c) insert the 3rd mounting blade between the chain and the tensioner shoe (see figure), using it as a lever, press the tensioner shoe towards the cap nut and tighten it; d) unscrew the sprocket bolt and remove it by hitting it with the wooden handle of a hammer; e) rearrange the chain so that the mark on the sprocket coincides with the boss on the camshaft bearing housing:

f) rotate the crankshaft to the required angle in one direction or another in order to install the camshaft sprocket on the mounting hole and pin; g) put the sprocket in place, screw in the bolt and tighten it slightly; h) loosen the cap nut:

i) rotate the crankshaft and align the marks again; if they do not match, then perform the operation from point “c” to point “i” again; j) tighten the sprocket bolt to a torque of 41.2-51.0 N. m and stop it with the edge of the washer; k) tighten the cap nut. 14. Tension the chain: a) unscrew the cap nut completely:

b) use a ratchet wrench to rotate the crankshaft 720 degrees; if an additional electric fan is installed, then jack up the front right wheel, engage fourth or fifth gear and smoothly, slowly, without jerking, rotate the wheel forward until the crankshaft rotates 720 degrees; in this case, the distributor rotor will make a full rotation (360 degrees); c) with the finger of one hand, feel the tensioner rod:

With your other hand, continue cranking the crankshaft. As soon as the rod is sunk, stop cranking the crankshaft; d) tighten the cap nut

e) align the marks on the crankshaft and camshaft sprocket:

Install the valve adjustment bar:

Above the valve being tested, in this case 6 or 8, secure the bracket with the rocker arm to the bar. The inside of the rocker should rest on the edge of the flat part of the rocker:

Install the micrometer into the hole in the bracket so that it fits tightly and the arrow stops at 0:

Insert a fork between the rocker and the adjusting bolt. Raise the rocker until it stops slightly; if the stop is not felt, then lift it with your fingers:

If the clearance in the intake valves is normal, then the micrometer needle should turn counterclockwise by 52 scale divisions, which corresponds to 0.15 mm, for the exhaust valves - by 69 divisions, which corresponds to 0.2 mm:

If the arrow has turned further, for example by 77 divisions, then subtract 52 or 69 from the result obtained, depending on which valve you are adjusting, and find out how many divisions you need to unscrew the adjusting nut. If the arrow did not reach the division 52 or 69, and stopped, for example, at 46, then subtract the resulting value, i.e. 46, from the required value of 52 or 69, and find out how many divisions you need to tighten the adjusting nut.

Loosen the locking nut by 17:

The micrometer needle will move clockwise several divisions. Hold the locking nut and the adjusting nut with a 13 key:

Unscrew or tighten the adjusting bolt to the previously obtained number of divisions. Tighten the lock nut and check the gap again. If it is not normal, then repeat the operation again; if it is normal, move on to adjusting valves 4 and 7.

Turn the crankshaft 180 degrees counterclockwise: with the key from top to bottom, and if by the wheel, then in the direction of travel of the car. The camshaft will rotate 90 degrees, and the rotor contact will be directed towards the second spark plug electrode on the distributor cap. Adjust valves 4 and 7 in the same way as valves 6 and 8:

Rotate the crankshaft another 180 degrees counterclockwise. The camshaft will rotate 90 degrees, and the rotor contact will be directed towards the first spark plug electrode on the distributor cap. Adjust valves 1 and 3 in the same way as valves 6 and 8:

The mark on the star should not be visible, it is at the very bottom! Rotate the crankshaft 180 degrees counterclockwise. The camshaft will rotate 90 degrees, and the rotor contact will be directed towards the third spark plug electrode on the distributor sensor cover:

Adjust valves 2 and 5 in the same way as valves 6 and 8.

The valve adjustment is completed.

Sometimes the tip of the rocker arm does not reach the rocker. In this case, you can place a 1 ruble coin on top of the flat part of the rocker:

The clearance in this valve is adjusted in the same way as a valve without a coin.

Wipe off any dirt and oil from the top of the cylinder head and install a new gasket. Reassemble in reverse order. Adjust the choke cable so that when the button is recessed, the air damper is in a strictly vertical position.

What can you do along the way?

1. Check the spark plug electrode gap, adjust or replace if necessary. 2. Wash with clean gasoline and check the distributor cap for cracks. If there is, replace it. 3. Check the play of the distributor sensor screen. 4. Adjust the tension of the generator belt. 5. Check the opening of the throttle valves in the carburetor. If they do not open, adjust the rods or eliminate the wedging. 6. Replace the fuel and air filter.

When turning the ignition key there was a loud bang - they forgot to remove the ratchet key. Tighten the ratchet nut to 101.3-125.6 N. m.

The engine started, but stalled when the choke button was pressed in - they forgot to insert the vacuum brake booster hose into the vacuum booster.

If you put the car in gear and the car doesn’t move, take the car off the jack :-)

The topic of the article is a rocker for engines 21213 and 21214. The complete mess that is going on in the heads of nivovods and Papuan services forced me to take up a separate writing for this spare part. Rockers come in “death to hydraulics” kits of the old and new models, but a number of questions still arise. These parts also come in two types in size. I’ll try to explain what the difference is.

