Environmental safety standards (Euro 3 and higher) require filtration of exhaust from cars with diesel engines. To meet these standards, car manufacturers use a special device called a particulate filter. In this article we will talk about what a particulate filter is, how it works and how it works.

Content

- 1 Mode of action

- 2 History

- 3 Particulate filter options 3.1 Cordierite wall-mounted flow filters

- 3.2 Wall-mounted silicon carbide flow filters

- 3.3 Ceramic fiber filters

- 3.4 Metal fiber flow filters

- 3.5 Paper

- 3.6 Partial filters

Is it possible to remove it yourself?

Yes, you can, but it is highly not recommended! The likelihood of breaking something is very high. Remember - you act at your own peril and risk!

- First you need to disconnect the sensors and cut the exhaust pipe, which is located after the filter, with a grinder.

- Then unscrew the bolts from the engine side, cut and open the filter casing.

- Take out the device itself. It may be necessary to knock out individual segments.

- Weld the housing and install it in place. Connect the sensors.

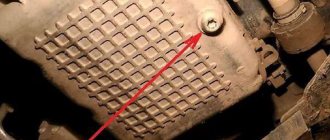

Diesel particulate filter housing without filter itself

After this, all that remains is to download the new firmware.

Method of action

Wall-mounted diesel particulate filters typically remove 85% or more of soot, and under certain conditions can achieve soot removal efficiencies approaching 100%. Some filters are disposable, designed to be disposed of and replaced once the accumulated ash is filled. Others are designed to burn off accumulated particulate matter either passively, using a catalyst, or through active means such as a fuel burner that heats the filter to the soot combustion temperature. This is achieved by programming the engine to operate (when the filter is full) in such a way that the exhaust gas temperature rises, in combination with an additional fuel injector in the exhaust stream that injects fuel to react with the catalytic element to burn accumulated soot into the DPF filter,[ 3] or other ways. This is known as filter regeneration. Cleaning is also required as part of periodic maintenance and should be done carefully to avoid damaging the filter. Failure of fuel injectors or turbochargers resulting in filter contamination with unrefined diesel fuel or engine oil may also require cleaning.[4] The regeneration process occurs at driving speeds higher than can usually be achieved on city streets; Vehicles driven exclusively at low speeds in city traffic may require periodic trips at higher speeds to clean the DPF.[5] If the driver ignores the warning light and waits too long for the vehicle to operate at speeds above 60 km/h (40 mph), the DPF may not recover properly, and continuing to operate beyond this point may ruin the DPF completely, so it must be replaced. [6] Some newer diesel engines, namely those found in combination vehicles, can also perform what is called "Park Regeneration", where the engine revs up to 1,400 rpm when parked to increase exhaust gas temperatures.

Diesel engines produce various particles when burning the fuel-air mixture due to incomplete combustion. Particle composition varies greatly depending on the type of engine, age, and emission characteristics for which the engine was designed. Two-stroke diesel engines produce more particulate matter per unit of power than four-stroke diesel engines because they burn the air-fuel mixture less thoroughly.[7]

Diesel particulate matter resulting from incomplete combustion of diesel fuel produces soot (black carbon) particles. These particles include tiny nanoparticles - less than one micrometer (one micron). Soot and other particles from diesel engines worsen particulate matter air pollution and are harmful to health.[8]

New particulate filters can capture 30% to more than 95% of harmful soot.[9] By using an optimum diesel particulate filter (DPF), soot emissions can be reduced to 0.001 g/km or less.[10]

The quality of the fuel also affects the formation of these particles. For example, diesel fuel with high sulfur content produces more particles. Low sulfur fuel produces fewer particles and allows the use of particulate filters. Diesel fuel injection pressure also affects the formation of fine particles.

When appeared, types of devices

In accordance with Euro 4 environmental standards, DPF particulate filters have been installed in European countries on diesel cars since 2001.

On some cars they are installed together with the catalyst in a metal casing, so for many they are difficult to find.

The pollutants captured by the diesel particulate filter are complex compounds of carbon with water, sulfur and metals. Their particle size ranges from 10 nm to 1 micron. Together they form soot and dirt that are harmful to the environment. Thanks to the diesel particulate filter, only 0.1% of these compounds remain in the exhaust gas.

DPF is the English abbreviation. There are also German (RPF - RubPartikelFilter) and French (FAP - Filtre a Particules) names.

