetor cannot be removed, it is better to pull out the “choke”; otherwise, you need to press the three-arm lever. When the damper is completely closed, the rod should be all the way and the lever should be recessed.

- Next, using a drill with a diameter of five and a half millimeters, measure the length between the chamber and the air damper.

- If there is a need for adjustment, you can turn the adjusting screw with a screwdriver.

- Then return the plug to its place.

Now, using a drill of the required diameter, check the distance (1 millimeter) between the chamber and the throttle valve. This kind of adjustment is carried out using a rod, which is bent or rearranged into another connector.

Adjusting the drive

- Checking the length between the tips. The required size is 80 millimeters.

- If you deviate from this size, remove one tip.

- Loosen its lock nut and by rotating adjust the distance to the desired size.

- Tighten the nut and return the rod.

- You need to check the adjustment. To do this, our assistant presses the gas pedal. We observe the throttle valve to see if it has opened completely.

- If not, then you need to remove the tip from the lever and reduce the length of the rod.

- Now you need to see what position the damper is in when the gas pedal is released: does it close completely. If not, the pull needs to be lengthened a little.

- Next we work with the air damper. We weaken its drive. In the cabin, we completely recess the damper.

- Press the three-arm lever so that the flap opens all the way. In this position, tighten the locking screw.

- Checking the adjustment. To do this, we completely close and open the door from the passenger compartment again. If the damper has not opened completely, we carry out the adjustment again. If the outcome is positive, fully tighten the screw.

How to adjust the damper

First the carburetor is removed:

- then the lever of the throttle valve wire must be turned until its upper tendril of the first chamber comes into contact with the lever that limits the opening of the second chamber;

- then the gap (6 mm) between the damper and the chamber wall is measured;

- if it needs adjustment, it is carried out by bending the upper tendril of the axle lever, the throttle valve of the 1st chamber;

- now, having turned the lever, you need to open the damper of the first chamber to the end (the distance between the wall and the damper is 13 millimeters);

- then the lower tendril of the throttle valve lever is bent, and thus the full opening of the 1st chamber is adjusted.

The distance between the damper and the wall of the 2nd chamber is 17 millimeters. The magnitude of its maximum closure is regulated by the necessary changes in the length of the pneumatic actuator rod.

Types of carburetors for VAZ 2106

On the assembly line, five types of carburetors were installed on the “sixes”:

- DAAZ 2106-1107010. Mounted with 1.6-liter internal combustion engines on vehicles manufactured before 1980.

- DAAZ 2103-1107010 "WEBER". Installed with 1.5-liter engines on cars manufactured before 1980.

- DAAZ 2105-1107010-20 “OZONE”. Mounted with 1.1-1.3-liter internal combustion engines on cars produced in 1980-1991.

- DAAZ 2107-1107010-20 “OZONE”. Mounted with 1.5-1.6-liter internal combustion engines on cars produced in 1980-1991.

- DAAZ 21053-1107010 "SOLEX". Installed on all cars from 1991 to the end of the 90s.

The first two types of carburetors can be distinguished from other units by the absence of a pipe - a thin black or yellow hose running from the carburetor to the distributor - the ignition timing vacuum corrector hose is put on it.

You can distinguish “OZONE” from other types of devices by the “flying saucer” - a pneumatic drive for opening the second chamber. If there is no connection for the vacuum corrector hose, but there is a “flying saucer”, this is a DAAZ 2107-1107010-10 carburetor device. This unit is quite rare; it was installed only at service stations to replace the first two types of devices after they broke down.

The design of the VAZ 2106 carburetor

High-quality independent maintenance of any vehicle system requires a detailed study of the components and mechanisms responsible for its operation.

Before adjusting the carburetor on the VAZ 2106, you need to consider the main units:

- System for supplying and dosing the combustible mixture;

- Control of mixture enrichment flaps, throttle position;

- The structure of the float chamber and its main purpose;

- Operation of the accelerator pump and idle mechanisms.

View of the carburetor from the throttle valve drive side: 1 - air damper; 2 — starting device; 3 — air damper control lever; 4 - telescopic rod; 5 — lever for driving the throttle valve of the primary chamber; 6 - lever that limits the opening of the throttle valve of the secondary chamber; 7 - return spring; 8 - rod connecting the throttle valve of the primary chamber with the air damper control lever; 9 — pneumatic drive rod; 10 - pneumatic drive.