How to define what rock is?

In general, there is no exact definition of rock. This is a mixture of art, symphonic, hard rock and other directions. Razin, considering the concept and phenomenon of rock, notes that it is difficult to give a clear definition to this phenomenon due to the following reasons. Firstly, it is difficult to identify the laws by which rock music lives, develops and interacts with other cultural phenomena. Secondly, the social formations that exist and coexist with this subculture have been practically unstudied. Thirdly, it is impossible to predict in which direction rock will develop. This is what makes rockers different. A subculture whose photos can shock people can no longer be considered an ordinary phenomenon.

VAZ classic - what kind of cars are they?

In terms of width and wheelbase, the VAZ classic is one of the smallest representatives of the subcompact urban class B. There is less space in the cabin than in any front-wheel drive Lada, but still the Zhiguli is more spacious than A-class supermini cars (such as Deo Matiz or Oka ).

All "classic" models are essentially versions of the same car with minor changes, mainly in appearance and interior. The structure of the body, over the years of production, has not changed at all - the safety of the car has remained at the level of the mid-20th century.

Manufacturing technology and quality of materials have also changed little, so the bodies of Zhiguli cars, even the latest versions, are characterized by extremely low corrosion resistance. The only way to protect a “classic” from rust is to not use it in winter. Otherwise, the Zhiguli will rust literally before our eyes.

By modern standards, the interior of the Zhiguli can only be called comfortable with a big stretch. At that time, they didn’t think about ergonomics on the VAZ, so trips in a “classic” for more than one hour could cause fatigue. However, the interior of the first versions had its own feature - it allowed you to transform into an almost flat bed, so it was quite comfortable to spend the night in the car. Finally, this feature was removed on the “seven”, when the headrests became an integral part of the back of the driver’s seat.

Even in a sedan, the trunk is very roomy - 350 liters. However, the top loading and high side reduce its practicality, preventing large items from being loaded into it.

Old and new standard

There is only one difference. This is the diameter of the landing ball on the soldier and, as a result, the different diameter of the rocker hole. Old-style rockers were installed on the assembly line somewhere up until 2008-2010. exclusively on engines 21213. Even on the classics at that moment, soldiers and rockers with small balls were installed. The photo clearly shows how different the diameter of the ball is. And one more very important point is the rocker profile. The camshaft lobe should "roll" onto the rocker, not strike. Only in this way can you achieve quiet engine operation and high-quality adjustment.

The “death to hydraulics” kits are equipped with a new type of rockers. That is, the soldier comes with a small ball.

Classic motors

What engines were installed on the Zhiguli?

- 1.2l 64hp (model 2101)

- 1.3l 69hp (model 21011)

- 1.5l 71hp carb/eng (model 2103)

- 1.3l 63hp with timing belt (model 2105)

- 1.6l 75-82 carb/eng (model 2106)

All “classic” engines are longitudinal in-line gasoline fours with a single camshaft located in the cylinder head. Early versions (models 2101 and 21011) had a problem with premature camshaft wear due to insufficient lubrication, but this problem was eliminated on subsequent models. The cylinder head here is 8-valve, the valves do NOT bend. Valve clearances are quite easily adjusted with nuts, but this procedure must be done often - every 30 thousand km.

Over the years of production, the “classic” engines have also changed little. All of them, in essence, are modifications of their ancestor - the 1.2 liter “penny” engine (model 2101). The main changes were in the geometry of the engines, due to which the volume and power were increased. All “classic” engines have a reliable timing chain drive except the “five” engine (model 2105) - here VAZ engineers unsuccessfully tried to convert the timing belt to a belt drive.

The 1.5 and 1.6l units (models 2103 and 2106) turned out to be more reliable and durable, so they were installed on the “classics” until the last minute.

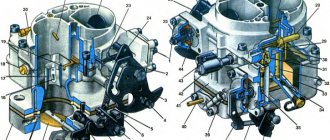

At first, Zhiguli engines were equipped with Italian Weber carburetors, since 1980 they were replaced with the domestic analogue of Ozon (manufactured by DAAZ), and since 1990, the DAAZ plant supplied AvtoVAZ with Solex carburetors, a French design.

They began installing injectors on “classic” engines only in 2006, when the state banned the production of “non-eco-friendly” carburetor versions. Of course, injection engines have a lot of advantages over carburet engines. The injector practically does not clog, it does NOT need to be cleaned or adjusted, and in winter it starts confidently, regardless of temperature. In addition, fuel consumption on a “classic” with an injector can easily fit into 7 liters per hundred, while on carburetor versions 10 liters per hundred is the norm.

Older versions of Zhiguli engines provide them with good dynamics. In the 0-60 acceleration exercise, a “classic” with a top-end 1.6L engine takes 16 seconds. Maximum speed – 150 km/h.

Maintenance and typical faults of rockers

Rockers do not require frequent maintenance. It is quite enough if, when carrying out service work on other elements of the timing mechanism, their current condition is assessed - the absence of visible mechanical damage and signs of critical wear. If no problems are identified, then they can be used further. But only after thorough cleaning of contaminants.