According to the method of regeneration (cleaning), they are divided into devices:

- With catalytic coating;

- With diesel additive injection (FAP).

Story

Diesel particulate filtration was first considered in the 1970s due to concerns about exposure to respirable particulate matter.[11] Diesel particulate filters have been used on off-road vehicles since 1980, and in cars since 1985[12][13] Historically, emissions from medium- and heavy-duty diesel engines were not regulated until 1987, when California's first heavy-duty truck rule was implemented, capping particulate emissions at 0.60 g/L.[14] Since then, increasingly stringent standards have been introduced for light and heavy-duty on-road diesel vehicles, as well as for off-road diesel engines. Similar rules have been adopted by the European Union and some individual European countries, most Asian countries and the rest of North and South America.[15]

Although no jurisdiction has made filters mandatory, increasingly stringent emissions standards that engine manufacturers must meet mean that eventually all on-road diesel engines will be equipped with them.[14] In the European Union, filters are expected to be required to meet Euro.VI heavy-duty truck engine emissions regulations currently under discussion and planning for the 2012-2013 period. In 2000, in anticipation of future Euro 5 regulations, PSA Peugeot Citroën became the first company to make filters standard on passenger cars.[16]

As of December 2008, the California Air Resources Board (CARB) established the 2008 California Truck and Bus Regulations which—with variations depending on the type, size, and use of the vehicle—requires that off-road diesel heavy duty trucks and buses in California have been retrofitted, retrofitted or replaced to reduce particulate matter (PM) emissions by at least 85%. One way to meet this requirement is to retrofit engines with CARB-approved diesel particulate filters.[17] In 2009, the American Recovery and Reinvestment Act

provided funding to help owners offset the cost of diesel engine upgrades for their vehicles.[18] Other jurisdictions have also launched modernization programs, including:

- 2001 - Hong Kong modernization program.[19]

- 2002 - In Japan, Tokyo Prefecture passed a law prohibiting trucks without filters from entering the city.[20]

- 2003 - Mexico City launched a truck modernization program.[21]

- 2004 - New York retrofit program (off-road).[22]

- 2008 - Milan Ecopass area traffic charge - high entry tax on all diesel vehicles except those with a particulate filter, either standard or retrofitted.[23]

- 2008 - London Low Emission Zone charges cars that fail to meet emissions standards, encouraging filter upgrades.[24][25]

Improperly maintained particulate filters on diesel vehicles are prone to soot accumulation, which can cause engine problems due to high back pressure.[4]

The UK made changes to its MOT test requirements in 2022.[26] including stricter inspection of diesel vehicles. One of the requirements was to have a properly fitted and functioning particulate filter. Driving without a particulate filter can result in a fine of £1,000.[27][28]

Removal

The particulate filter serves only environmental purposes, so it can be removed without consequences for the car. Then the engine will become easier to operate, and environmental standards will drop to the Euro-3 standard - which is not critical. The procedure will require some skill and effort due to the relationship of the element with the power unit ECU.

Pros and cons

Pros of removal:

- absence of errors and engine emergency mode due to a clogged filtration element;

- there is no need for a regeneration mode (mandatory procedure);

- reduction of fuel consumption;

- improving the dynamic performance of the car (increasing power);

- stable operation of the power unit;

- There is no need to maintain the filter element.

Minuses:

- deterioration of environmental indicators. The level of soot emissions into the atmosphere increases sharply, although technical inspection can be passed;

- problems with operating a vehicle in countries with mandatory requirements for the necessary environmental standards (European Union).

Diesel Particulate Filter Options

Cordierite Diesel Particulate Filter on GM 7.8 Isuzu

Unlike a catalytic converter which is a flow-through device, a DPF traps larger exhaust particles, forcing the gas to pass through the filter;[2][29] however, a diesel particulate filter does not trap small particles, but a diesel particulate filter does. maintenance-free, breaks larger particles into smaller ones.[ citation needed

] There are many diesel particulate filter technologies on the market. Each is designed to meet the same requirements:

