Every car owner has encountered a situation where a fuse in a car has blown and part of the electrical equipment does not work. The complication of the machine design led to the introduction of additional electronic elements interconnected. Fuse links located in the engine compartment and passenger compartment de-energize circuits during short circuits, preventing fire or damage to expensive components.

The main reasons for fuses failure

Common reasons for fuse links to trip:

- broken contact when driving on uneven roads causes current surges in the circuit, which leads to burnout of the jumper;

- the use of low-quality fuses that fall out of their sockets and disconnect some consumers from the on-board network;

- connecting equipment with excessive power;

- short circuits caused by faulty consumers or wiring;

- installation of a fuse-link with a reduced rating, not designed for the rated load.

A number of vehicles provide protection for electrical circuits by control units. When the current increases, an error is entered into the controller’s memory; it is impossible to turn on the device, but the fuse will be fine. For example, VAG cars have double protection for the washer fluid supply pump. In the event of a short circuit, the fuse link will burn out, but when you try to turn on the pump with frozen water in the tank, an error will be recorded in the controller’s memory. You can restore the functionality of the equipment by disconnecting the battery for 10-15 minutes.

Automotive fuses and their classification

On a car, most fuses are located in blocks. Most often there are two or more fuse boxes on a car. One of them is located under the hood or in the luggage compartment area. It is called the main one and includes the largest number of fuses. The other unit is located under the front panel in the passenger compartment, but in different places for all cars. Also, fuses can be located separately throughout the machine - 1, 2 or 3 pieces.

Automotive fuses are classified according to two parameters - size and rated operating current.

When choosing a car fuse, you should pay attention to the size:

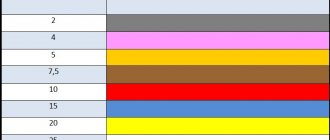

In addition to the size, when purchasing a fuse, you should know its current rating. Most often, elements are installed in cars that have a rated current of 5 to 30 A. The easiest way to determine the fuse current is by its color, and below is a table that shows how the color and rated current of the fuse are related.

Visual inspection of the fuse

The standard blade fuse has a transparent plastic housing that allows you to see the condition of the jumper. To check, you need to turn off the engine, open the box lid and use special pliers to remove the element from the mounting socket. If the metal jumper has a break, you will need to install a new insert. For additional control, there is a rectangular window at the end of the insert through which the wire is visible. If the fuse fails, a gap will be visible on the jumper.

On cylindrical elements, the plate between the contacts is placed on the side. During a short circuit, the material melts and the breaking point is clearly visible on the removed element.

Melting of the housing is not allowed, since reducing the length leads to broken contact and breaking the circuit (the jumper will be intact in this case).

Replacing fuses yourself

Replacing a burnt-out device with your own hands is a matter of just a few minutes. Naturally, in order to avoid subsequent replacement of the entire fuse box, this simple manipulation should be taken with full responsibility. After accurately identifying the source of the problem, replacing the fusible protector should begin with selecting a new one that exactly matches the damaged one. For ease of “identification”, all devices have a different color - in accordance with their power.

It is best to purchase fuses in advance, without waiting until one of them fails. At the same time, you should be based not on your own preferences and cost, but on the recommendations of the manufacturer. If they are not available for sale, it makes sense to place an order and wait a little rather than put your car and yourself at risk. As a last resort, temporary use of fuses of suitable size and characteristics is allowed. A detailed algorithm of actions for correctly replacing a faulty fuse can be seen in the video:

How to check a fuse with a multimeter?

If the inspection is carried out in poor visibility conditions, it is difficult to determine a blown fuse. The problem also arises when checking elements with matte plastic housings. In addition, the jumper may burn near the leg; upon inspection, it is difficult to detect a defect. In this case, it is necessary to use a test device (multimeter), which allows you to check the part for voltage or resistance.

If there is no test device for testing, use a battery with soldered wires and a socket with a light bulb. The bare ends of the cables are connected to the fuse contacts; if the jumper is intact, the lamp will light. When making a homemade device, take into account the correspondence of the battery voltage and the characteristics of the light bulb.