Rocker failures, although they do not occur very often, can lead to serious problems with other engine components. For example, a broken rocker arm can lead to the failure of the corresponding valve. A sign of a breakdown may be a drop in engine power during normal operation and the appearance of a characteristic knocking sound in the cylinder head.

If you need to install new rockers, you need to select them only according to the original catalog and VIN code. No other catalogs will be suitable, as they cannot guarantee applicability. If buying original rockers seems like an expensive pleasure to you, then when you search by original article number, the system will offer you a set of analogues of various price categories.

- Rockers, or rocker arms in a car

- Rocker device.

- Operating principle of valve rocker arms.

- Common breakdowns.

It happens that when repairing a car, it is necessary to replace or repair the rocker. Many people, encountering this problem for the first time, do not know what it means. Rockers (or valve rockers as they are also called) are a mechanism used to transfer energy from the camshaft cam to the intake valve stem. Valve rocker arms are part of the gas distribution mechanism (GRM) of a car engine with a “classical” structure. Nowadays, rockers in engines are quite rare.

Conclusion

Valve rocker arms are far from being the elements of automotive power units that often fail. If this does happen, they should be replaced as soon as possible. If the rocker breaks (the worst case scenario), engine performance also changes for the worse. It is recommended to entrust the replacement of the rocker to trusted specialists, however, if there is a strong desire, all the work can be done by an ordinary car enthusiast. Regarding spare parts for repairs, give preference to either originals or products from well-known manufacturers with an impeccable reputation.

History of origin and characteristic features.

During World War II and the post-war years in Great Britain, a motorcycle was considered a sign of wealth. Motorcycles were quite expensive, and their owners were treated with respect and reverence. In the early 1950s. the middle class could afford to buy cars. Coupled with the demilitarization of production, motorcycle prices fell sharply. The motorcycle has become a means of transport for the poor.

Several factors contributed to the emergence of rockers as a subculture. The rise in production after the war, as I already said. In addition, the working class began to have surplus money, which, coupled with available credit, allowed for an increase in purchasing power. To a large extent, the emergence of rockers was influenced by American culture - music and films.

But rockers switched to cafe racers precisely because of the characteristic features of British roads and roadside infrastructure. The thing is that the highways around many British cities were very suitable for racing, since they were circular and had good coverage. And the abundance of roadside 24-hour cafes determined the places not only for parties, but also for the start and finish.

Rockers were a very energetic and sports-oriented subculture. They regularly organized speed races, and even at that time they were tuning their motorcycles in such a way that they could easily reach a speed of 160 km/h. (100 miles per hour or “a ton.” “Make a ton!” ;)) Naturally, they often fought, had drinking parties, and fought. All this formed a negative opinion about them among the public.

Then the subculture gradually died out, but then was revived many times around the world.

Rockers often used a skull and crossbones in their symbolism, since the deep tuning of motorcycles made them extremely dangerous to ride. Typical clothing is leather biker jackets with many studs, open motorcycle helmets, flight goggles and long silk scarves. Well, the truth is, most often we rode without helmets at all) On our feet we wore either jeans or leather pants and leather motorcycle boots (usually from Lewis Leathers). Esso key chains and 59 club of England patches were in vogue. In general, the rockers must have looked pretty cool, given the fact that almost all of them wore hairstyles a la Elvis

The rockers did not look very neat, and also had a certain tendency to violence, so they were soon no longer allowed into many pubs, clubs and dance floors, and they hung out in roadside cafes, which also served as the start and finish place for races. The most famous “party” cafes of rockers are The Ace Cafe, Chelsea Bridge tea stall, Ace of Spades, Busy Bee and Johnsons.

Who are rockers? We'll tell you!

→ Subcultures

The word rockers , initially, served to define British youth in Britain in the sixties of the last century, who allowed themselves to very irreverently ride along the roads on motorcycles. Rockers have become a concept opposed to mods - their peers who only use scooters as transport.

Rockers appeared as a subculture in the fifties and early sixties during the era of rock and roll, representatives of the music and style of which were Chuck Barry, early Elvis Presley, Gene Vincent and others. However, the first rockers were united by only one principle - the manner of riding a motorcycle, and only then the concept of style appeared. These guys could drive at speeds of up to 160 kilometers per hour on London's ring roads.

The rocker style was born out of necessity and practicality. Rockers wear leather motorcycle jackets, abundantly decorated with buttons, patches, stripes and pins. They often wear quite fashionable leather caps on their heads. They usually ride a motorcycle wearing an open-face helmet, aviator goggles, and a white silk scarf to protect their mouths from hypothermia. Every rocker's wardrobe includes Levi's jeans, leather trousers, high-top motorcycle boots from Lewis Leathers or military boots and T-shirts. Also popular are symbols that indicate a person’s involvement in the 59 Club of England, a youth church organization that later transformed into a club for motorcycle enthusiasts around the world. The rocker's hairstyle can, in principle, depend on personal preference, but it is often described as a smoothed or, on the contrary, enhanced pompadour hairstyle that characterizes the representatives of rock and roll of the fifties.