- Fine filtration

- Minimum pressure drop

- Budget

- Suitable for mass production

- Product durability

Cordierite wall-mounted flow filters

The most common filter consists of cordierite (a ceramic material that is also used as catalytic converter supports). Cordierite filters provide excellent filtration efficiency, are relatively inexpensive, and have thermal properties that make them easy to package for installation in a vehicle. The main disadvantage is that cordierite has a relatively low melting point (about 1200 °C) and cordierite substrates melt during filter regeneration. This is mainly a problem if the filter has been loaded more heavily than normal, and is more of a problem for passive systems than for active systems unless the system crashes.[2][30]

Cordierite filter cores look like catalytic converter cores that have had their alternative passageways plugged—the plugs force exhaust gas flow through the wall and particles to collect at the inlet surface.[31]

Wall-mounted silicon carbide flow filters

The second most popular filter material is silicon carbide, or SiC. It has a higher melting point (2700 °C) than cordierite, however it is not as thermally stable, which creates packing problems. Small silicon carbide cores are made from individual pieces, while larger cores are made in segments that are separated by special cement so that thermal expansion of the core will be carried by the cement rather than the housing. Silicon carbide cores are generally more expensive than cordierite cores, however they are produced in similar sizes and one can often be used to replace the other. Silicon carbide filter cores also look like catalytic converter cores that have had their alternative passages plugged—again, the plugs force the flow of exhaust gases through the wall and particles collect at the inlet surface.[2][32]

Characteristics of wall flow particulate filter substrate:

- broadband filtration (diameter of filtered particles 0.2–150 µm)

- high filtration efficiency (up to 95%)

- high fireproof

- high mechanical properties

- high boiling point.[32]

Ceramic fiber filters

Fiber ceramic filters are made up of several different types of ceramic fibers that are mixed together to form a porous media. This media can be shaped into almost any shape and can be customized for a variety of applications. Porosity can be adjusted to provide high flow rates, lower efficiency, or high filtration efficiency at a lower volume. Fiber filters have an advantage over flow-wall designs because they produce lower back pressure. Fiber ceramic filters remove nearly all carbon particles, including fine particles less than 100 nanometers (nm) in diameter, with efficiency greater than 95% by mass and greater than 99% by particle number over a wide range of engine operating conditions. Since a continuous flow of soot into the filter will eventually block it, it is necessary to "regenerate" the filter's filtration properties by regularly burning the collected particulate matter. When soot particles burn out, water and CO.2 are formed in small quantities, amounting to less than 0.05% of the CO2 emitted by the engine.[2]

Metal fiber flow filters

Some cores are made of metal fibers - usually the fibers are "woven" into a monolith. Such cores have the advantage that electrical current can be passed through the monolith to heat the core for regeneration purposes, allowing the filter to regenerate at low exhaust gas temperatures and/or low exhaust gas flow rates. Metal fiber cores are generally more expensive than cordierite or silicon carbide cores and are generally not interchangeable with them due to electrical requirements.[2][33]

Paper

Disposable paper cores are used in some special applications without a recycling strategy. Coal mines are common users - the exhaust gases are usually first passed through a water separator to cool it, and then through a filter.[34] Paper filters are also used when a diesel machine must be used indoors for short periods of time, such as on a forklift that is used to install equipment inside a shop.[2][35]

Partial filters

There are many devices that provide greater than 50% particulate filtration but less than 85% particulate filtration. Particulate filters come in a wide variety of materials. The only thing they have in common is that they produce more back pressure than a catalytic converter and less than a diesel particulate filter. Partial filter technology is popular for retrofitting.[36]

Design and principle of operation

Let's look at an example of the operation of DPF particulate filters with a catalytic coating - as a rule, they are installed on Volkswagen (VW) cars.

The exhaust gases leaving the catalytic converter have a high temperature, so high-strength and heat-resistant materials are used in the manufacture of the particulate filter: ceramics based on silicon carbide, cerium, aluminum oxide and platinum. The latter metal acts as a catalyst.

Structurally, the DPF particulate filter is a metal housing that contains a matrix of porous ceramic cells with thin holes that penetrate through it (crypts are blind perforated gas channels). The latter can be 4 or 8 coals.

The holes are parallel to the movement of exhaust gases. Some are open on one side and closed on the other. Therefore, some of them are considered incoming, others - outgoing.

The cleaning elements themselves are made in the form of filter walls. They are made of porous silicon carbide, which is first coated on top with a mixture of cerium oxide and aluminum, and then with platinum.