The process occurs by filling the float chamber with fuel, which must have a stable level. The fuel is transferred to the spray mechanism, where, in turn, it is mixed with air in proportions of 1 to 15, the quality of the mixture is regulated by the throttle valve.

Preparing to adjust the carburetor

Car repair and maintenance requires prepared tools and space.

Setting up the carburetor of the six is no exception; for fast, competent work you need to carry out the following steps:

- Before work, the car is placed on a flat surface, a place is prepared for disassembling components in the form of a table or a clean area. A container for washing and clean rags will definitely be needed.

- Prepare a set of keys and screwdrivers; without tools, it will not be possible to carry out the work.

- Purchase a repair kit from an auto parts store that contains all the O-rings, gaskets and mechanisms.

- Disassembly and adjustment of the VAZ 2106 carburetor occurs after completing the tool and the necessary materials.

What to put?

Sometimes there is a need to completely replace the carburetor. Therefore, you immediately need to decide which model to buy. Today there are two most common families: Solex and Ozone carburetors.

Many car owners don’t even know what kind of device they have. Externally, these devices can be distinguished by the following characteristics.

- In Ozone, the fuel intake fitting has the shape of an oblong tube, in Solex it is a return

- Ozone consists of three parts: the throttle valve axis, the float chamber and the cover. Solex consists of only two parts: the lower part with the float chamber and the upper part - the cover in which the float is held.

- The ozone has a vacuum valve that controls the opening of the throttle valve of the second chamber.

- On a Solex carburetor, the air damper is controlled by such a large lever: On ozone, this lever looks completely different. It is also called a three-arm lever.

In the 90s, a massive hobby began to replace the standard Ozone with Solex. Taxi drivers were especially guilty of this. This was explained by the fact that fuel consumption decreased slightly, and engine dynamics became a little better.

Repairing a faulty device

The procedure for dismantling the carburetor using the example of OZONE.

That's it. The collector must be covered with a cloth. From the removed device, you can unscrew the pneumatic drive of the second chamber and the accelerator pump cover. After this, the faulty parts should be replaced and the breakdowns described above in paragraphs 4 and 5 should be repaired.

If you don’t know how to clean a carburetor, we attach instructions from specialists.

Sources

- https://avtovx.ru/karburator/soleks-na-vaz-2106-178/

- https://expertvaz.ru/2106/strelyaet-neispravnosti-pochistit-karbyurator.html

Setting up the VAZ 2106 carburetor

On a VAZ 2106 car, idle adjustment should be carried out provided that all filters are clean (at least install a new air filter), the spark plugs are practically new, and the ignition system works perfectly

Please note that the air filter must be installed when adjusting the carburetor. You also need to take into account that the level in the float chamber must be adjusted in advance if necessary

Don't forget about the valve clearances either.

Adjusting the idle speed on a VAZ 2106 car occurs by rotating two screws - the quality and quantity of the fuel mixture. The procedure begins by turning the fuel mixture quality screw. This is done using a flat-head screwdriver to achieve the maximum engine crankshaft speed.

Then, turning the quantity screw, set the frequency to about 1100 revolutions. And the last step is to set the final idle speed at 800-900 by turning the mixture quality screw.

If the idle speed sensor does not work on a VAZ 2107 with an injector engine, this manifests itself in unstable operation at idle and during startup. In the event of a malfunction of the DZH, an emergency situation may be created, since it is not visible that the driver is backing up. The article provides instructions for replacing the DZH and IAC, and also includes photos.

Setting idle speed

The process involves two screws that set the quantity and quality of the mixture. For high-quality settings, having a gas analyzer will not hurt. Before adjusting the carburetor on a VAZ 2106, you need to know about the restrictive plastic bushings that are pressed onto the adjusting screws. These plugs do not allow you to violate the factory settings. If this factor prevents you from setting XX normally, then you should break them out with a slotted screwdriver.

Idle speed control technology:

- With the air damper open, set the crankshaft speed screw to 800-900 rpm.

- Rotate the quality screw to set the maximum engine speed.

- Using the quantity screw, set the speed on the tachometer to 950-1030 rpm.

- Use the quality screw to set the maximum speed again.

- Repeat these operations until the speed of 950-1030 rpm does not coincide with the maximum speed set using the quality screw.

- After the moment of coincidence, return the quality screw to the position where the engine speed was 800-900 rpm.

If you have a gas analyzer, use a quality screw to achieve a CO concentration in the exhaust gases of 0.5-1.2%. The final position of the screws must be secured with plastic sealant to prevent spontaneous unscrewing.