It is interesting that despite the fact that rockers arose already in the fifties, they became associated with the subculture, and, accordingly, rock and roll music only in the sixties. Their main features were their affinity for rock and roll and motorcycle riding, which helped create the image of an English street hooligan. In our country, as usual, our attachment to rock and roll has acquired more unobtrusive forms. A motorcycle of “that class” was a pipe dream for Soviet students, so it was kept at home only as an image on posters. Music became the main segment of the rocker subculture in the USSR.

Who has not addressed the theme of rock and roll throughout its history? This is perhaps the only movement that does not expect anything from its representatives other than a positive attitude towards music. Often, rock fans start playing this kind of music without leaving the box office, creating their own small musical teams. Motorcycle enthusiasts in later years created a biker culture parallel to the rockers. Both of them are absolutely apolitical and put themselves above social problems. Bikers become one with their motorcycles and have their own code of honor, which includes the expression of high moral principles.

Another side of rocker culture is the abuse of alcohol, drugs, and cigarettes. It is rocker culture that is characterized by the promotion of departure from an imperfect world. This culture is built on philosophical ways of perceiving the world, which can be clearly seen in the lyrics (by the way, their ideological coloring can range from quite harmless to calling for specific actions). Ideally, a rocker is a well-read person who understands the social situation, knows how to think independently and draw conclusions, which he sets out in appropriate lyrics set to music.

Due to the versatility of this most widespread culture among us, its representatives can be named endlessly. We associate Viktor Tsoi (“Kino”), Yuri Shevchuk (“DDT”), Konstantin Kinchev (“Alice”), Vyacheslav Butusov, Andrey Makarevich and others with rock legends. Russian rock is a separate concept that has no analogues, but is very respected in the rest of the world.

Valve rocker

Rocker (valve drive lever) is a structural element of the valve drive mechanism. There is also the name roller lever or rocker arm. The purpose of the rocker is to transfer force from the camshaft cam to the valve stem (rod) with an overhead camshaft position. This solution in the valve drive device provides the timing belt with less weight and reduces friction.

The rocker arm (valve rocker) absorbs the forward movement of the pusher rod and transmits this movement to the valve stem. The initial force is transmitted from the camshaft cam. The rockers are located at the top of the cylinder head. An axle is pressed into the central part of the rocker, the position of which is fixed using two rocker support pins. The support pins are inserted into special racks, which in some design options are made in the cylinder head housing.

The rocker arm, on one side, rests on the valve stem, and on the other, it can rest on the hydraulic compensator. Some designs of the valve drive mechanism provide for the rocker to rest on a special ball joint. The contact point between the rocker and the distribution cam is made in the form of a roller.

Valve rocker arms in modern engines are gradually being eliminated from the timing device due to the active use of overhead camshaft designs. The main purpose of using rockers today is to reduce the size of the engine. This may be necessary to place the internal combustion engine in the engine compartment of a small car.

A rocker is a lever that has two “shoulders” (a double-arm lever). The valve rocker arm is made by forming steel, casting or forging. The latter option is more preferable, since forged elements have increased strength. Forged rockers are installed on powerful power units.

A hydraulic compensator (hydraulic pusher) is a cylinder that is based on a piston with a spring, a check valve and special channels for supplying engine oil from the internal combustion engine lubrication system. If the hydraulic compensator is located on the valve tappet, the device is called a hydraulic tappet (hydraulic tappet).

Additionally, there is a hole in the short arm that provides access to engine oil to lubricate the elements. To prevent the rocker from moving along the axis, the rocker arm is held in place by a coil spring. The rocker arm works on the following principle: when the camshaft cam exerts force on the short arm of the rocker, thereby lifting occurs. The long arm moves down, pressing on the valve stem. Additional elements in the rocker design are bushings to reduce friction.

During operation, the rocker striker, bearings and the rocker itself are subject to mechanical and thermal loads, which leads to wear and damage. The rocker arm may break, which means the valve stops working. If the rocker breaks, then the malfunction manifests itself in the form of a characteristic knocking sound in the cylinder head and a decrease in output from the internal combustion engine in various operating modes.

Purpose of the gas distribution mechanism. Components of the timing belt on a four-stroke piston engine, distinctive design features of the mechanism.

Why is it necessary to adjust the thermal clearance of the valves, manual and automatic adjustment. Features of operating an engine with hydraulic compensators.

Why and when do you need to adjust the valves? Self-adjustment of valve clearances using a feeler gauge and shims. Recommendations.

Purpose of the timing valve. Inlet and exhaust valves, design and features of the part. Layout diagrams and valve drive of an internal combustion engine.

Purpose of the hydraulic compensator. Types, design of hydraulic compensators, principles of operation and main malfunctions.

What is a valve desiccant and why is it needed? Existing ready-made varieties of special tools. How to make a valve desiccant yourself.

Design features

Let's look at what VTEC is on a Honda using the example of an engine with a DOHC timing system, since it was first used on this engine and is structurally the simplest. The peculiarity of this gas distribution mechanism is the use of 4 valves for each cylinder (a pair of intake and exhaust, operating synchronously) and two camshafts, each of which is responsible for opening its own valves.

Operating principle of VTEC rocker activation

VTEC rocker switch off

VTEC on this engine has two operating modes and involves the use of three cams per pair of valves (both intake and exhaust), instead of two. The third cam has an increased height and smooth geometry (repeats the shape of a sports camshaft cam) and is placed between two regular ones.