The peculiarity of platinum is that this metal has a beneficial effect on the course of a chemical reaction, but does not change its structure, does not decompose or create other chemical compounds, which is very important during filtration.

Differential pressure and temperature sensors are also located on the particulate filter housing. They monitor the degree of contamination of the device and transmit data to the engine control unit. The number, type and location of sensors may vary depending on the vehicle brand.

The operating principle is as follows. Exhaust gases, entering the particulate filter through the intake pipes, begin to look for an outlet, and only porous silicon carbide remains, after passing through which the soot and soot are oxidized (burned) as a result of a complex chemical reaction, turning into carbon dioxide.

In addition, clean gases enter the exhaust pipe through the exhaust pipes and enter the atmosphere. Moreover, their smell is significantly different from ordinary untreated wastewater.

This process continues until the particulate filter becomes clogged. As soon as this happens, the self-cleaning process begins, as a result of which all contaminants are burned. Read more.

Service

Filters require more maintenance than catalytic converters. Ash, a byproduct of oil consumption during normal engine operation, accumulates in the filter because it cannot be converted into gas and pass through the filter walls. This increases the pressure in front of the filter. Warnings are provided to the driver before filter restriction causes handling problems or engine or filter damage. Regular filter maintenance is a must.[4]

DPF filters undergo a regeneration process that removes this soot and reduces filter pressure. There are three types of regeneration: passive, active and forced. Passive regeneration typically occurs while driving, when engine load and the vehicle's driving cycle create temperatures that are high enough to regenerate soot deposits on the DPF walls. Active regeneration occurs during vehicle operation when low engine load and lower exhaust gas temperatures prevent natural passive regeneration. Sensors before and after the DPF (or differential pressure sensor) provide readings that initiate the metered addition of fuel to the exhaust gas flow. There are two methods of fuel injection: downstream injection directly into the exhaust stream, after turbocharging, or injection into the engine cylinders during the exhaust stroke. This mixture of fuel and exhaust gases passes through a diesel oxidation catalyst (DOC), creating a temperature high enough to burn off the accumulated soot. As soon as the pressure drop across the DPF is reduced to the calculated value, the process ends until soot accumulation begins again. This works well for vehicles that travel long distances with few stops, compared to those that make short trips with a lot of starts and stops. If the filter creates too high pressure, the last type of regeneration must be used - forced regeneration. This can be achieved in two ways. The vehicle operator can initiate regeneration using a switch mounted on the dashboard. Various signal interlocks are required to initiate this process, such as parking brake engaged, transmission in neutral, engine coolant temperature, and no engine fault codes (varies by OEM and application). When soot buildup reaches a level that could potentially damage the engine or exhaust system, the solution involves the garage using a computer program to manually trigger DPF regeneration.

Safety

In 2011, Ford recalled 37,400 diesel-powered F-Series trucks after fuel and oil leaks caused the trucks' diesel particulate filters to catch fire. There were no injuries prior to the recall, although one grass fire was started.[37] A similar recall was issued for the 2005–2007 Jaguar S-Type and XJ diesels, where large amounts of soot were trapped in the particulate filter. In the affected vehicles, smoke and fire were coming from the underbody of the vehicle, accompanied by flames from the rear exhaust pipe. Heat from the fire can cause heating through the transfer tunnel into the interior, melting internal components and potentially causing internal fires.[38]

Removal process: physical and software stages

The procedure consists of two stages - physical and software.

Physical is not difficult. Experts find the jar containing the filter and catalyst and cut it out. In some car models, you will have to remove the exhaust pipe to do this. You need to put something in place of the filter - these can be either ordinary metal plugs or flame arresters. Installing a flame arrester will slightly increase the life of the muffler. If the component is equipped with temperature sensors and carbon dioxide probes, they may need to be removed and installed in a blank to help avoid software errors.

Appearance of the removed particulate filter

Then you need to reprogram the engine block. If this is not done, the sensors will assume that the filter is constantly clogged. The result is a display of fault codes, and in some cases the emergency mode is even activated.

This part of the procedure is performed exclusively by service center experts. There are three ways to achieve this result.

- Install the firmware from the version of the car that does not have a particulate filter by default. The method is fraught with a decrease in functionality - for example, cruise control is disabled on a Honda CRV.

- Install firmware created by enthusiasts. It's a kind of lottery - you might get lucky, maybe you won't. The quality of firmware varies greatly.