Voltage test

Verification algorithm:

- Switch the test device to voltage measurement mode.

- Start the engine or activate the ignition, and then turn on the power to the devices connected to the circuit with the failed fuse.

- Connect the negative probe of the device to the negative terminal of the battery or any unpainted metal part that has contact with the body.

- Alternately apply the positive probe to the input and output of the fuse. If there is no power, then install a new element and then check the operation of the consumers. If it was not possible to restore functionality, then you will need to check the integrity of the wiring harnesses in the areas before and after the fuse. The problem may occur when the cable breaks or the core is destroyed as a result of force or corrosion.

Sometimes a blown fuse appears intact; in this case, you can check the integrity of the jumper by testing it. To perform the work, switch the test device to the appropriate mode and apply the probes to the metal contacts of the fuse link. If the circuit is closed, the multimeter will give a sound signal; if the signal is broken, there will be no signal. On the top of the blade fuse there are 2 windows for quickly checking the condition of the jumper with a test device; just connect the probes and the multimeter will show the condition of the fuse link.

Resistance test

A resistance test is analogous to a “continuity test”, but the test device is switched to ohmmeter mode. Then apply the probes to the metal terminals of the protective element and look at the indication.

If the circuit resistance is zero, then the current does not pass through the jumper due to an open circuit. When a working fuse is switched, the rated resistance of the element will be displayed on the screen.

Types of Electrical Fuses

In most cars, safety components are located in special blocks. As a rule, we are talking about two blocks: one is located in the engine compartment next to the windshield or in the luggage compartment; the second is in the cabin under the panel. Additionally, several protective components may be located in other parts of the machine.

Safety elements are distinguished by size: large, medium and small. Also, protective elements differ in ampere rating - from 2 to 30 A.

Checking using a diagram

The location of the specific fuse can be found in the owner's manual for any machine. A detailed diagram can also be seen on the inside of the block cover. Based on the malfunction of the car, it is necessary to check a specific protective element and replace it if necessary. If spare parts are not available, you can swap fuses with the same ampere rating and see if this makes a difference.

Visual inspection

This method consists of sequential diagnostics of all protective elements of the car. You can understand the serviceability by removing and inspecting; when shorted, the wire inside will be torn or slightly melted. The method is ineffective due to the presence of a large number of protective elements and such diagnostics will take a lot of time. For this reason, experienced car enthusiasts check with a multimeter.

Checking with a multimeter

The advantage of this method is the possibility of diagnosis without extraction. If the safety element is removed, you need to switch the multimeter to sound test mode and place the probes on the contacts. If the device makes a sound signal, the fuse is good, but if there is no signal, it should be replaced.

If it is not possible to familiarize yourself with the diagram or there is no certainty that a particular fuse is faulty, the process of removing and testing all protective elements will take considerable time. Using a multimeter, you can check without removing it: the probes must be installed on the open contact points of the outer part of the fuse. If the protective element is working properly, the device will emit a sound signal.

Checking with a tester

The test can be carried out with a tester with a light bulb. One end must be connected to ground (frame or body of the car), and the second in series to the open contact points of the external part of the fuse. The protective element is operational if the light comes on on both contacts.

You can make your own tester using a wire, battery and light bulb. The battery and light bulb must be of the same voltage. One wire must be connected to the “+” of the battery and the light bulb, the second wire will become an interrupted circuit for diagnostics (part of the wire is attached to the light bulb, the other part to the battery).

Recommendations for replacement

Basic tips for installing a new fuse:

- Replacement work should be carried out on the vehicle with the ignition turned off.

- Before servicing or repairing the vehicle's electrical system, you must ensure that you have spare fuses. The elements can be located in special slots on the covers of the distribution box or installed in reserve slots in the blocks. When selecting spare parts, you should choose products with the specified place of production. The rating of the insert is determined by the color of the plastic; additional information about the permissible current strength is applied with paint on the top of the blade element.