The outer cams (with the usual shape) act on the valves not directly, but through rockers, rocker arms, and pushers (depending on the timing mechanism design). The central cam also has a rocker (rocker arm), but they do not have any effect on the valves. But an oil channel is made in them and retractable pins are installed, which, entering special recesses of the outer rockers (rods), connect the rockers to each other and ensure their synchronous movement.

The oil channel made in the rocker axles and the central rocker is equipped with a solenoid valve controlled by the engine ECU, which allows you to control the flow of oil that is supplied to the VTEC.

Valve rocker

Rocker (valve drive lever) is a structural element of the valve drive mechanism. There is also the name roller lever or rocker arm. The purpose of the rocker is to transfer force from the camshaft cam to the valve stem (rod) with an overhead camshaft position. This solution in the valve drive device provides the timing belt with less weight and reduces friction.

The rocker arm (valve rocker) absorbs the forward movement of the pusher rod and transmits this movement to the valve stem. The initial force is transmitted from the camshaft cam. The rockers are located at the top of the cylinder head. An axle is pressed into the central part of the rocker, the position of which is fixed using two rocker support pins. The support pins are inserted into special racks, which in some design options are made in the cylinder head housing.

The rocker arm, on one side, rests on the valve stem, and on the other, it can rest on the hydraulic compensator. Some designs of the valve drive mechanism provide for the rocker to rest on a special ball joint. The contact point between the rocker and the distribution cam is made in the form of a roller.

Valve rocker arms in modern engines are gradually being eliminated from the timing device due to the active use of overhead camshaft designs. The main purpose of using rockers today is to reduce the size of the engine. This may be necessary to place the internal combustion engine in the engine compartment of a small car.

A rocker is a lever that has two “shoulders” (a double-arm lever). The valve rocker arm is made by forming steel, casting or forging. The latter option is more preferable, since forged elements have increased strength. Forged rockers are installed on powerful power units.

A hydraulic compensator (hydraulic pusher) is a cylinder that is based on a piston with a spring, a check valve and special channels for supplying engine oil from the internal combustion engine lubrication system. If the hydraulic compensator is located on the valve tappet, the device is called a hydraulic tappet (hydraulic tappet).

Additionally, there is a hole in the short arm that provides access to engine oil to lubricate the elements. To prevent the rocker from moving along the axis, the rocker arm is held in place by a coil spring. The rocker arm works on the following principle: when the camshaft cam exerts force on the short arm of the rocker, thereby lifting occurs. The long arm moves down, pressing on the valve stem. Additional elements in the rocker design are bushings to reduce friction.

During operation, the rocker striker, bearings and the rocker itself are subject to mechanical and thermal loads, which leads to wear and damage. The rocker arm may break, which means the valve stops working. If the rocker breaks, then the malfunction manifests itself in the form of a characteristic knocking sound in the cylinder head and a decrease in output from the internal combustion engine in various operating modes.

Purpose of the gas distribution mechanism. Components of the timing belt on a four-stroke piston engine, distinctive design features of the mechanism.

Why is it necessary to adjust the thermal clearance of the valves, manual and automatic adjustment. Features of operating an engine with hydraulic compensators.

Why and when do you need to adjust the valves? Self-adjustment of valve clearances using a feeler gauge and shims. Recommendations.

Purpose of the timing valve. Inlet and exhaust valves, design and features of the part. Layout diagrams and valve drive of an internal combustion engine.

Purpose of the hydraulic compensator. Types, design of hydraulic compensators, principles of operation and main malfunctions.

What is a valve desiccant and why is it needed? Existing ready-made varieties of special tools. How to make a valve desiccant yourself.

What is a gas distribution mechanism (GRM)?

The gas distribution mechanism (GRM) is a mechanism designed to inject fresh charge into the engine cylinders (fuel mixture in classic gasoline engines or air in diesel engines) and release exhaust gases in accordance with the operating cycle, as well as to ensure reliable isolation of the combustion chamber from the environment during time of compression strokes and power stroke.

Depending on the type of devices that inject charge and exhaust exhaust gases, there are two types of gas distribution mechanisms:

- valve

- spool

The valve train is the most widely used and is used in all four-stroke engines. Upper and lower valve locations are possible. The upper location is currently used more often, since in this case the gas exchange process is more efficient. Typical designs of gas distribution mechanisms with overhead valves are shown in the figure.

We recommend: How to properly fasten a child seat in a car: concern for safety

Replacing rocker arms on a VAZ 2107

Rockers (rocker arms) are one of the elements of the valve timing mechanism of the VAZ 2107 engine. The purpose of the part is to transmit energy from the camshaft cam to the valve stem. Since the rocker is constantly exposed to mechanical and thermal stress, it wears out over time.

Determining the suitability of rocker arms

If during operation of the “Seven” there is a decrease in engine power or a characteristic knocking sound is heard in the cylinder head, then the likely cause is a broken rocker arm. During repair work, it is necessary to clean the rockers from dirt and carbon deposits and check them for wear and damage. If any defects in parts are found, they are replaced with new ones. If the rocker arms are in normal condition, install the products on the cylinder head.