- Install firmware from the vehicle manufacturer. The best option that carries virtually no risk.

In some Nissan, Toyota, Mazda and Ford models it is impossible to perform a standard flashing - you have to resort to emulation. A decoy device is installed that makes the unit think that the filter is in its place. The controller receives the signals and does not notice the removal of the component. However, this option has a drawback - the regeneration mode will still be activated, so fuel consumption will not decrease.

Regeneration

Metering pump for injection of diesel fuel or additives, 3 l/h at 5 bar Regeneration scheme Hino truck and it's Selective Catalytic Reduction (SCR) next to the DPF with a regeneration process by late fuel injection to control the temperature of the exhaust gases to burn soot. [39][40]

Regeneration is the process of burning (oxidizing) accumulated soot on the filter. This is done either passively (by using heat from the engine exhaust during normal operation, or by adding a catalyst to the filter) or by actively introducing very high heat into the exhaust system. Built-in active filter control can use different strategies:[9]

- Engine control to increase exhaust gas temperature through late fuel injection or injection during the exhaust stroke

- Using a fuel catalyst to reduce the soot burnout temperature

- Fuel burner after turbocharging to increase exhaust gas temperature

- Catalytic oxidizer for increasing exhaust gas temperature with post-injection (HC-Doser)

- Resistance heating coils to increase exhaust gas temperature

- Microwave energy to increase the temperature of solid particles

All onboard active systems use additional fuel, whether combustion to heat the DPF or provide additional power to the DPF electrical system, although the use of a fuel catalyst significantly reduces the energy required. Typically, the computer monitors one or more sensors that measure back pressure and/or temperature, and based on preprogrammed set points, the computer makes decisions about when to activate the regeneration cycle. Additional fuel can be supplied by a metering pump. Cycling too frequently with low exhaust back pressure will result in high fuel consumption. If the regeneration cycle is not started quickly enough, the risk of engine damage and/or uncontrolled regeneration (thermal runaway) and possible DPF failure increases.

Diesel particulates burn when temperatures reach above 600 °C. This temperature can be reduced to approximately 350–450 °C through the use of a fuel catalyst. The actual soot burnout temperature will depend on the chemistry used. The onset of combustion causes a further increase in temperature. In some cases, in the absence of a fuel catalyst, combustion of particulate matter can result in temperatures above the filter media's structural integrity threshold, which can cause catastrophic failure of the substrate. Various strategies have been developed to limit this possibility. Note that unlike a spark ignition engine, which typically has less than 0.5% oxygen in the exhaust stream upstream of the emission control device(s), diesel engines have a very high ratio of available oxygen. While the amount of oxygen available makes rapid filter regeneration possible, it also contributes to uncontrolled regeneration problems.

Some applications use off-board regeneration. External regeneration requires operator intervention (i.e. the machine is either connected to a wall/floor mounted regeneration station, or the filter is removed from the machine and placed in the regeneration station). External regeneration is not suitable for road vehicles, except in situations where the vehicles are parked in a central warehouse when not in use. External regeneration is mainly used in industrial and mining applications. Coal mines (with the attendant risk of explosion due to coal moisture) use external regeneration if disposable filters are installed, with the regeneration stations located in an area where the use of non-permissible equipment is permitted.

Many loaders may also use off-board regeneration - typically mining machinery and other equipment that spend their life in one location, making it practical to have a permanent regeneration station. In situations where the filter is physically removed from the vehicle for regeneration, there is also the benefit of being able to check the filter core daily (DPF cores for off-road applications are typically designed to last a single shift, so regeneration is an everyday occurrence).[41]

How is the filter removed?

So, first it is removed from the car. In our case, this has already been done, and the filter is ready to survive all subsequent procedures. More precisely, it won’t survive, because now it will have to be removed from the jar.

To do this, cut the jar with a grinder. Now, on the one hand, we have a catalyst left, which we will not touch, and on the other, the filter itself. The latter is removed in two ways: pressed out entirely or hollowed out in pieces. Then the empty jar is brewed. This can be done with argon welding, or with a regular “semi-automatic”. The first method is more suitable for wealthy aesthetes, because it is long and expensive, but the seam turns out beautiful. But there is no need to weld with argon; semi-automatic welding is quite sufficient here. The main thing is to then treat the seam with an anti-corrosion agent.