- To remove cylindrical inserts, no tool is required; the element is pulled out from the spring contacts with your fingers. To remove the blade fuse, use standard plastic pliers placed in the junction box or attached to the lid. It is forbidden to sharply pull the element or pull it out at an angle; if the body is destroyed, it is difficult to remove the remains of the legs. The driver will need pliers with thin jaws, which may not be included in the tool kit.

- Before installing a new element, you should inspect the mounting socket; there should be no traces of oxidation or carbon deposits on the metal contacts. Otherwise, it is necessary to clean the surfaces with fine sandpaper; if there are deep damages, new contact plates will need to be installed under service conditions.

- A fuse with the rating specified by the vehicle manufacturer must be installed. Information is available in the operating instructions and on the cover of the mounting block. You should not use inserts designed for increased power, as the wiring will not withstand the load and will melt. Broken insulation will lead to a short circuit and fire. It is prohibited to use homemade elements (for example, rolled wire or aluminum foil) that do not protect electrical circuits.

- Before installing a new fuse, you must accurately determine the socket for the element. There are numbers on the circuit board of the box; a description of the purpose of the fuse links is on the cover. It should be taken into account that some of the sockets are redundant; the contacts are not connected to the vehicle’s on-board network.

- If the insert burns out on a country road and there is no fuse with the required rating, then it is necessary to install an element designed for reduced power. You should not turn on all consumers; after arriving at your destination, you will need to purchase and install an insert that meets the requirements of the vehicle manufacturer.

- If the new protective element burns out immediately after installing or connecting the load, then you should check the circuit and find the cause of the malfunction. Trying to experimentally select an insert with a higher rating is prohibited.

- If there are traces of exposure to elevated temperatures in the installation box (deformation, burning smell), then the cause of overheating should be found out. Continued use will result in fire or damage to electrical equipment.

- After installing the new fuse, remove the pliers into the standard socket and tightly close the cover of the distribution block. If elements from the emergency reserve have been used, the stock should be replenished. It is recommended to carry a set of fuses in the glove box; the parts do not take up space, but may be required to repair the car.

The replacement procedure does not require special knowledge and skills. The car owner needs to know the installation locations of the mounting boxes and the purpose of the fuses. If the driver is not confident in his own abilities, then it is recommended to get to the nearest service center and have the replacement done by a hired technician.

Identifying a blown fuse in a car

In order to ensure completely safe operation of electrical equipment, fuses are used in the car to protect the electronics from overloads or short circuits. These are the simplest in design and inexpensive protection elements, which make it possible to prevent damage to other blocks, which cost much more. This greatly reduces the owner’s costs for car repairs. How can you determine which fuse has blown in your car? Principle of operation. The essence of the operation of fuses is quite simple: if an overload or short circuit occurs, the braided wires in the network may melt, which will lead to failure of devices and units, and sometimes to a car fire. Precisely in order to prevent this kind of trouble, fuses are used that take the entire blow. If an overload or short circuit occurs, such a system simply burns out, preventing damage to more valuable devices.

If there are problems in the power supply circuit, damage to various types of electrical units and modules does not occur, but only a fuse blows, which is not difficult to replace. Modern types of machines can have a fairly large number of fuses, each of which is responsible for the safety of its own group of devices. Sometimes finding a damaged relay can be quite difficult, since you need to find the electronic module itself that has failed and determine which fuse is responsible for its operation.

Methods for performing verification. You can find all the required information on the location of fuses by looking at the instructions for the car. In order to simplify the search, many automakers put a location diagram on the inside of the cover that covers the electronic unit. If you have such a high-quality circuit, finding the required fuse responsible for the operation of the desired relay or electronic device will not take much time.

Another feature that makes it easier to find problematic fuses is the presence of a transparent cover. This makes it possible to identify a burnt-out internal core that requires replacement. According to the recommendations of experts, it is worth replacing the problematic fuse when the slightest doubt arises, which will make it possible to ensure the correct operation of the electronics. But sometimes damaged fuses may have a whole core, so the matter will not be limited to just a visual inspection.