Is it possible to level the rocker arm?

When adjusting valves or repairing the cylinder head, you may notice that the rocker arms are slightly at odds with respect to the camshaft, i.e., the distance between the rocker plane and the camshaft journal is not the same. To eliminate this nuance, some owners of “classics” align or change the springs that press the rocker arms, or replace the rocker itself, but the problem may still remain. In fact, on all classic Zhiguli models, including the VAZ 2107, misalignment is not as bad as incorrect valve clearance

Therefore, it is the gap that deserves attention. The main thing is that the parameter is adjusted properly and is 0.15 mm when cold

How to replace a rocker arm

If there is a need to replace the rocker arms on the “seven”, for example, 1 part in case of its breakdown, then it is not necessary to dismantle the camshaft. To do this, it will be enough to pry the spring with a screwdriver, remove it, and then remove the rocker itself. The new part is installed in the reverse order. If all the rocker arms are being replaced, then it is wiser to dismantle the camshaft.

Video: replacing the rocker on a “classic” without removing the camshaft

Equipping the VAZ 2107 engine with hydraulic compensators improves its operation and characteristics. Installing the mechanism will not take much time and effort, but will require material costs. Therefore, whether there is a need for such an engine modernization or not, each motorist decides for himself.

On absolutely any classic engine, including the VAZ 2106, the thermal valve clearances must be adjusted from time to time. If this is not done, then over time some valves may be clamped, or, on the contrary, the gap will be too large and they will knock. To avoid this, adjustments must be made in a timely manner. To begin with, I will give a list of tools that will be needed to complete this work with the VAZ 2106.

- Open-end wrench 13

- 17 open-end wrench

- A set of probes, or rather, we need exactly one probe, 0.15 mm thick

- And also a list of tools needed to remove the valve cover

General concept

To understand what VTEC is, let's look at the differences between regular and sports camshafts. Structurally, both shafts are the same, but the latter has a higher cam height than the usual one, and its geometry is smoother. Due to this cam shape, sports camshafts provide better cylinder filling due to increased valve opening time and height.

VTEC combines the design features of simple and sports camshafts, which allows you to automatically adjust the valve timing depending on the operating conditions of the engine. At low speeds, the system uses cams with a regular geometry, therefore saving fuel, and at high speeds, with an increased height, providing maximum power output.

Timing device

The gas distribution mechanism has the following main elements:

1. Camshaft. Opens valves in a specific sequence depending on the order of operation of the cylinders. It is made of cast iron or steel, and the rubbing surfaces are hardened by high-frequency currents. It can be mounted in the cylinder head or in the crankcase. Multi-valve engines have two camshafts, one of which controls the intake valves and the other the exhaust valves. The shaft rotates on cylindrical bearing journals. Direct or indirect action on the valve is carried out by cams located on the shaft. Each cam corresponds to one valve.

2. Valve drive. The valves are driven in various ways: when the camshaft is located in the crankcase, the force from the cams is transmitted to the pushers, rods and rocker arms.

The rocker arm (rocker or roller lever) is made of steel and is mounted on a hollow axle fixed in the cylinder head struts. One side of it rests on the shaft cam, and the other presses on the end of the valve stem. When the engine is running, the valves heat up and elongate, which threatens them with incomplete seating in the seat. Therefore, a thermal gap must be maintained between the valve and the rocker arm.

The cam can also act on the valve through a lever or directly on its pusher. Pushers can be made in a mechanical (rigid), roller version or in the form of a hydraulic compensator. The first type is almost never used due to noise, while the latter is soft and does not require adjustments. Roller tappets are used in high-performance and sports engines.

3. Camshaft drive mechanism. It is carried out by chain, belt or gear transmission. The chain one is reliable, complicated to design and expensive, the belt one is cheaper, but less reliable, and if the belt breaks, it can cause engine damage due to the impact of the valves on the pistons.

4. Valves. Designed to open and close the inlet and outlet channels. They consist of a rod and a head, on which there is a narrow chamfer beveled at an angle, tightly adjacent to the chamfer of the seat, for which they are ground together. The intake valve heads are made larger than the exhaust valve heads. But the outlets heat up more, so they are made of heat-resistant steel and filled with sodium inside for better cooling.

The cylindrical valve stem is machined on top to attach a spring that prevents it from coming off the rocker arm, which rests on the washer on the head and is fixed with a thrust plate. The rod is placed in a guide sleeve pressed into the cylinder head to prevent oil from entering the combustion chamber; an oil-reflecting cap is placed on it.

Use in measuring instruments [ edit | edit code]

In laboratory analytical balances, equal-arm rocker arms are used (arm ratio 1:1) [11].

In industrial mechanical scales, unequal-armed rocker arms are used (arm ratio 1:10 - 1:100). However, the term unequal-armed rocker arm is often replaced with the term unequal-armed lever [12].

In the first mechanical watches of the 12th-16th centuries, the role of an oscillator was performed by a special type of rocker - a bilyanets; later it gave way to the Huygens pendulum oscillator. [13]

Analytical balance with equal-arm beam.