That's it, the bank is collected. Some people prefer to install a downpipe instead - they say that an empty can will make unpleasant sounds. In fact, due to the design of the diesel engine, the sound of operation will not change, it will not become louder. Although, of course, if the client wants, then why not.

Now all that remains is to install the can in place and... start programming.

As we remember, there is a set of sensors that monitor the operation of the filter. Physically removing the filter will change their readings, which can confuse the ECU. For example, the absence of a difference in temperature or pressure at the inlet and outlet will make him doubt the correct operation of the sensors or filter. And then the error will appear again, and perhaps emergency mode too.

And don't forget about regeneration. Even if the ECU does not start it based on sensor readings, it is quite capable of doing this based on the fuel consumed. Since after such “regeneration” of an empty can nothing in the readings will change, the control unit can run it endlessly. In the end, this will again lead to an error at best. At worst, the release will be thoroughly “fried” at high temperatures, which is also not very good and even dangerous. Finally, do not forget that additional fuel is needed for regeneration. The easiest consequence is significantly increased fuel consumption. But it’s better not to deal with heavy things at all. It occurs when diesel fuel begins to enter the oil, as a result of which its concentration in the crankcase increases so much that the oil no longer becomes oil, but a completely suitable fuel for diesel engines. As you know, a diesel engine does not need a spark to ignite, so if the engine starts running on a mixture of oil and fuel from the crankcase, it will not be possible to stop it by turning off the ignition. And the engine will begin to run wildly. The spectacle is terrible, and for the engine itself, this mode usually ends in exactly the same blowout.

But it is worth noting that the main reason for going into overdrive is not the removal of the particulate filter, but its malfunction, due to which frequent attempts at regeneration lead to an increase in the oil level. Spread can also occur if the filter is not removed. However, this is a topic for another discussion. For now, let’s just say that such an outcome is possible if the work is carried out incorrectly, and monitoring the oil level can reduce the risk. If it is higher than normal, this is a cause for concern, and it is better not to start the engine at all.

In a word, it is simply necessary to disable the filter in the program. It is best when it is possible to simply turn off this system. If there is no switch, then there are other ways that we won’t talk about - a professional secret.

It is also necessary to remove particulate filter errors, but not affect the entire diagnostic system. Some not-so-best “specialists” screw up all the diagnostics, after which the car owner then drives to other service stations, where innocent servicemen dance with a tambourine around the car, which says that everything is OK in its life, but does not drive .

Recommendations

- Tom Nash (May 2003) "Diesels: The Smoke Clears", Motor

Vol.199 No. 5, p. 54, Hearst Business Publishing Inc. - ^ a b c d f g gram

Emission technology: DPF - diesel particulate filters, Axces.eu - Jung Hoon Kim and others.

(November 2010) "Soot Regeneration Behavior by NO2 in a Heavy Duty Diesel Exhaust Particulate Filter",

Numerical Heat Transfer

Part A Vol.58 No.9 pp.725-739, Chonbuk National University, Korea Doi:10.1080 /10407782.2010.523293 - ^ a b c

"DPF Maintenance" (January 2010) HDT Freight Information - "The Diesel Dilemma" (7 November 2011) BBC News

- "DPFs cut diesel soot emissions by 80%, but are not suitable for everyone" (December 5, 2013) Automobile Association

- "Study: 'Clean Fuel' Not Always Successful" (March 1, 2011) UPI NewsTrack, Vancouver, British Columbia "Canadian researchers say one of the world's largest cities [New Delhi]'s clean-fuel vehicle program has failed to a significant increase in emissions."

- [1]

- ^ a b

Barone

et al.

(August 2010) "Analysis of Spent Diesel Particulate Filter Performance: Particulate Emissions Before, During and After Regeneration,"

Journal of the Air and Waste Management Association

Vol. 60 No8 p. 968-76 Doi:10.3155/1047-3289.60.8.968 - DPF - diesel particulate filters, Axces.eu

- Vincent D. Blondel: Recent Advances in Training and Control, p. 233, Springer Science & Business Media, 2008, ISBN 9781848001541

- Diesel Particulate Regeneration

- ""Modern diesel particulate filters and exhaust gas purification systems", LLC "Hus" (PDF). Archived from the original (PDF) on 2014-09-06. Retrieved 2014-09-05.