Maximum accuracy in determining a faulty fuse can be provided by a multimeter, which can be used to “ring” the entire circuit. Such devices have a special sound mode, and all that needs to be done is to close its contacts on the two terminals of the fuse, which should result in a characteristic squeak. No sound means that current cannot pass through the fuse, which means it needs to be replaced.

Perform fuse replacement. Each fuse used to protect electronics has its own power rating. Therefore, you should choose the right parameters that fully correspond to those being replaced. You can buy them in almost all automobile stores and radio parts stores, they are inexpensive. It is better for each driver to have several protective relays in the trunk of his car, differing in power parameters.

Bottom line. In order to ensure the safety of the car's electronic devices, the cars are equipped with a special protection unit, which takes the full impact in the event of overloads and short circuits. In such a situation, the thread instantly breaks and de-energizes those systems and modules in the car for which the fuse is responsible.

Extra situation: the fuse accidentally burned out, but you need to drive

Accidentally dropped a foreign object into the cigarette lighter socket? Have you powered a faulty device from a cigarette socket? Finally, did they purposely close the plus and minus together with a screwdriver? Nothing critical, the fuse will immediately de-energize the circuit. We install a working safety element of the same rating and successfully continue to operate the car. But what if this happens on the road, the de-energized circuit is vital, and there is no spare fuse?

If the load rating doesn't match, it's okay. For example, the cigarette lighter branch is protected by a 15A element. As a temporary replacement, you can use a denomination that is half the required value. In the case of a cigarette lighter socket, 7.5 A is quite enough for ordinary gadgets in the form of a navigator or video recorder.

In extreme cases, you can get out of the situation in a barbaric way. We break off a piece of the stranded wire and connect the legs of the faulty fuse. We put the structure back, and at the first opportunity we replace it with a serviceable and high-quality “pre-built”.

It is important to distinguish between the causes of fuse failure. If this is an accidental oversight of a repair nature, then you can install a new safety element in the circuit without hesitation. If this is not a human factor, then attention should be paid to finding the reasons. Overloading an electrical circuit is not a toy, and it’s not far from a fire.

Tips for choosing a quality fuse for your car

It is recommended to select fuses for the car taking into account the following recommendations:

- buy products from familiar brands whose quality you are confident in;

- follow the same approach when choosing a place of purchase, so that the seller always offers original products and not superficially similar parts of unknown origin;

- pay attention to the thickness or width of the fusible insert, which is the same for all denominations - fake;

- if, despite all the signs, there are doubts about the quality of the fuses, test one of them with a short circuit by connecting it to the battery (it should burn out as soon as possible).

The fuse must not have high resistance, cause excessive power loss, or interfere with the operation of the equipment. At the same time, to reliably perform protective functions, the insert should not be massive in order to be able to disconnect the load from the power source in a short period of time.

The listed parameters contradict each other, and an acceptable ratio has been achieved in products of brands that have been on the market for a long time. Keep a supply of fuses of various ratings in your vehicle at all times.

VAZ 2106 fuses

Every car is equipped with various electrical appliances. The power circuit of each of them is protected by a special element - a fuse. Structurally, the part is made of a body and a fusible element. If the current passing through the fuse-link exceeds the calculated rating, it is destroyed. This breaks the electrical circuit and prevents overheating of the electrical wiring and spontaneous combustion of the car.

From the factory, cylindrical fusible links are installed in the VAZ 2106 fuse box

How can I remove the fuse?

For this purpose, special plastic tweezers are used, which, as a rule, are placed in a separate socket of the mounting block. Using these tweezers, take the fuse by the plastic flag housing and pull it out of the socket.

Interesting materials:

Is it possible to work in the civil service with tattoos? Is it possible to work on Epiphany? Is it possible to work on a laptop if it is charging? Is it possible to work part-time at your main job? Is it possible to work on a PC without a video card? Is it possible to work officially in retirement? Is it possible to work officially during bankruptcy? Is it possible to work with an ID card in Germany? Is it possible to work as a nurse without education? Is it possible to work with the second disability group?