Lever scales with an unequal beam (illustration from the Brockhaus and Efron dictionary).

Rocker (bilyanets) as an oscillator (first row, third from left)

Rockers, or rocker arms in a car

- Rockers, or rocker arms in a car

- Rocker device.

- Operating principle of valve rocker arms.

- Common breakdowns.

It happens that when repairing a car, it is necessary to replace or repair the rocker. Many people, encountering this problem for the first time, do not know what it means. Rockers (or valve rockers as they are also called) are a mechanism used to transfer energy from the camshaft cam to the intake valve stem. Valve rocker arms are part of the gas distribution mechanism (GRM) of a car engine with a “classical” structure. Nowadays, rockers in engines are quite rare.

The reason for this is the fact that modern engines have completely moved to overhead camshafts. And, as a rule, the main reason for using rockers in modern engines is the desire to reduce the size of the latter. There may be several reasons for making such a decision, but the first place is occupied by the need to place an internal combustion engine (ICE) under the hood of a small car.

Rocker device.

A rocker is a lever with two “shoulders”, and it is made by forming steel using forging or casting technology. If you choose, the forging method is much better, because forged parts are incomparably stronger. Both “shoulders” of the rocker have a T-shaped section.

Traditionally, there are long and short arms of the rocker arm. At the end of the long arm there is a hardened cylindrical plane - the rocker striker. The striker of the rocker rests against the end end of the valve stem.

At the end of the short arm there is a bolt with which the depth of the gap between the valve itself and the valve drive lever is adjusted. If there is a hydraulic compensator, this gap is adjusted automatically. At the same time, the noise is significantly reduced, and the operation of the timing belt becomes smoother and softer. There is also a special hole in the short arm, which provides access to engine oil for lubricating parts.

The rocker arm is restrained by a coil spring. This is necessary in order to prevent the rocker from moving along the axis. The axle itself, which serves to attach the rockers, is hollow, and the outer side of the axle is hardened, which increases wear resistance.

Operating principle of valve rocker arms.

The principle of operation of the rocker arm is as follows: when the camshaft cam puts pressure on the short arm, lift occurs.

The long arm lowers, while pressing on the valve stem. Auxiliary elements in the rocker structure are bushings that reduce friction.

Common breakdowns.

Since during operation the rocker striker and the rocker itself are subjected to various thermal and mechanical loads, this, in turn, leads to their damage and wear.

If you notice that the output from the internal combustion engine is decreasing in different operating modes, or you hear a characteristic knocking sound in the cylinder head, this means that the rocker is broken. Also, very often the rocker itself breaks, which means that the valve has failed. External signs of a broken rocker are exactly the same as in the case of a malfunction of any timing part.

Rockers, or valve rockers, are part of the timing mechanism parts of some automobile engines, most often of the so-called classic design. In modern engines, after the final transition to overhead camshafts, rockers are rare. Typically, their use may be caused by a deviation from the standard design of the valve mechanism, for example, to reduce the size of the engine. In other words, the engine bay can be so small that engineers have to change the layout of engine parts to make the resulting unit fit into the given space.

Forged sports engine parts are stronger than conventional ones, since during forging the metal structure is strengthened from mechanical stress

Prospects for use in timing [edit | edit code]

In modern engines there is a steady tendency towards a gradual increase in rotation speed [16]. The use of the OHV timing circuit is currently limited to relatively low-speed internal combustion engines with large displacements. The SOHC circuit gives way to DOHC. The applicability of rocker arms in high-speed internal combustion engines is therefore decreasing, due to the following reasons:

- the more parts between the cam and the valve, the higher the inertia of the drive;

The more parts between the cam and valve, the less rigidity.

In low-speed, for example, marine internal combustion engines, the use of the OHV circuit is the main one, so rocker arms are now used by all major manufacturers [17].

A rocker is not only a motorcycle owner and a representative of a subculture that originated in Great Britain in the late 50s and early 60s. If we talk about the structure of the car, then the rocker (or valve rocker) is an important part of the timing mechanism on engines with a classic camshaft arrangement.

Many modern cars do not have rockers in the timing mechanism. This is due to the fact that the camshaft in them is structurally located at the top. However, rockers cannot completely get out of use. They are still used in engines in cases where there is a need to save on camshaft sizes. This is typical for small car engine designs.

A little theory

The main difference between rockers for the field “Made in USSR” and “Made in Russia” is the material. According to Soviet metal classification and state standards, cast iron was divided into two large categories. Cast iron of the highest quality, KCH - malleable cast iron. And the rest, the warhead, is white cast iron. These materials differed not only in specific gravity, but also in crystal structure. Frames for machine tools, engine blocks, and gearbox housings were made from CP. From warheads - weights, counterweights, manhole covers.....and other important details))) As you might guess, the old rockers are made from warheads, the new ones from warheads))) Well, since nothing can be done in this case, let's move on to specifics at the moment .