- ^ a b

Bahadur

and others.

(2011) "The Impact of California Air Pollution Laws on Black Carbon and Their Implications for Direct Radiative Forcing", Archived 2014-09-06 at the Wayback Machine

Atmospheric Environment

Vol. 45 pp. 1162–1167, Scripps Institution of Oceanography, University of California, San Diego - Global emission standards for diesel vehicles and engines

- James Scoltock (June 2014) "Diesel Particulate Filter: PSA Peugeot Citroën was the first to introduce particulate filters to make diesels cleaner", Automotive Engineer

para 9 - "Frequently Asked Questions - Heavy Duty DECS Installation and Maintenance." Retrieved October 28, 2011.

- American Recovery and Reinvestment Act Archived 2014-09-05 at the Wayback Machine

- ""BASF Technology Makes Hong Kong's Air Purifier" (April 2, 2008) BASF The Chemical Company." Archived from the original on September 23, 2015. Retrieved September 5, 2014.

- "Introduction to Diesel Vehicle Control" (PDF). Archived from the original (PDF) on 2012-10-30. Retrieved 2014-09-05.

- "Cleaning up Mexico City Diesel Emissions" (July 12, 2012) EPA

- "New York Passes Diesel Emissions Rules" (April 21, 2005) FleetOwner

- "Milan Ecopass To Evolve" (September 2, 2011) Italy Chronicle

- Low Emission Zone, Transport for London

- Install filter, Transport for London

- “Go through your MOT 2022 - New rules.

- "Europe Bans Diesel for Cleaner Air - Fixter Blog." Blog Fixter

. 2018-07-12. Retrieved 2018-07-26. - "Get Your MOT 2022 - New Rules and Regulations - Fixter Blog." Blog Fixter

. Retrieved 2018-07-26. - Diesel Particulate Matter - Emission Reduction Techniques Archived 2012-10-17 in the Wayback Machine (2009) Mine Safety and Health Administration (MSHA), US Department of Labor]

- "White Papers" (2013) Corning Environmental Technologies

- "Cordierite" (2009) Diesel Emission Technologies Inc.

- ^ a b

"Silicon Carbide (SiC)" (2009) Diesel Emission Technologies Inc. - "Metal Fibers and Screens" (2009) Diesel Emission Technologies

- "Best Practices for Underground Diesel Emissions" - CDC Stacks

- Technology Guide, DieselNet

- Jacobs et al.

(2005) "Development of Partial Filter Technology for HDD Retrofit", SAE International - "Ford Recalls F-150 Over Exhaust Pipe Fire Fear" (March 21, 2007) NBC News

- "Jaguar S Type XJ Diesel Particulate Filter Recall" (March 22, 2007) CarAdvice

- "Hino Standardized SCR Unit." Hino Motors. Archived from the original on August 5, 2014. Retrieved July 30, 2014.

- “The Future of the DPR” (PDF). Hino Motors. Retrieved July 30, 2014.

- Bruce R. Conrad Archived 2006-09-02 on the Wayback Machine, "Diesel Emissions Estimation Program - INCO" Diesel Emissions Estimation Program Website (May 2006)

What is good and what is bad

There are several ways to solve the problem, but only one is good.

The first method is to replace the filter with a new one. OK, seems good. Only the original filter sometimes costs a hundred thousand rubles. Therefore, no one actually decides to install a new particulate filter.

The second method is to install an analogue. This is one of the most unfortunate solutions to the issue. The fact is that the original filter is expensive for a reason; it uses precious metals, so its cost cannot be low. Those analogs or universal filters are not only useless, but also dangerous. You remember about regeneration, right? So, not all of them are able to survive this operation, and enough cases of fire have been recorded to give up the idea of installing some dubious nonsense instead of a filter. By the way, sometimes they suggest filling a jar with metal filings instead of a removed filter - they say it will be the same as the filter, but cheaper. This also applies to “dubious nonsense.” Such a home-made filter will not ensure that the filter sensors are within acceptable limits, and errors will occur again and again. And it’s better not to even imagine what could happen with such a packing and with the rest of the release when trying to regenerate.

And finally, the third method is to physically remove the particulate filter and programmatically remove it from the system. This is the best way to get rid of the problem once and for all. There will be no fatal consequences, except that that same sourness in the exhaust smell will disappear.