Transmission and drive

At first, the VAZ classic was equipped with a 4-speed gearbox, and a 5-speed gearbox began to be installed here in the 90s

However, a 4-speed gearbox is often found on cars of later years of production - pay attention to this. Of course, a 5-speed transmission is better, because on the highway it allows the engine to operate at lower speeds, which means it is quieter and more economical

The classic rear-wheel drive also leaves its mark on the driving performance of the Zhiguli. This is not very noticeable on dry asphalt, but is very noticeable on slippery surfaces. The engine located at the front, with its weight, does NOT press the driven rear wheels to the ground. Therefore, when the rear of the car is not loaded, the classic can experience a severe lack of traction.

Simply put, on a slippery surface, the drive wheels on a classic easily slip and the car spins. This will be beneficial if you like to drive sideways, but for beginners this behavior of the car can be downright dangerous.

How do rockers dress today?

In wide circles there is an opinion that rockers are mostly unkempt and unwashed homeless-looking people who do nothing but drink and go to concerts. Some classify them as sexual minorities. This, however, is not the case. Firstly, compared to metrosexuals, rockers really seem overly brutal. But there's a reason for that. Rockers, whose photos can be seen almost everywhere, position themselves as strong personalities, so various mannered habits are not for them. Moreover, many fans of heavy music are homophobic. The “rockers” subculture is one of the few who treat fans of other genres and styles with understanding and tolerance. The only exception is, perhaps, pop music. This explains both the style of rockers and their clothing preferences. Regardless of the material, dark colors predominate. What style a person prefers also leaves a certain imprint. Fans of gothic style will most likely prefer a combination of red and black, folk rock - dark green and black. The clothes can be anything, but they are practical, comfortable and dark. Chains and spikes are not a required attribute. Most often they can be seen on fans of punk rock. This is not surprising, since they are one of the most aggressive branches of rockers. Russian rockers prefer not to wear this. For them, appearance is of secondary importance. At the same time, the opinion that there are no females among rockers is incorrect. Rocker girls, whose photos every music lover now has - vocalists of the groups "Arkona", "Kalevala", Nightwish, Within temptation, and others.

They are equal creators of the subculture, its integral part. Moreover, female-fronted rock is becoming more and more popular. There is nothing strange about this - what could be better than the combination of good music and a beautiful girl with wonderful vocals?

Suspension

The chassis of classic VAZs also remained unchanged. The front suspension here is independent, double wishbones on springs

It is important to know that the design of the Zhiguli front suspension contains a dangerous design flaw. The weight of the body is transferred here to the wheel, through the lower ball joint, which acts as a suspension - the lower suspension arm, which bears the weight of the body, is suspended from the lower ball joint

When this joint wears out, it pops out of the “cup” and the wheel turns under.

You've probably seen a classic car with a twisted wheel lying on the side of the road - this is just such a case. Unfortunately, this can happen not only at low speed, and it is not always possible to stop the car on the side of the road. To avoid an emergency, check the lower ball joints every 5-10 tkm, and if there is play, change them without hesitation.

The rear suspension on the Zhiguli is dependent, the axle is on springs, secured by 4 longitudinal and 1 transverse rod. This design is highly reliable and durable, but performs poorly at speed and in corners. The brakes are efficient disc brakes at the front and cheap and durable drums at the rear.

In general, the suspension on the “classic” is high and energy-intensive, it allows you to drive on the worst roads, but on asphalt this car, although soft, is rolly. Without a doubt, the Zhiguli suspension is designed for bad roads, and this is confirmed by the impressive ground clearance of 17 cm.

VAZ classic - Expenses

In addition to the low purchase price of a car, “classics” also attract with affordable prices for repairs and maintenance. Spare parts and consumables for Lada cars are as cheap as possible – there is simply nothing cheaper. At the same time, classics are the most common car in our country, their number is in the millions. The VAZ-2107 “seven” alone is registered for more than 1.7 million units. Therefore, buying spare parts for classics is not a problem at all, you don’t even need to order them - they are sold literally everywhere.

Since the Zhiguli was equipped with low-power engines up to 82 hp, insurance and taxes are quite inexpensive here. In a word, “classics” will definitely NOT ruin you.

You can buy a good Zhiguli in 2020 for 50-60 thousand rubles, and for 70 it’s quite possible to find a copy with an injection engine in perfect condition, after 1-2 owners. All competitors for this money will be in a deplorable state and, even if they are on the move, will require serious financial investments in the near future.

As for the issue of image, having become old and affordable, Zhiguli certainly lost its authority, but not completely. Many years ago, in a great country, they were so desirable that even now, a certain aura of solidity still remains around them. Therefore, a well-preserved “classic” still arouses interest and respect today.

As a result, friends, we come to the conclusion that today’s “classics” have many disadvantages and, in fact, one significant advantage - accessibility. Let's once again list the main pros and cons of the Zhiguli.

Flaws

- Low level of comfort and safety

- Low reliability and durability

- Rapid aging and loss in value

Advantages

- Wide choice when buying, liquidity when selling

- Availability of consumables, spare parts, maintenance and repairs

- Cheap insurance and tax

Of course, today this is no longer a car for everyone, but then who will it suit? “Classic” is a good option for short, leisurely trips, over short distances, for example in a village, town or small town. If you have bad roads in your area, this is exactly her element. Well, young drivers love the “classic” for its affordable tuning and the fact that it can drive sideways.

Kak-Kupit-Auto.ru

Links: